Device and method for eliminating, regulating and controlling residual stress of alloy ring piece

A residual stress and alloy ring technology, applied in the field of electromagnetic manufacturing, can solve the problems of difficulty in meeting the processing requirements of large-sized workpieces, affecting the performance and service life of the device, and difficult to improve the electromagnetic force, so as to achieve flexible and controllable adjustment of the electromagnetic force, reducing Design difficulty, effect of eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

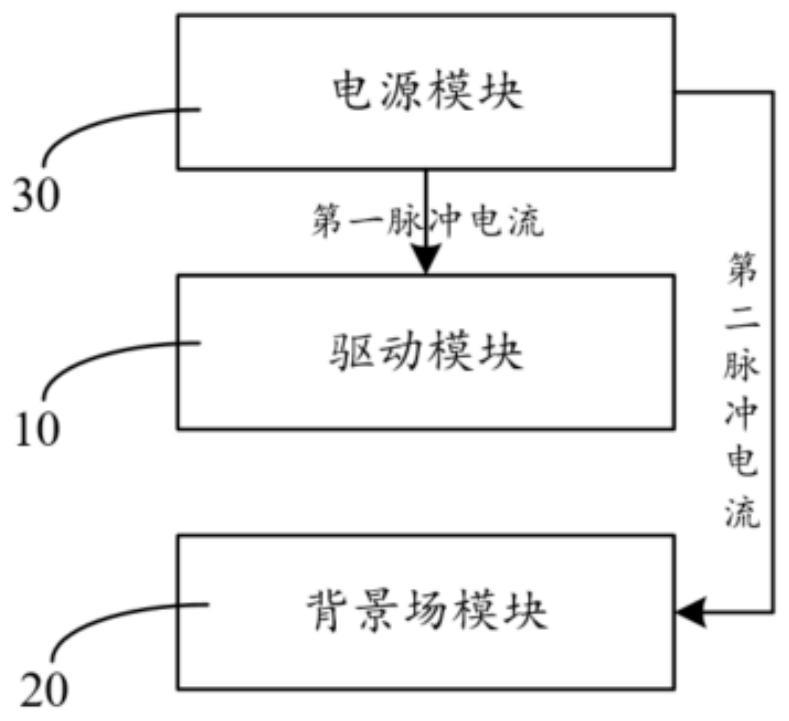

[0054] Figure 5 Schematic diagram of the structure of the device for eliminating and regulating the residual stress of alloy rings provided by an embodiment of the present invention, such as Figure 5 As shown, the device includes a driving coil 110, which is in the shape of a hollow column, and is located inside the alloy ring 50; a background field coil 210 is in the shape of a hollow column, and is located outside the alloy ring 50; Between the background field coils 210, it is connected with the background field coils 210; and the supporting power supply module and device frame, including the first power supply unit 310, the second power supply unit 320, the device end plate 420, the coil end plate 410, the coil frame 120 and Coil reinforcement layer 230 .

[0055] (1) press Figure 5 In the shown structure, the drive module (drive coil 110 and coil frame 120) is placed inside the alloy ring 50, and the background field module (background field coil 210) is placed outsi...

