Austenitic stainless steel pipe piece elbow local solid solution treatment method and device

A solution treatment technology for austenitic stainless steel, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as high cost of flaw detection, increased sensitivity to stress corrosion, overheating, etc., to avoid coarse tissue, eliminate residual stress, The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

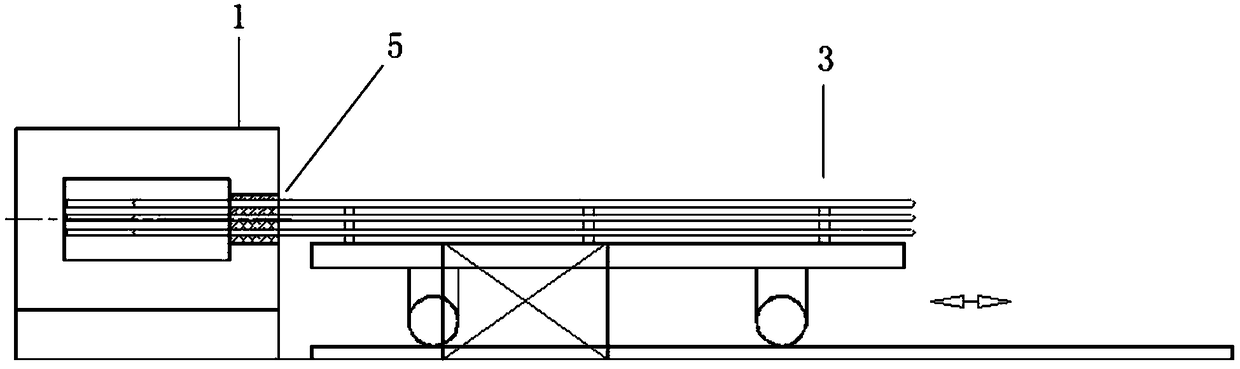

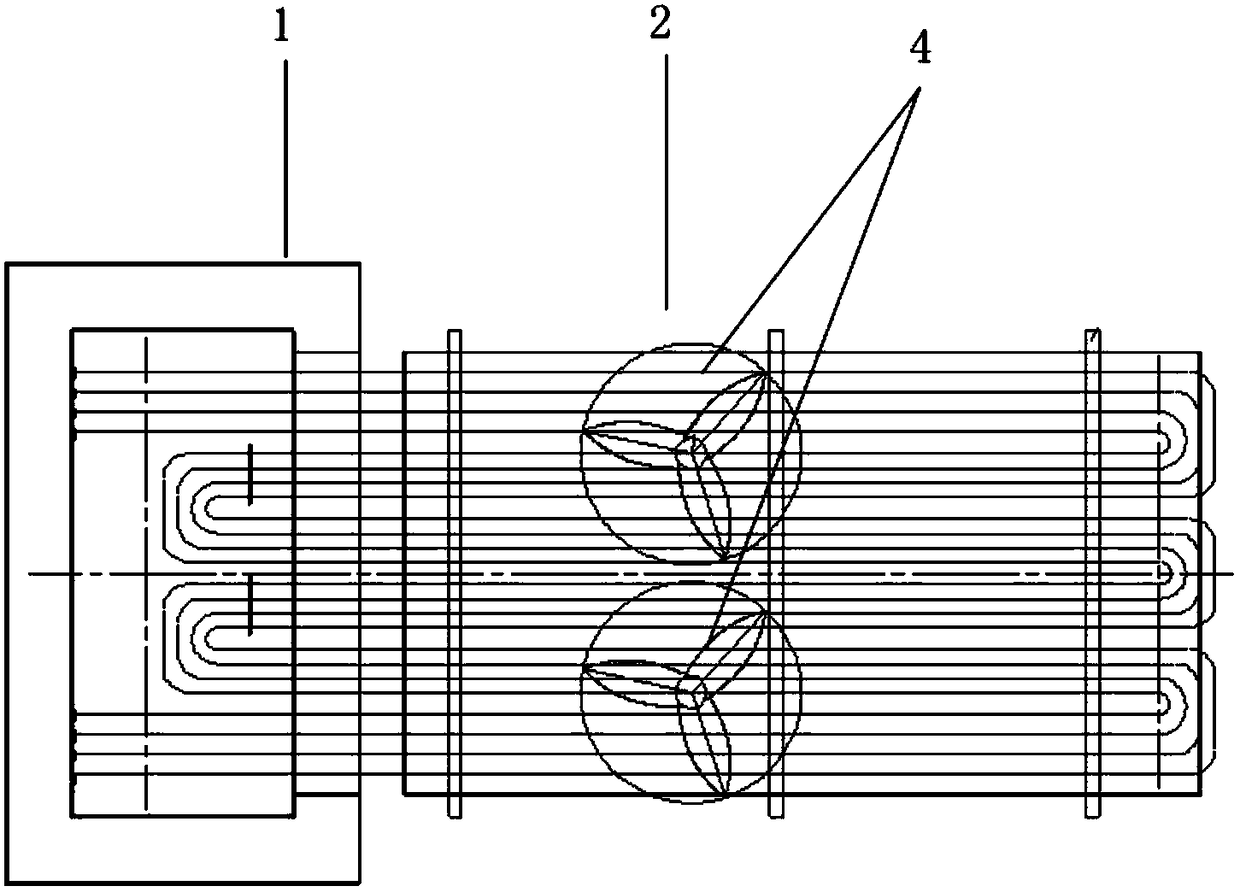

[0022] The local solution treatment method of the austenitic stainless steel segment elbow of the present invention, the preparation method comprises the following preparation steps:

[0023] Step 1: Bending the stainless steel segment to make multiple continuous elbows;

[0024] Step 2: Position and fix the elbow on the stainless steel tube to avoid deformation of the heating elbow, and then perform primary heating, secondary heating, and soaking on multiple consecutive elbows at the same time, primary heating, secondary heating, and continuous soaking Carry out, and keep warm after soaking, the first stage heating is to heat the segment rapidly to 425°C, the second stage heating is to heat up to 1095°C at a rate of 3°C / min, and keep hold for ≥15min;

[0025] Step 3: Rapidly cool the heat-preserved stainless steel tubes to room temperature at a rate of 25° C. / min to obtain solution-treated austenitic stainless steel tubes. The cooling adopts air cooling, and the blowing direc...

Embodiment 2

[0027] The local solution treatment method of the austenitic stainless steel segment elbow of the present invention, the preparation method comprises the following preparation steps:

[0028] Step 1: Bending the stainless steel segment to make multiple continuous elbows;

