Patents

Literature

124results about How to "Large crystal size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SAPMAC method for preparing sapphire single-crystal with size above 300mm

ActiveCN101580963AHigh purityReduce defect densityPolycrystalline material growthBy pulling from meltSingle crystalLarge size

The invention provides a SAPMAC method for preparing sapphire single-crystal with size above 300mm. In a 300mm sapphire single-crystal growing furnace, technical processes of charging as well as melting material, seeding, shouldering, isometric growing, pulling out, cooling, annealing and discharging are finished. On the basis of the existing SAPMAC method, the invention is greatly improved, so that the SAPMAC method of the invention has the advantages of larger size of crystal, higher quality, more reasonable size, higher utilization rate of material, lower unit production cost and the like, and can produce sapphire single-crystal with the size above Phi320*260mm, high purity, low defect density and favorable optical performance; in addition, the SAPMAC method of the invention can better satisfy demand of sapphire single-crystal with large size and high quality by national defense and military industry field as well as civil field, and reduces defect occurrence probability by controlling seeding structure; meanwhile, the SAPMAC method of the invention controls crystal shoulder structure, decreases shoulder stress and lowers possibility of crystal cleavage by changing pulling speed and cooling rate.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

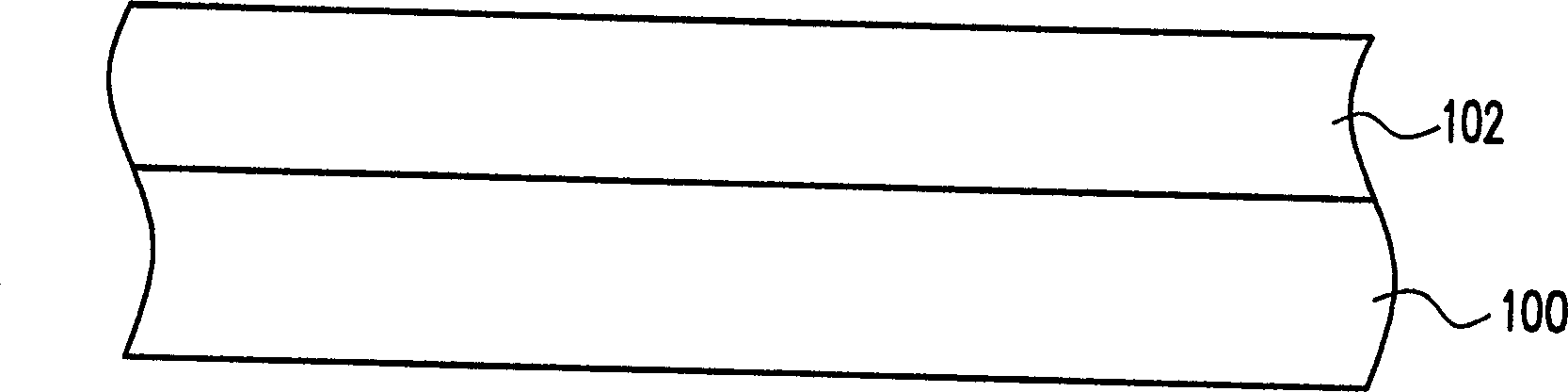

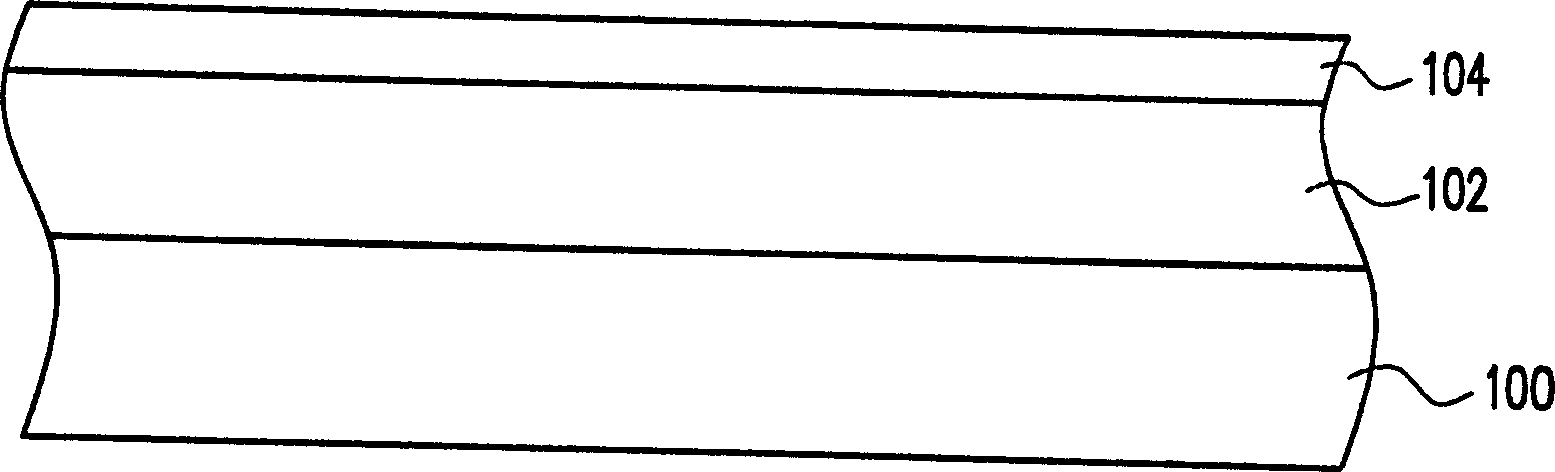

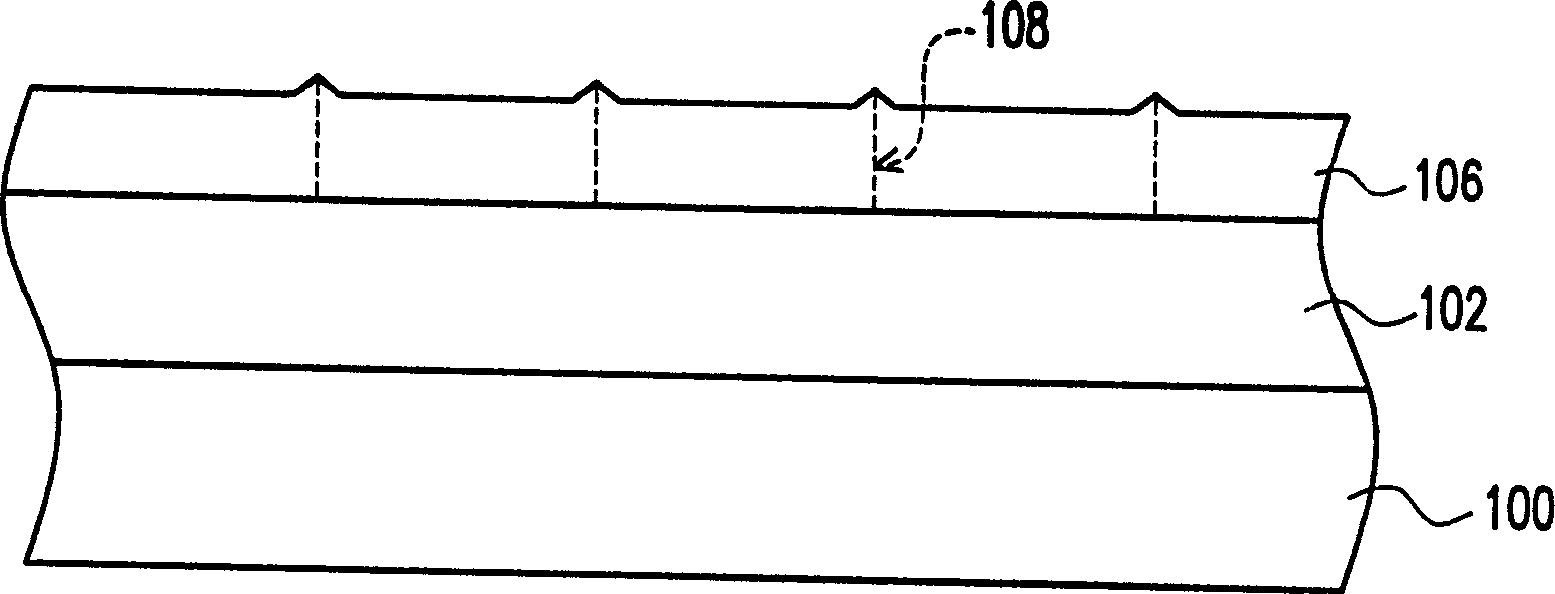

Method for making polysilicon layer

InactiveCN1501449ALarge crystal sizeImprove uniformityPolycrystalline material growthSemiconductor/solid-state device manufacturingLiquid-crystal displayCrystalline silicon

The present invention discloses a method for making polycrystalline silicon layer which comprises, providing a substrate, forming a breaker having a plurality of ditches on the substrate, forming a non-crystalline silicon layer on the breaker, proceeding a laser annealing process to form a polycrystalline silicon. The invention can be applied into the production of low-temperature polycrystalline silicon thin film transistor LCDs.

Owner:AU OPTRONICS CORP

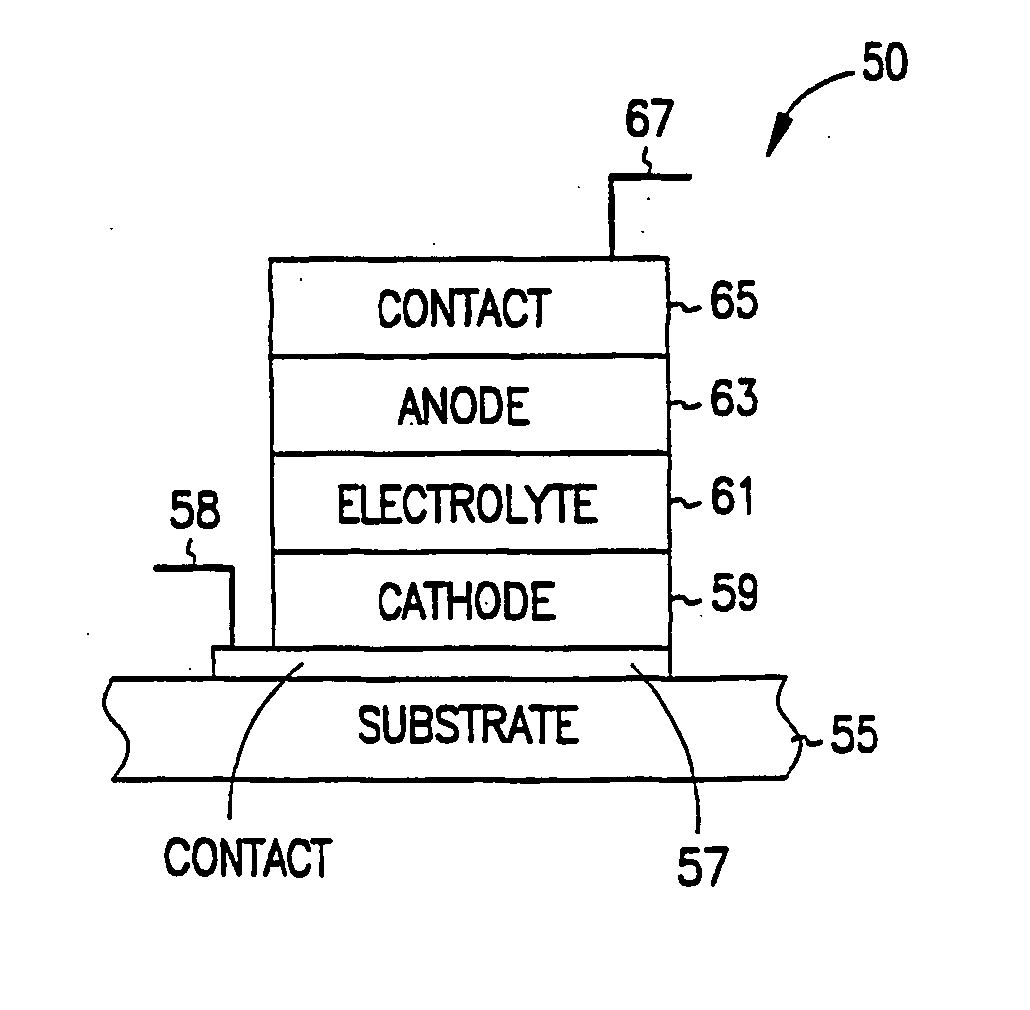

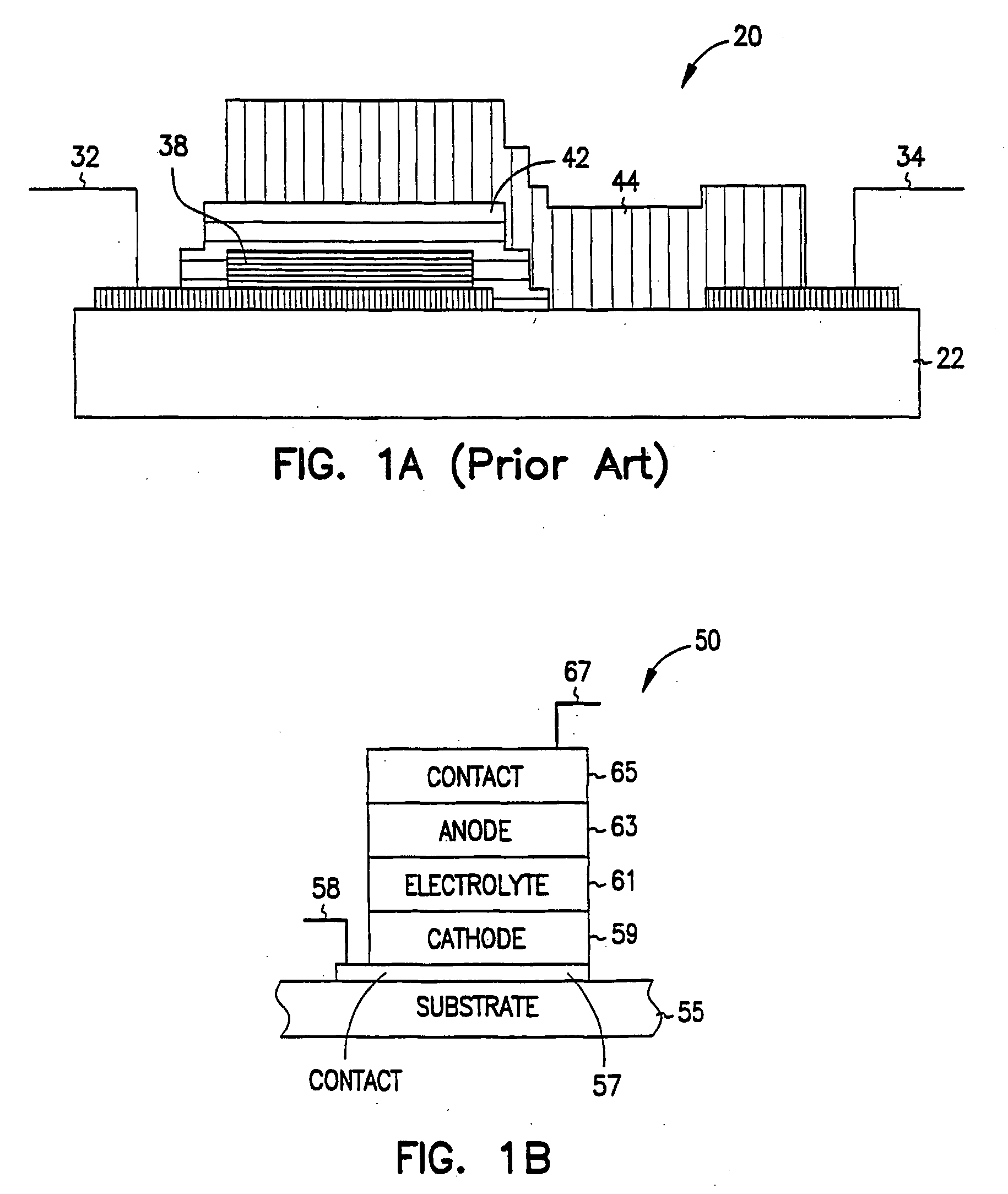

Integrated capacitor-like battery and associated method

InactiveUS20050045223A1Excellent electrical propertiesLarge crystal sizeElectrolytic capacitorsCell electrodesElectrical batteryCrystal structure

A method and system for fabricating solid-state energy-storage and energy-conversion devices including fabrication of films for devices without an anneal step, especially for the fabrication of supercapacitors and photovoltaic cells. A film is fabricated by depositing a first material layer to a location. Energy is supplied directly to the material forming the film. The energy can be in the form of energized ions of a second material. Supplying energy directly to the material and / or the film being deposited assists the growth of the crystalline structure of the film and controls stoichiometry.

