Copper pillar and copper wire oxide layer shelling processing technology

A processing technology and oxide layer technology, applied in the field of oxide layer, can solve the problems of difficult to handle oxide layer process, complicated and cumbersome, damage to copper materials, etc., to ensure the oxidation resistance of copper body, reduce deformation and crack tendency, stable The effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

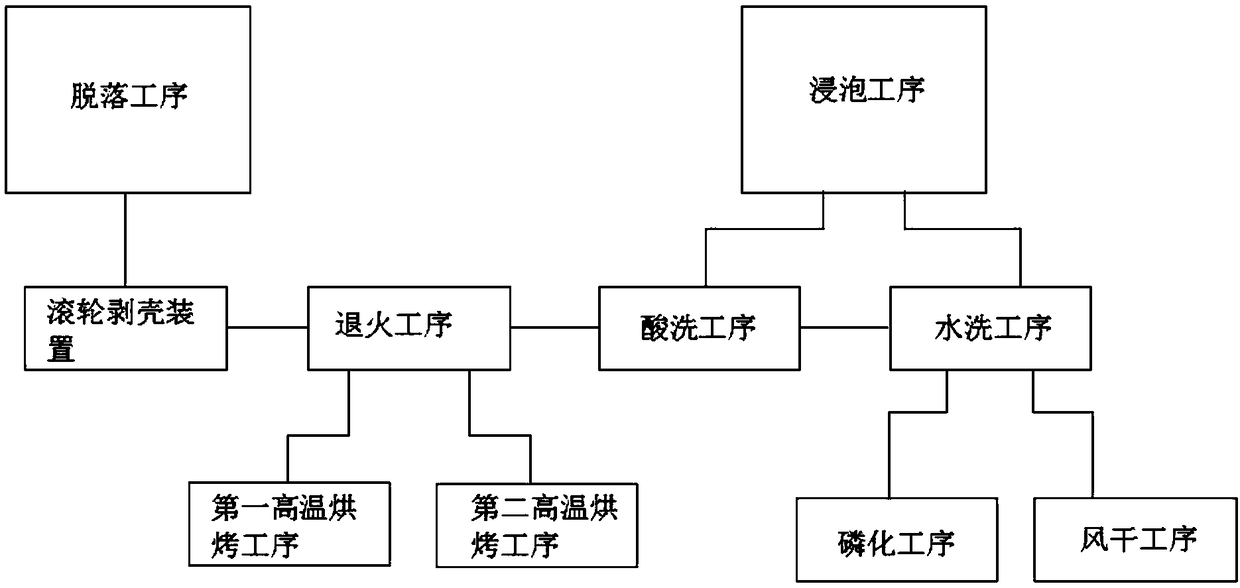

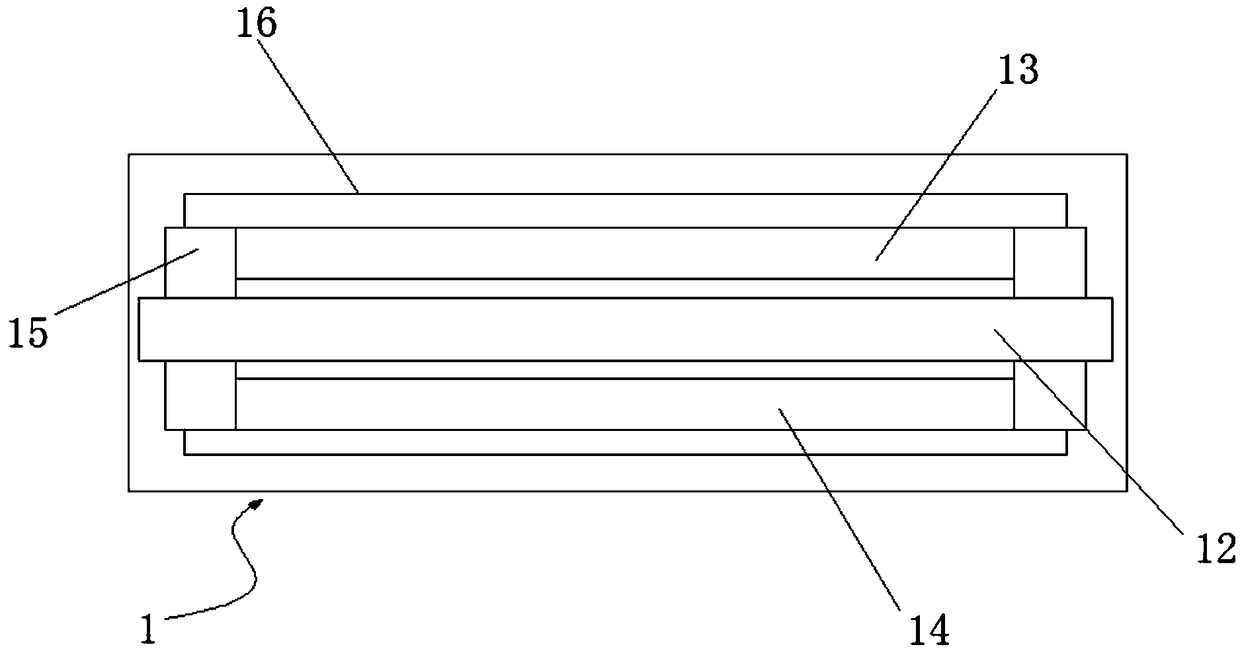

[0016] refer to Figure 1 to Figure 2 , the present invention provides copper column copper wire oxidation layer peeling process, including copper body, soaking process and shedding process, soaking process includes pickling process and water washing process, the shedding process adopts roller shelling device 1 to carry out copper body Shelling and falling off, the roller peeling device 1 is equipped with a rotating shaft 12, the two ends of the rotating shaft 12 are respectively connected to the first roller 13 and the second roller 14, and the copper body is placed on the first roller 13 and the second roller in the roller peeling device 1 Rolling peeling between 14, the annealing process is carried out on the copper body after peeling, the copper body after the annealing process is placed in the pickling tank for pickling process, and the copper body after the pickling process is placed in the washing tank for Washing process.

[0017] As mentioned above, it is effective t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com