Patents

Literature

623results about How to "Improve production rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Elastic polyester fibre and preparation method thereof

InactiveCN101126180AIncrease elasticityConvenient careFilament/thread formingMonocomponent polyesters artificial filamentFiberPolymer science

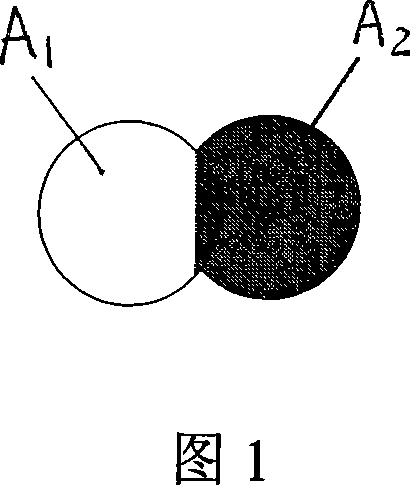

The invention relates to a springy polyester fiber and the preparing method. The technical problem of the invention to be solved is that the invention provides a springy fiber and the preparing method to make up the disadvantages of the capability of the spandex and the applying arrange. The springy fiber of the invention adopts the method of the compound filature and uses two screw extrusion machines to respectively melt the two components, and the product is obtained through the extrusion of the compound filature component. The invention is characterized in that the components of the springy fiber comprise two of the following high polymers which have heat shrinking capability difference: the high fasculation PETP, the PET, the PBT, the PTT with the weight proportion of 30-70:50.

Owner:ZHEJIANG HENGYI GRP CO LTD

Preparation and use of raw liquid of ceratin of animal hairs

ActiveCN1680467AImprove production ratePrevent oxidationMonocomponent protein artificial filamentChemistryCamel hair

The invention discloses a preparation and use of raw liquid of ceratin of animal hairs, such as wool, camel hair, bristle, human hair, bird feather and animal hair. The method comprises preparing combination reducing agent by sulfite, carbon amide compound and sodium salt organic matter, reducing the material hairs and producing raw liquid of ceratin of animal hairs. The keratin spinning fluid can be mixed with a plurality of materials, if mixing together with the nano silver series antiseptic material, then producing spinning fluid by grafting with the cellulose graft. The wet processing device and art can produce filament yarn or short fiber.

Owner:SICHUAN YIBIN WULIANGYE GROUP

Ultra fine soft wool yern and its production method

The present invention provides a superfine flexible wool yarn. It is characterized by that in the described yarn 60%-95% of superfine wool and 5%-40% of acrylic fiber, its single twist is 460-1200 twist / m, yarn number is 26-68 metric counts, the wool fibre length in the described yarn is 35mm-68mm, the wool fibre fineness is 22.6-15.5mic, and the acrylic fiber length is 35mm-68mm. Said invention also provides its production method and concrete steps.

Owner:顾民强 +3

Method for producing crimpy type high-grade green tea

InactiveCN102246866AResolution timeSolve quality problemsPre-extraction tea treatmentProduction rateGreen tea

The invention discloses a method for producing crimpy type high-grade green tea, which comprises the following sequence of operations: tedding fresh leaves, removing water in rollers, rolling to deblock, performing secondary water-removing, performing third water-removing, tedding to cool, shaping and rubbing, performing secondary tedding to cool and fragrance-extracting, wherein the secondary water-removing means that deblocked tea leaves are put in a 40 type well-known tea water remover for 20-25 seconds at the temperature of 130-140 DEG C; and the third water-removing means that the tea leaves after the secondary water-removing are returned back to a roller and are subjected to another time of water-removing for 15-22 seconds. The method for producing the crimpy type high-grade green tea has the advantages that the problem of long-time baking in a baking machine and many factors causing quality change can be completely solved, the occurrence of damage to tea leaves during warming up or stewing caused by slow manual stir-frying, and uneven stir-frying or not-required temperature at some time is prevented, so that the quality of the tea leaves is unified and is obviously improved; the labor force is reduced, and the yield is enhanced; the production rate is effectively increased, the tea leave dust is reduced, and the color and the luster are stable; and the method is convenient to operate and has little cost for machinery.

Owner:句容市春城馨香园茶场

Natural cotton fiber spunlaced nonwoven fabric for medical health and production method thereof

ActiveCN104313795AImprove removal efficiencyImprove pass rateCarding machinesHeating/cooling textile fabricsEngineeringMoisture absorption

The invention relates to a natural cotton fiber spunlaced nonwoven fabric for medical health and a production method thereof. The method is performed according to the following steps: preprocessing fibers; preliminarily combing cotton fibers; performing fine mixing; performing fine combing; forming a fiber net and performing drafting; performing hydraulic entanglement on the fiber net to form a cotton fiber spunlaced nonwoven fabric, and squeezing a bleaching solution into the fabric; performing cold pad-batch; removing cotton wax and pectin substances through a one-step method; performing cloth cover modification or jacquard treatment on a jacquard spunlaced device; drying the cotton fiber spunlaced nonwoven fabric on a tentering and setting machine; cutting the natural cotton fiber spunlaced nonwoven fabric, packaging the cut cotton fiber spunlaced nonwoven fabric, and warehousing the packaged cotton fiber spunlaced nonwoven fabric. According to the natural cotton fiber spunlaced nonwoven fabric for medical health, the gram weight deviation of the unit area does not exceed the range of minus 7% to plus 7%, the whiteness is greater than and equal to 85, the water absorption time is smaller than or equal to 5 s, the pH value is 6-8, the water-soluble matters are less than or equal to 0.5%, the soluble matters in ether are less than or equal to 0.5%, and the surface active substances are smaller than or equal to 2 mm. The natural cotton fiber spunlaced nonwoven fabric for medical health, provided by the invention, has the advantages of good hand feeling, good moisture absorption, good air permeability and no irritation to skins, the nonwoven fabric can be naturally degraded after being used, and the nonwoven fabric completely meets the requirement of environmental protection. The nonwoven fabric can be widely applied to the fields of medical care, hygiene, cosmetology, daily life, industrial cleaning, clean rooms and the like.

Owner:XINLONG HLDG GROUP +1

A continuous preparing method for polyether modified copolyester

ActiveCN105585701AChange the order of additionQuick responseMonocomponent copolyesters artificial filamentPolymer scienceCopolyester

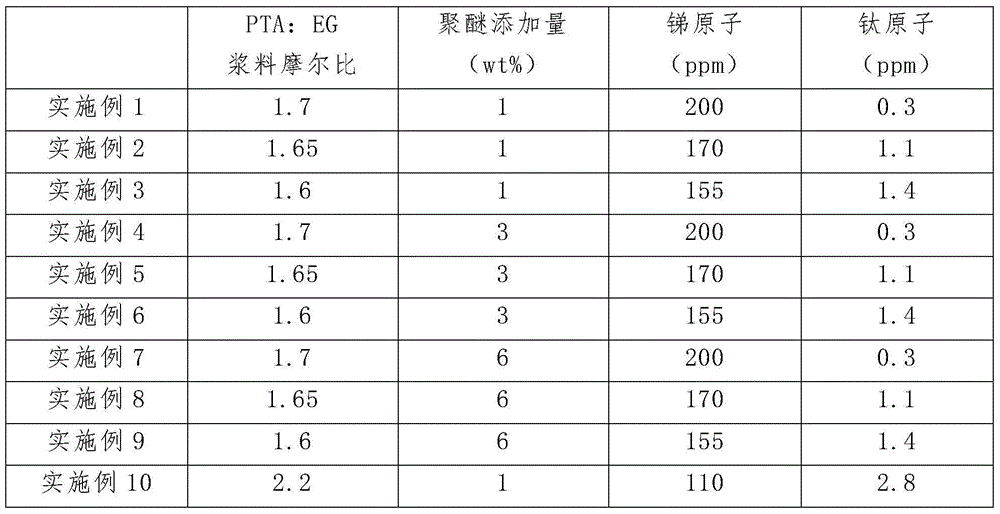

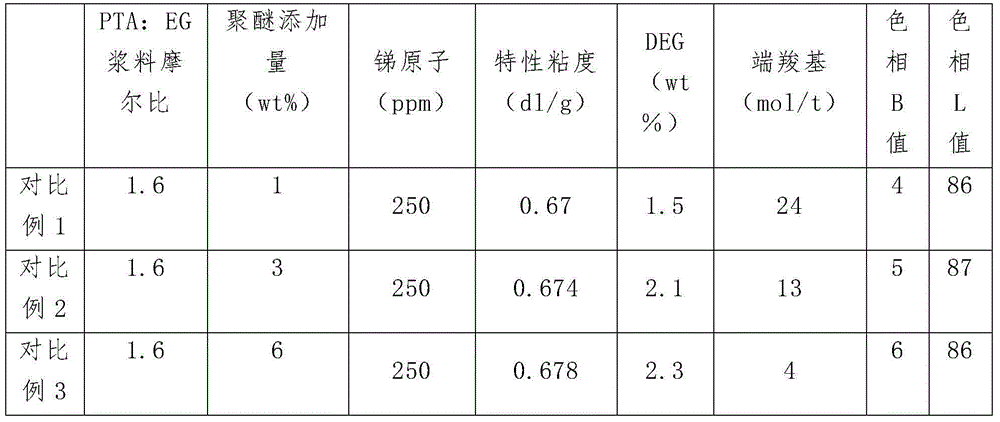

The invention relates to a continuous preparing method for polyether modified copolyester. The method includes mixing an ethylene glycol solution of a titanium catalyst, terephthalic acid and ethylene glycol to prepare slurry, esterifying, mixing an ethylene glycol solution of an antimony catalyst, an ethylene glycol solution of polyether and an intermediate that is bis(hydroxyethyl) terephthalate, pre-polymerizing, performing condensation polymerization, and the like. Problems that polyether macromolecules are prone to thermal degradation and are degraded into chain segments with low molecular weights at high temperature with long reaction time, and modification effects of the chain segments with low molecular weights on polyesters are weakened are overcome by the preparing method. The polyether that is a modifying agent in the prepared polyether modified copolyester is uniform in distribution and stable in molecular weight. A copolyester product is excellent and stable in performance and good in spinnability.