Owner:CYMBET CORP

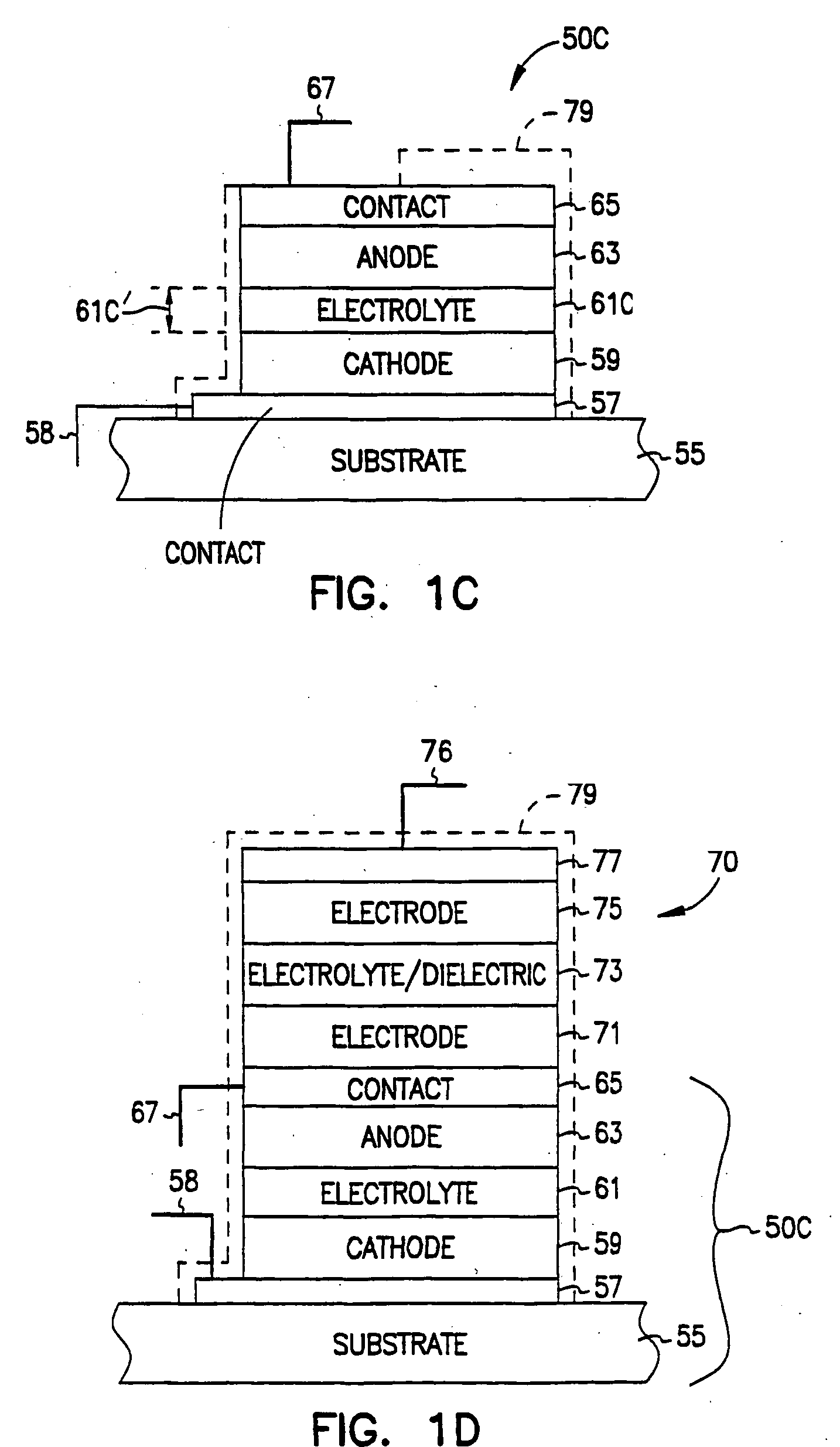

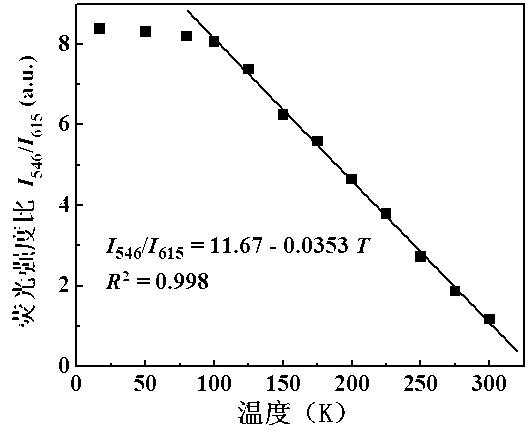

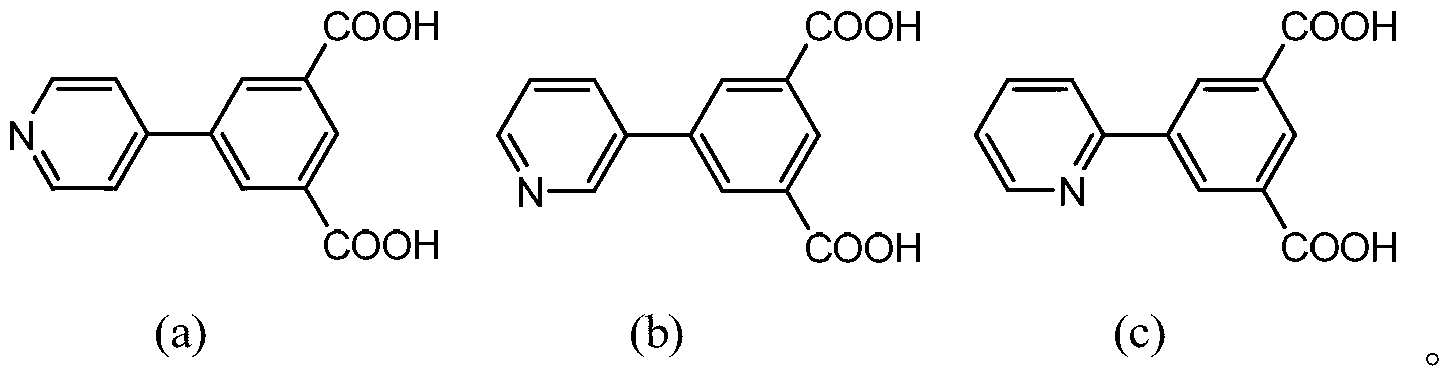

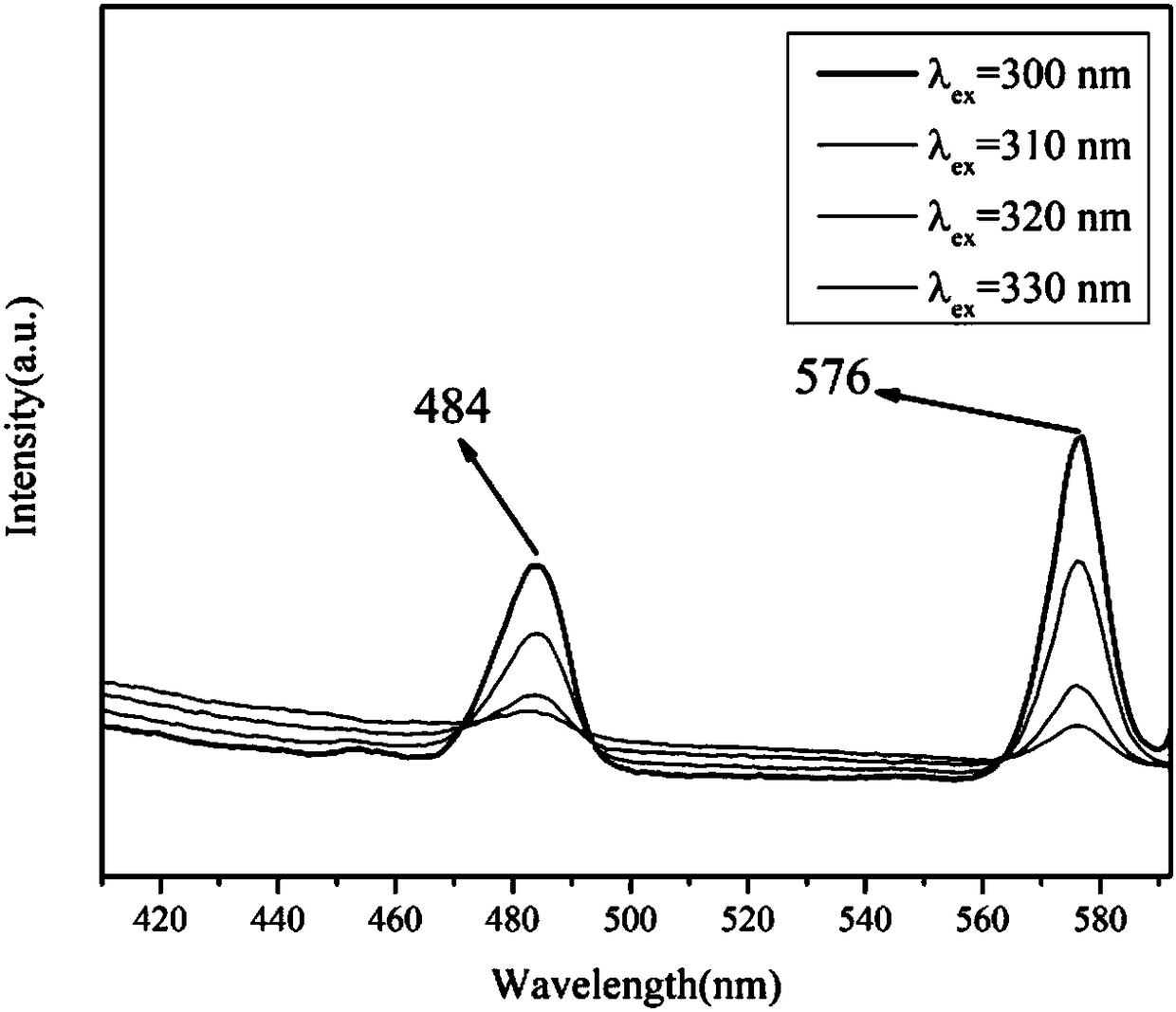

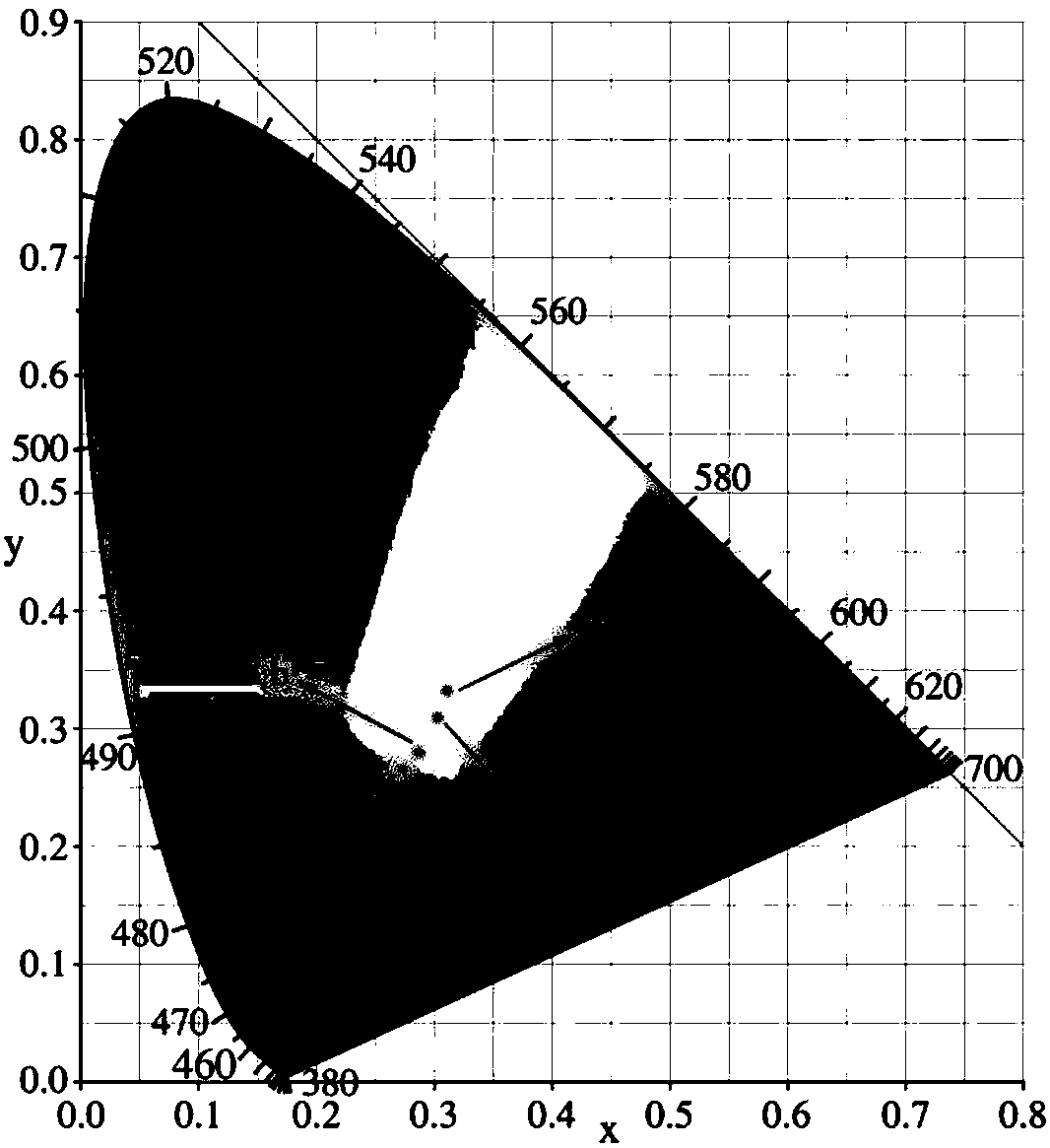

Dual-rare-earth-metal organic frame material used in temperature detection and preparation method of dual-rare-earth-metal organic frame material

InactiveCN103319509AHigh degree of crystallinityLarge crystal sizeThermometers using physical/chemical changesGroup 3/13 element organic compoundsRare earthCarboxylic acid

The invention relates to a dual-rare-earth-metal organic frame material used in temperature detection and a preparation method of the dual-rare-earth-metal organic frame material. The dual-rare-earth-metal organic frame material has a structure general formula (Tb1-xEux)Ln, wherein L is an organic ligand containing a pyridine carboxylic acid group, x is more than 0 or not more than 0.5, and n is equal to 1-4. The dual-rare-earth-metal organic frame material is prepared through a hydrothermal or solvothermal reaction. The dual-rare-earth-metal organic frame material is simple in preparation process, high in yield and good in stability. The dual-rare-earth-metal organic frame material simultaneously has characteristic light-emitting peaks of rare earths of europium and terbium, is capable of realizing self-calibrating temperature detection because a good linear relation exists between a strength ratio of the two peaks and the temperature, and is high in sensitivity reaching 3.53.K<-1>; the dual-rare-earth-metal organic frame material to be expected as a novel temperature sensing material is practically applied to the field of low-temperature detection because the light-emitting color within a temperature range of 14-300K changes with the change of the temperature.

Owner:ZHEJIANG UNIV

Method of forming particles for use in chemical-mechanical polishing slurries and the particles formed by the process

InactiveUS6596042B1Low efficiencyPrevent and delay aqueous decompositionMaterial nanotechnologyPigmenting treatmentAbrasive agentCerium

The present invention provides a process for producing particles suitable for use as abrasives in chemical-mechanical polishing slurries. The process according to the invention includes adding a crystallization promoter such as Ti[OCH(CH3)2)]4 to an aqueous cerium salt solution, adjusting the pH of the solution to higher than 7.0 using one or more bases, and subjecting the solution to hydrothermal treatment at a temperature of from about 90° C. to about 500° C. to produce the particles.

Owner:FERRO CORP

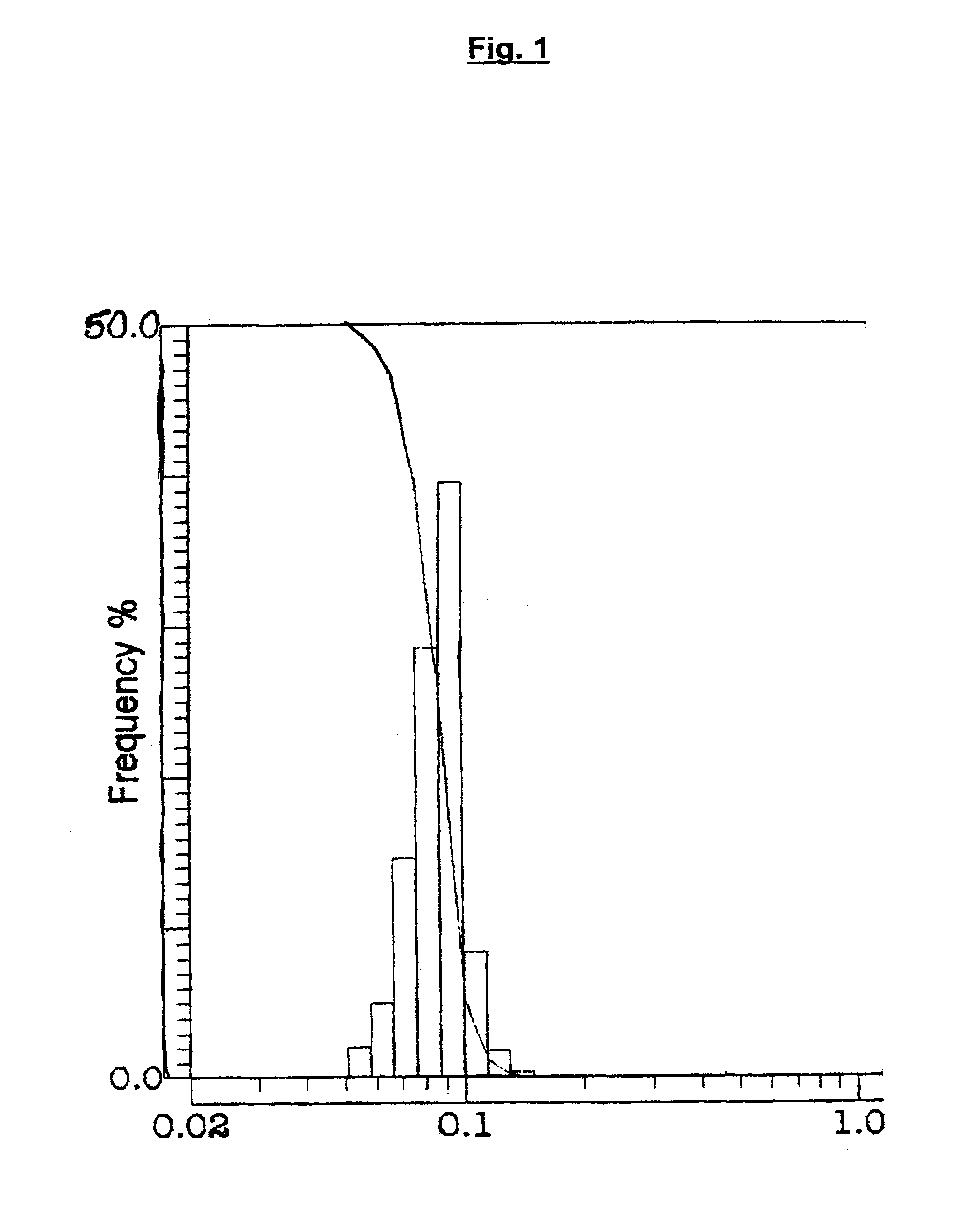

Toner and toner production method

A toner which includes a binder resin, a colorant and a hydrocarbon wax has a ratio W1 / W2 of the half width W1 (° C.) of a endothermic peak derived from melting of the hydrocarbon wax in a first temperature rise process on the toner to the half width W2 (° C.) of a endothermic peak derived from melting of the hydrocarbon wax in a second temperature rise process, as measured with a differential scanning calorimeter, with the ratio W1 / W2 being not less than 0.50 and not more than 0.90.

