Semi-coke supported tar steam reforming catalyst and its preparation method and application

A steam reforming, supported technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Weak force and low utilization of metal active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

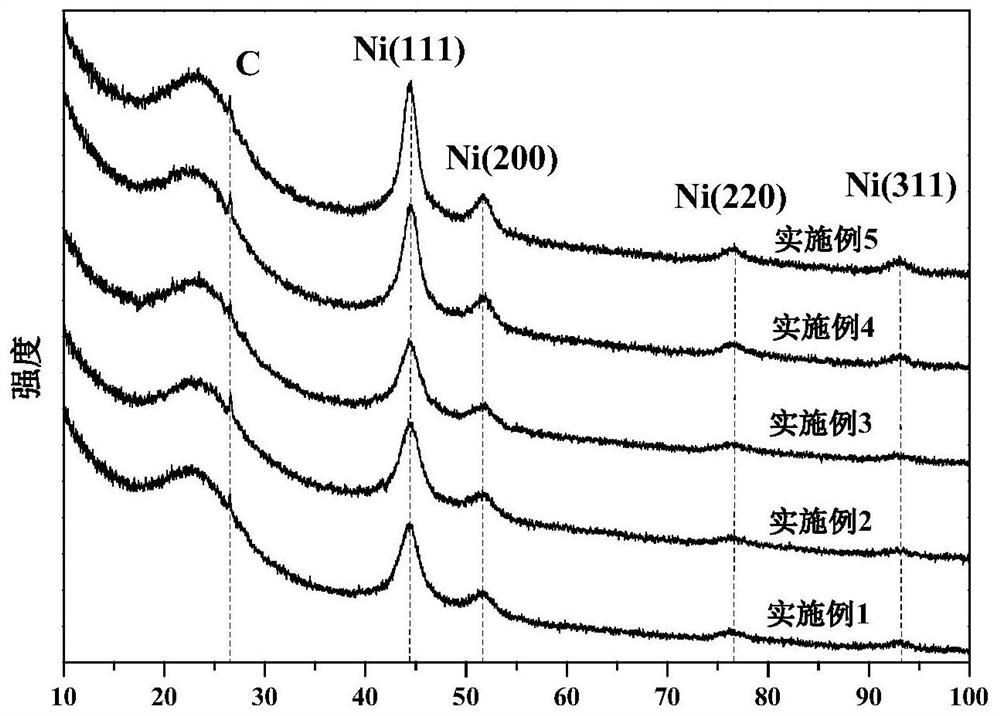

Embodiment 1

[0054] Prepare 100 mL of aqueous hydrogen peroxide solution with a mass fraction of 10%.

[0055] Preparation of oxidized low-rank coal:

[0056] Immerse 20g of low-rank coal in the above hydrogen peroxide solution with a mass fraction of 10%, mix well, stir at 40°C for 4h, filter and wash the filter residue with water until neutral, and dry at 70°C until the water content is 5%; rank coal;

[0057] Preparation of metal salt solution: weigh 5g of nickel acetate tetrahydrate, dissolve it in 100mL of deionized water; add ammonia water with a mass concentration of 25%, and adjust the pH of the salt solution to 11;

[0058] Ion exchange: Take 10 g of the oxidized low-rank coal and add it to the nickel salt solution prepared above, stir at 30°C for 24 hours, filter, wash the filter residue with water until neutral, and dry at 70°C until the water content is 3%;

