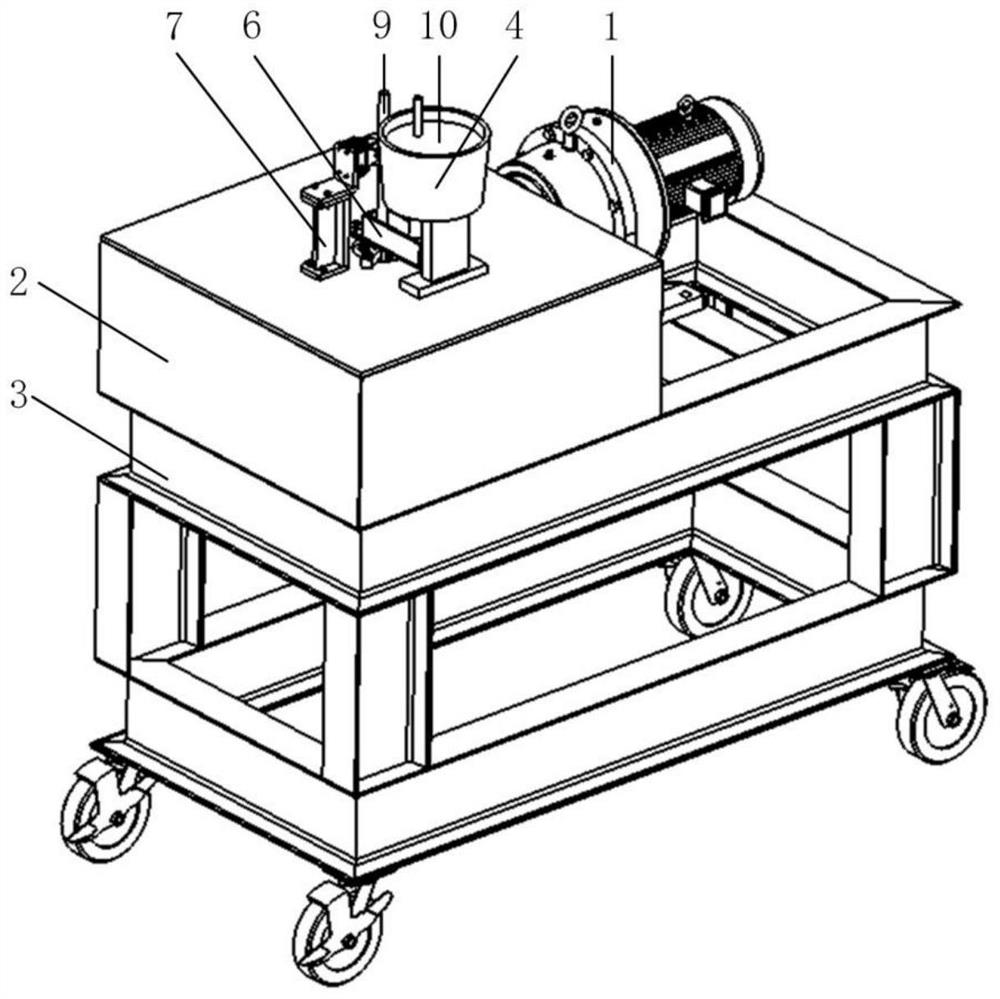

Multi-roll continuous casting and rolling equipment and method for preparing high-conductivity metal-clad materials

A metal-clad, high-conductivity technology, which is applied in the field of multi-roll continuous casting and rolling equipment for preparing high-conductivity metal-clad materials, can solve problems such as poor product quality uniformity, and achieve improved product quality uniformity, short process characteristics, and production. Efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Taking the copper-clad steel composite wire rod as an example, adopt the equipment of the present invention to process and produce the copper-clad steel composite rod, and select the outer diameter of The Q345 bar is used as the solid matrix metal 9 to be composited, and the industrial pure copper is used as the liquid cladding metal 10. The total diameter of production Copper-clad steel composite rods, where the wall thickness of the cladding metal is 2mm.