Owner:CANON KK

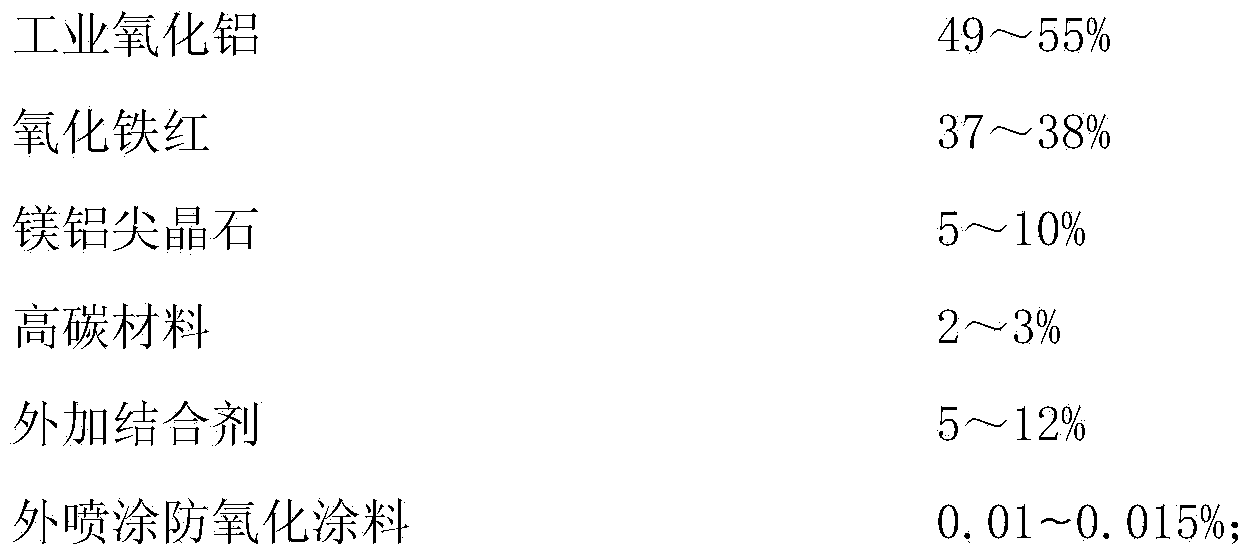

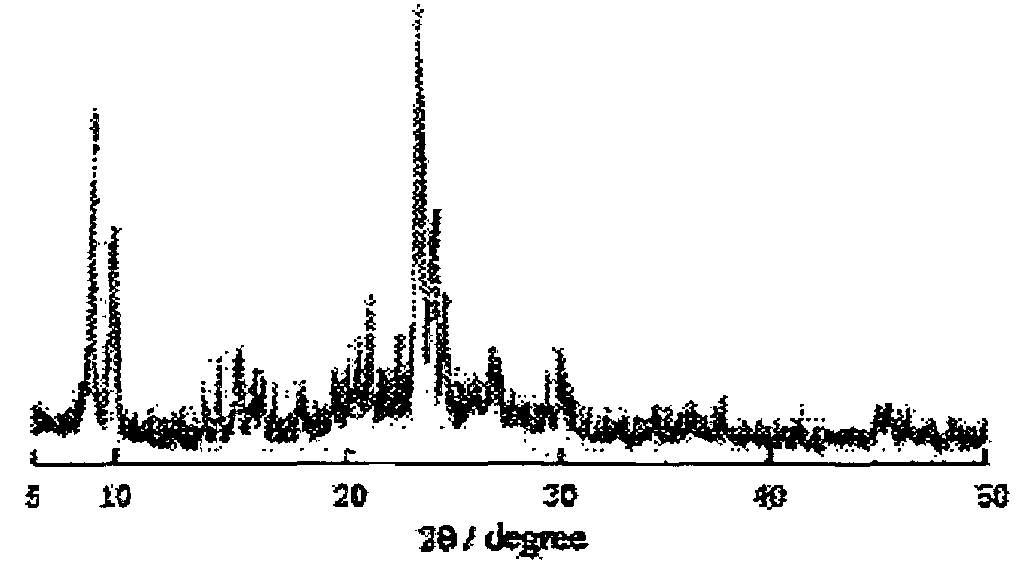

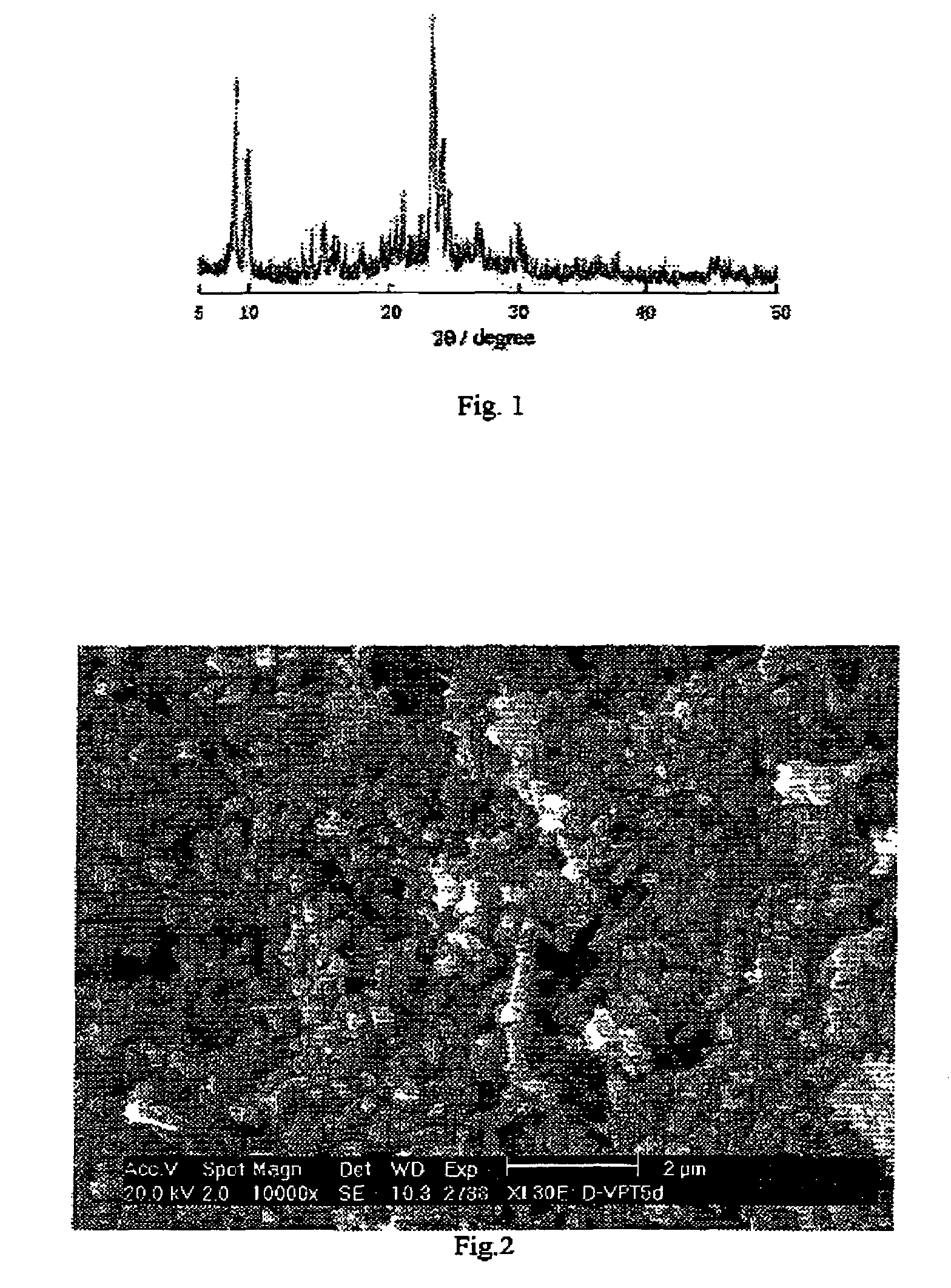

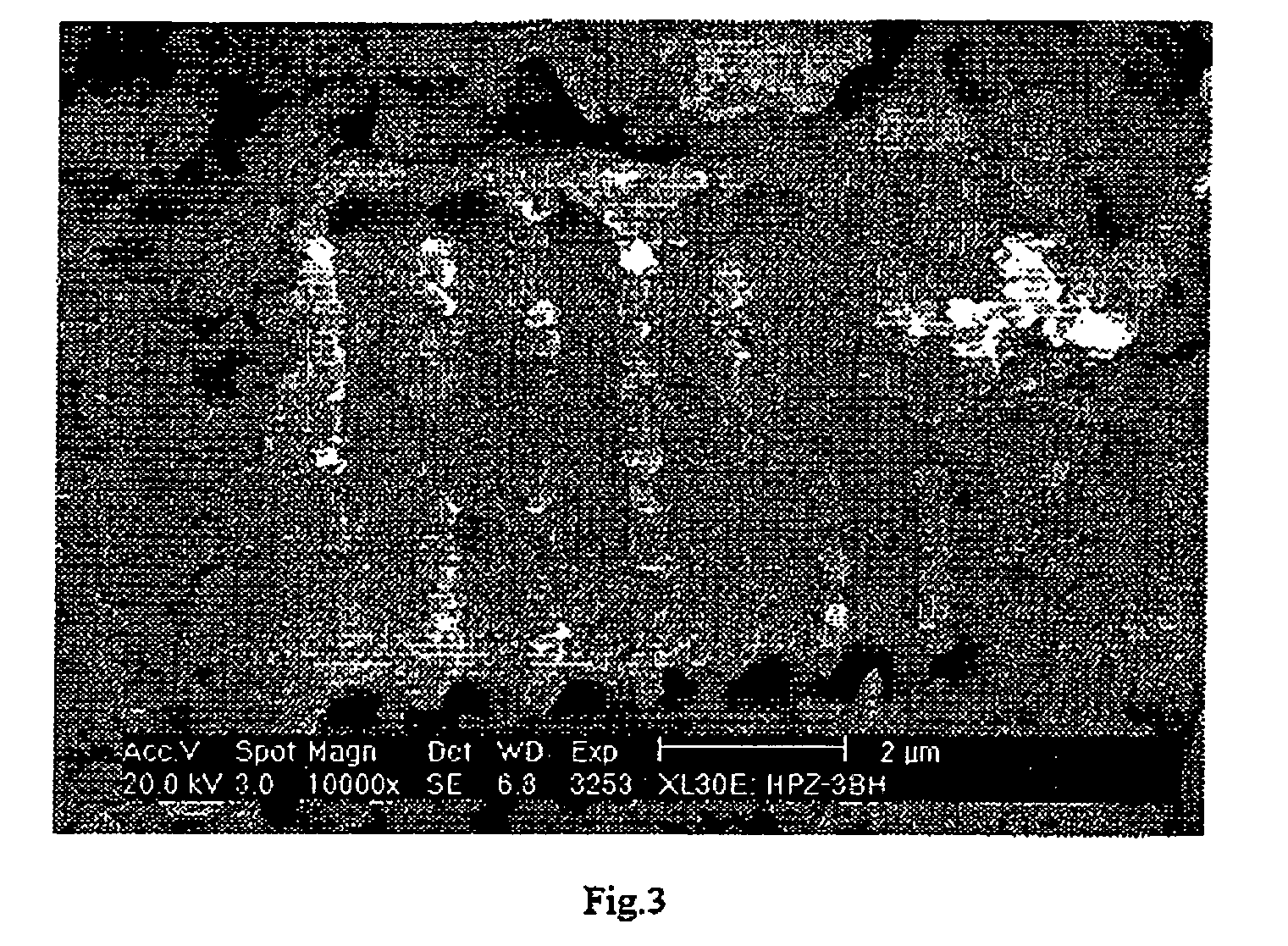

Synthetic hercynite and production method thereof

The invention provides synthetic hercynite and a production method thereof. The synthetic hercynite can be sintered by using a tunnel at a large scale. The synthetic hercynite comprises the following chemical components: industrial aluminum oxide, iron oxide red, magnesium aluminate spinel, a high-carbon material, an additional binder and an out-spayed antioxidant coating. The production method of the synthetic hercynite comprises the following steps: burdening, premixing, mixing, molding, thermal treatment, spraying a billet surface, sintering and synthesizing, and inspecting. The characteristics that the Fe2<+> and Mg2<+> ions are similar in radius, the magnesium aluminate spinel and the hercynite have the same crystal structures are utilized, so as to generate solid solutions of two spinels, and stabilization of the hercynite is utilized. The obtained hercynite is high in purity, large in crystal size, and good in stability. Meanwhile, the dead space of a tunnel kiln is utilized, an energy source is saved, the production technology is simplified, the cost is reduced, and large-scale production can be achieved.

Owner:UNIV OF SCI & TECH LIAONING

Process for producing binder-free ZSM-5 zeolite in small crystal size

ActiveUS7601330B2Readily availableLarge crystal sizeAluminium compoundsMolecular sieve catalystsEffective surfaceWater vapor

The present invention relates to a process for producing a binder-free ZSM-5 zeolite in small crystal size. The invention is primarily used for solving the problems in the practical application, e.g., the zeolite powder is difficult to be recovered and easily inactivates and aggregates, and the addition of the binder in the shaping process will result in the reduction of effective surface areas and introduce the diffusional limitation. Said problems are better solved in the present invention by using diatomite or silica aerogel as the main starting material, adding a seed crystal orienting agent, a silica sol and sodium silicate for kneading and shaping, and then converting to integrative ZSM-5 in small crystal size by vapor-solid phase crystallization with organic amine and water vapor. Said process can be used in the industrial preparation of ZSM-5 molecular sieve catalyst in small crystal size.

Owner:CHINA PETROCHEMICAL CORP +1

Blue-jewel-crystal multi-crucible melt growth technolgoy

ActiveCN101024898AThe structure of the temperature field is stableAdjustable temperature gradientPolycrystalline material growthFrom frozen solutionsFurnace temperatureHearth

The invention provides a multi-pot melt growth technique for growing sapphire crystals, comprising: (1) pretreating aluminum oxide raw material; (2) placing the pretreated aluminum oxide blocks and the oriented seed crystals into pots and moving into high temperature descending furnace, sealing the whole system and power-on to raise temperature, starting mechanical pump and diffusion pump in turn, vacuumizing to 10-3-10-4Pa, and when the furnace temperature up to 1500-1800deg.C, charging inert gas and continuing raising temperature to the set temperature (2100-2250deg.C); (3) when the furnace temperature up to the set temperature, preserving heat for 4-8 hours, regulating hearth temperature and pot positions to smelt raw material and seed crystal top to implement inoculation growth and setting solid-liquid interface temperature gradient at 10-50deg.C / cm and controlling pot descending rate at 0.1-3.0mm / h; and (4) after the crystal growth ends, making in-situ annealing treatment. And the process has features of raw material pretreatment, special temperature field design, multi-pot technique, in-situ annealing treatment, etc, and advantages of stable temperature field, adjustable temperature gradient, operating convenience, low average energy consumption, high yielding by one furnace, and beneficial to industrialized production.

Owner:苏州晶生新材料有限公司

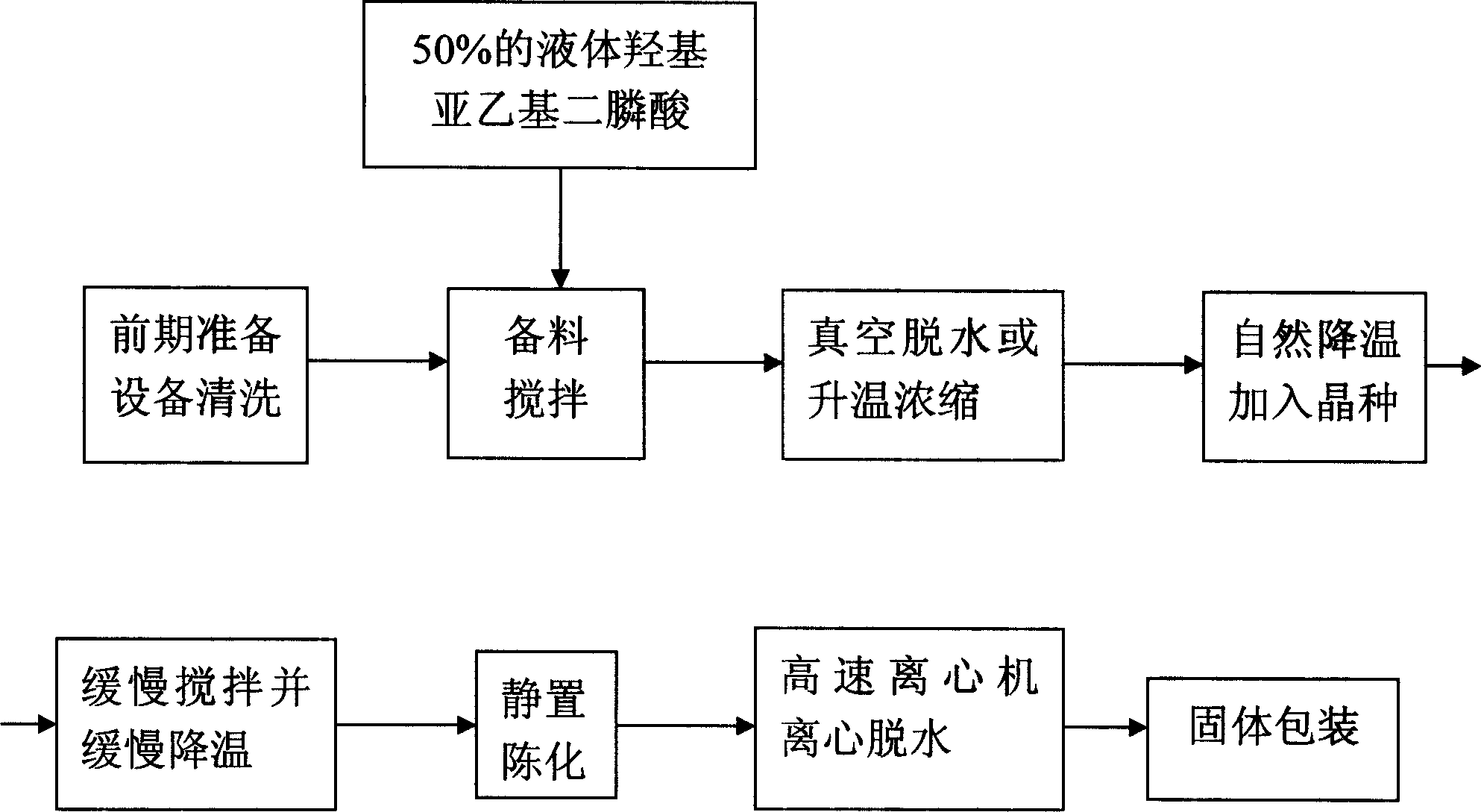

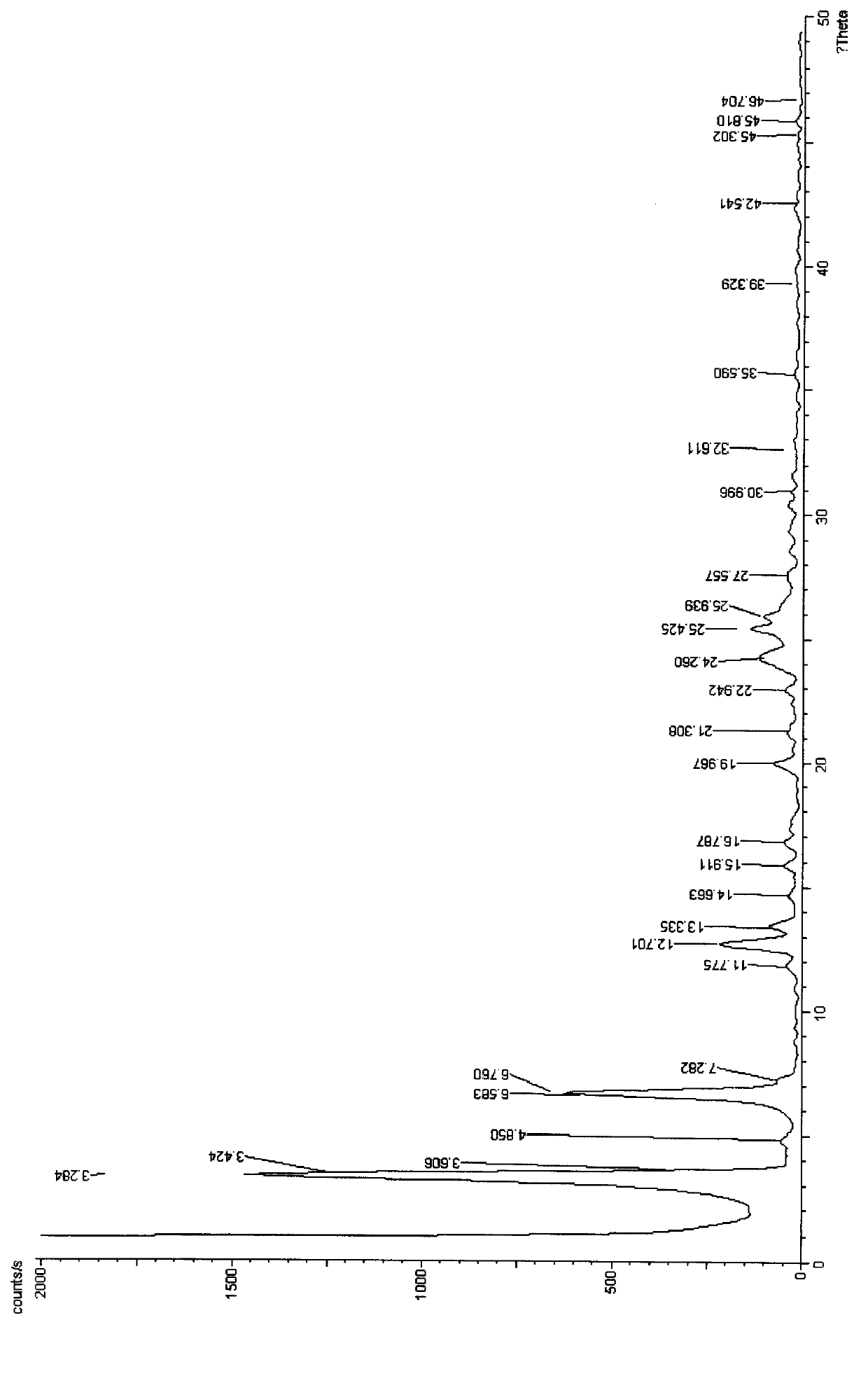

Preparing process adapted for electronic grade solid hydroxyethylidene diphosphonic acid

ActiveCN101016315AEasy to packEasy to storeGroup 5/15 element organic compoundsHydroxyethylidene Diphosphonic AcidMetal

The invention discloses a making method of electron-grade solid hydroxy trimethylphosphine, which comprises the following steps: (1) cleaning autoclave, condenser and relative equipment clearly; (2) weighing liquid hydroxy trimethylphosphine into autoclave; stirring; (3) dehydrating in the vacuum under 35-120 deg.c; (4) cooling to 40-90 deg.c naturally; adding seed with quantity at 50-50000ppm; (5) cooling to indoor temperature; stewing; aging 4-20h; (7) centrifuging at high-speed centrifuger to dehydrate with velocity at 500-5000r / min; (8) packing the solid HEDP with activity over 95% and arsenic content less than 7ppm.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

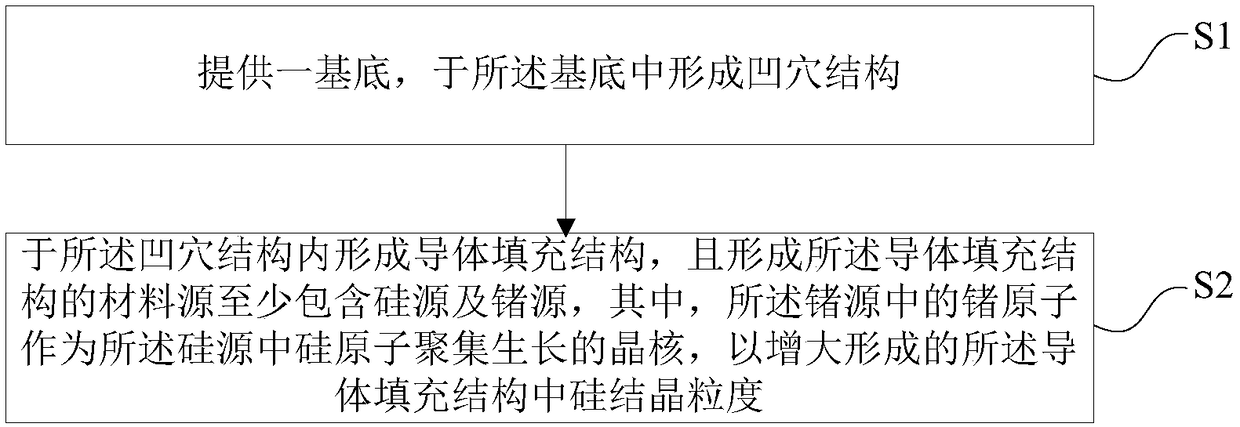

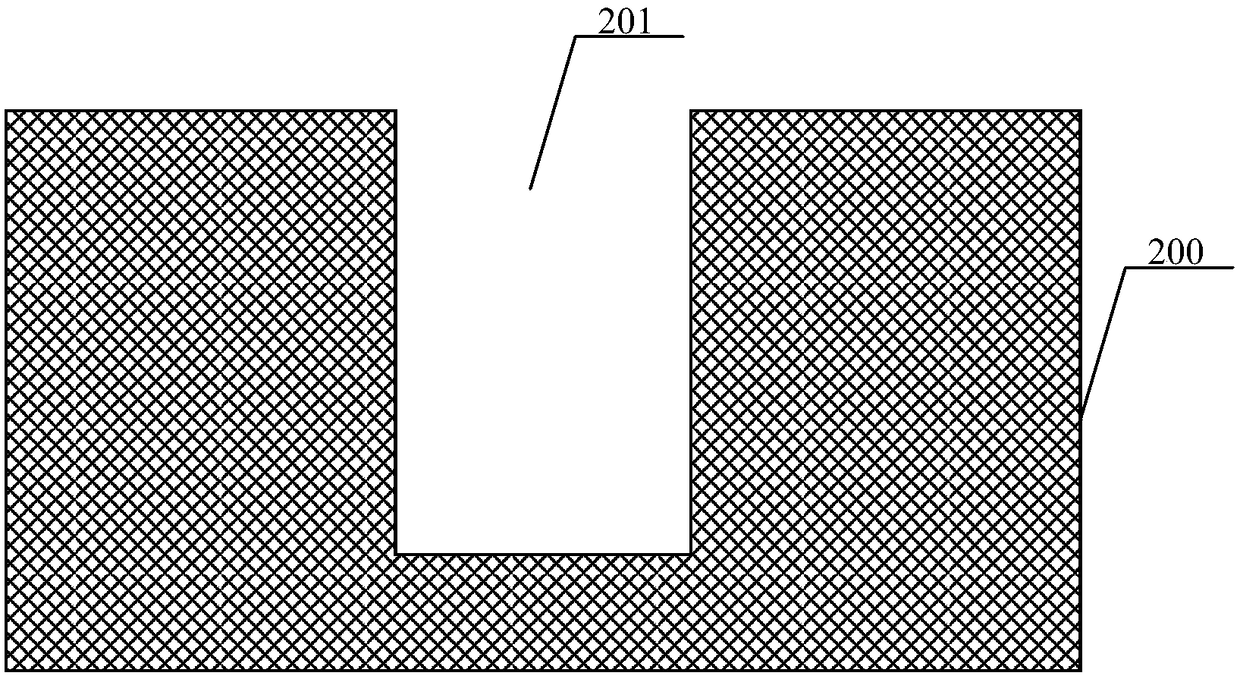

Conductor structure, capacitor array structure and preparation method

ActiveCN108155152AActive connectionIncrease the crystal sizeTransistorSemiconductor/solid-state device manufacturingElectrical conductorStructure based

The invention provides a conductor structure based on a polysilicon process, a capacitor array structure and a preparation method. The preparation method of the conductor structure comprises the stepsthat a substrate is provided, and a recess structure is formed in the substrate; a conductor filling structure is formed in the recess structure, and a material source which forms the conductor filling structure at least comprises a silicon source and a germanium source; and germanium atoms in the germanium source serve as crystal nucleuses for aggregating and growing silicon atoms in the siliconsource to increase the silicon crystal grain size in the conductor filling structure. According to the scheme provided by the invention, the method of manufacturing large-grain polycrystalline silicon is proposed; the crystal nucleus element for aggregating and growing silicon crystal grains is introduced, such as germanium, so that silicon atoms are aggregated to increase the crystal grain size;increasing the crystal grain size of polycrystalline silicon can reduce the influence of grain boundary traps on carriers and further increases the conductivity; a protective layer is arranged to prevent the influence of germanium in the conductor filling structure on the process; and the conductor filling structure and other structural layers are effectively connected, which further improves theelectrical properties of the conductor filling structure.