Owner:CHINA PETROLEUM & CHEM CORP +1

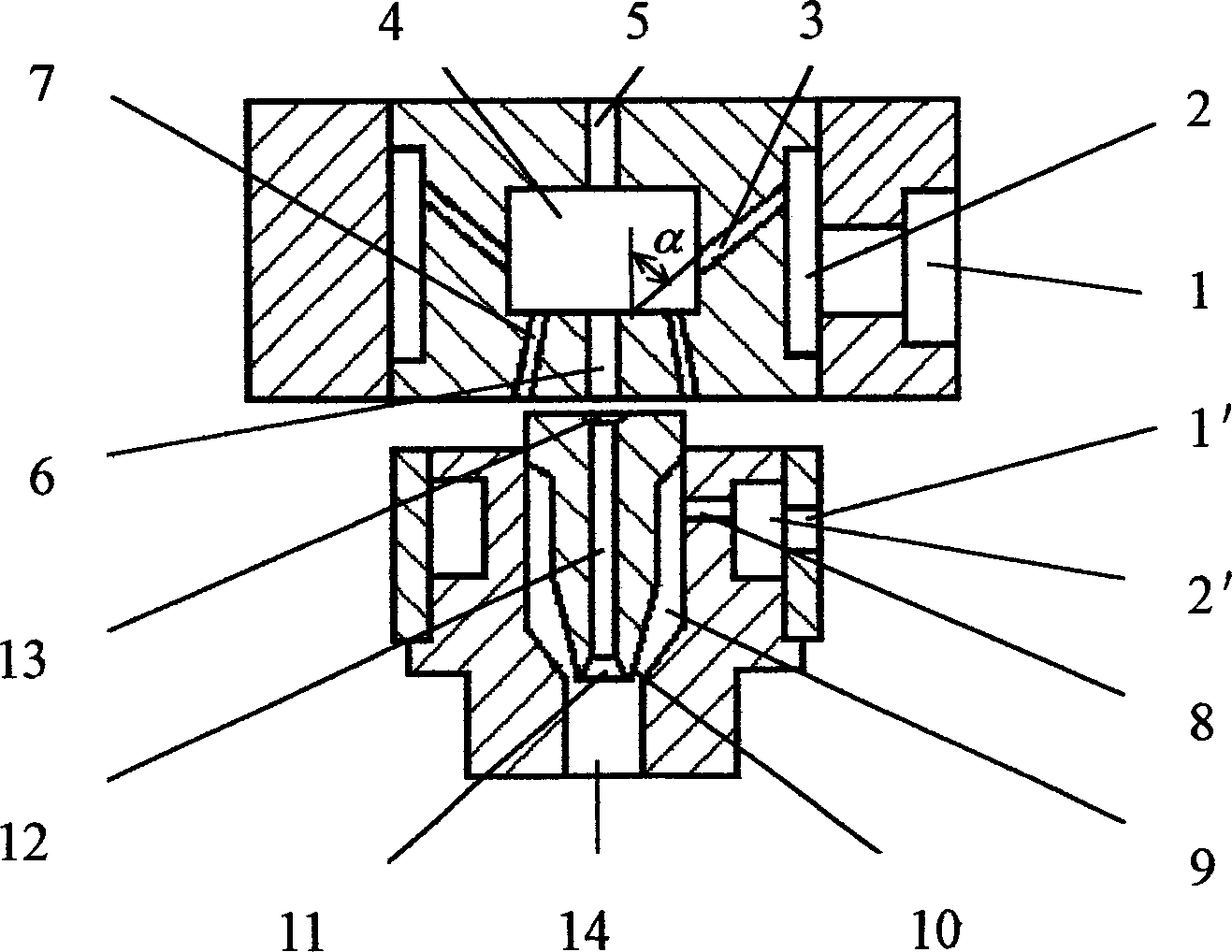

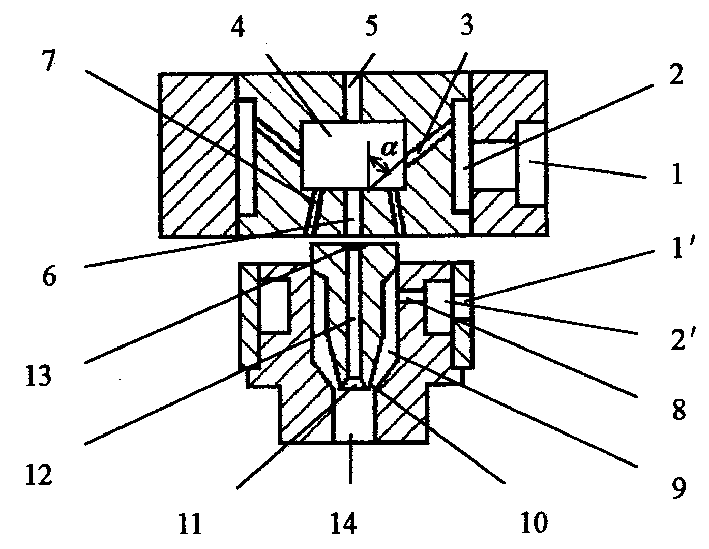

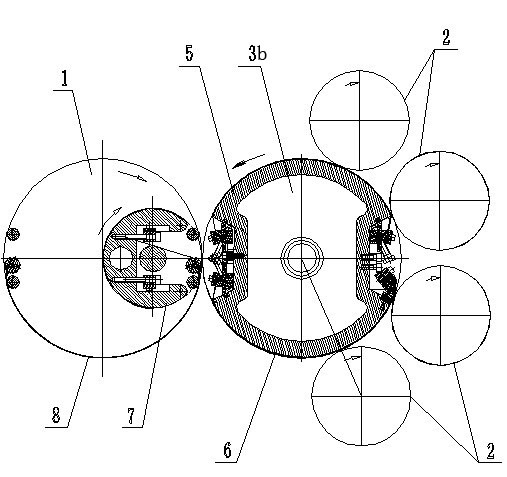

Complex twisting device for air-jet eddy-current spinning

InactiveCN1388278ANo suction phenomenonImprove production rateContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The complex twisting device for air-jet eddyc-current spining to twist fiber strand consists of the upper twisting unit and the lowr twisting unit. Positive pressure air flow is utilized to produce eddy-current field and pipe flow and the fiber is fed to the eddy-current field via the conveying pipe. Fiber strand rotates with the high-speed rotating air flow while the pipe flow protects and guides the twisted fiber strand to leave from the eddy-current field. During the process, fiber strand is twisted to produce twisted yarn in high speed. The present invention makes it possible to produce high-quality yarn at low cost and high speed.

Owner:DONGHUA UNIV

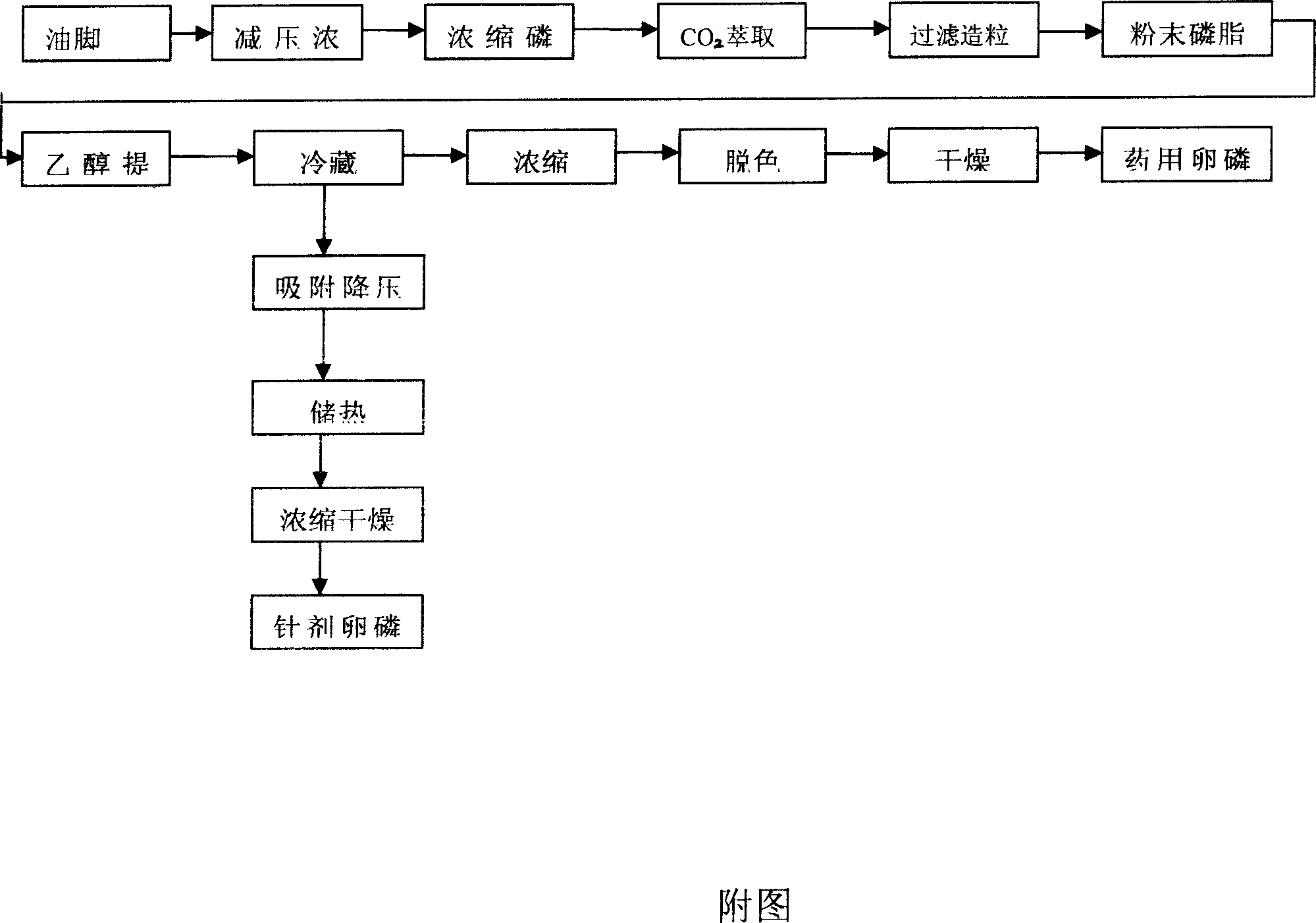

Method of preparing powder phosphatide and lecithin for medicine and injection from soybean oil residue

InactiveCN101016312AImprove production environmentReduce production inputOrganic active ingredientsPharmaceutical non-active ingredientsActivated carbonAlcohol

The invention discloses a making method of powder phosphatide, medical and injection lecithine, which comprises the following steps: decompressing and condensing raw material; proceeding CO2 hypercritical extraction; filtering; selecting grain; drying; obtaining soybean powder phosphatide; extracting powder phosphatide through alcohol; freezing extract more than 12h; filtering in the vacuum; distilling under normal pressure; adopting active charcoal to decolor; condensing; drying; obtaining the medical lecithin; extracting soybean powder phosphatide through alcohol; freezing; adding activated adsorber to adsorb decompression material; adsorbing heat source through active charcoal; decoloring; filtering; condensing; degerming; drying; obtaining injection lecithin; fitting for making industrial phosphatide.

Owner:崔澎

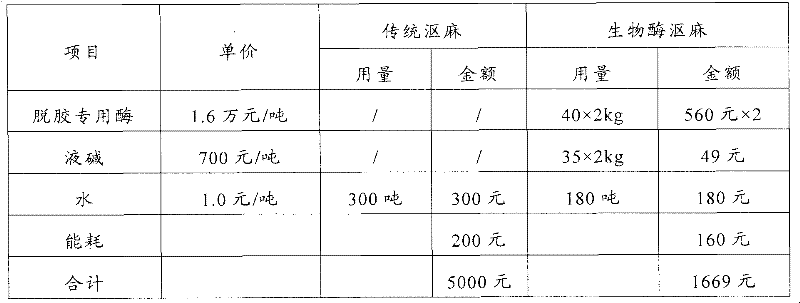

Degumming method of flax and enzyme preparation for using in degumming

ActiveCN102206874AHigh hemp strengthHigh hemp strength, high production rate of flax long fibersEnzymesVegetable materialChemistryPectinase

The invention provides a degumming method of flax, comprising the following steps: adjusting the PH value of water to 8.5-9.5, heating to 20-55 DEG C, adding the enzyme preparation composed of hemicellulase and alkaline pectinase with enzyme activity of 50-5000 U / ml in the water to obtain a mixed solution, adding flax in the heated mixed solution to ret and degum, and drying, cultivating and scotching the degummed flax to obtain linen fibers. The invention also provides an enzyme preparation for degumming of the flax, comprising hemicellulase and alkaline pectinase with enzyme activity of 50-5000 U / ml. According to the invention, by using the enzyme preparation for degumming, the degumming time is short, the intensity of the scotched flax is high, the yielding of linen fibers is high, the evenness is good, the operation is simple without the process of bacteria producing enzyme, and degumming waste can be reused or discharged to farmland so as to reduce the cost of industrialization of degumming.