[0029] Step 2: Position and fix the elbow on the stainless steel tube to avoid deformation of the heating elbow, and then perform primary heating, secondary heating, and soaking on multiple consecutive elbows at the same time, primary heating, secondary heating, and continuous soaking Carry out, and keep warm after soaking; the first-level heating is to quickly heat the tube to 425°C, and the second-level heating is to heat to 1122°C at a rate of 3.5°C / min, and keep warm for ≥15min;

[0030] Step 3: Rapidly cool the heat-preserved stainless steel tubes to room temperature at a rate of 30° C. / min to obtain solution-treated austenitic stainless steel tubes. The cooling adopts air cooling, and the blowing direc...

Embodiment 3

[0032] The local solution treatment method of the austenitic stainless steel segment elbow of the present invention, the preparation method comprises the following preparation steps:

[0033] Step 1: Bending the stainless steel segment to make multiple continuous elbows;

[0034] Step 2: Position and fix the elbow on the stainless steel tube to avoid deformation of the heating elbow, and then perform primary heating, secondary heating, and soaking on multiple consecutive elbows at the same time, primary heating, secondary heating, and continuous soaking Carry out, and keep warm after soaking; the first-level heating is to quickly heat the segment to 425°C, and the second-level heating is to heat the tube to 1150°C at a rate of 4°C / min, and hold the heat for ≥15min;

[0035] Step 3: Rapidly cool the heat-preserved stainless steel tubes to room temperature at a rate of 35°C / min to obtain solution-treated austenitic stainless steel tubes. Cooling is by air cooling, and the blowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com