Owner:CHANGXIN MEMORY TECH INC

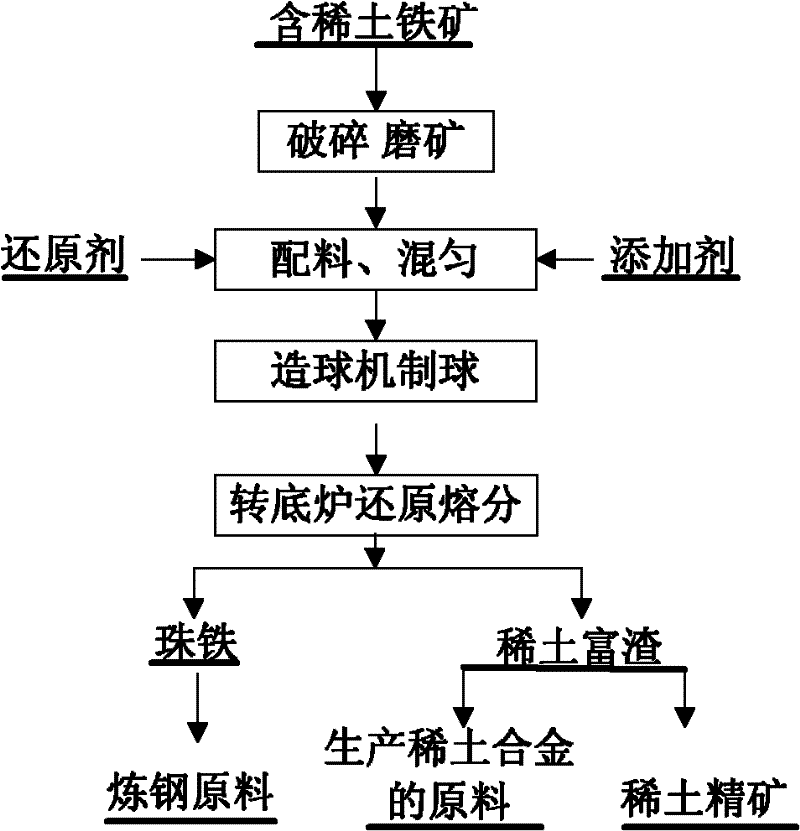

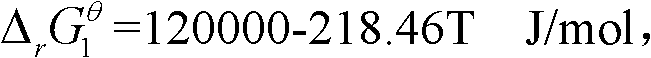

Method for separating and enriching iron and rare earth in rare earth crude ore containing iron

The invention discloses a method for separating and enriching iron and rare earth in rare earth crude ore containing iron, which belongs to the field of ironmaking, relates to a method for separating and enriching rare earth and iron in the rare earth crude ore containing iron and is used for the comprehensive utilization of the rare earth crude ore containing iron. The method is characterized inthat: the rare earth crude ore containing iron, a carbon-containing reducer, a bonding agent and an additive are used as raw material; and the process comprises the steps of ore grinding, material preparation, uniform mixing, agglomeration, reducing and melt extraction, crushing and magnetic separation; and thus, beaded iron and rare earth enriched slag can be prepared. The produced beaded iron can be used as a raw material for steelmaking in an electric furnace or a converter; the rare earth enriched slag can be used for producing rare earth silicoferrite or dressed to produce rare earth concentrate; and thus, the iron resources and rare earth resources can be fully utilized, and the rare earth crude ore containing iron can be comprehensively used. The method can satisfy the needs of steel industry and rare earth industry and can create great social and economic benefit.

Owner:UNIV OF SCI & TECH BEIJING

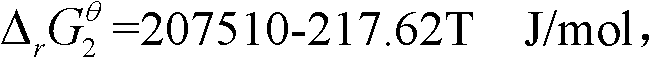

Clean production method for co-production of ammonium bicarbonate through combination of high purity carbon dioxide and melamine tail gas

InactiveCN102897796AIncrease concentrationIncrease production capacityAmmonium carbonates/bicarbonatesCarbonizationCarbon dioxide binding

The present invention relates to a clean production method for co-production of ammonium bicarbonate through combination of high purity carbon dioxide and melamine tail gas. According to the clean production method, carbon dioxide gas in a large nitrogen fertilizer device is subjected to decompression; the decompressed carbon dioxide gas and melamine tail gas are subjected to a reaction in a main carbonization tower, wherein the melamine tail gas is subjected to absorption condensation; and then a thickener treatment, centrifugation separation and packaging are performed to obtain an ammonium bicarbonate product, wherein the carbonized dilute mother liquor and the centrifugated waste liquid enter recycling. According to the present invention, high purity carbon dioxide gas is adopted, such that the effective concentration of the carbon dioxide actually participating in the reaction is increased, and production capacity is significantly increased compared with the carbonation equipment having the same size; the dilute mother liquor from the ammonium bicarbonate production is recycled so as to achieve clean production; and the purity of the carbon dioxide gas is high, and the impurity content is significantly reduced so as to easily improve product quality.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

Laminated glass article with ceramic phase and method of making the article

InactiveUS10357945B2High transparencyHigh dielectric constantLamination ancillary operationsLaminationMetallurgyGlass-ceramic

A method for forming a laminated glass article with a ceramic phase, such as a beta-spodumene phase, located at least at the junctures between a glass core and directly adjacent glass clad layers, and in some embodiments located throughout the laminated glass article. In some embodiments, a method is disclosed herein for forming a beta-spodumene glass-ceramic sheet, or a laminated glass article having a ceramic phase, or a laminated glass article having a beta-spodumene glass-ceramic, is disclosed.

Owner:CORNING INC

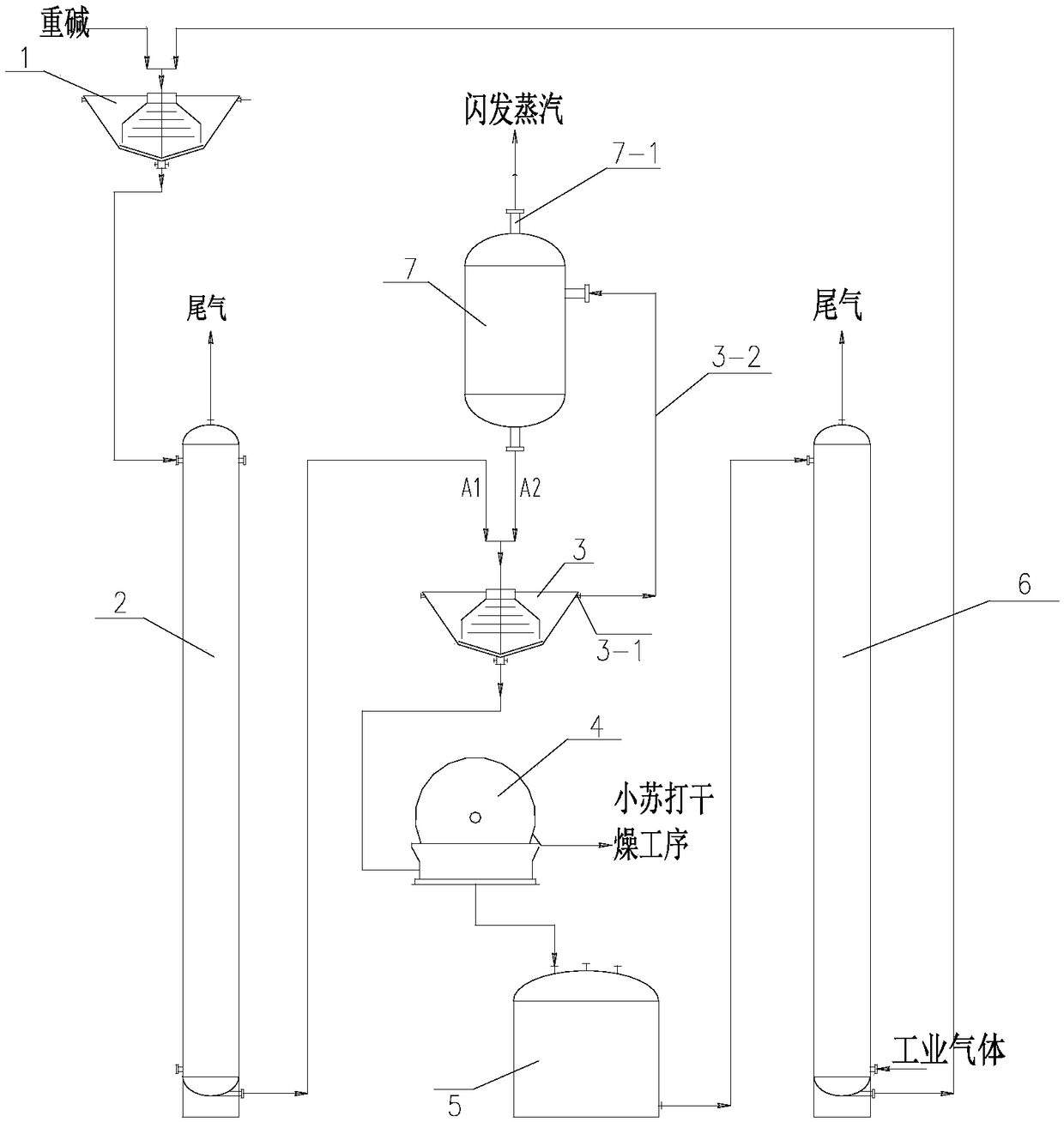

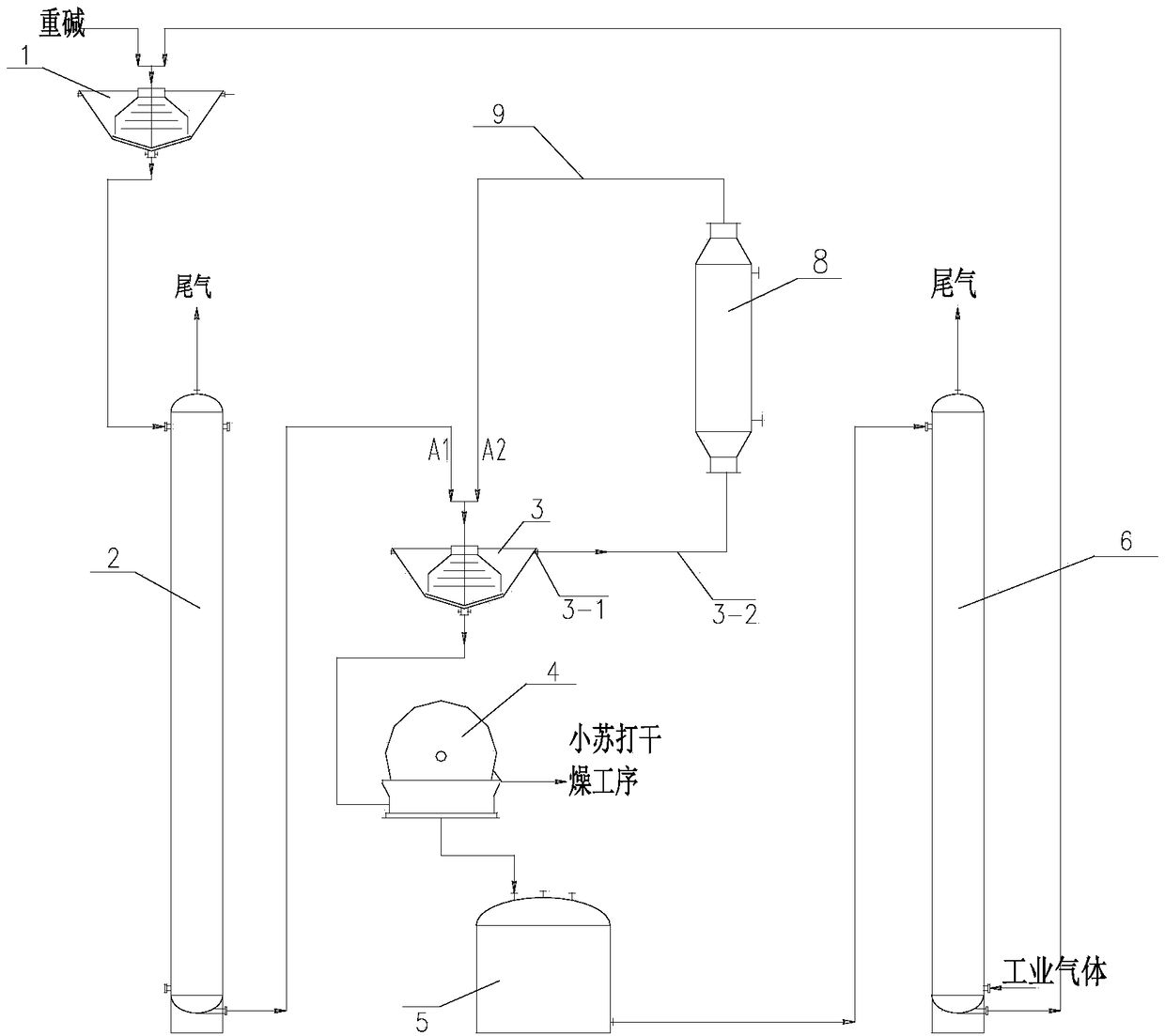

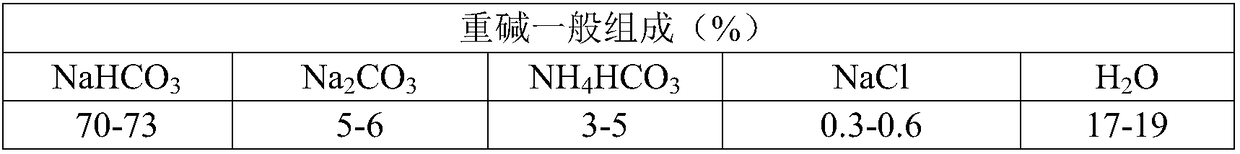

Method and device for producing baking soda

ActiveCN108439434AImprove production rateReduce solubilityProductsBicarbonate preparationSodium bicarbonateCooking & baking

The invention provides a method and a device for producing baking soda, wherein sodium bicarbonate is added to a dissolving tank to prepare raw material slurry containing a sodium bicarbonate solid, the raw material slurry enters an ammonia still, high temperature solution A1 containing high-concentration sodium bicarbonate and low-concentration sodium carbonate flowing out of the ammonia still fully enters a mixer, and is mixed with low temperature solution A2 containing low concentration sodium bicarbonate in the mixer, a clear liquid at the top of the mixer enters a cooler or a flasher to cool down to obtain the low temperature solution A2, and the low temperature solution (namely A2) enters the mixer; bottom crystal slurry of the mixer is subjected to solid-liquid separation to obtainsolid sodium bicarbonate crystal and filtrate; the solid sodium bicarbonate crystal is sent to a drying process to obtain the target product baking soda; the filtrate is sent to a filtrate barrel, thefiltrate of the filtrate barrel is sent to a carbonization tower, the sodium carbonate in the filtrate and carbon dioxide contained in an industrial gas are carbonized in the carbonization tower, anda reaction liquid flowing out from the carbonization tower is sent to the dissolution tank to complete the circulation of the liquid. The method has the advantages that the process flow is short, theenergy consumption is small, and the operation cost is low.

Owner:武汉德泽环保科技有限公司

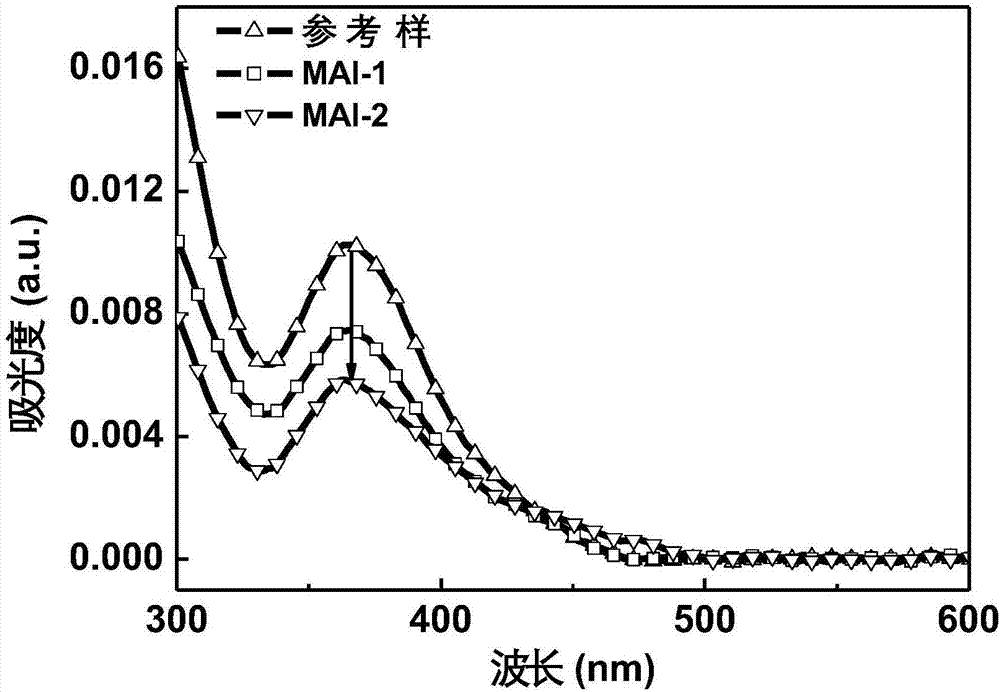

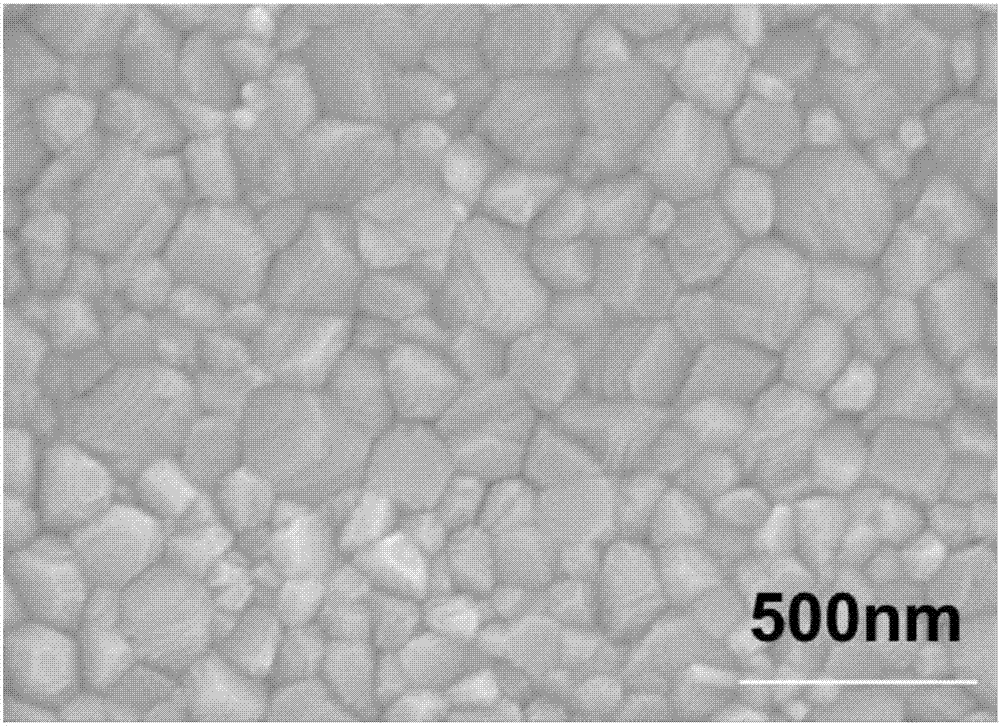

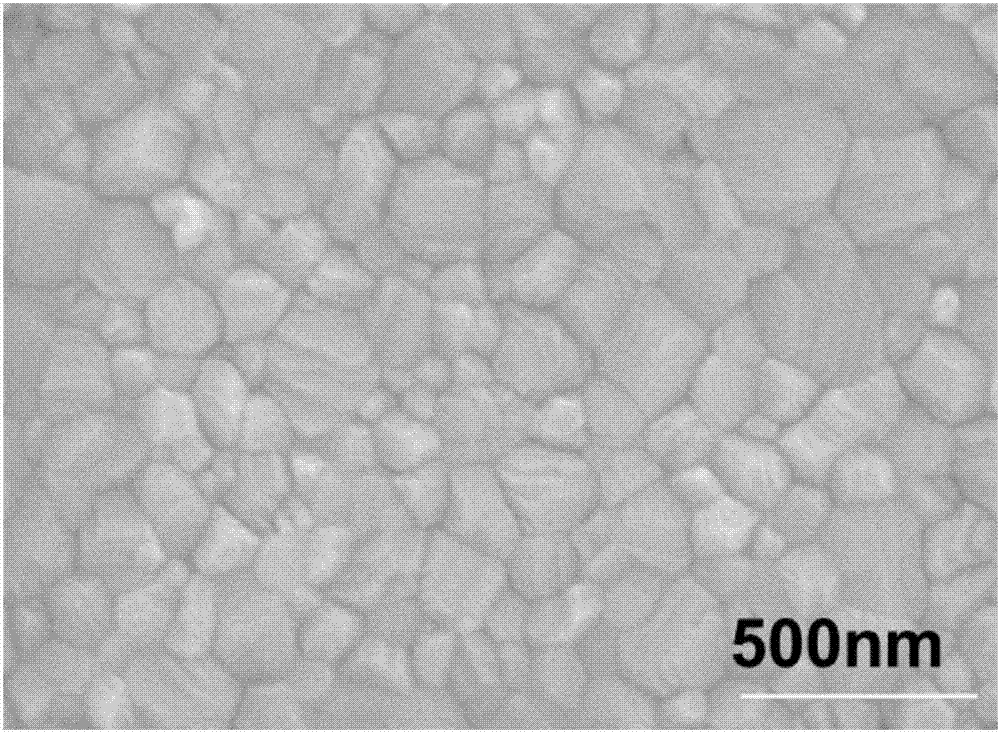

Preparation method for methylammonium iodide

ActiveCN107337607APromote generationSuppress generationAmino compound purification/separationOrganic compound preparationNitrogen gasState density