Owner:SHANGHAI KDN BIOTECH +1

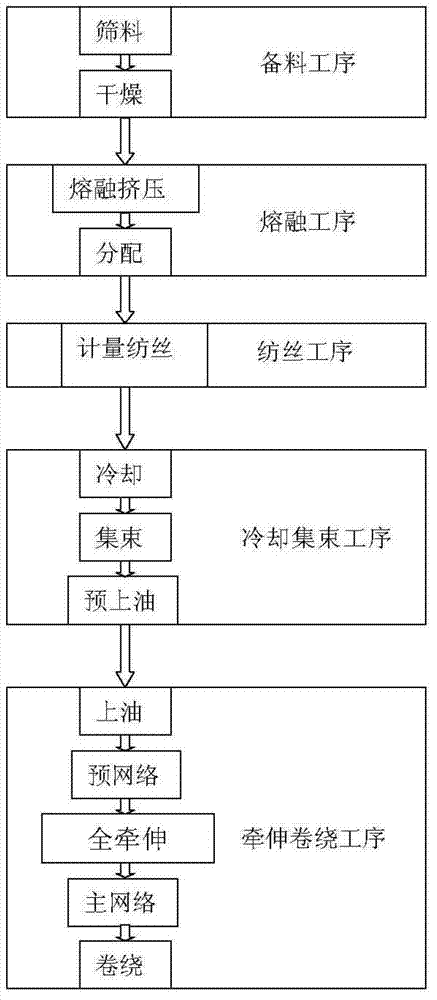

Spinning-winding united manufacturing process of corterra fully-drawn long yarns

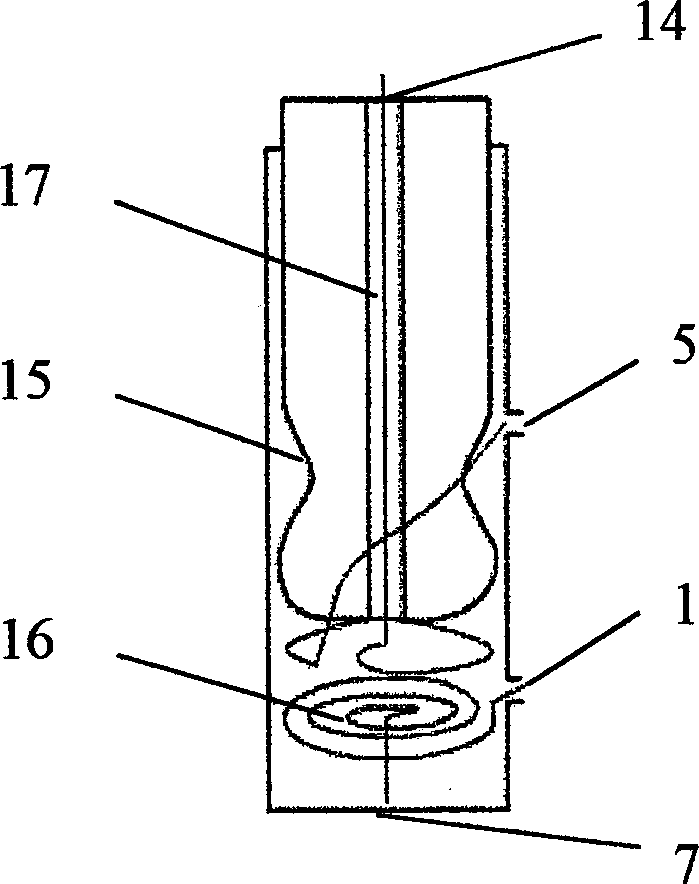

InactiveCN102776588AHigh technical contentIncrease added valueNew-spun product collectionFilament forming substance formingEngineeringConductor Coil

The invention discloses a spinning-winding united manufacturing process of corterra (PPT) fully-drawn long yarns, belonging to the technical field of production process of chemical fibers. The process comprising the following procedures: a procedure of preparing for raw corterra slices, a procedure of fusing, a procedure of spinning, a procedure of cooling and bundling, and a procedure of drawing and winding, wherein the procedure of drawing and winding comprises a step of fully drawing corterra yarns; the step is as follows: heating a pre-weaved corterra yarn bundle at low temperature through a first spinning heat roller set GR1; then drawing the corterra yarn bundle heated at low temperature through a second spinning heat roller set GR2 to form a corterra long yarn, and initially and thermally shaping the corterra long yarn at high temperature; and then further shaping the initially and thermally shaped corterra long yarn at high temperature independently through a third spinning heat roller set GR3 to form the corterra fully-drawn long yarns. The manufacturing process provided by the invention can effectively reduce internal drawing stress of the yarn bundle, increase winding quality, and meet the demand on production process of high-quality corterra long yarns so as to produce high-quality long yarns.

Owner:BEIJING CHONGLEE MACHINERY ENG

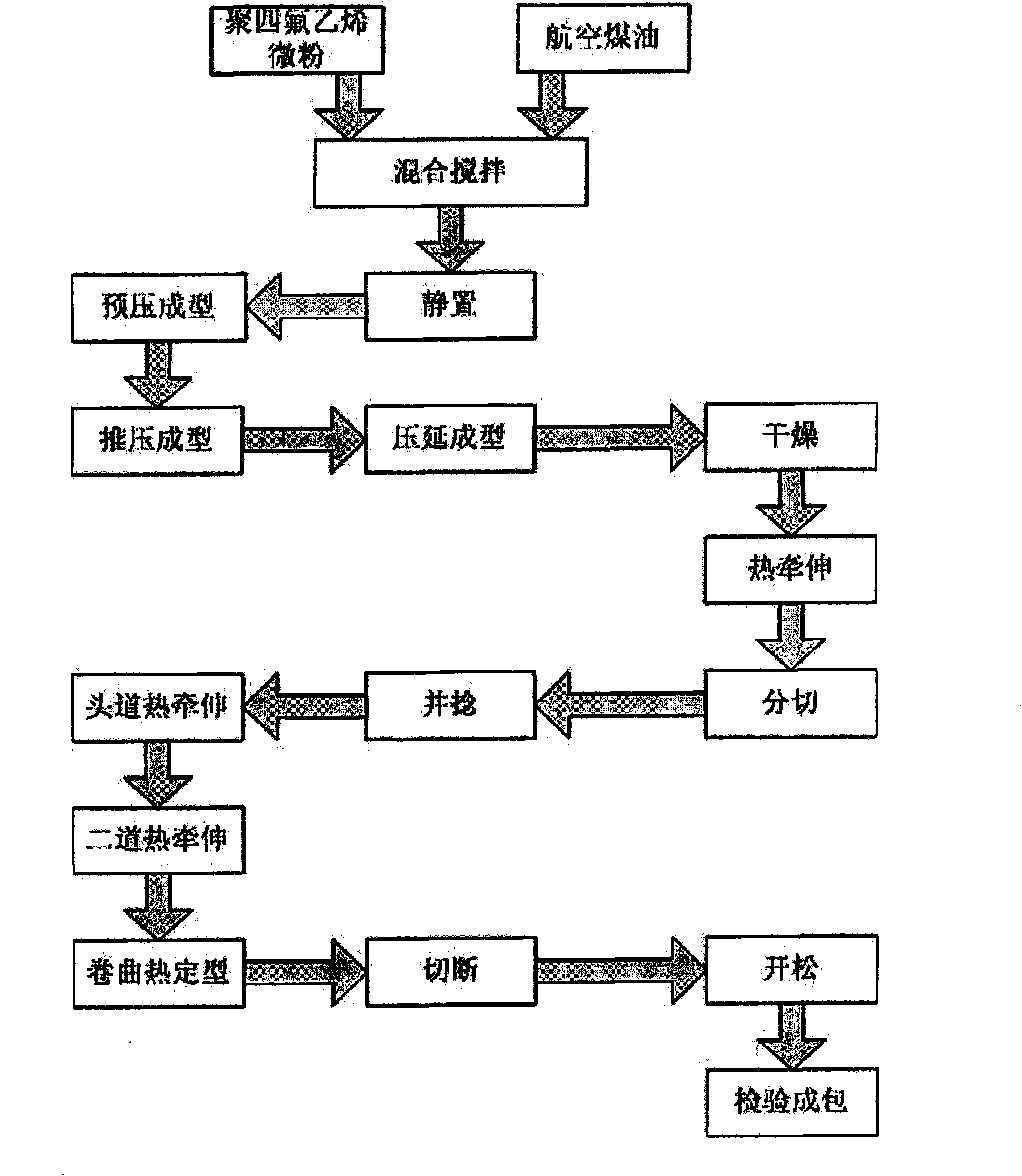

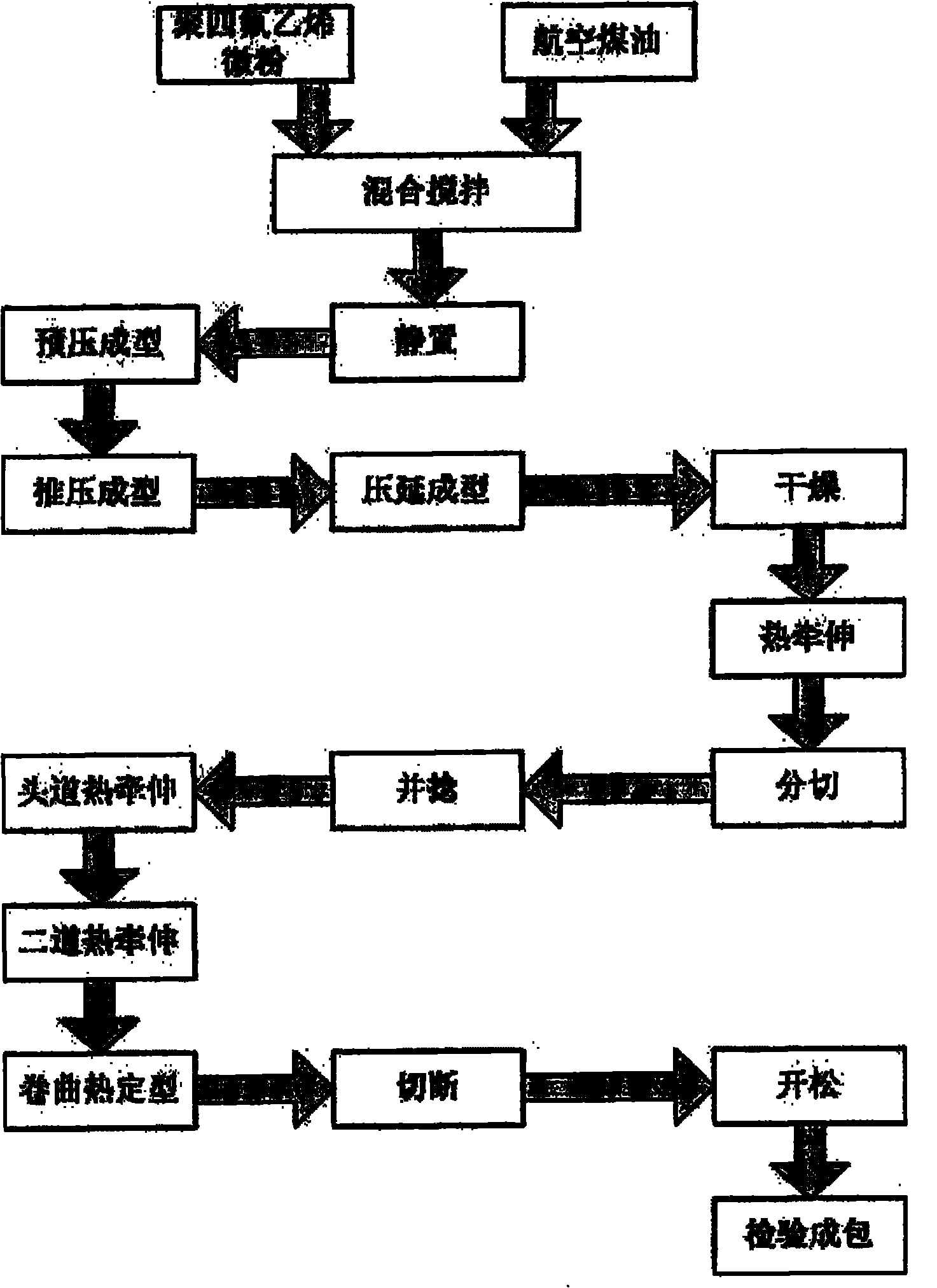

Preparation method of polytetrafluoroethylene chopped fiber

InactiveCN102071483ASimple processing equipmentEasy to operateFilament/thread formingMonocomponent halogenated hydrocarbon artificial filamentFiberPre compression