[0060] 1. First, clean and dry the outer surface of the Q345 bar to be compounded, heat the industrial pure copper to 1100°C to melt, and keep it warm for 60 minutes;

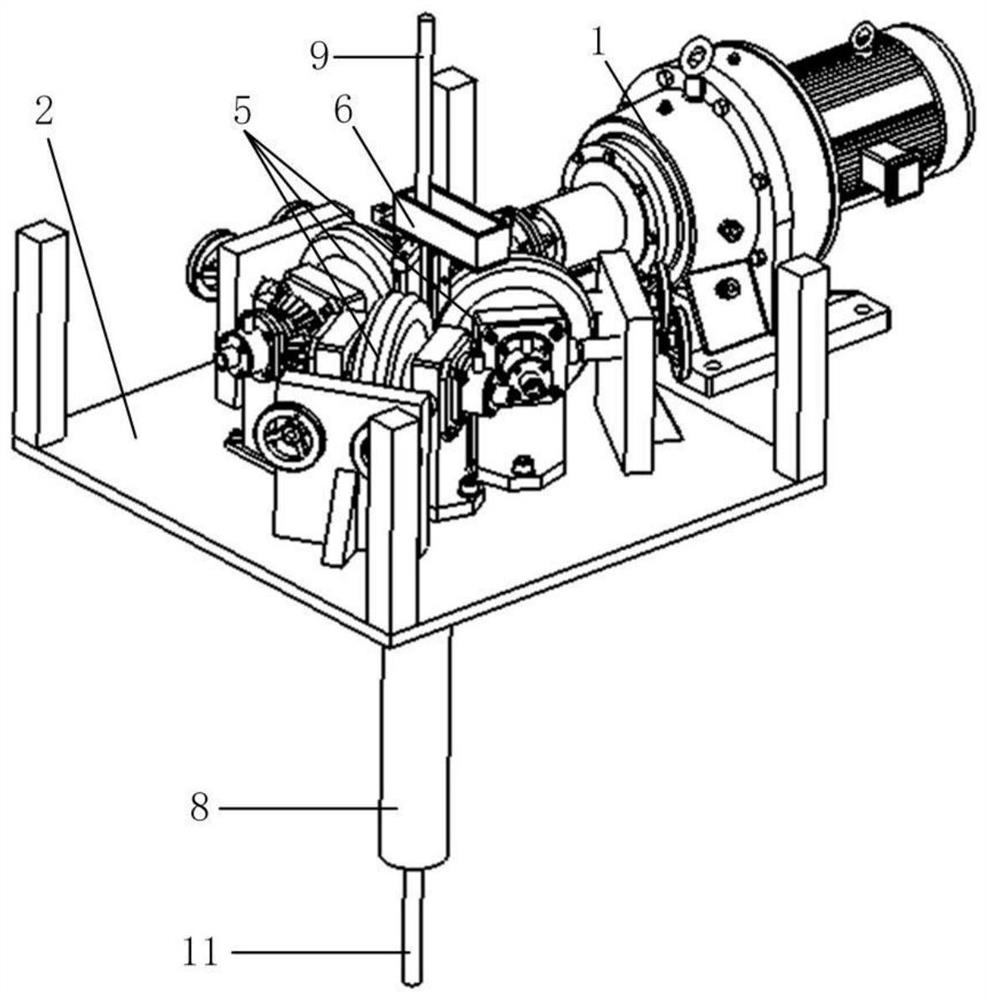

[0061] 2. After the Q345 bars to be compounded pass through the guide bracket 7 and the flow distribution device 6 in sequence, they are fed into the pass smoothly, the casting speed is set at 3.5m / min, and the multi-roll continuous casting and rolling equipment is turned on to enter the idling standby state. At the same time, the liquid industri...