The invention relates to a preparation method for methylammonium iodide, belonging to the technical fields of organic-inorganic hybrid materials and photoelectric materials. According to the method in the invention, under the protection of nitrogen, a crude product is purified by using an alcoholic solution of organic amine capable of providing an alkaline environment; the alcoholic solution of organic amine facilitates disproportionation of I2 to produce iodide ions and effectively inhibits generation of I2, so the content of elemental iodine in the prepared methyl ammonium iodide is greatly reduced; a perovskite film prepared by using the methyl ammonium iodide as a precursor has large crystal size, low defect state density and long carrier life; and a solar cell prepared from the perovskite film has photoelectric conversion efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

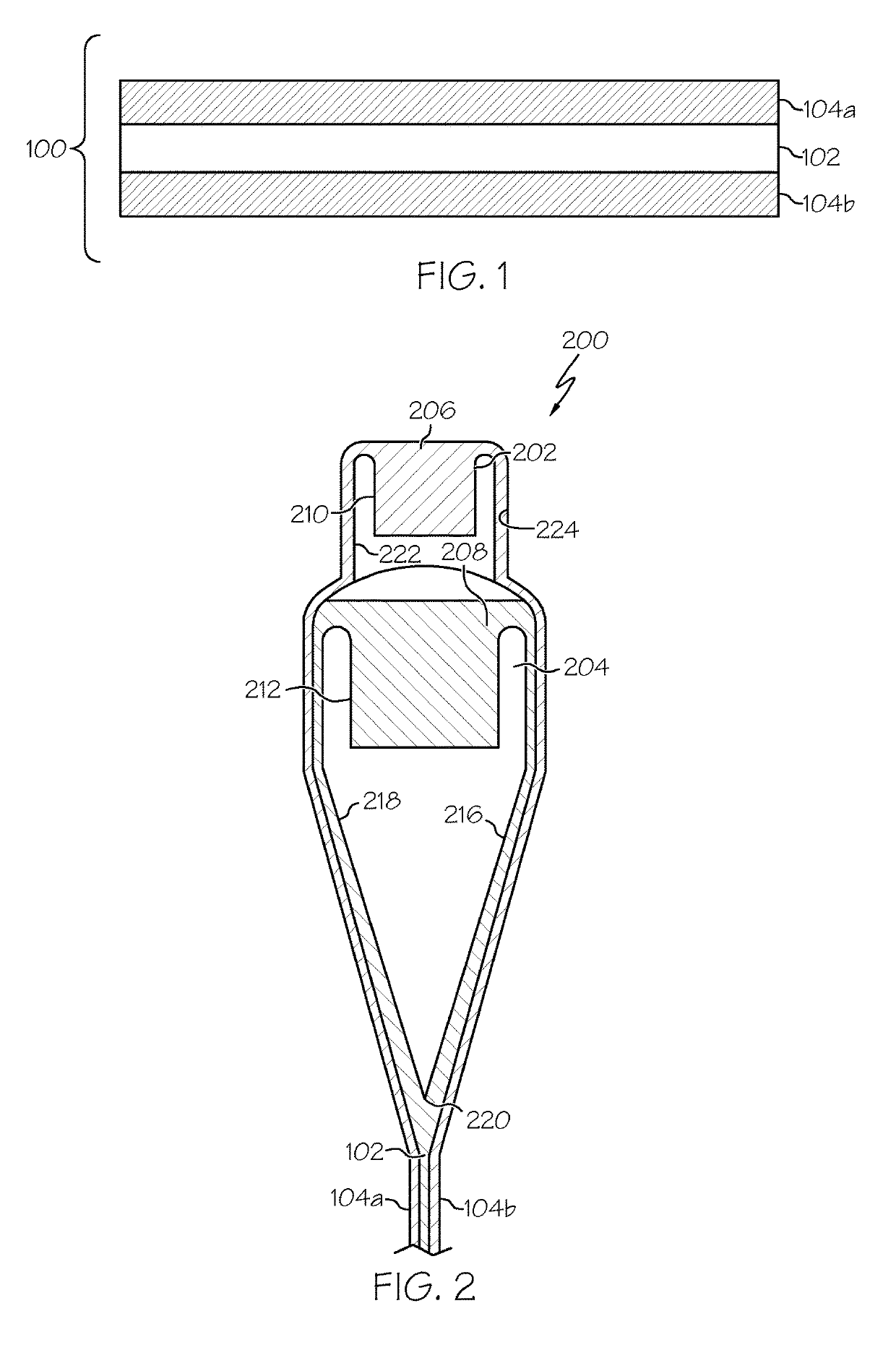

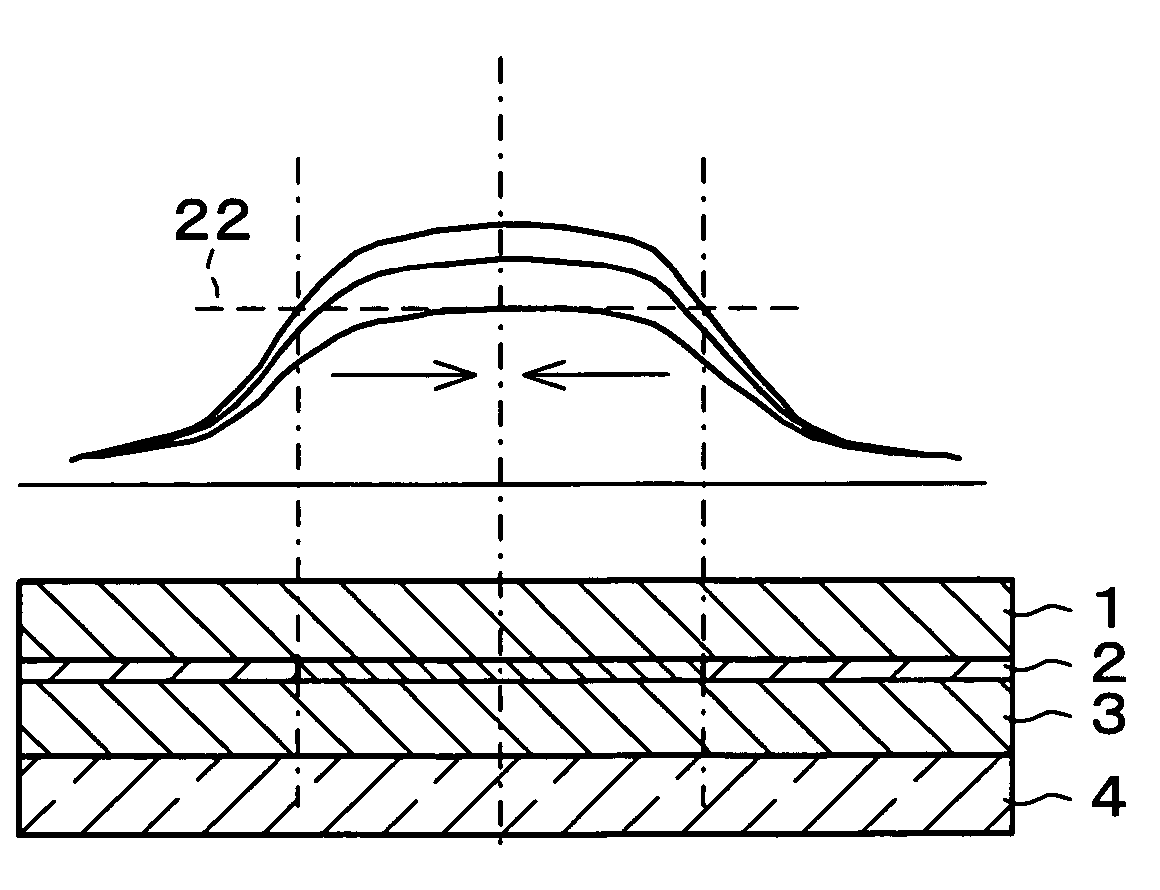

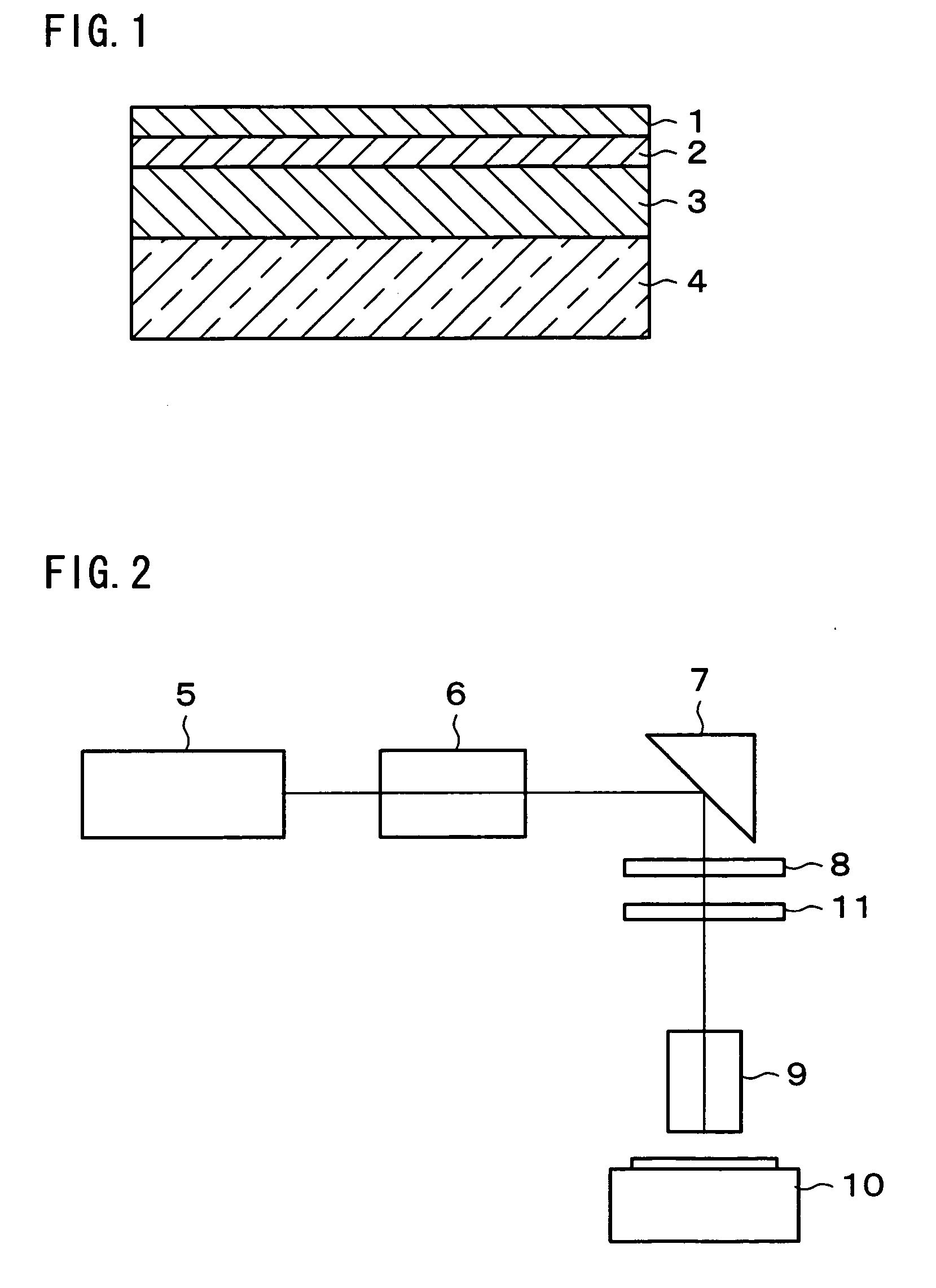

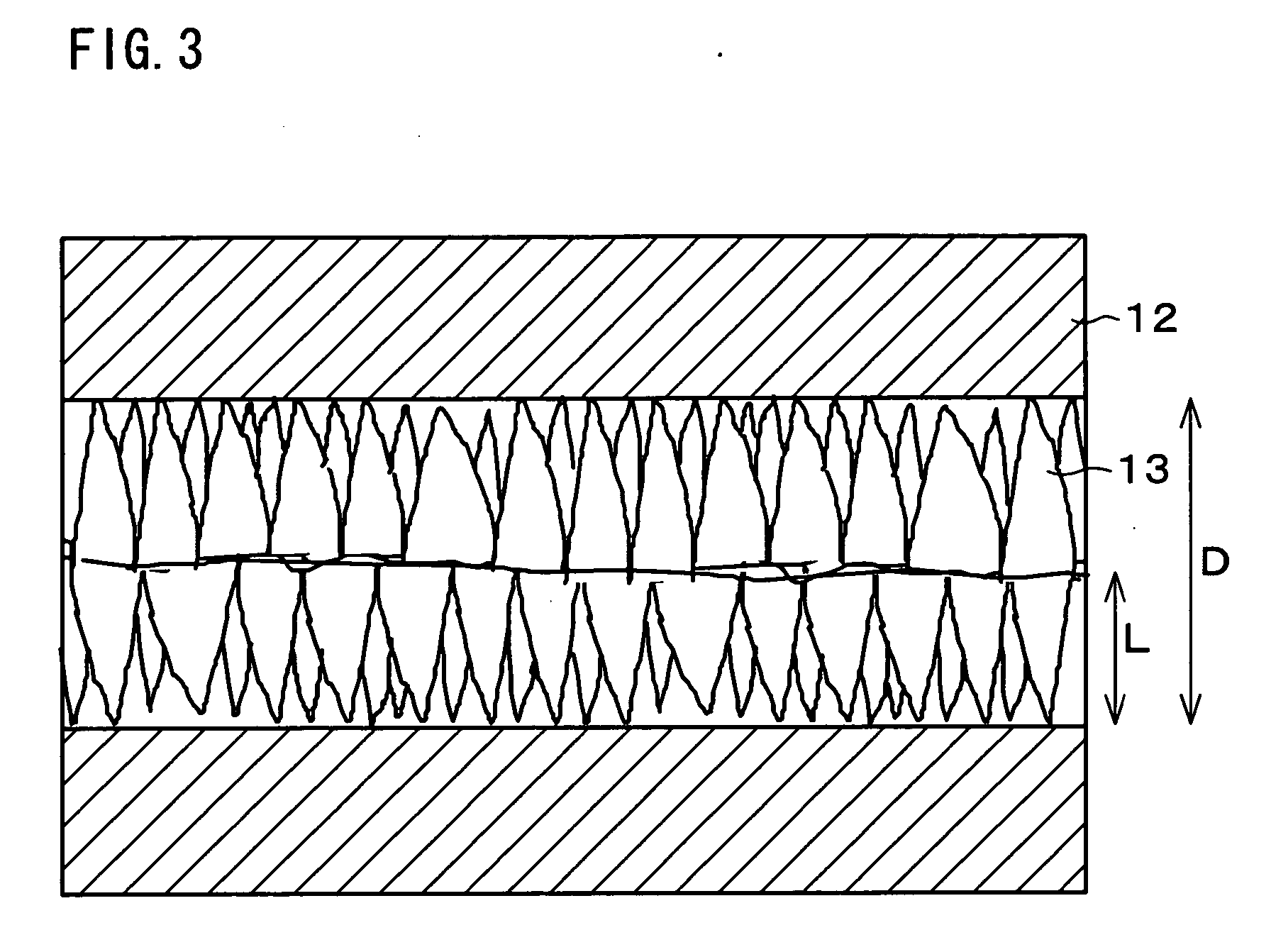

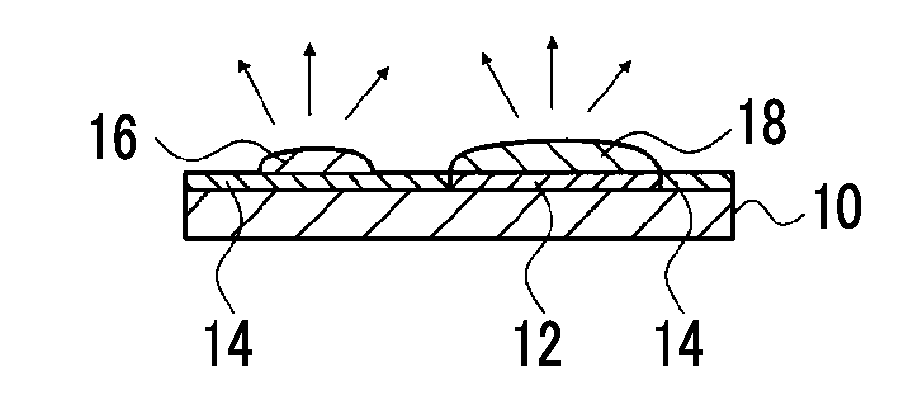

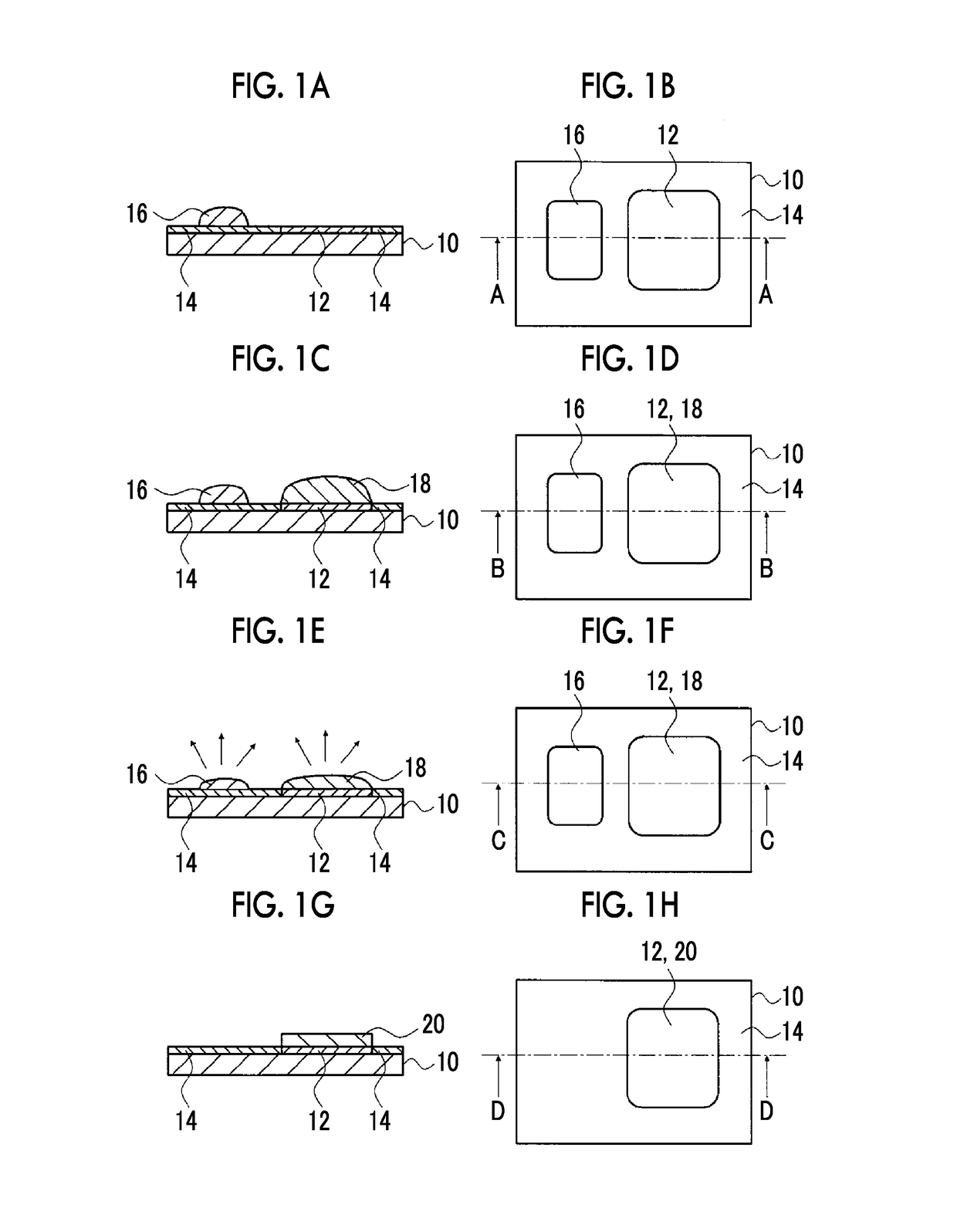

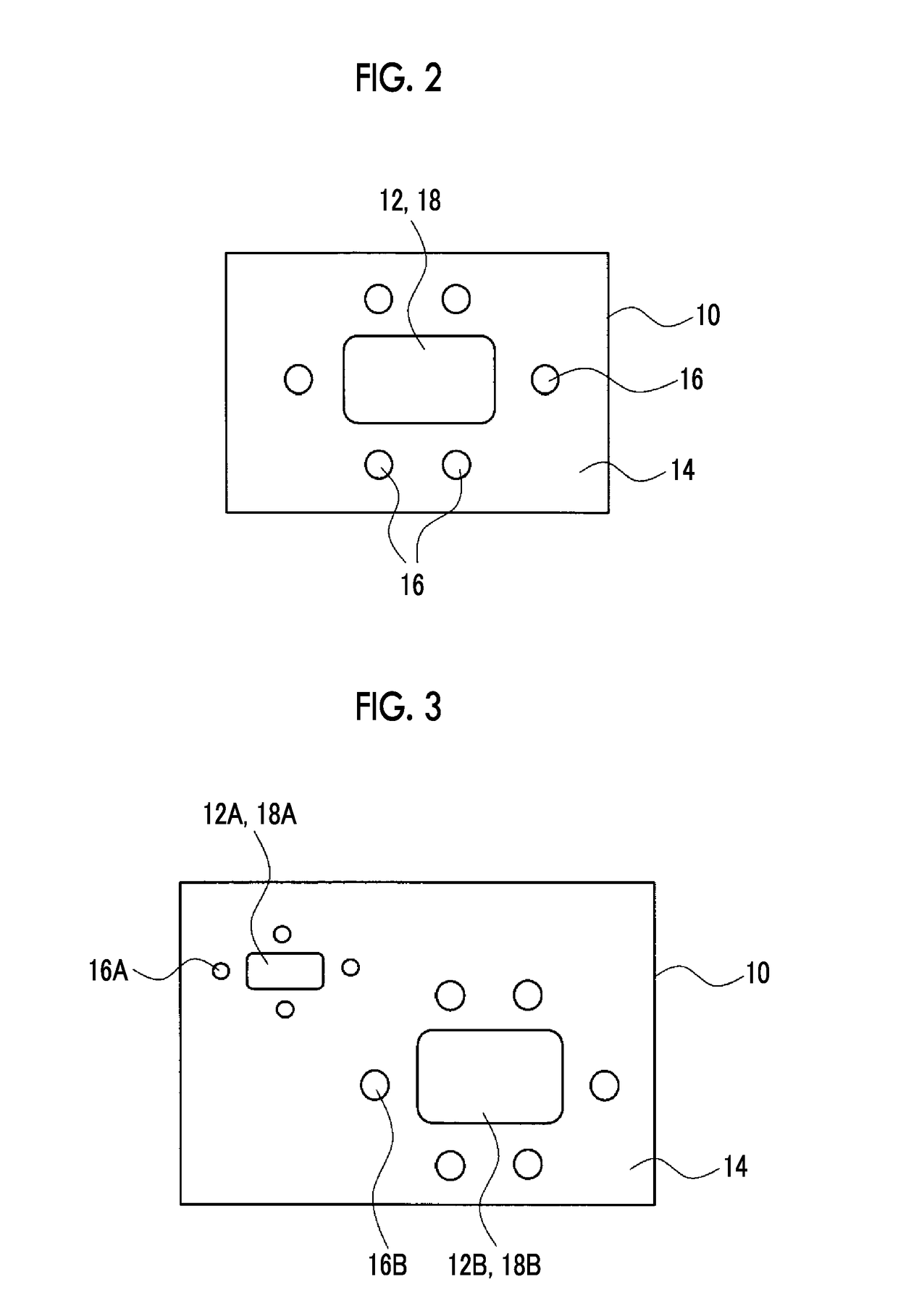

Crystallized semiconductor device, method for producing same and crystallization apparatus

InactiveUS20060183303A1Slow downReduce the temperatureTransistorSemiconductor/solid-state device manufacturingDevice materialLaser light

In a method of manufacturing a crystallized semiconductor device of the present invention, a thermal diffusion layer (1) having higher thermal conductivity than that of a substrate (4) is formed on a surface of a semiconductor layer (2), and then laser light is applied to the semiconductor layer (2) from above the thermal diffusion layer (1). As a result, it becomes possible to manufacture the crystallized semiconductor device in which a crystal is longer than that of a conventional arrangement. According to the present invention, it is possible to provide the crystallized semiconductor device having the semiconductor layer in which the size of the crystal grain is larger than that of the conventional arrangement.

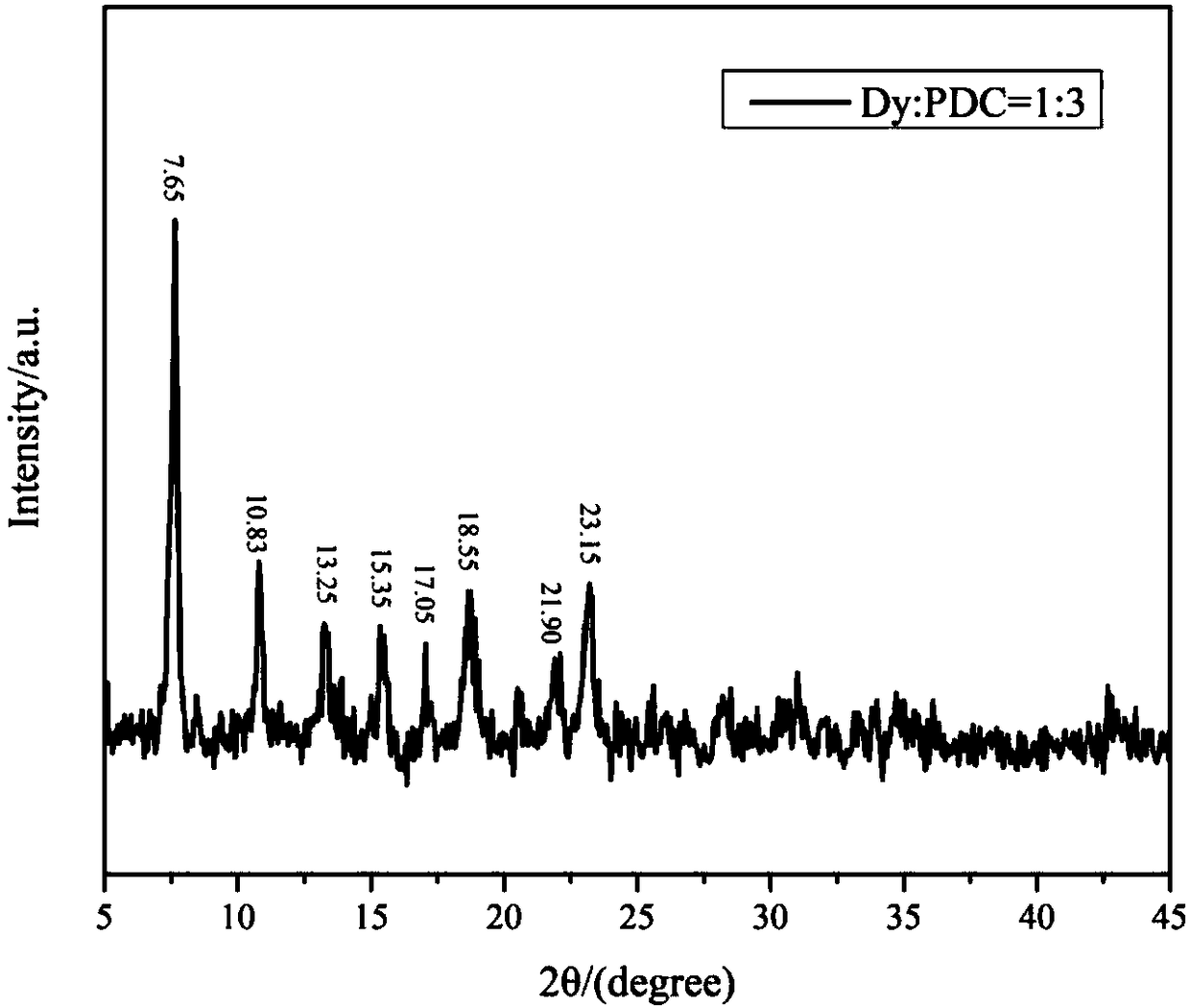

Pyridine acid type metal organic framework white light material and preparation method thereof

ActiveCN108192111AHigh degree of crystallinityLarge crystal sizeLuminescent compositionsSolventRare-earth element

The invention discloses a pyridine acid type metal organic framework white light material and a preparation method thereof. The pyridine acid type metal organic framework white light material is prepared from 2,3-dipicolinic acid and dysprosium, wherein the 2,3-dipicolinic acid is an organic ligand; the dysprosium is rare earth metal. The preparation method of the pyridine acid type metal organicframework white light material comprises the following steps of dissolving 2,3-dipicolinic acid and dysprosium into a mixed solvent; after the uniform mixing, performing constant temperature sealed reaction for 2 d to 4 d at 90 to 150 DEG C to obtain a coarse product; purifying the coarse product to obtain the pyridine acid type metal organic framework white light material. The dysprosium is usedas the rare earth metal; the 2,3-dipicolinic acid is used as the organic ligand; the crystallization degree is high; the crystal dimension is large; the stability is high; the nonradiative jump probability is greatly reduced through pore passages, so that the common luminous intensity and luminous efficiency of various rare earth ions are enhanced; the thermal stability is improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

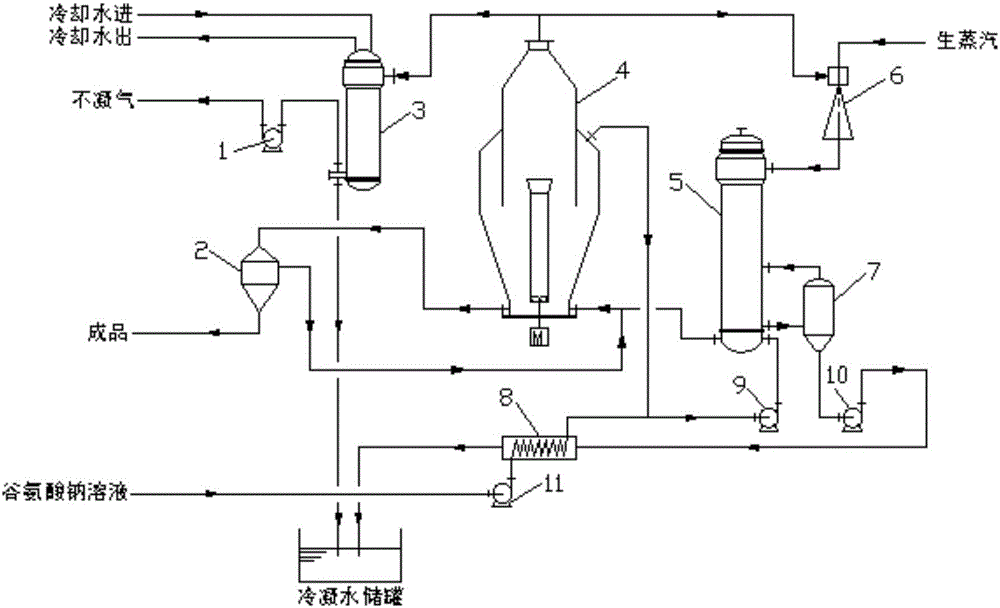

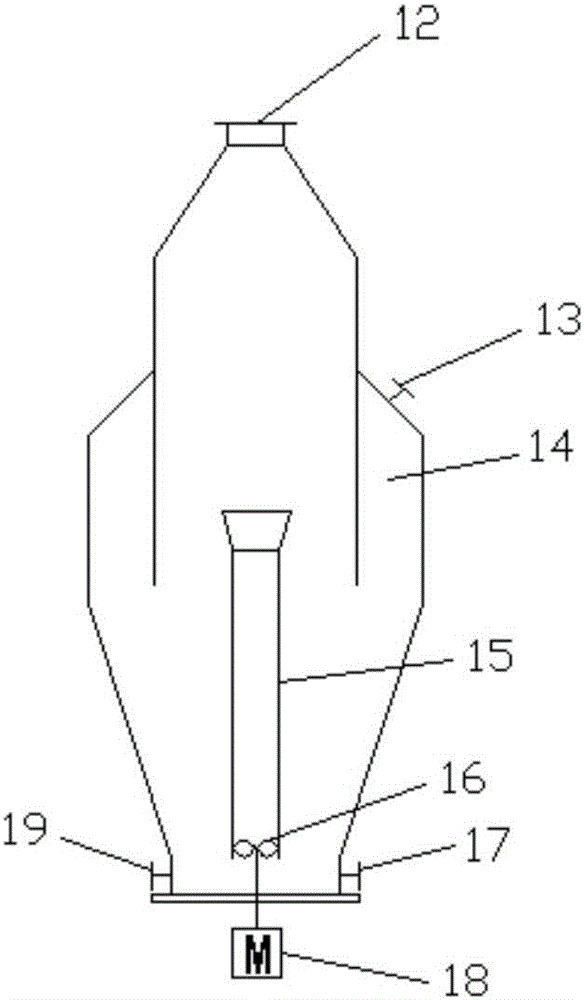

Continuous single-effect vacuum evaporation crystallization system as well as application and technology