The invention aims to provide polytetrafluoroethylene chopped fiber with high intensity, high uniformity and low production cost and preparation technology thereof. A process flow comprises the following steps of: mixing polytetrafluoroethylene micro powder and a lubricating agent; stirring; standing; performing pre-compression molding; performing push molding; performing rolling molding; drying; performing hot stretching; parting off; twisting; performing primary hot drawing; performing secondary hot drawing; curling and thermally forming; cutting off; loosening; and inspecting and packaging so as to obtain high-intensity polytetrafluoroethylene chopped fiber. In a manufacturing process, the temperature rises gradually from the primary hot stretching to the secondary hot stretching to the curling and thermally forming.

Owner:宋朋泽

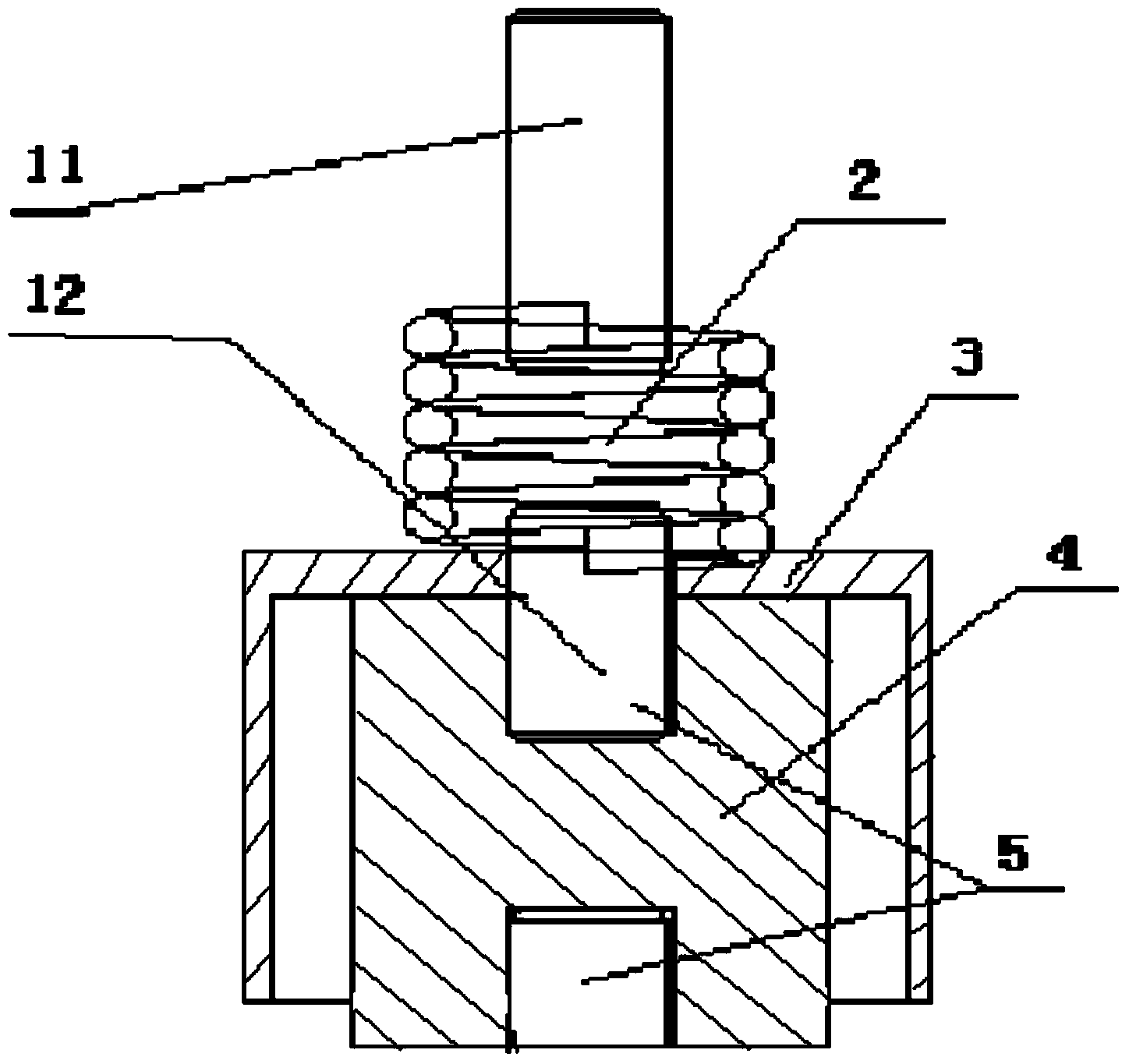

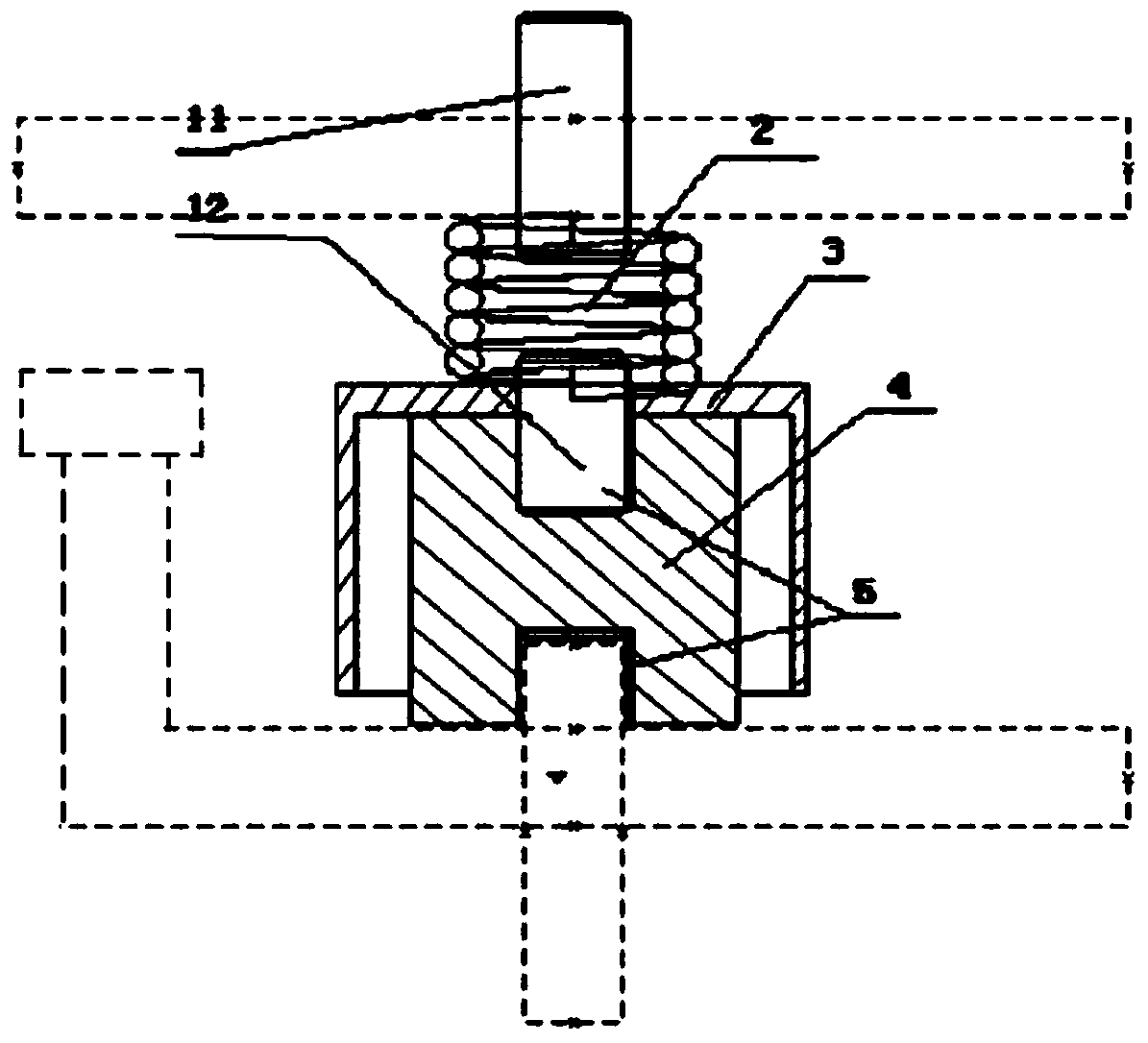

Flexible insulator for grid component of ion thruster

ActiveCN104343651AHigh working reliabilityReduce failure rateMachines/enginesUsing plasmaScrew threadScrew joint

The invention discloses a flexible insulator for a grid component of an ion thruster. The insulator comprises a first screw rod, a second screw rod, a spring and insulating ceramic, preferably the insulator further comprises a shielding hood, wherein the shielding hood is of a cavity structure, an opening is formed in one side of the cavity structure, the insulating ceramic is placed in the cavity of the shielding hood, and threaded holes are formed in both end surfaces of the insulating ceramic; the both ends of the spring are respectively connected with the first screw rod and the second screw rod in a welding manner, and the second screw rod penetrates through the bottom surface of the shielding hood and is connected with the threaded hole of one end surface of the insulating ceramic by screw threads, so that the shielding hood and the insulating ceramic are connected together to form the flexible insulator; the threaded hole of the other end surface of the insulating ceramic is used for being in threaded connection with a support ring of a piece of grid through the screw rods, and the first screw rod is used for being in screw joint with the other piece of grid by screw threads. Through the utilization of the grid component of the ion thruster, which is assembled by the flexible insulator, the changes of the spacing between the two grid pieces of the grid component can be effectively reduced, the spacing and the insulation of the two grid pieces are ensured, and the reliability of the ion thruster and the stability of the thrust are ensured.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Chinlon 6 anion short fiber and producing method thereof

InactiveCN1772982AImprove surface activityTo promote metabolismStaple fibre formationArtifical filament manufactureFiberNylon 6

The present invention relates to a nylon 6 negative ion staple and its production method. Said staple includes negative ion function mother granules and nylon 6 chips, their weight ratio is 1:5-10. The described negative ion function mother granules include function powder body, carrier chip, dispersing agent, coupling agent and antioxidant, their weight ratio is 20:79.5:0.2:0.1:0.2. Besides, said invention also provides the concrete steps of its production method.

