A kind of noble metal quantum dots and preparation method and application thereof

A technology of gold quantum dots and quantum dots, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the limitations of large-scale preparation of small-sized nanoparticles, To solve the problems of poor practicability, environmental pollution, etc., and achieve the effect of excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

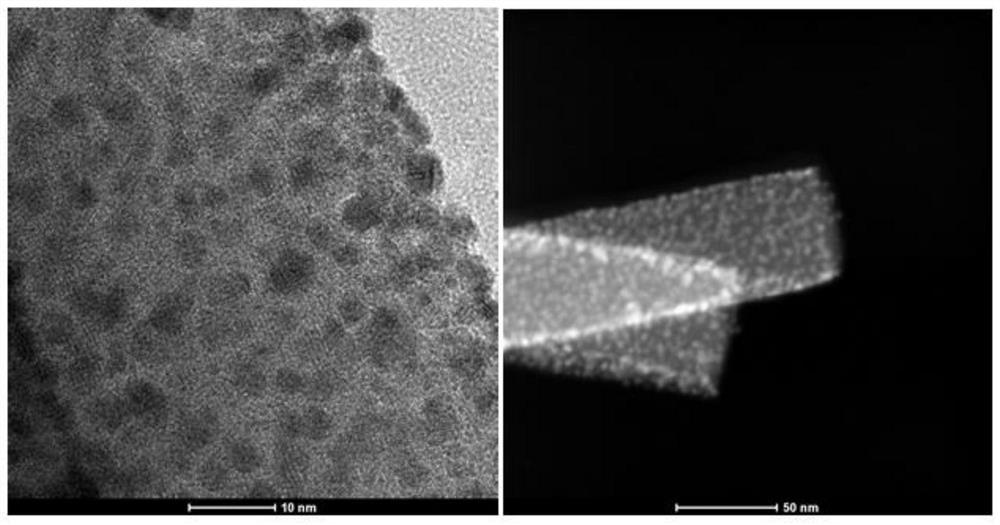

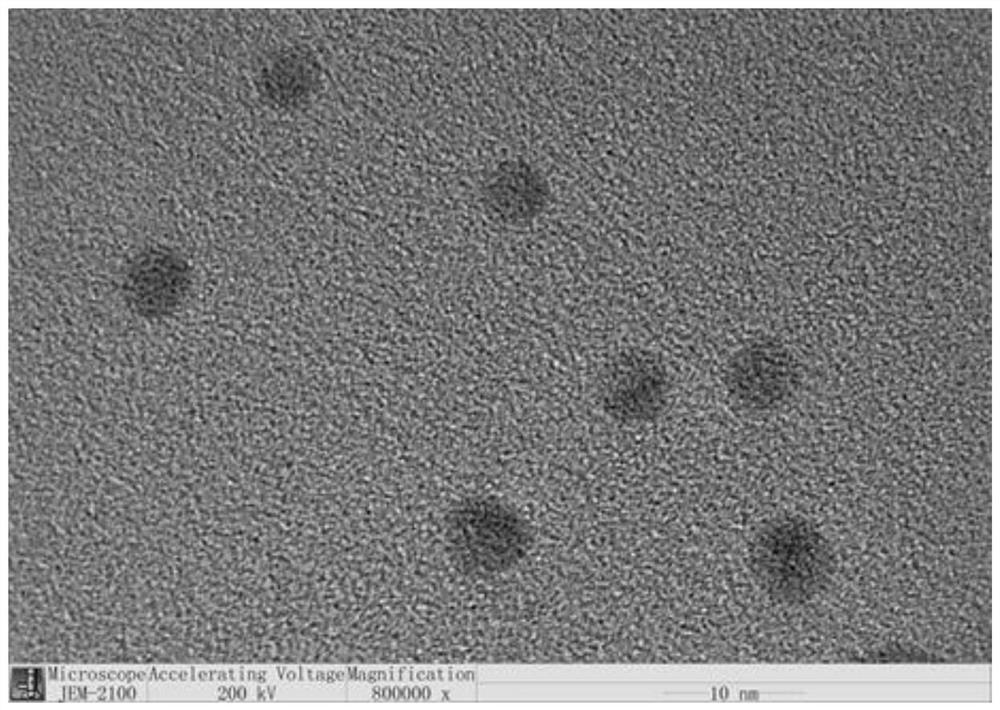

[0052] The lithium vanadate LiV 3 O 8 The nano-powder is soaked in 0.001mol / L chloroauric acid solution, soaked for 1 h to perform ion exchange, and then undergoes solid-liquid separation, washing and drying at 50°C in sequence to obtain gold vanadate;

[0053] The obtained gold vanadate was calcined at a calcination temperature of 800 °C, a calcination time of 72 h, and a heating rate of 10 °C / min to obtain gold quantum dots embedded in V. 2 O 5 mixed powder;

[0054] The obtained mixed powder was washed with 1mol / L oxalic acid for 72h to remove V 2 O 5 , to obtain gold quantum dots, the size of which is less than 20 nm.

Embodiment 2

[0056] Lithium vanadate 0.01 V 3 O 8 The nano-powder is immersed in 1mol / L gold acetylacetonate solution, soaked for 72 hours for ion exchange, and then undergoes solid-liquid separation, washing and drying at 80°C in sequence to obtain gold vanadate;

[0057] The obtained gold vanadate was calcined at a calcination temperature of 200 °C, a calcination time of 1 h, and a heating rate of 0.5 °C / min to obtain gold quantum dots embedded in V. 2 O 5 mixed powder;

[0058] The obtained mixed powder was washed with 1 mol / L formic acid for 1 h to remove V 2 O 5 , to obtain gold quantum dots, the size of which is less than 20 nm.

Embodiment 3

[0060] Lithium vanadate 2 V 3 O 8 The nano-powder was soaked in 1 mol / L silver nitrate solution, soaked for 36 hours for ion exchange, and then successively underwent solid-liquid separation, washing and drying at 60 °C to obtain silver vanadate;

[0061] The obtained silver vanadate was calcined at a calcination temperature of 500 °C, a calcination time of 5 h, and a heating rate of 5 °C / min to obtain silver quantum dots embedded in V. 2 O 5 mixed powder;

[0062] The obtained mixed powder was washed with 1 mol / L acetic acid for 1 h to remove V 2 O 5 , the quantum dots of silver are obtained, and the size of the quantum dots is equal to 20 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com