InactiveCN106310704AReduce consumptionRealize continuous productionEvaporator accessoriesSolution crystallizationSlurryEngineering

The invention discloses a continuous single-effect vacuum evaporation crystallization system as well as application and technology. The system comprises a preheater, a heating chamber and a vacuum crystallizer, wherein the preheater is used for preheating a solution; a solution inlet of the heating chamber is communicated with the preheater; steam is introduced into the heating chamber and performs heat exchange with the solution in the heating chamber; the vacuum crystallizer is connected with the heating chamber, a centrifuge and a surface condenser respectively; the solution heated by the heating chamber is crystallized in the crystallizer; the crystallized crystal slurry enters the centrifuge and is separated to obtain a finished product of crystal; one part of the secondary steam generated by the vacuum crystallizer enters the surface condenser to be condensed, and the other part of the secondary steam enters the heating chamber for cyclic utilization; through the arrangement of the heating chamber, the solution is heated for the second time, and the heating chamber can make use of live steam as well as secondary steam generated by an evaporator; and the whole system realizes continuous circular generation of sodium glutamate particles, and the crystal product has the advantages of high quality, large crystalline particle size, uniform particles and smooth surface.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

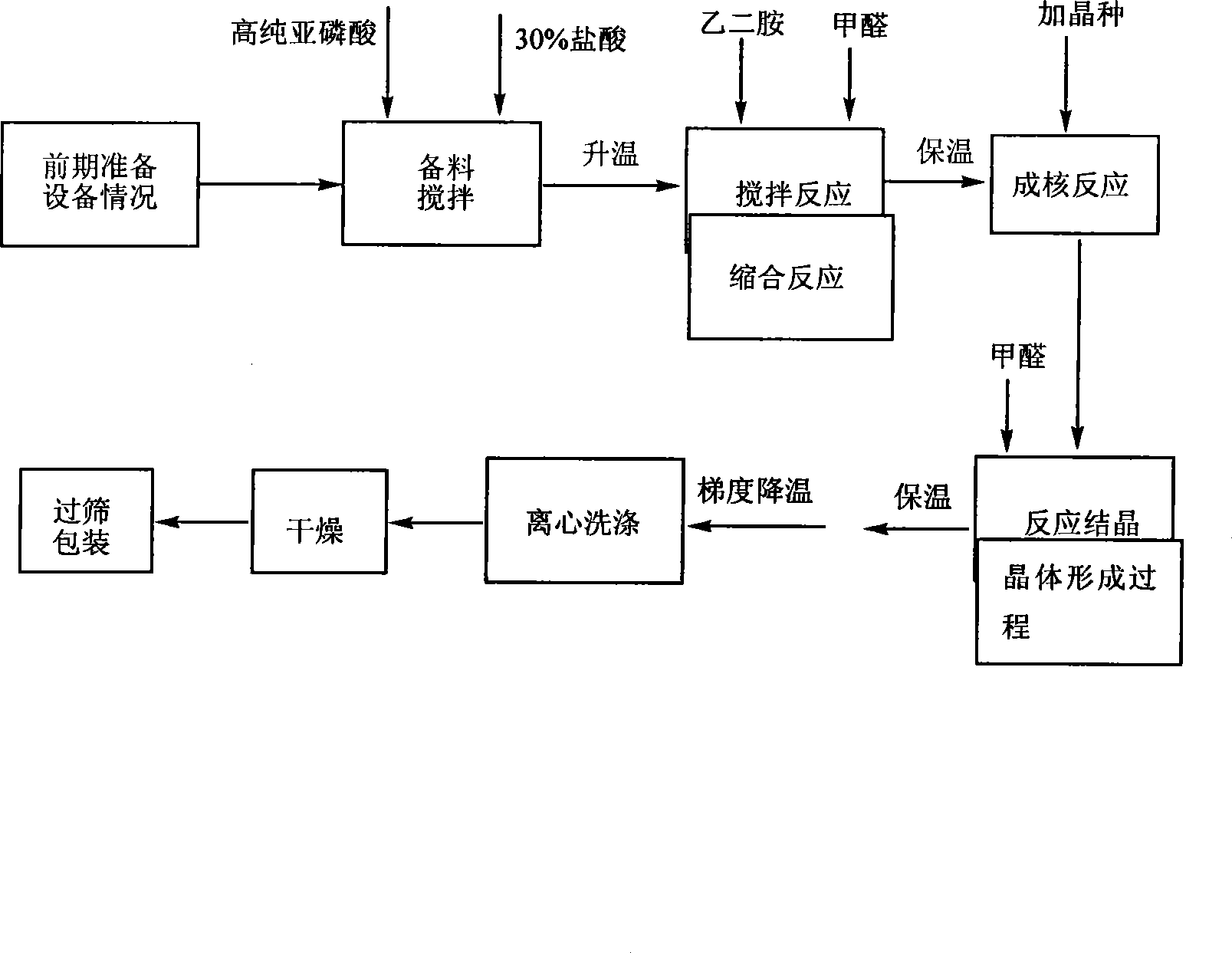

Preparation technology suitable for electronic grade solid ethylenediamine tetramethylene phosphonic acid

ActiveCN101381376AEasy to packEasy to storeGroup 5/15 element organic compoundsN-methylene phosphonic chitosanPhosphoric acid

The invention discloses a production process of high-purity solid ethylene diamine tetra (methylene phosphonic acid). The production process comprises the following steps: (1) first-phrase preparation which is to clean related equipment; (2) dissolving orthophosphorous acid crystals in high-purity water for recrystallization, and obtaining high purity orthophosphorous acid for later use; (3) placing the high-purity orthophosphorous acid and hydrochloric acid into a reaction kettle with stirring and temperate raising, and dripping ethylene diamine into the reaction kettle; (4) dripping methyl alcohol and keeping temperature; (5) dripping crystal nucleating agent till crystals are precipitated; (6) raising temperature and continuing to dripping methyl alcohol; (7) decreasing temperature step by step; (8) centrifugation, drying, screening and packaging. The white solid particles of EDTMPA has a content of active EDTMPA of more than 95 percent, a content of arsenic less than 0.5 mg / L. The high-purity solid ethylene diamine tetra (methylene phosphonic acid) can be used as metal-chelator for textile dyeing industry, a washing agent for electronic industry, a metal conditioner, etc., and has the advantages of simple package, convenient storage and transportation.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

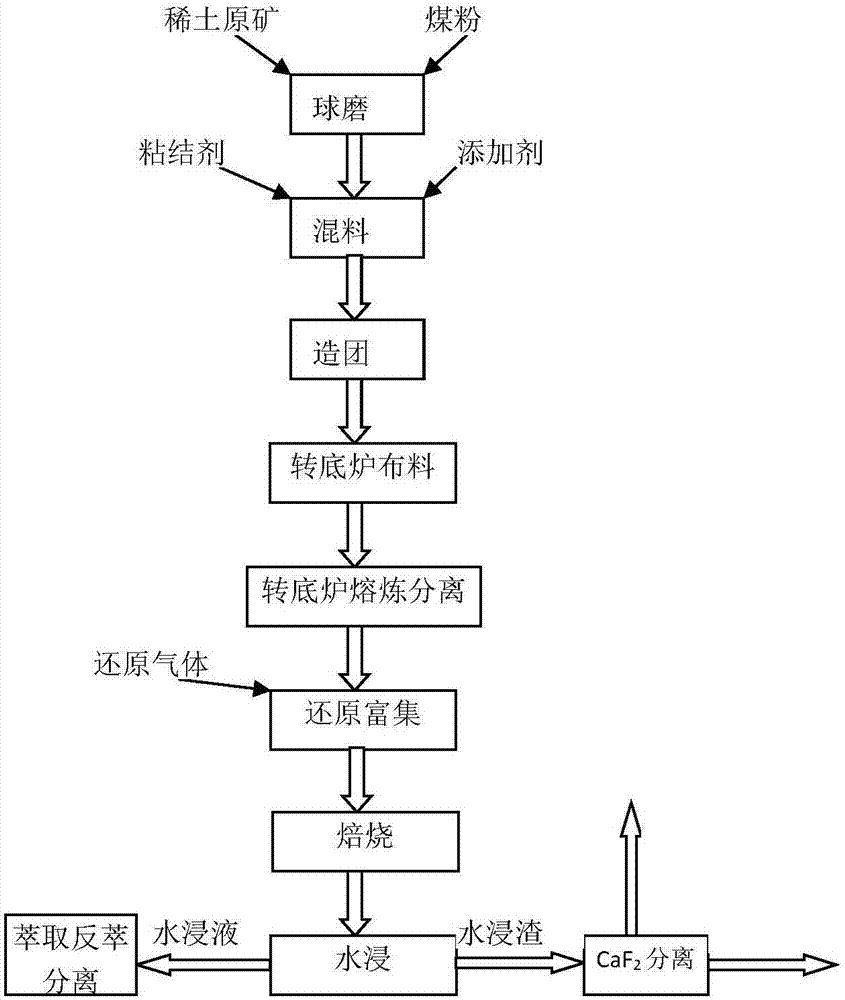

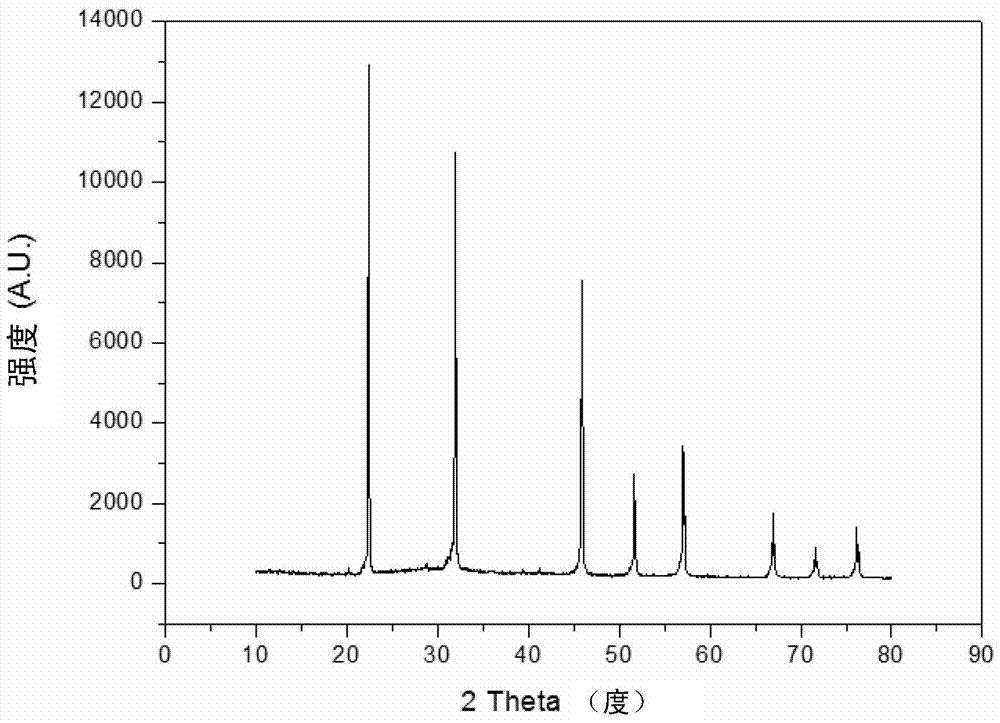

Method for separating and producing rare earth from iron-containing rare earth raw ore

The invention belongs to the field of firing and wet comprehensive smelting of rare earth ore and particularly relates to a method for separating and producing rare earth from iron-containing rare earth raw ore. An iron bead product and a rare earth product are obtained through steps as follows: grinding, mixing, agglomerating, distribution in a rotary hearth furnace, smelting separation in the rotary hearth furnace, roasting, water leaching and the like. Under the condition of relatively lower cost, production efficiency and rare earth leaching rate are greatly increased.