Owner:天津市发博纺织材料有限责任公司

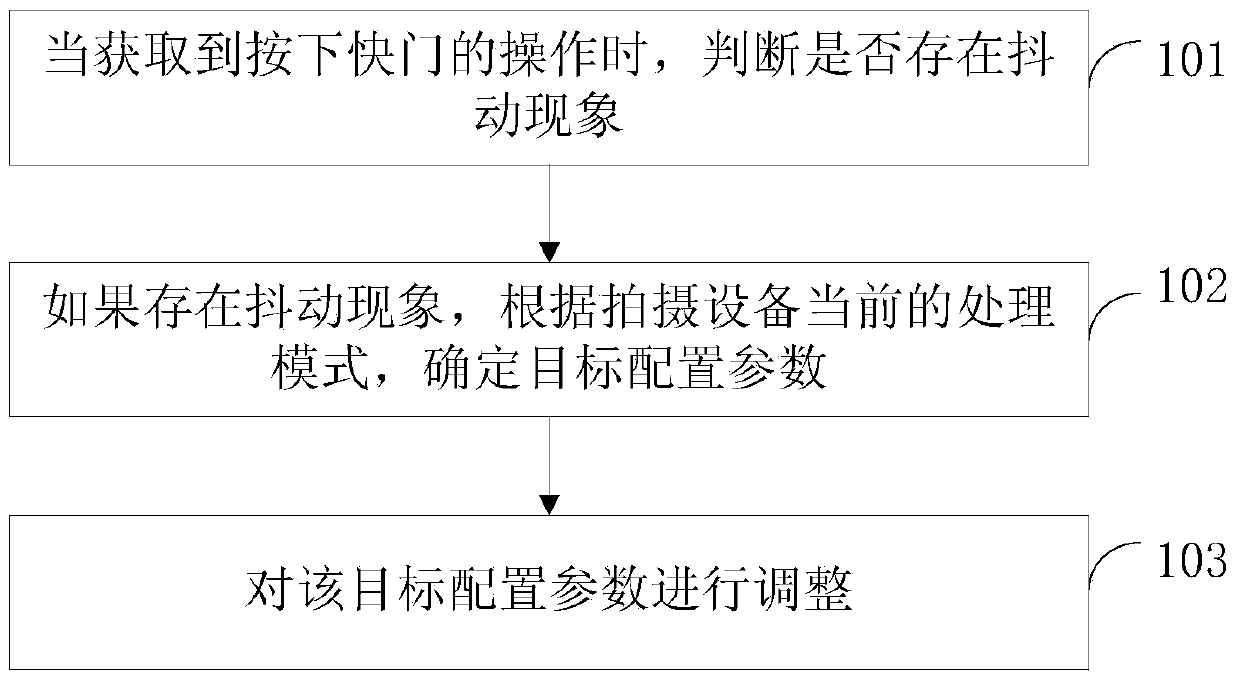

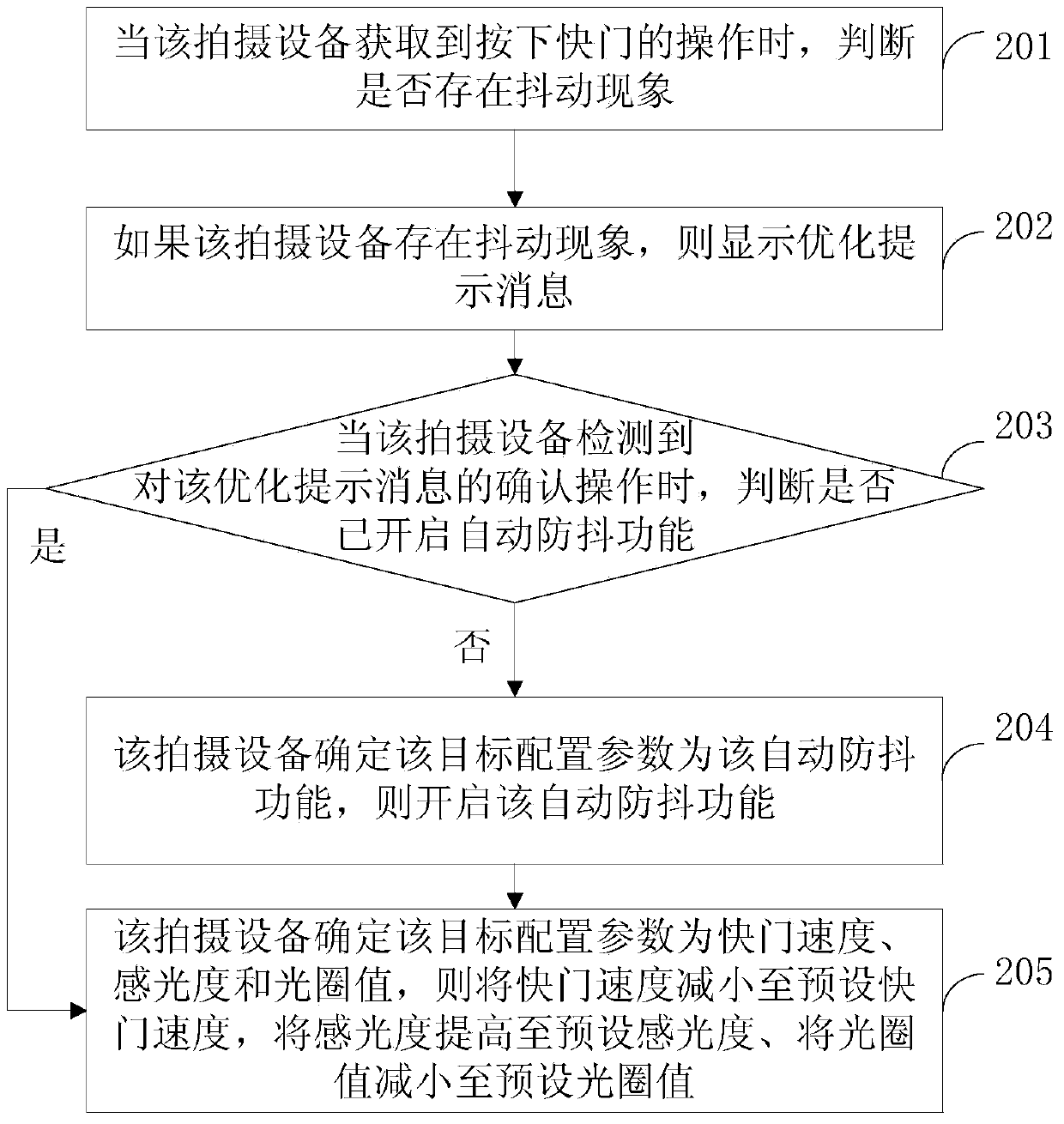

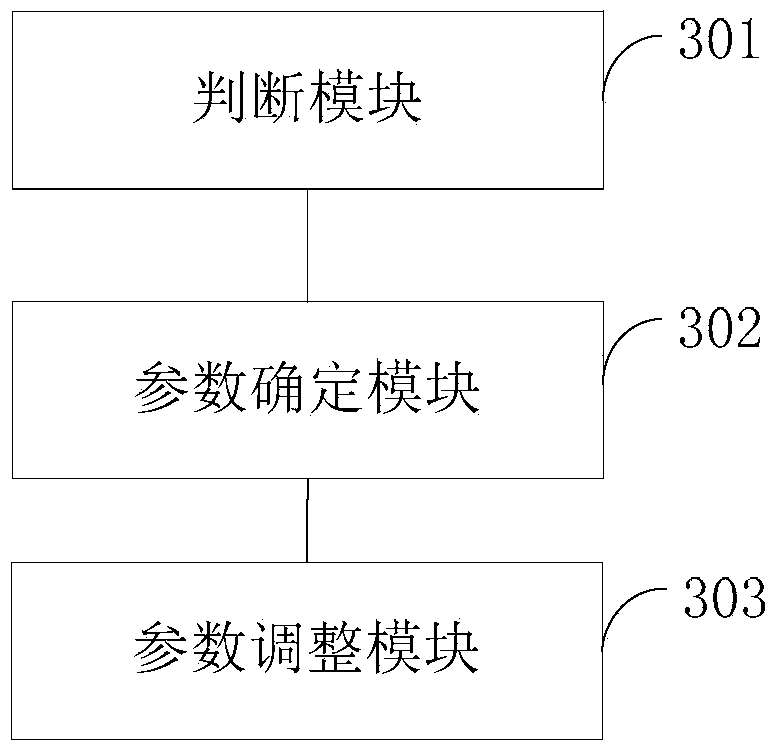

Shooting method and shooting device

ActiveCN104219448AQuality improvementAvoid blurTelevision system detailsColor television detailsImaging processingSimulation

The invention relates to a shooting method and a shooting device, and belongs to the field of image processing. The shooting method includes judging whether shaking phenomena exist or not when shutter pressing operation is acquired; determining target configuration parameters according to current processing modes of shooting equipment if the shaking phenomena exist; adjusting the target configuration parameters. The shooting method and the shooting device have the advantages that whether the shaking phenomena exist or not is judged when photos are shot, the target configuration parameters are determined according to the current processing modes if the shaking phenomena exist, and are adjusted, accordingly, blurred pictures of the photos due to shaking of the shooting equipment can be prevented, the quality of the photos can be improved, and the photo yield of the shooting equipment can be increased.

Owner:XIAOMI INC

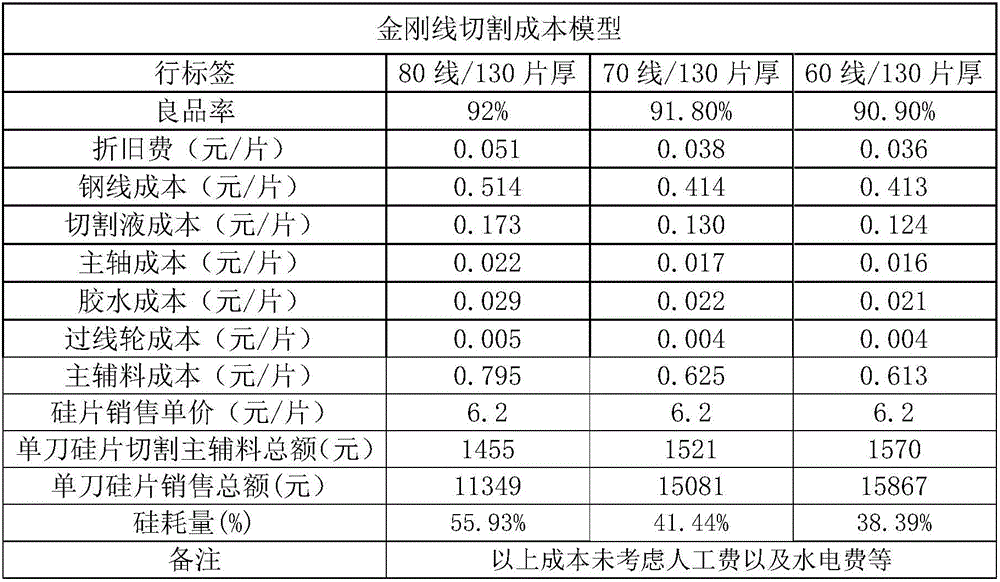

Method for cutting ultra-thin silicon wafer by superfine steel wire

The invention relates to a method for cutting ultra-thin silicon wafer by a superfine steel wire. The method comprises the following steps of: (1) forming slots in a man shaft; (2) sticking bars; (3) preparing a cooling liquid; (4) cutting; (5) unloading; (6) degumming and cleaning; and (7) detecting; the cooling liquid prepared in the step (3) is pure water and a water-based cutting fluid with concentration being 0.6%-2.0%; and during cutting in the step (4), cutting steel wires are 60 [mu]m diamond wires, diamond particles are particles with diameter being 6-8 [mu]m, tension is set to be 7-9 N, and slot pitch of the main shaft is 0.19-0.210 mm. According to the method, single crystal slicing yield is further reduced, slicing thickness is reduced, silicon loss is reduced and processing cost is reduced; and meanwhile, a wire braking rate can be reduced, yield is increased, and wire doubling is avoided.

