Tablet candy suitable for children and manufacturing method thereof

A technology for tableting candy and its production method, which is applied in the fields of confectionary, confectionary industry, food science, etc., and can solve problems such as bad taste and obesity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

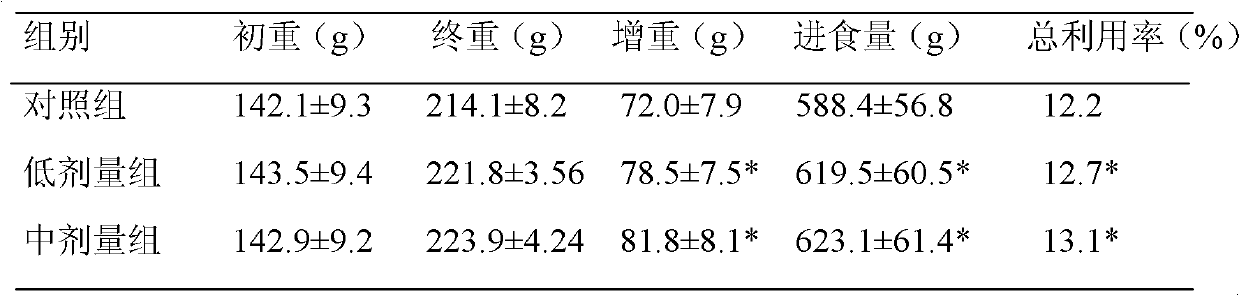

Examples

Embodiment 1

[0049] Composition prescription: Hawthorn 800 grams, Poria cocos 200 grams, fried malt 300 grams.

[0050]The extract (extract or dry extract powder) preparation process of composition:

[0051] Hawthorn, Poria cocos, and fried malt are broken into coarse particles individually or mixed in proportion, then decocted twice with appropriate amount of water, each decocting for 1 hour, combined for 2 decoctions, cooled and left for 24 hours, then used for 200 mesh filter cloth; the filtrate is concentrated under vacuum and reduced pressure to 1 gram of extract equivalent to 4 grams of raw medicinal material; Extract powder. The filter cloth can also be a filter cloth of more than 200 mesh.

Embodiment 2

[0053] Tablet candy formula: Hawthorn 1.0g, Poria cocos 1.0g, malt 1.0g, gallinacea 1.0g, zinc sulfate 0.220g, zinc lactate 0.225g, maltitol 49.455g, sorbitol 25.0g, dextrin 15.0g, fruit powder 5.0g grams, 0.2 grams of malic acid, 0.2 grams of citric acid, 0.2 grams of food flavor, 0.1 grams of vitamin C, 0.4 grams of magnesium stearate

[0054] The manufacturing method includes the following steps:

[0055] a. Hawthorn, Poria cocos, malt and gallinacea are pulverized into fine powders with a particle size less than 0.15 mm;

[0056] b. Premix fine powder of traditional Chinese medicine, zinc sulfate, zinc lactate and some auxiliary materials, and then mix them evenly with the remaining auxiliary materials to make soft materials;

[0057] c. Take out the soft material, push it into the boiling dryer for the first drying until the moisture content of the material is 4.0%-7.0%; pass through a 16-18 mesh screen to shake and granulate, and then dry the granules again until the mo...

Embodiment 3

[0060] Tablet candy formula: 2.0 kg of hawthorn extract, 0.5 kg of poria cocos extract, 0.75 kg of malt extract, 1.25 kg of gallinaceous gold, 0.63 kg of zinc glycinate, 73.27 kg of xylitol, 15.0 kg of dextrin, 5.0 kg of fruit powder, apple 0.2 kg acid, 0.2 kg citric acid, 0.3 kg food flavor, 0.1 kg vitamin C, 0.8 kg magnesium stearate

[0061] The manufacturing method includes the following steps:

[0062] a. Get gallinaceous gold and pulverize into a fine powder with a particle diameter less than 0.15mm; the preparation method of the extract is referring to embodiment one;

[0063] b. Premix chicken gold powder, zinc glycinate and some auxiliary materials, then mix them evenly with the remaining auxiliary materials, and add the extract to make soft materials;

[0064] c. Take out the soft material, push it into the boiling dryer for the first drying until the moisture content of the material is 4.0%-7.0%; pass through a 16-18 mesh screen to shake and granulate, and then dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com