Owner:UNIV OF SCI & TECH BEIJING

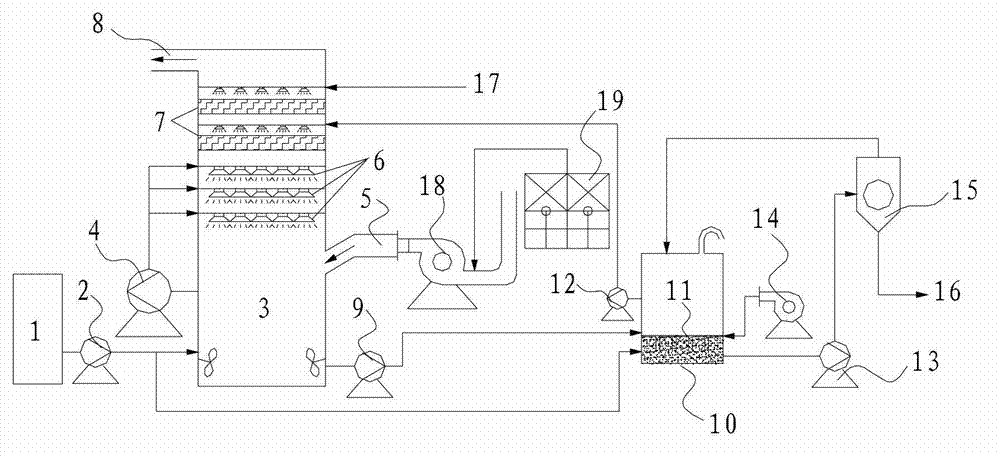

Amino wet combined desulfurization and denitration device and process

InactiveCN102824824AImprove desulfurization efficiency and ammonium sulfate crystal qualityEasy to separateDispersed particle separationAmmonium sulfatesNitric oxideNitrogen dioxide

The invention discloses amino wet combined desulfurization and denitration device and a process. The device comprises a desulfurization tower with an inlet flue, a liquid ammonia storage tank, an ozone generator, and a booster fan on the inlet flue; and a defogging layer, a spraying layer and a tower kettle are orderly arranged inside the desulfurization tower from top to bottom. The device also comprises an oxidization slot communicated with the tower kettle, and an oxidization fan connected to the oxidization slot; the liquid ammonia storage tank is communicated to the tower kettle through one path of pipeline, and is communicated to the bottom part of the oxidization slot through another pipeline; the ozone generator is communicated to an air inlet of the booster fan through the pipeline; ozone is sprayed into smoke from the air inlet of the booster fan; nitric oxide in the smoke is oxidized into nitrogen dioxide; the smoke oxidized by ozone is conveyed to the desulfurization tower; liquid ammonia is sprayed to desulfurize and denitrate; the smoke is discharged after being defogged and dried; and circulating liquid by which sulfur dioxide and nitrogen dioxide are absorbed is oxidized outside the tower, and the liquid ammonia is conveyed to the oxidization slot to adjust the pH (Potential Of Hydrogen) value in the oxidization slot during the oxidization process.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Method for preparing cellulose acetate from wheat straws

InactiveCN102391378AImprove accessibilityGood removal effectChemical recyclingSolventCellulose diacetate

The invention discloses a method for preparing cellulose acetate from wheat straws. The method comprises the following steps of: performing activating and bleaching pretreatment on the wheat straws; mechanically crushing; performing acetylation reaction; recovering the esterified liquid in a low-temperature condensation mode; separating acetylized products; and extracting the acetylized products with different components by using solvents to separate out the products such as cellulose triacetate, cellulose diacetate, acetylized hemicellulose, acetylized lignin and the like. The invention provides an economic and effective method for pretreating the wheat straws. By the method, the defect of the single catalyst in the traditional acetylation process is overcome; the cellulose acetate with high substitution degree and polymerization degree is prepared in a new catalyst system; and the wheat straws are utilized reasonably.

Owner:GUANGDONG SHANGJIU BIODEGRADABLE PLASTICS

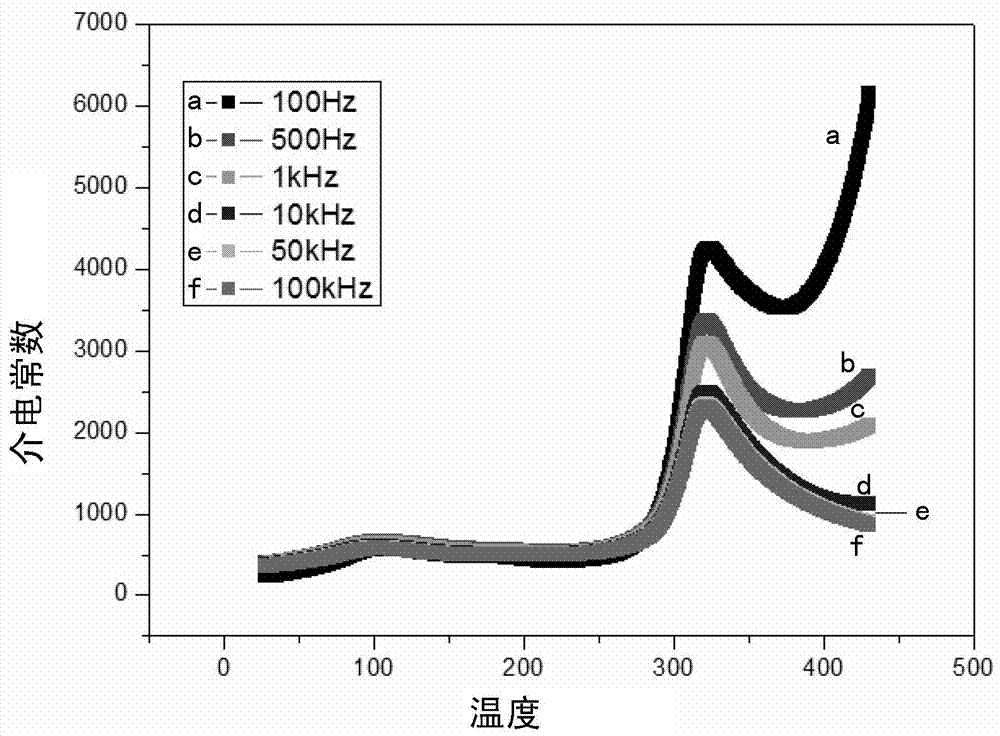

Potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal and growing method thereof

ActiveCN107268084ASolve sizeSolve the problem of many cracksPolycrystalline material growthFrom frozen solutionsCrucibleSingle crystal

The invention relates to a potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal and a growing method thereof. The chemical formula of the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal is (1-y)(KxNa(1-x))NbO(3-y)(Bi0.5Na0.5)ZrO3, wherein x is larger than or equal to 0.4 and smaller than or equal to 0.6, and y is larger than or equal to 0 and smaller than or equal to 0.1. According to the method, raw materials and a growth auxiliary are mixed and presintered, and the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal is obtained by growing with a Bridgman-Stockbarger method; the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal growing with the Bridgman-Stockbarger method after addition of the growth auxiliary has the advantages that a nucleus is formed easily, the crystal size is larger (2-20 mm), fewer cracks are formed and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

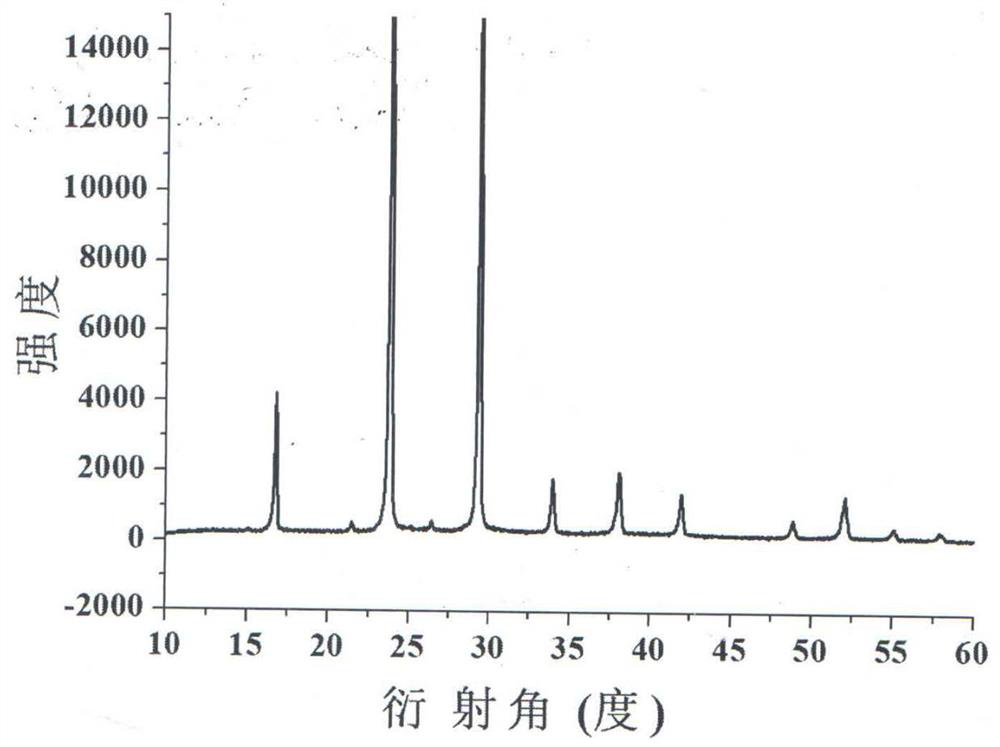

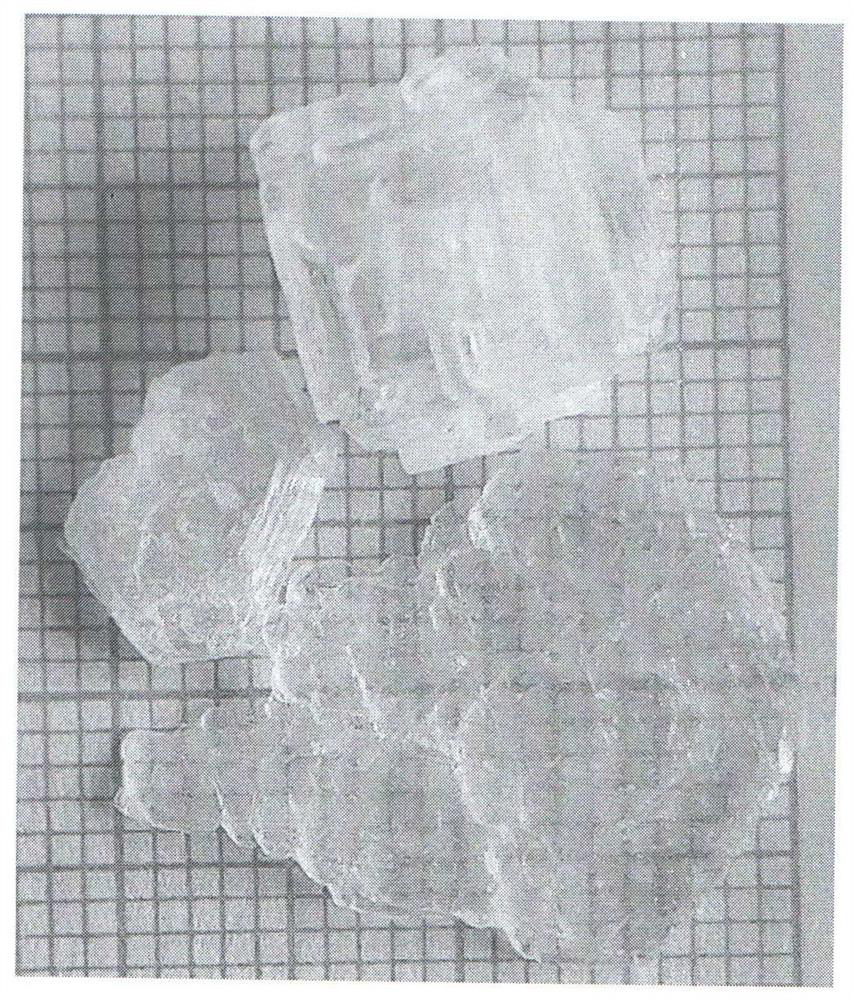

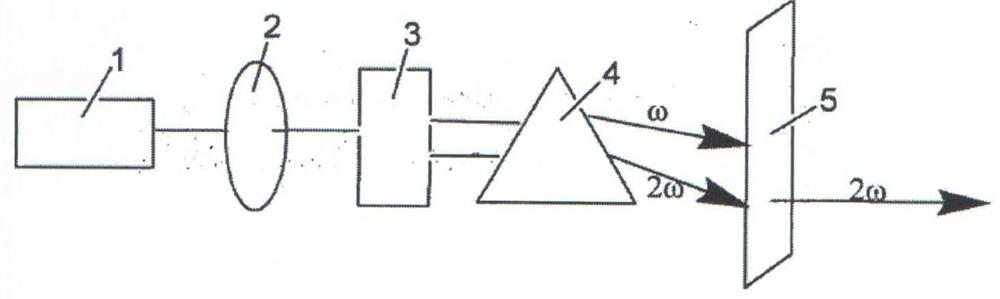

Guanidine tetrafluoroborate nonlinear optical crystal and preparation method and application thereof

ActiveCN112760717AQuality improvementLarge crystal sizePolycrystalline material growthFrom normal temperature solutionsNonlinear optical crystalCrystal system

The invention relates to a guanidine tetrafluoroborate nonlinear optical crystal and a preparation method and application thereof. The chemical formula of the crystal is [C (NH2) 3] BF4, the molecular weight is 146.89, the crystal belongs to a trigonal system, the space group is R3m, and the cell parameters are as follows: a = 7.4634 (10) angstroms, b = 7.4634 (10) angstroms, c = 9.1216 (19) (6) angstroms and Z = 3. The ultraviolet cut-off edge is 200 nm, the frequency doubling response is 4-5 times that of a commercial nonlinear optical crystal KDP, and the crystal with the centimeter-level size is grown by adopting a hydrothermal method, a room-temperature solution method, an evaporation method or a solvothermal method; the invention relates to the application of the crystal for preparing harmonic light output with frequency doubled or frequency tripled or frequency quadrupled or frequency quintupled or frequency sextupled of 1064 nm fundamental frequency light outputted by an Nd: YAG laser, or generating ultraviolet and deep ultraviolet frequency doubled light output lower than 200 nm, or for preparing a frequency doubled generator, an upper or lower frequency converter or an optical parametric oscillator. The crystal has the advantages of wide light-transmitting wave band, stable physical and chemical properties, high mechanical hardness, difficulty in fragmentation and deliquescence, easiness in cutting, polishing, processing and storage and the like, and has important application in the fields of optics, laser lithography and communication.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Method for producing organic semiconductor film and organic transistor

InactiveUS20170179388A1Large crystal sizeFinal product manufactureSolid-state devicesSolventOrganic crystal

A method for producing an organic semiconductor film includes performing, in random order, applying an ink including an organic semiconductor, a first solvent having high affinity for the organic semiconductor, and a second solvent having lower affinity for the organic semiconductor than the first solvent and having a higher boiling point than the first solvent, to a lyophilic region of a substrate having at least one of a lyophilic region or a liquid repellent region disposed in the vicinity of the lyophilic region on a surface, and applying a solvent composed of the same type of solvent as the first solvent and used for controlling a volatilization rate of the first solvent in the ink applied to the lyophilic or the liquid repellant region; and then causing the first and second solvent in the ink applied to the lyophilic region to volatilize to produce an organic semiconductor film.