Owner:SHANGHAI SHENHE THERMO MAGNETICS ELECTRONICS CO LTD

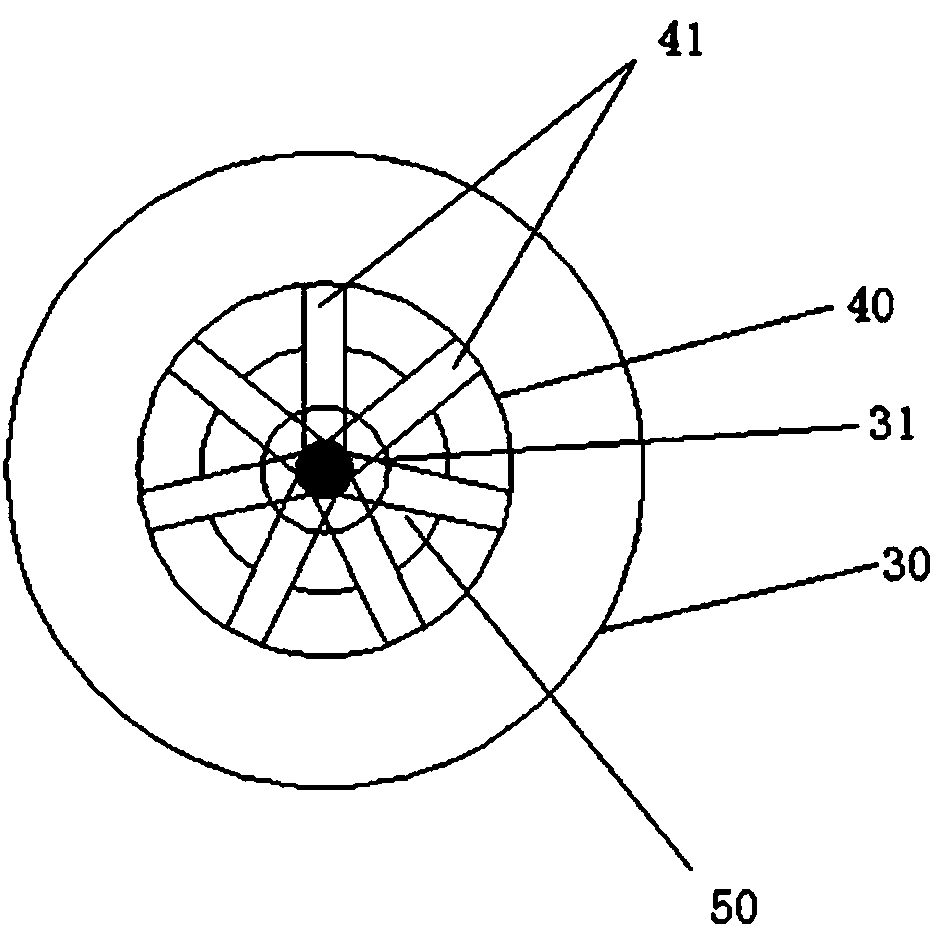

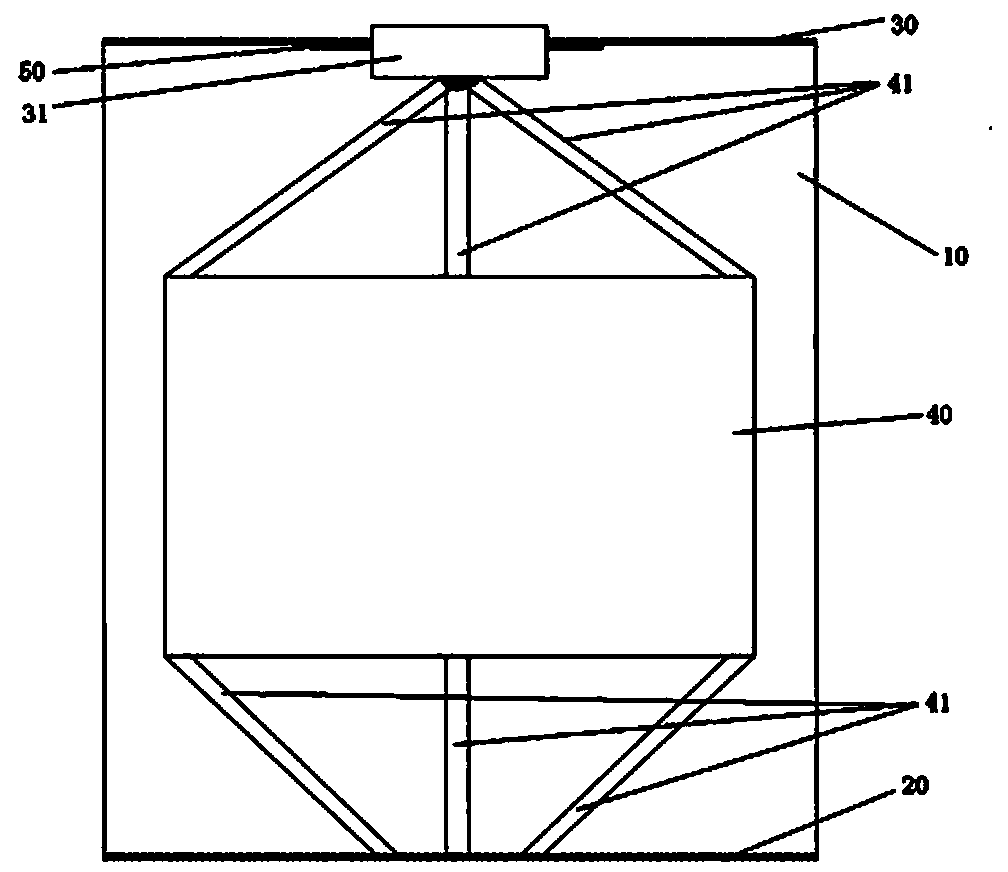

Cylindrical multi-lug lithium ion battery and preparation method thereof

InactiveCN103500844AImprove consistencyImprove production rateFinal product manufactureSmall-sized cells cases/jacketsEngineeringLithium-ion battery

The invention discloses a cylindrical multi-lug lithium ion battery and a preparation method thereof. The lithium ion battery comprises a cylindrical housing, a positive-electrode cover plate, a negative-electrode cover plate, a battery core wound body, and electrolyte. A protruding platform extending into the inner part of the cylindrical housing is provided on the negative-electrode cover plate. The battery core wound body is prepared by winding by using a positive-electrode sheet, a separation sheet, and a negative-electrode sheet. A plurality of lugs are arranged on the positive-electrode sheet and the negative-electrode sheet. The electrolyte is filled in the cylindrical housing. The plurality of lugs on the negative-electrode sheet extend to the center of the battery core wound body and are connected on the protruding platform. With the design structure, the plurality of lugs on the negative-electrode sheet are directly arranged on the protruding platform through a welding point, such that battery performance consistency and manufacturing yield are improved, internal space of the battery is saved, battery design capacity is improved, and cost is reduced. With the preparation process, no large-scale instrument and equipment is needed, and operation is simple. The method is suitable for automation transformation of production lines.

Owner:ZHEJIANG JINKAILAI NEW ENERGY TECH

Milk protein fiber or its filament or its blended yarn dyeing method and coloured woven fabric producing method

ActiveCN1865574ASolve the problem of not being able to dyeHigh dye utilization rateHeating/cooling textile fabricsWoven fabricsAlcoholPolyvinyl acetate

The invention discloses a manufacturing method of milk protein fiber or filament or blended yarn dyeing and yarn-colored product, which is characterized by the following: changing coiling density of yarn; controlling heating temperature; adopting segmented contraction in the cylinder yarn dyeing course; adding self-producing milk protein fiber dyeing specific adjuvant; utilizing polyacrylonitile or polyvinyl acetate alcohol as carrier realize active dyeing technology of milk protein fiber; solving the difficulties of flower color, weak color and bad fastening degree problem to produce excellent washing shrinkage and stable size yarn-dyed product through weaving, shrinking and softening and final disposal.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

Capron 6 bamboo charcoal staple fiber, and fabricating method

InactiveCN1760413AWith far infraredFunctionalStaple fibre formationArtifical filament manufactureNylon 6Extrusion Granulation

The present invention relates to a nylon 6 bamboo carbon staple and its production method. Said staple includes bamboo carbon function mother granules and nylon 6 chips, their weight ratio is 1:5-10; and the described bamboo carbon function mother granules include function powder body, carrier chips, dispersing agent, coupling agent and antioxidant, their weight ratio is 20:79.5:0.2:0.1:0.2. The present invention also provides the concrete steps of its production method. Said method includes the steps of preparing raw materials, mixing them, spinning, end winding, tow collecting, drafting, dewatering, crimpting, finalizing design and cutting.

Owner:天津市发博纺织材料有限责任公司

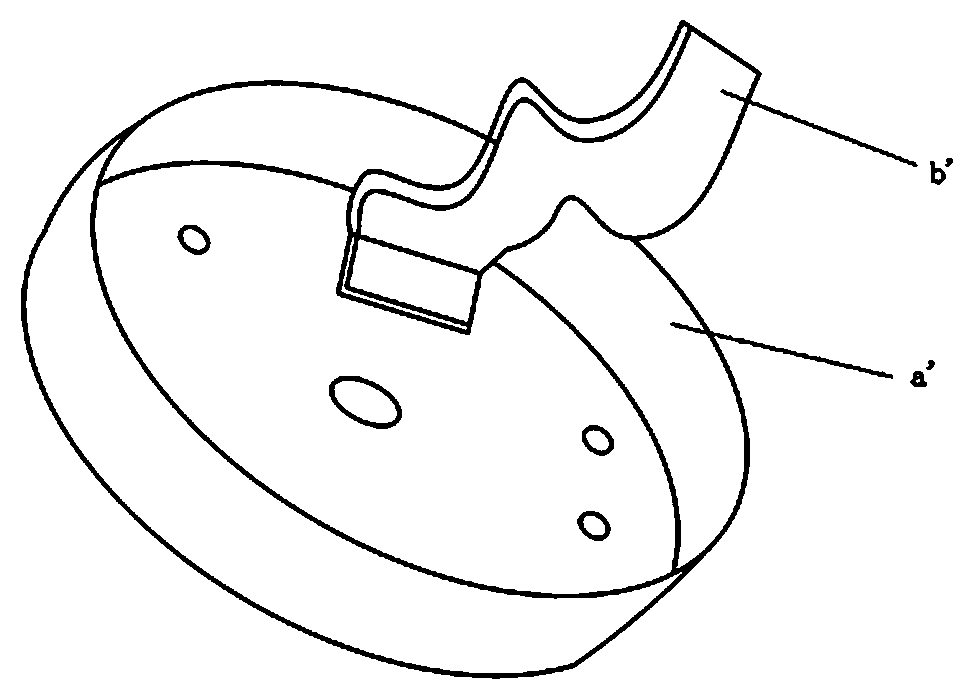

Non-contact smart card and its production method

InactiveCN101145212AImprove bending resistanceImprove stabilityRecord carriers used with machinesEngineeringElectrical and Electronics engineering

The invention relates to a non-contact smart card and a manufacturing method of the non-contact smart card. The non-contact smart card comprises a core layer composed of a chip, a polymer base layer containing an antenna, and a packed layer, wherein, the thickness of the packed layer is larger than or equal to that of the chip; the chip, which connects with the antenna, is positioned in a hole arranged in the packed layer. The invention adopts the metal-etching method to make the antenna, thereby not only improving the anti-bending property and stability of the product and leading the antenna adaptable to humid and high-temperature environments, but also lowering the cost. Due to adoption of the inverted-patch technology, the chip can be directly dismounted from a wafer and put on the etched antenna in the polymer base layer to form the tight connection between the chip and the antenna without the need of module capsulation, so the cost for chip capsulation is lowered. The use of the perforated packed layer reduces the stress onto the chip in lamination, strengthens the protection on the chip and improves the product yield rate.

