Method and device for producing baking soda

A technology of baking soda and ammonia distillation tower, which is applied in chemical instruments and methods, alkali metal compounds, inorganic chemistry, etc., can solve the problems of fine sodium bicarbonate crystal, short operation period, expansion of mother liquor, etc., and achieve a narrow particle size distribution range. , Guarantee the effect of crystal grain size and large crystal grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

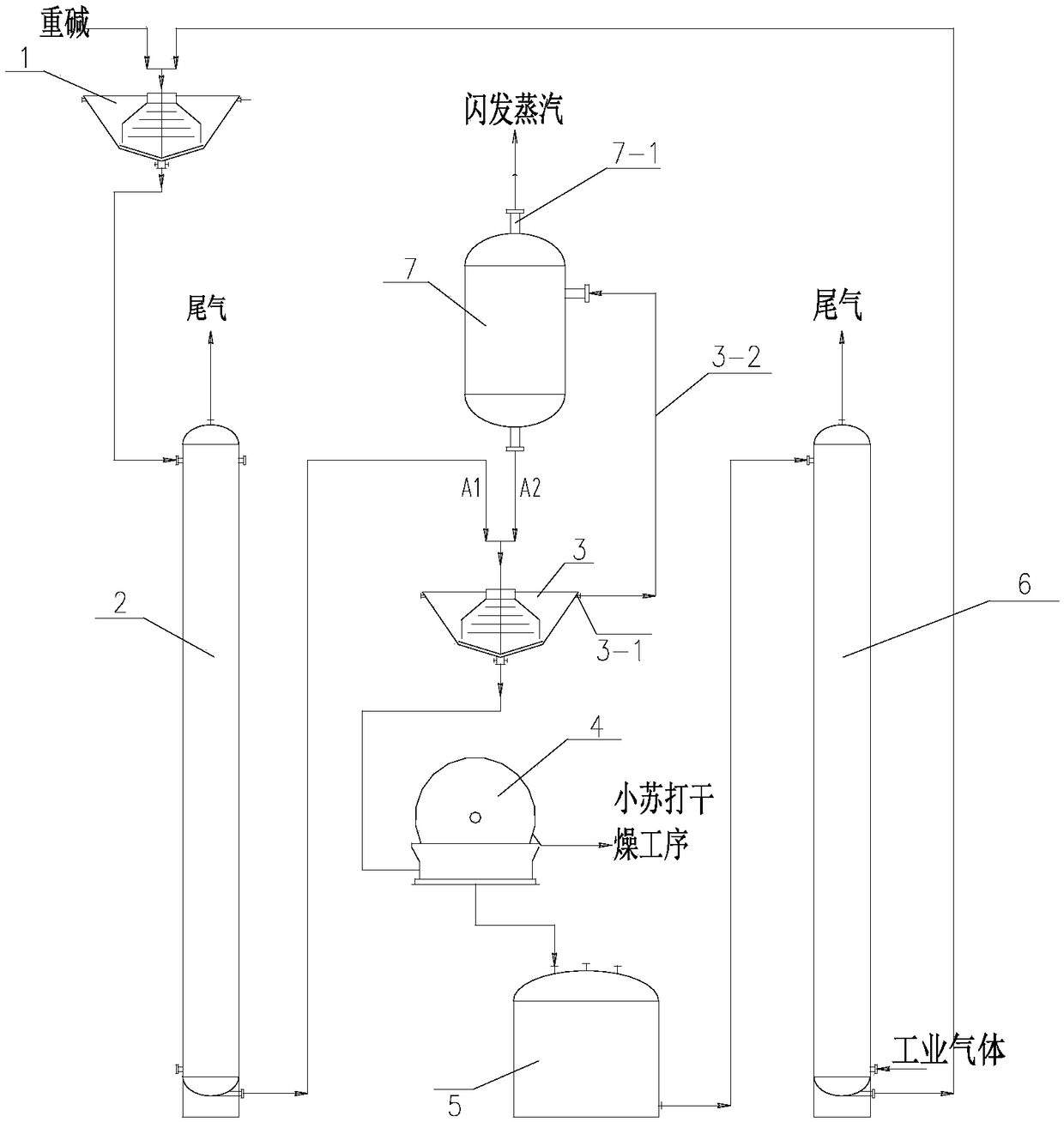

[0045] Such as figure 1 A kind of device of producing sodium bicarbonate shown, comprises dissolving tank 1, ammonia distillation tower 2, mixer 3, flasher 7, solid-liquid separator 4 and filtrate tank 5 connected successively, the bottom of described dissolving tank 1 The discharge port is connected to the feed port of the ammonia distillation tower 2 through a pipeline, and the discharge port of the ammonia distillation tower 2 is connected to the feed port of the mixer 3, and a clear liquid nozzle 3 is respectively provided on both sides of the top of the mixer 3 -1, the clear liquid nozzle 3-1 communicates with the feed port of the flasher 7 through the clear liquid pipeline 3-2, and the top of the flasher 7 is provided with a flash steam outlet 7-1, and the flasher 7 The outlet at the bottom of the mixer is connected to the inlet of the mixer 3, and the outlet at the bottom of the mixer 3 is connected to the solid-liquid separator 4 through a pipeline, and the filtrate of...