Owner:FUJIFILM CORP

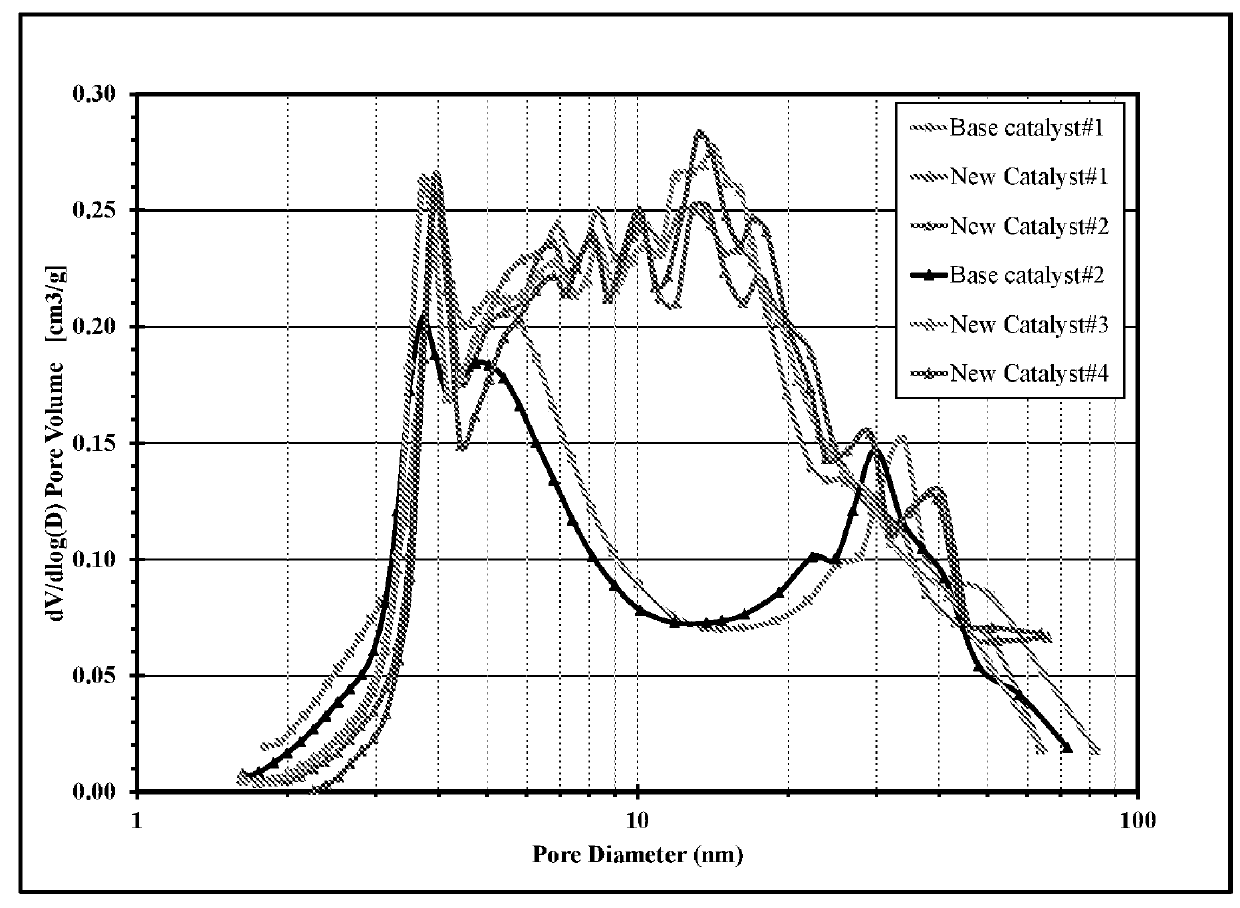

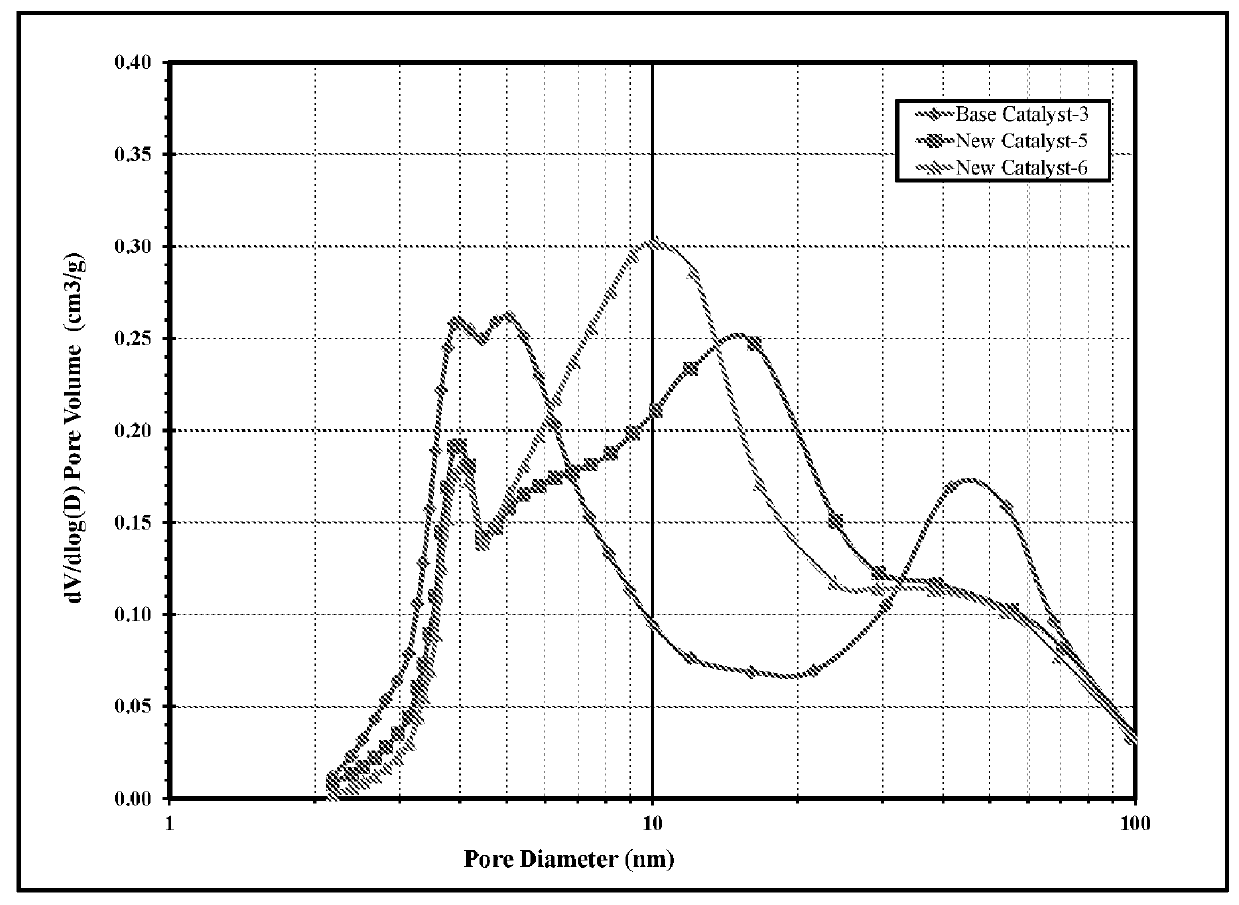

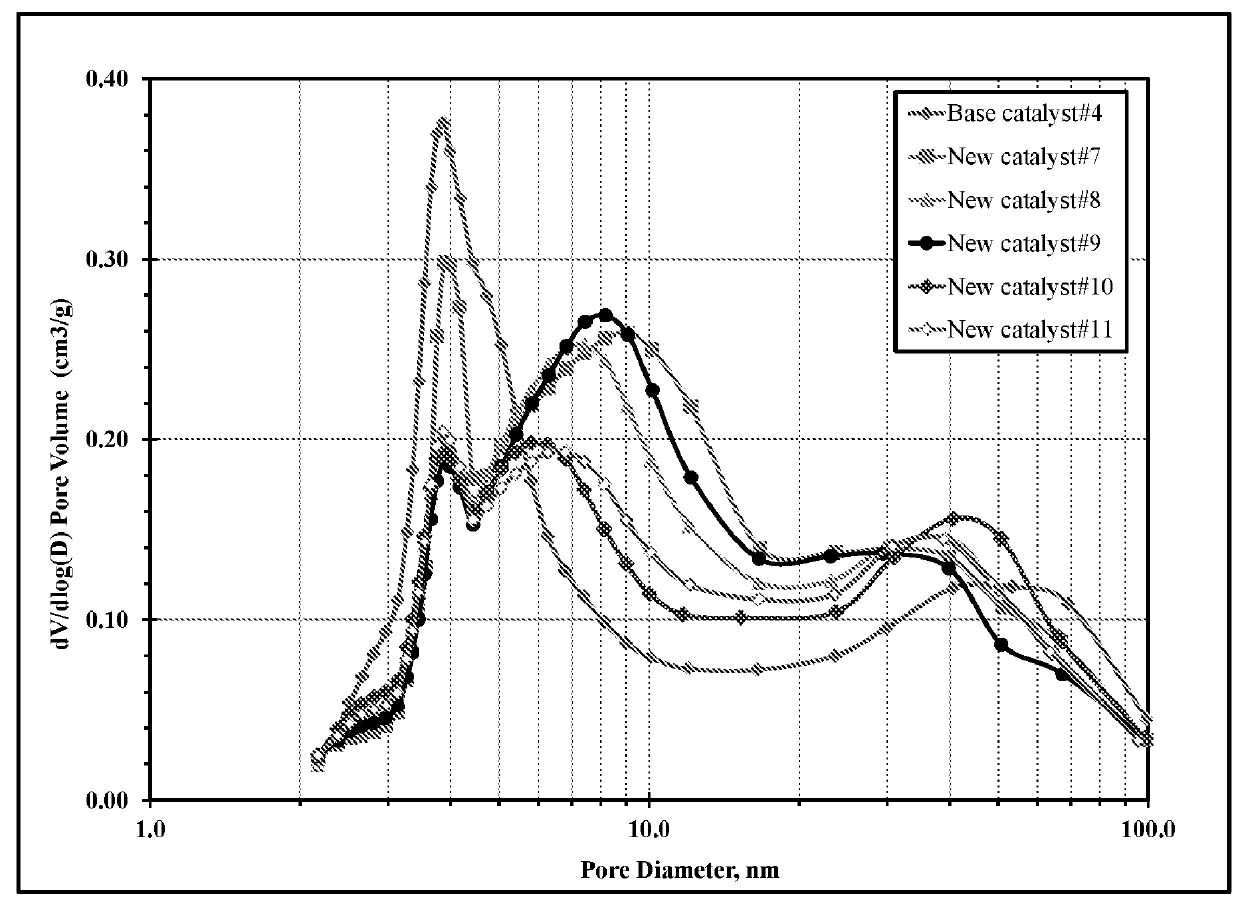

Fcc catalyst with enhanced mesoporosity, its preparation and use

PendingUS20200338536A1Large specific surface areaLarge hole volumeCatalytic crackingMolecular sieve catalystsPtru catalystPhysical chemistry

Process for the preparation of a catalyst and a catalyst comprising enhanced mesoporosity is provided herein. Thus, in one embodiment, provided is a particulate FCC catalyst comprising 2 to 50 wt % of one or more ultra stabilized high Si02 / A1203 ratio large pore faujasite zeolite or a rare earth containing USY, 0 to 50 wt % of one or more rare-earth exchanged large pore faujasite zeolite, 0 to 30 wt % of small to medium pore size zeolites, 5 to 45 wt % quasi-crystalline boehmite 0 to 35 wt % microcrystalline boehmite, 0 to 25 wt % of a first silica, 2 to 30 wt % of a second silica, 0.1 to 10 wt % one or more rare earth components showiomg enhanced mesoporosity in the range of 6-40 nm, the numbering of the silica corresponding to their orders of introduction in the preparation process.

Owner:ALBEMARLE CORP

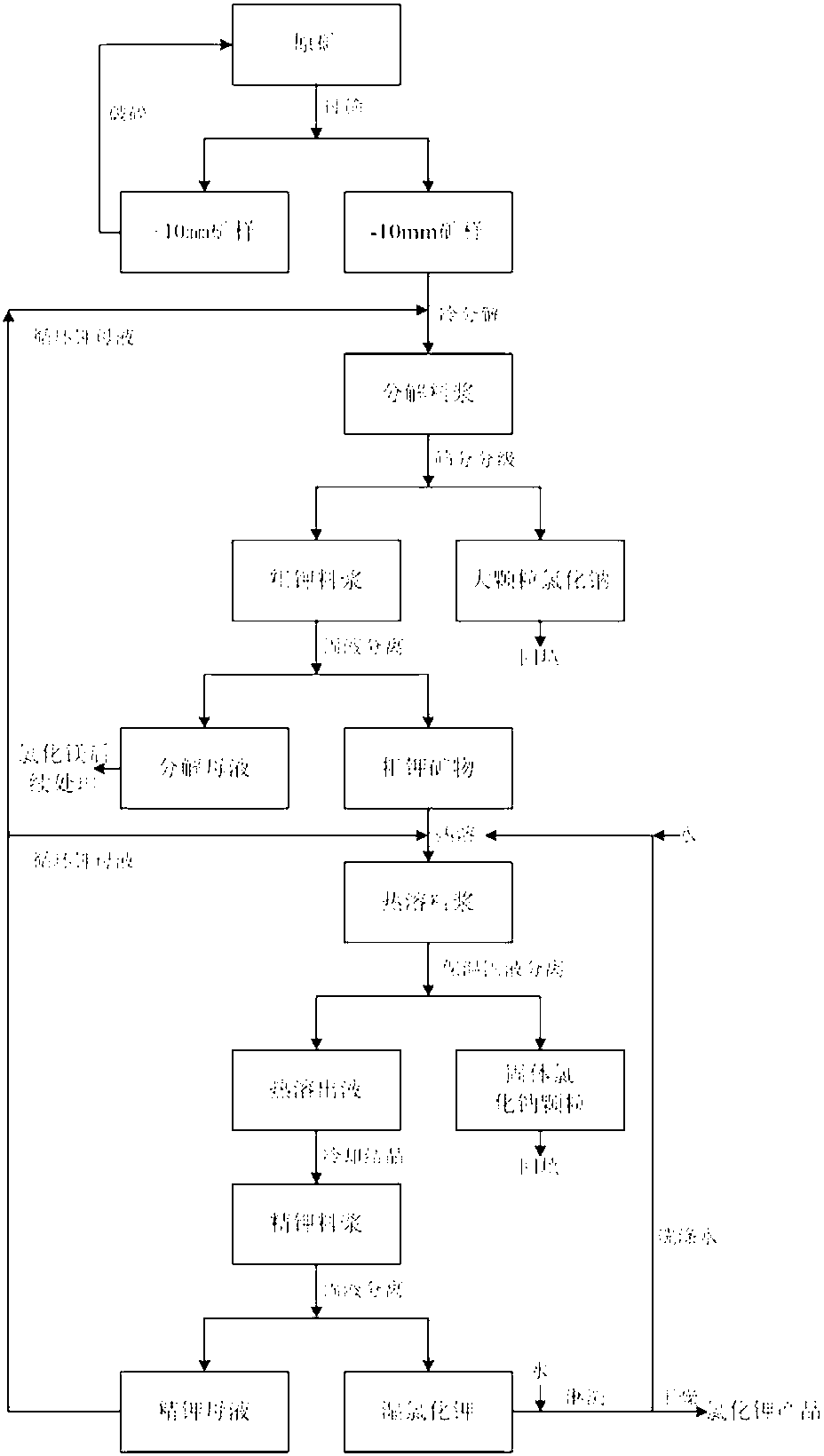

Method for producing industrial potassium chloride through hot melting crystallization of underground embedded solid potassium salt mine

ActiveCN103253685ANo emissionsMeet environmental protection requirementsAlkali metal chloridesChemical industryPrill

The invention belongs to the field of chemical industry mineral processing, and particularly relates to a method for producing industrial potassium chloride through hot melting crystallization of underground embedded solid potassium salt mine. The method comprises: crushing underground embedded solid potassium salt mine to achieve a particle size of less than 10 mm; adding a circulation potassium mother liquor to decompose the potassium salt mine; screening the obtained decomposed slurry, wherein the material on a sieve is large particle sodium chloride and is thrown out; carrying out solid-liquid separation on the material under the sieve to obtain a potassium chloride-containing crude potassium mineral; adding the circulation potassium mother liquor and water to carry out hot melting, and carrying out thermal insulation filtration on the hot melting slurry to remove solid phase sodium chloride; and carrying out circulation cooling on the hot melting liquid, crystallizing to obtain large particle potassium chloride, and carrying out solid-liquid separation, washing and drying to obtain the industrial grade potassium chloride. According to the present invention, based on the decomposition grading characteristic of the underground embedded solid potassium salt mine, the hot melting crystallization method is adopted to produce the industrial potassium chloride, and advantages of reliable technology, stable process, high product purity, large particle size, high potassium yield, and no pollutant emission are provided.

Owner:YUNNAN CHEM RES INST +1

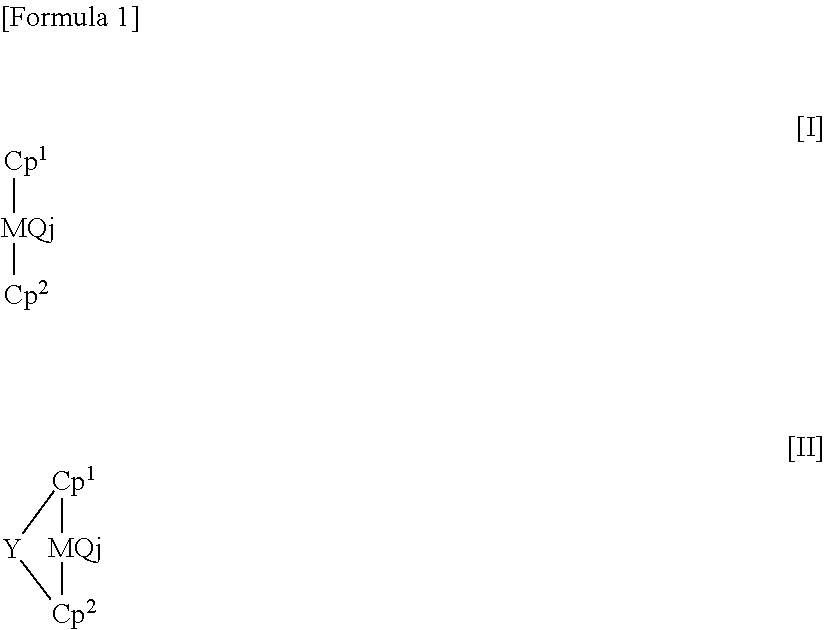

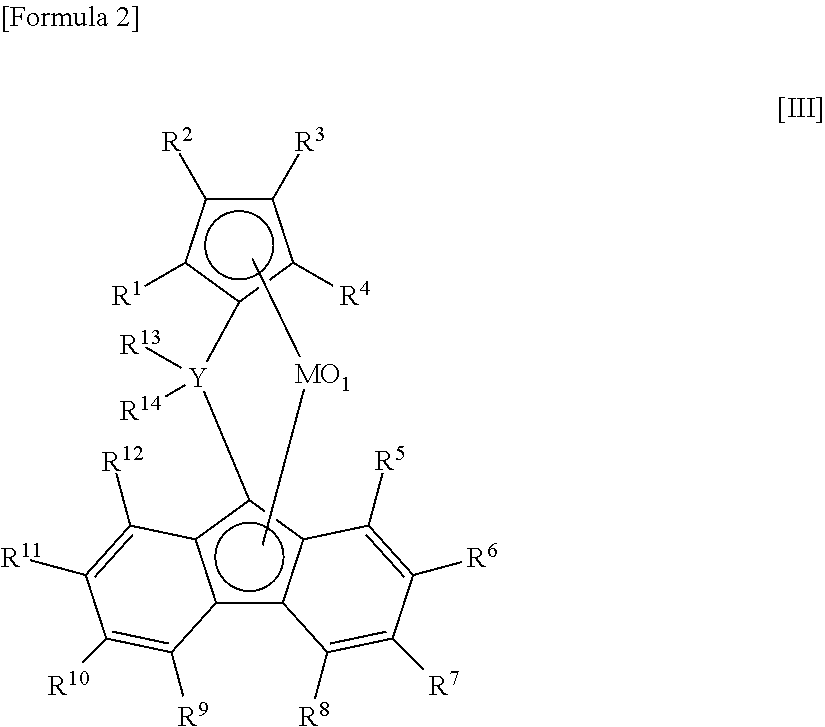

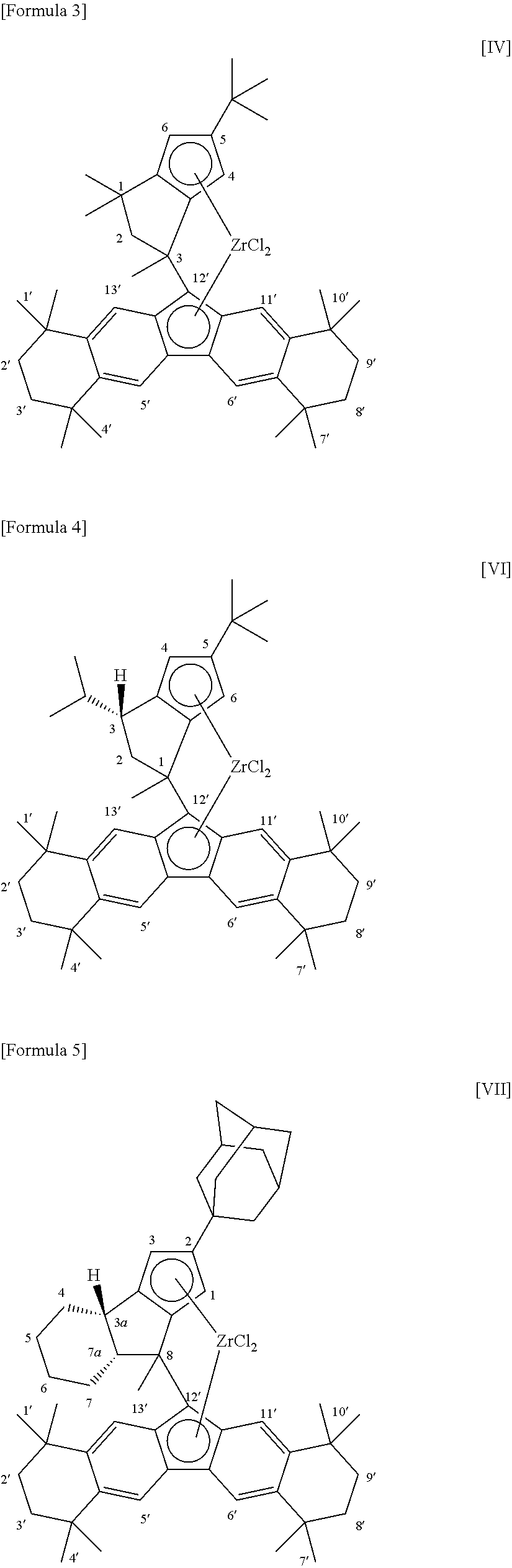

Propylene homopolymer composition for capacitor film, method for producing the same, and capacitor film

ActiveUS20170190891A1Easy to produceExcellent high-temperature voltage resistanceFixed capacitor dielectricVehicular energy storageEthylene HomopolymersCapacitor

Provided are a propylene homopolymer composition for a capacitor film, from which a thin film can be easily produced and which can provide a film with excellent high-temperature voltage resistance, a method for producing the same, and a capacitor film. The propylene homopolymer composition for a capacitor film contains 1% by mass or more and less than 50% by mass of a propylene homopolymer (A1) having predetermined characteristics and more than 50% by mass and 99% by mass or less of a propylene homopolymer (B1) having predetermined characteristics, and has (i) a melt flow rate (MFR) of 1.0 to 10.0 g / 10 min and (ii) a chlorine content of 2 ppm by mass or less.

Owner:MITSUI CHEM INC +1

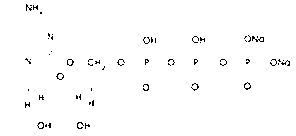

Gamma-cytidine-5'-disodium triphosphate crystal compound, and preparation method and drug composition of crystal compound

ActiveCN103044509AOperating conditions are easy to controlSuitable for industrial productionOrganic active ingredientsNervous disorderPharmacyPhosphoric acid

The invention relates to a gamma-cytidine-5'-disodium triphosphate crystal, and a preparation method, a drug composition, and a drug preparation of the crystal. The solubility and the stability of the crystal are better than those of a substance in the prior art, and the crystal is more beneficial for pharmacy and long-term storage. The preparation is particularly suitable for being prepared into an injection and a powder injection.

Owner:宁辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com