Owner:SHANGHAI LUNENG SMART CARD

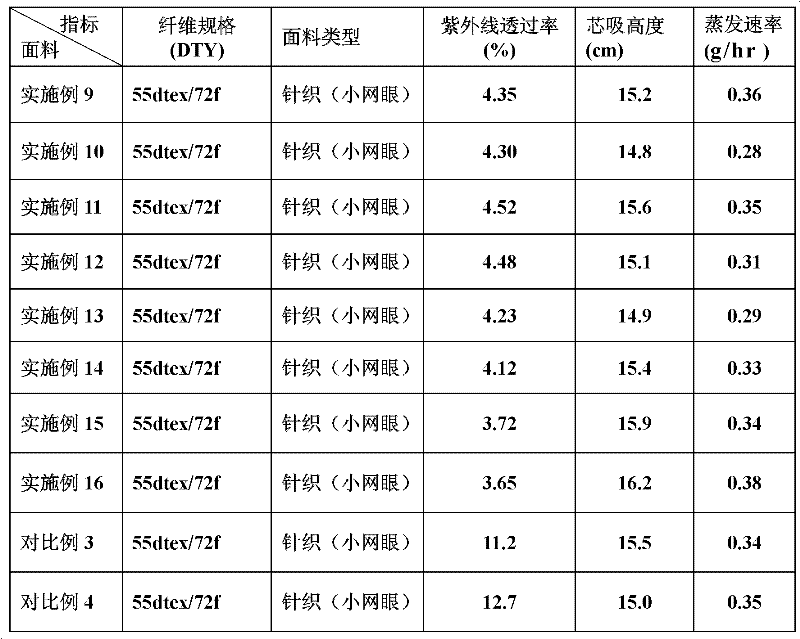

Preparation method for polyester fiber with compound ultraviolet ray resisting, aging resisting, moisture absorbing and quick drying functions

ActiveCN102443876AImproves UV resistanceReduce permeationMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method for a polyester fiber with compound ultraviolet ray resisting, aging resisting, moisture absorbing and quick drying functions. The method comprises an esterification reaction process, a polymerization reaction process and a spinning process in sequence, and comprises the following specific steps of: in an esterification reaction, introducing a third monomer with relatively large steric hindrance; after the esterification reaction and before a pre-polymerization reaction, adding titanium dioxide serving as a high-content delustering agent, a hindered amine light stabilizer and a hindered phenol antioxidant; after the pre-polymerization of polymerization reaction process and before final polymerization, adding an ultraviolet absorber; and beforethe spinning process, pre-crystallizing and drying polyester slices obtained in the polymerization reaction process, and designing a special-shaped section for the fiber. The polyester fiber obtainedby using the method has superior ultraviolet ray resisting, aging resisting, moisture absorbing and quick drying functions. As provided by testing, relevant technical indexes are that: the ultraviolet transmission is less than or equal to 5.0 percent, the wicking height is more than or equal to 120 millimeters, and the evaporation rate is more than or equal to 0.20g / hr after the polyester fiber is woven into a knitted fabric and a woven fabric.

Owner:JIANGSU GUOWANG HIGH TECH FIBER CO LTD

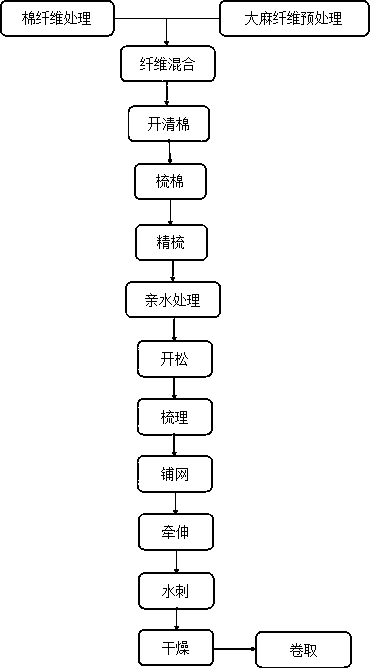

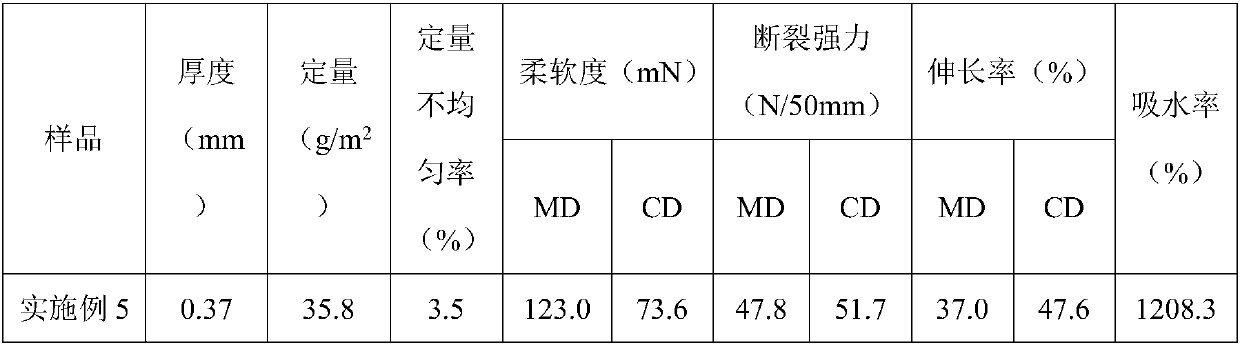

Natural antibacterial fiber spunlaced non-woven fabric and preparation method and application thereof

The invention relates to the field of sanitary articles, and provides a natural antibacterial fiber spunlaced non-woven fabric and a preparation method and application thereof. The natural antibacterial fiber spunlaced non-woven fabric comprises hemp fibers and cotton fibers. The preparation method includes the following steps that the hemp fibers and the cotton fibers are pretreated respectively;the pretreated hemp fibers and the pretreated cotton fibers are mixed; the mixed fibers are subjected to opening and picking, carding and combing in sequence to form fine silvers, the fine silvers are pull apart to form fine webs, and then hydrophilic treatment, opening, carding, lapping, drawing, spunlacing, drying and reeling are carried out to obtain the natural antibacterial fiber spunlaced non-woven fabric. According to the method, damage to the hemp fibers is small, the loss is low, and the antibacterial property of the hemp fibers is well retained; the natural antibacterial fiber spunlaced non-woven fabric is good in evenness and combines the advantages that the cotton fibers are soft and comfortable and the hemp fibers are natural antibacterial, dry and breathable; the fabric truly has the advantages of being good in evenness, soft and comfortable, natural antibacterial, dry and breathable, can be widely used in the fields of sanitary napkins, wet wipes, cotton wipes and the like, and has broad application prospects.

Owner:ZHUZHOU QIANJIN PHARMA +1

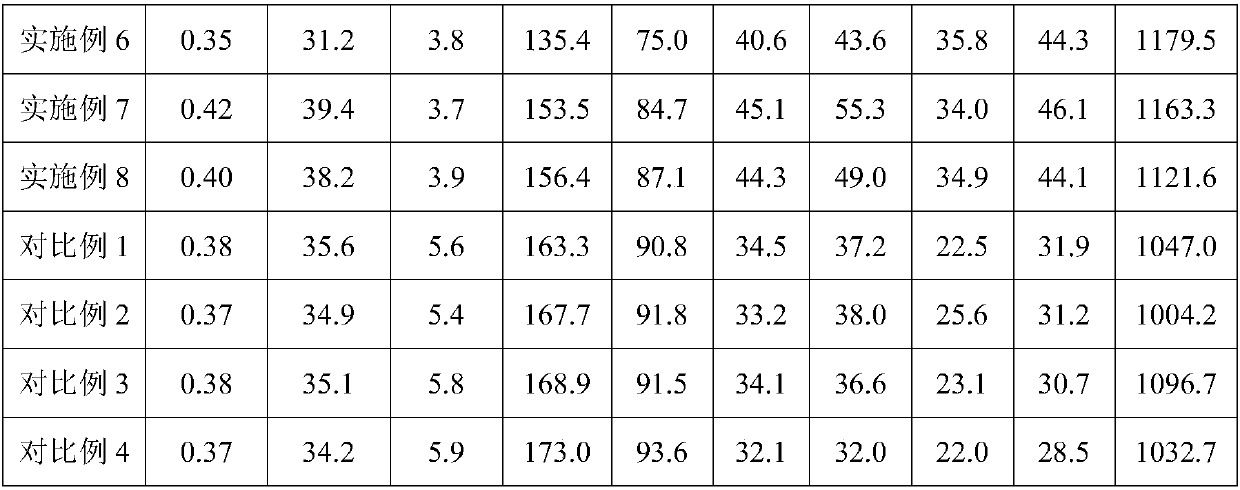

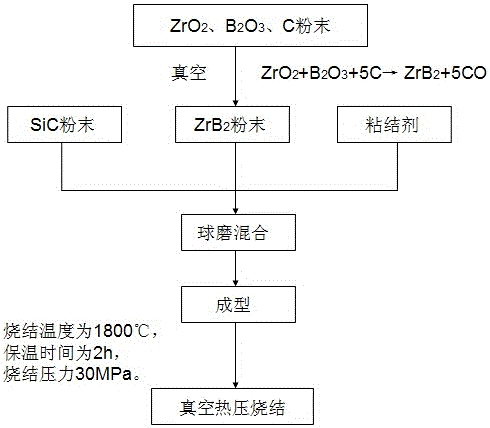

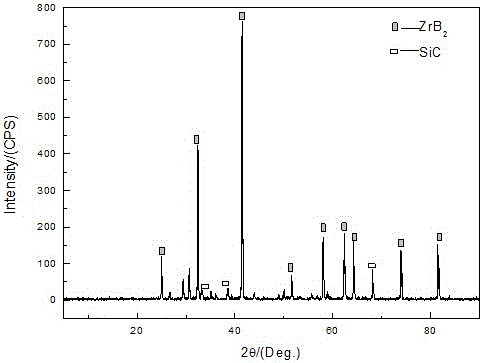

Preparation method of ZrB2-SiC composite ceramic

The invention discloses a preparation method of ZrB2-SiC composite ceramic. The preparation method includes the steps of firstly, sufficiently mixing ZrB2 powder and SiC in a ball milling tank, and calcining the mixed powder in a vacuum furnace to obtain ZrB2-SiC mixed powder; secondly, adding adhesive into the ZrB2-SiC powder, evenly stirring, loading into a mould to perform compression moulding, and demoulding to obtain a biscuit; thirdly, flatly placing the biscuit on a high-purity aluminum oxide ceramic plate, sintering the ceramic plate with the biscuit in a vacuum sintering furnace, and cooling along with the furnace to obtain the ZrB2-SiC composite ceramic. The preparation method has the advantages that the ZrB2-SiC composite ceramic is prepared by using the vacuum sintering method, ZrB2-SiC does not have direct reaction, and deviated component proportion is avoided; the ZrB2-SiC composite ceramic is easy in preparation operation, and yield is increased effectively.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