Embodiment 2

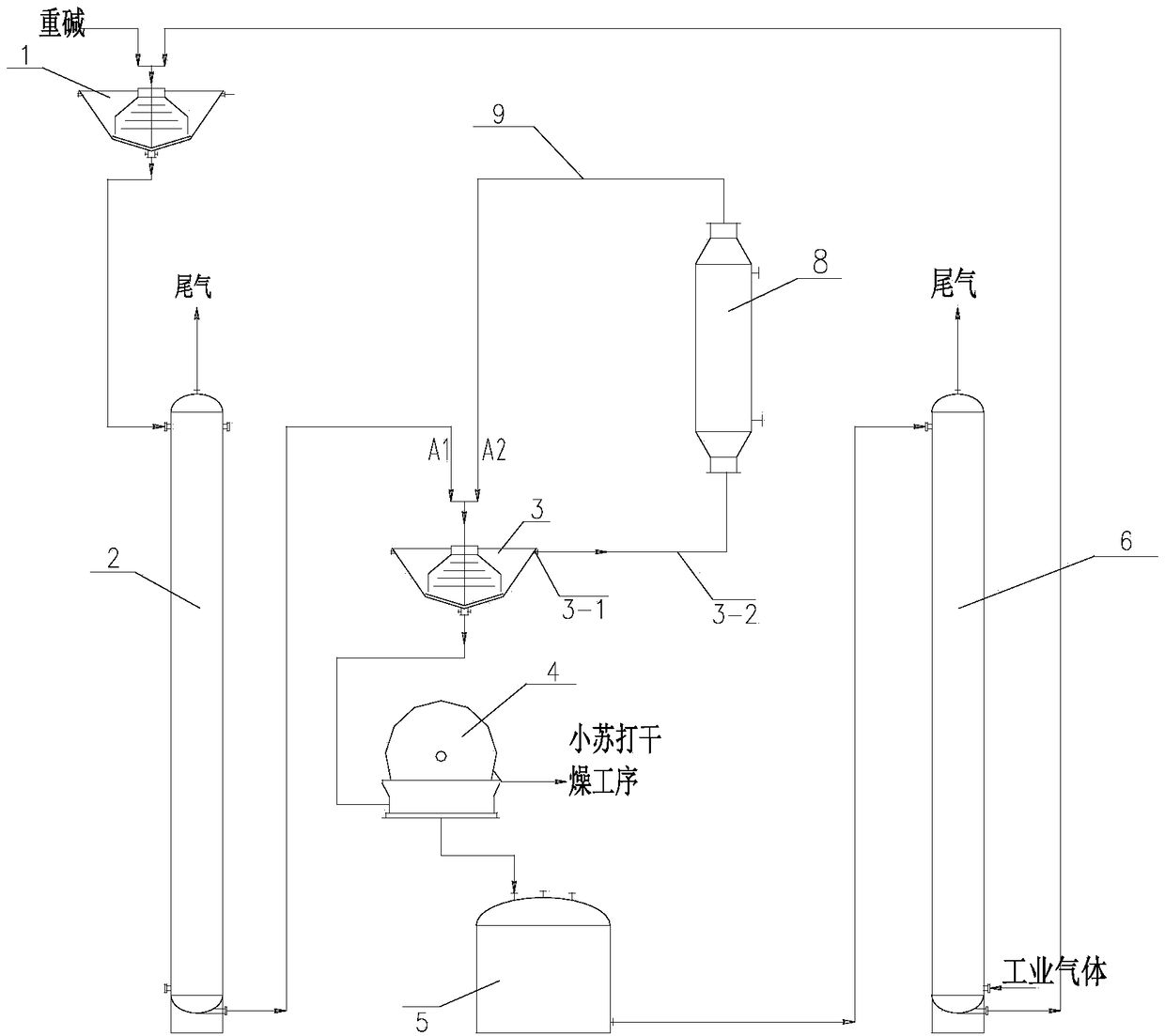

[0049] Such as figure 2 The device of producing sodium bicarbonate shown, adopts cooler 8 to replace described flasher 7 in embodiment 1, and described clear liquid nozzle is communicated with the bottom of cooler 8 by clear liquid pipeline, and the top of cooler 8 It communicates with the inlet of the mixer 4 through the return line 9 . The cooler 8 is connected with a cold energy refrigerant generating device, and the cold energy refrigerant generating device is a circulating water pipe, an air compressor or a refrigerator, and the cold energy refrigerant entering and leaving the cooler is cold air, circulating water, low-temperature water or The refrigerant. The cooler 8 is a coil heat exchanger, a shell and tube heat exchanger, a plate heat exchanger, a kettle heat exchanger or a combination thereof.

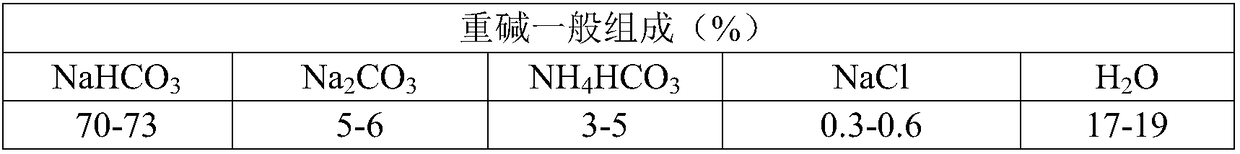

[0050] Heavy alkali raw materials containing sodium bicarbonate, sodium carbonate, ammonium bicarbonate and other substances are added to the dissolution tank to obtain a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com