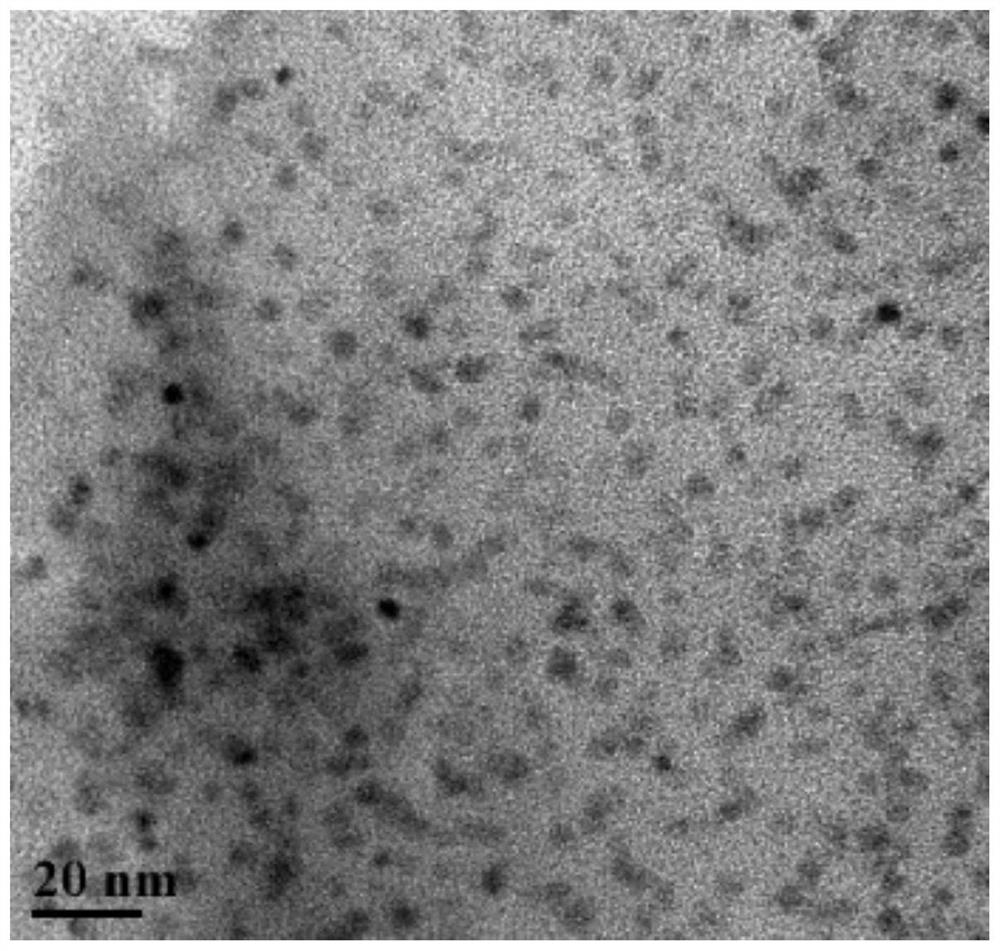

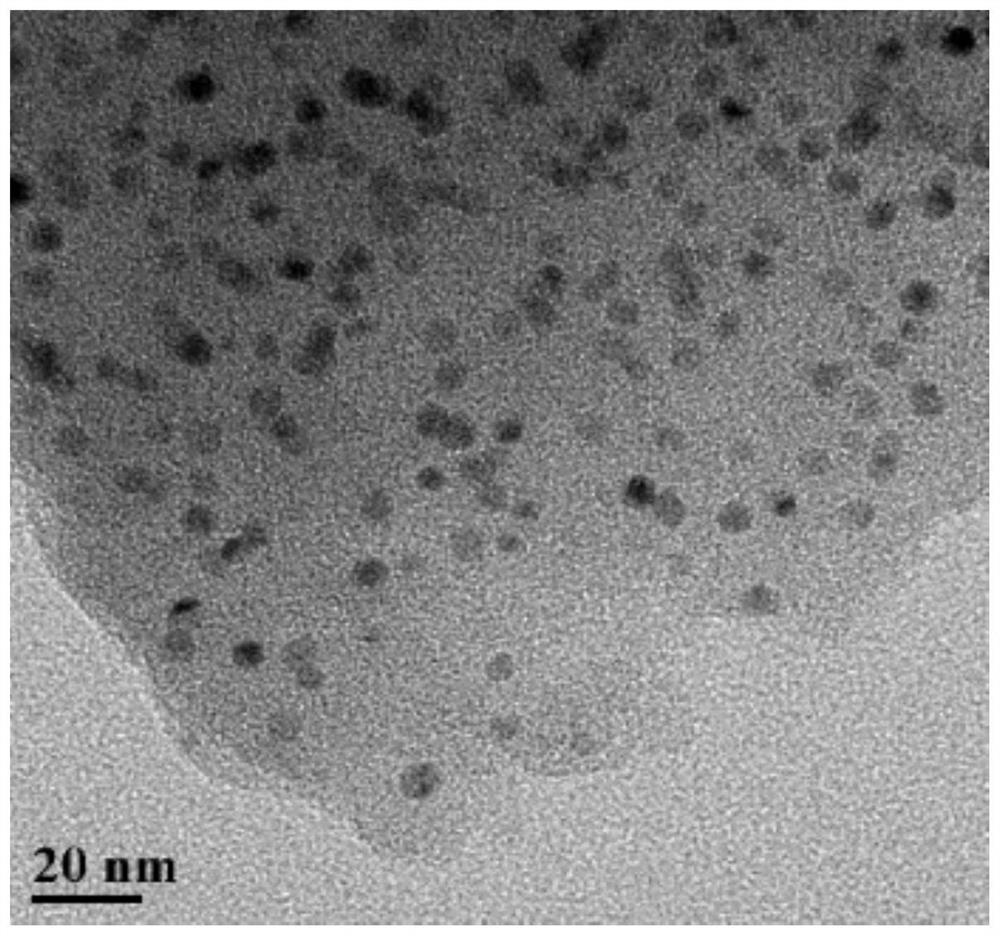

[0059] Catalyst molding: pyrolyze the above-mentioned dried filter residue under an inert atmosphere to stabilize the ...

Embodiment 2

[0068] Prepare 100 mL of aqueous hydrogen peroxide solution with a mass fraction of 20%.

[0069] Preparation of oxidized low-rank coal:

[0070] Immerse 20g of low-rank coal in the above hydrogen peroxide solution with a mass fraction of 20%, mix well, stir at 30°C for 6h, filter and wash the filter residue with water until neutral, and dry at 80°C until the water content is 3%; rank coal;

[0071] Preparation of metal salt solution:

[0072] Weigh 3.9g of anhydrous nickel chloride, dissolve it in 100mL of deionized water; add ammonia water with a mass concentration of 25%, and adjust the pH of the salt solution to 10;

[0073] Ion exchange: Take 20g of the oxidized low-rank coal and add it to the above-mentioned prepared nickel salt solution, stir at 25°C for 32h, filter, wash the filter residue with water until neutral, and dry at 80°C until the water content is 3%;

[0074] Catalyst molding: pyrolyze the above-mentioned dried filter residue under an inert atmosphere to ...

Embodiment 3

[0083] Prepare 100 mL of aqueous hydrogen peroxide solution with a mass fraction of 30%.

[0084] Preparation of oxidized low-rank coal:

[0085] Immerse 10 g of low-rank coal in the above hydrogen peroxide solution with a mass fraction of 30%, mix well, stir at 50°C for 2 hours, filter and wash the filter residue with water until neutral, and dry at 60°C until the water content is 4%, to obtain low-oxidation rank coal;

[0086] Preparation of metal salt solution: weigh 2.7g of nickel nitrate hexahydrate, dissolve it in 100mL of deionized water; add sodium hydroxide solution with a mass concentration of 40%, and adjust the pH of the salt solution to 12;

[0087] Ion exchange: Take 7g of the oxidized low-rank coal and add it to the nickel salt solution prepared above, stir at 35°C for 16 hours, filter, wash the filter residue with water until neutral, and dry at 60°C until the water content is 4%;

[0088] Catalyst molding: pyrolyze the above-mentioned dried filter residue un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com