Embodiment 2

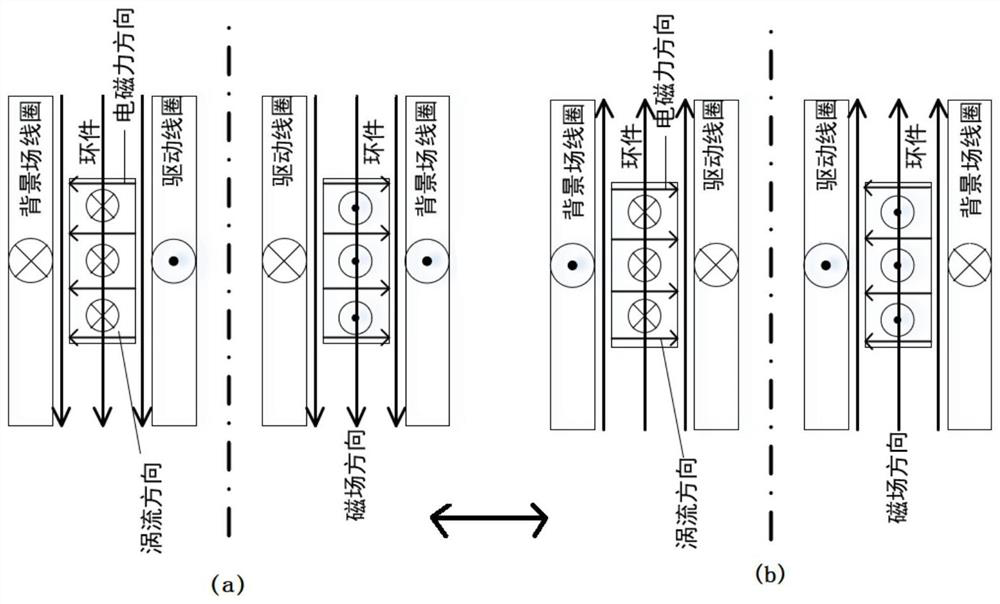

[0062] The control of residual stress is also of great significance to improve the performance of rings and expand its application value. Appropriate compressive residual stress can improve fatigue strength and inhibit cracking. The double-coil structure can simultaneously apply electromagnetic repulsion to the inner and outer sides of the alloy ring 50, so that the alloy ring 50 is in a state of compressive stress, and the stress distribution inside the ring is controlled, including the following steps:

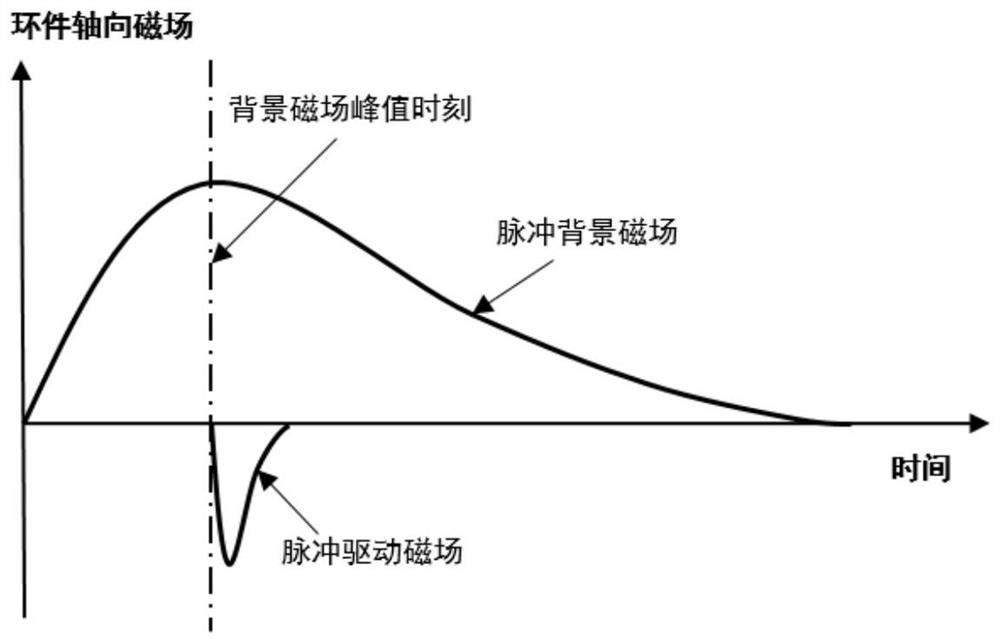

[0063]S1, the background field coil 210 is connected to the second power supply unit 320 to generate an axial background magnetic field; the driving coil 110 is connected to the first power supply unit 310 to generate an axial pulse driving magnetic field, and then induces an eddy current in the alloy ring 50 , the interaction between the magnetic field and the eddy current drives the alloy ring 50 to bulge outward.

[0064] S2, adjust the discharge energy (capacitance, volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com