Embodiment 2

[0065] Taking copper-clad titanium equilateral hexagonal composite rod as an example, adopt the equipment of the present invention to process and produce copper-clad titanium equilateral hexagonal composite rod, and select the equilateral hexagonal titanium alloy rod with a side length of 10mm as the Composite solid matrix metal 9 and industrial pure copper as liquid cladding metal 10 to produce copper-clad titanium equilateral hexagonal composite rods with a cladding wall thickness of 2 mm.

[0066] Such as Figure 9 As shown, unlike the production of high-conductivity metal cladding materials with circular cross-sections, when producing copper-clad titanium equilateral hexagonal composite rods, the first main casting roll unit 501, the first auxiliary casting roll unit 502 and the second On the surface of the casting roll sleeves 5013, 5023, 5033 of the auxiliary casting roll unit 503, there are circumferential holes 500 rotating along the axis. The cross section of the circ...

Embodiment 3

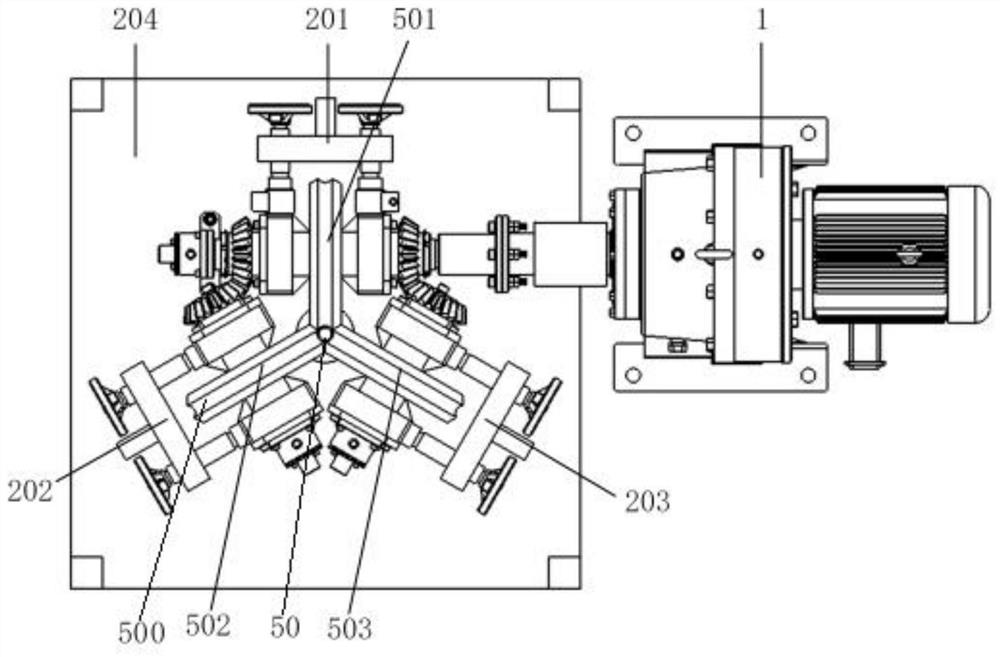

[0072] On the basis of the present invention, when the number of casting roll units in the multi-roll casting unit 5 is 4, it is a four-roll continuous casting equipment. Such as Figure 10 as well as Figure 11 As shown, the casting unit includes a first main casting roll unit 501, a first secondary casting roll unit 502, a second secondary casting roll unit 503 and a third secondary casting roll unit 504, and the surface of the casting roll sleeve is provided with a casting The axis of the roll unit rotates around the circumferential hole, the cross section of the circumferential hole is arc-shaped, the first main casting roll unit 501, the first secondary casting roll unit 502, the second secondary casting roll unit 503 and the third secondary casting roll unit The circumferential slots of the casting roll unit 504 jointly form a circular pass at adjacent positions, the circular pass is for the composite solid matrix metal 9 to pass through, and the diameter of the circula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com