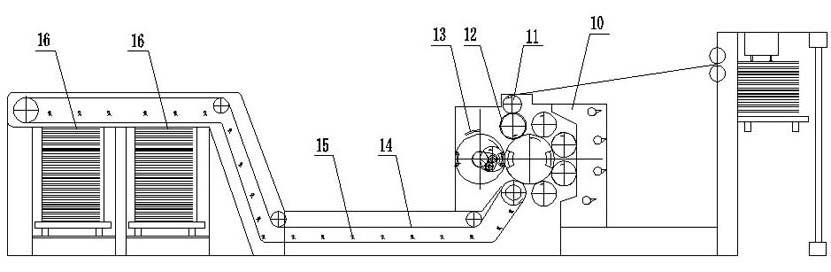

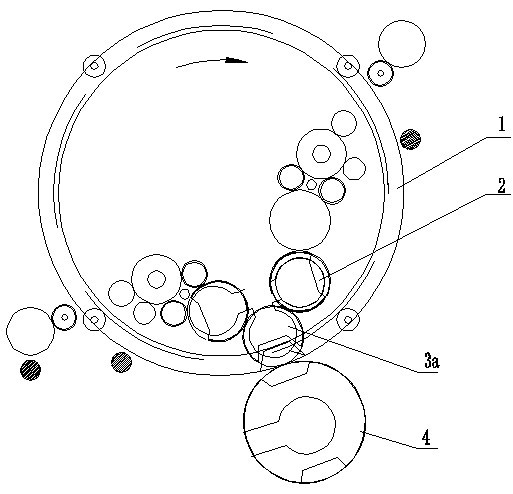

Polychrome connection silk screen printing process and equipment thereof

ActiveCN101982319AImprove anti-counterfeiting performanceSolve process problemsScreen printersPattern printingScreen printingPrinting ink

The invention discloses a polychrome connection silk screen printing process and equipment thereof, and relates to the technical field of sheet-fed rotary screen printing. The printing process comprises the following steps: transferring the printing ink to relief printing plates on four color mould drums by utilizing a four-color-group ink supply unit in satellite-type layout; converging the different colors onto the color gathering rubber blankets of a double-diameter impression cylinder in different zones by different color mould relief printing plates; transmitting the different colors onto a connection cylinder printing plate in a silk screen cylinder by combining a special money printing connection process through a big neutral position to form an accurate printing ink pattern; and finally rolling the printing ink pattern onto the paper sheet through the silk screen plate to form a polychrome connection pattern. The invention can realize the connection silk screen printing process of different-color counterfeiting inks, such as OVI and OVMI, and also can realize a puzzle connection silk screen printing process and a mixed-color silk screen printing process of common printing ink, OVI, OVMI and colorless fluorescent ink and the like. The printing production has high yield and accurate connection, and is convenient in operations of washing, replacing and tightening the silk screen plates.

Owner:CHENGDU BANKNOTE PRINTING +1

Formula of flux for hot tinning of copper wire and preparation method thereof

InactiveCN102121088AStir wellHigh chemical activityHot-dipping/immersion processesWelding/cutting media/materialsCopper wireTin plating

The invention relates to a formula of a flux for hot tinning of a copper wire and a preparation method thereof. The formula is used for tight tinning on the surface of the hot tinned copper wire and characterized by comprising the following components in percentage by mass: 0.5 to 1.5 percent of ammonium chloride, 2.0 to 5.0 percent of zinc chloride, 0.2 to 5.0 percent of triethanolamine, 0.1 to 2.0 percent of OP-10 emulsifying agent, 5.0 to 7.0 percent of hydrochloric acid and the balance of deionized water. Through the flux, the tinned copper wire has uniform coating, tight structure and excellent performance, and environmental pollution and resource waste are not caused.

Owner:震雄铜业集团有限公司

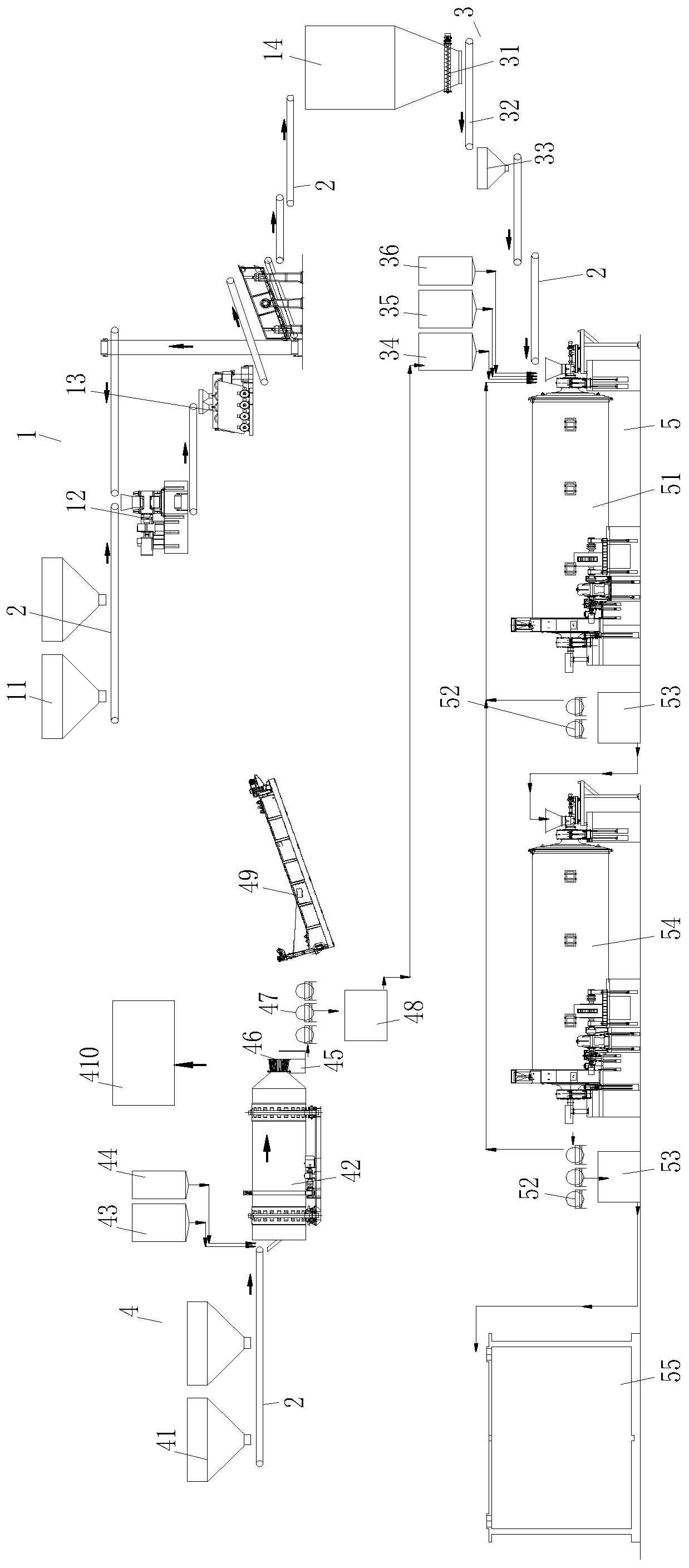

Intelligent wet powdering production technology for ceramic raw materials

InactiveCN110404657ARealize full automationIncrease production capacityGrain treatmentsNumerical controlProduction line

The invention relates to the technical field of ceramic raw material powdering and particularly relates to an intelligent wet powdering production line for ceramic raw materials. The intelligent wet powdering production line for ceramic raw materials comprises a raw material pre-crushing system, a belt conveying line, an automatic metering and batching system, a pug slurrying system and a continuous ball miller system. Transferring and conveying at the discharge end of the raw material pre-crushing system are carried out through a belt conveying line, the automatic metering and batching systemis located on the raw material pre-crushing system, the discharge end of the automatic metering and batching system is communicated with the feeding end of the pug slurrying system, and the other discharging end of the automatic metering and batching system is communicated with the continuous ball miller system. By means of the intelligent wet powdering production line for ceramic raw materials,the purposes of whole process automation, numerical control production and intelligent manufacturing of ceramic wet powdering technology are achieved, and thus the superior product rate and the production efficiency of ceramic products are improved; and besides, good mobility can be still ensured under the condition that the water content of slurry is low, and product defects are reduced.

Owner:广东鼎汇能科技股份有限公司

Lavender grey glaze and manufacture method of products thereof

InactiveCN101768017ASolve the problem of easy overheating and foamingSolve the problem of \"smoking\"Strong acidsSlurry

The invention relates to a lavender grey glaze. After raw materials of the lavender grey glaze are proportioned according to the prescription, the ball milling, sieving and de-ironing procedures are carried out to obtain slurry. The raw material comprises dehydrated and dried powder. By introducing talc, chromic oxide and the like into the raw materials, the invention solves the problems of easy burnt blistering and smoke absorption in the high-temperature roasting process of the traditional lavender grey glaze ceramic. The glaze surface is green, smooth, fine and beautiful, the color is pure, and the ceramic is clean and similar to jade. The invention also discloses a method for manufacturing the ceramic products by using lavender grey glaze, and the lavender grey glaze ceramic finished product manufactured by the method has the advantages of high yield rate, good density and strong acid and alkaline corrosion resistance property.

Owner:汤秋影

Magnetic nylon-6 short fiber and its making process

InactiveCN1740413AHigh strengthImprove featuresStaple fibre formationArtifical filament manufactureFiberNylon 6

The magnetic nylon-6 short fiber is made with magnetic functional agglomerate and nylon chip in the weight ratio of 1 to 5-10. The magnetic functional agglomerate includes functional powder, carrier chip, dispersant, coupler and antioxidant in certain weight proportion. The making process of the magnetic nylon-6 short fiber includes the following steps: 1. preparing the magnetic functional agglomerate through preparing functional powder of Fe3O4, drying and activating the functional powder, mixing the functional powder with carrier chip, dispersant, coupler and antioxidant in certain weight proportion via high speed stirring, cooling the mixture to room temperature, and extruding and pelletizing in extruder; and 2. producing magnetic nylon-6 short fiber through mixing magnetic functional agglomerate and nylon chip, spinning the mixture, winding, bundling, drafting, dewatering, crimping, setting and cutting.

Owner:任晓林

Straw rubbing process

The invention provides a straw rubbing process, which comprises the following operating steps: 1) carding raw material straws, removing sundries, such as broken pieces and the like, and cutting fringe pulling ends away; 2) rolling the straws with a continuous roll squeezer; 3) softening the straws with vapor; 4) drying the straws and controlling water content; 5) rubbing the straws with a straw rubbing machine to obtain straw threads and removing dust during the rubbing process; and 6) screening the straw threads to extract the straw threads with lengths not less than 5cm and diameters of 1 to 3mm. The process has the advantages of simple operation, easy implementation, low cost, high efficiency, no pollution to the environment, relatively longer silky fibers and high mechanical strength, and is mainly used for manufacturing products, such as a vegetation carpet, a green pad and the like.

Owner:SICHUAN UNIV

Tablet candy suitable for children and manufacturing method thereof

InactiveCN102599322ASuitable for consumptionRelieves symptoms of anorexiaConfectionerySweetmeatsIcing sugarMedicine

The invention relates to a tablet candy suitable for children and a manufacturing method thereof. Hawthorn, tuckahoe, grist, endothelium corneum gigeriae galli and zinc-rich material are taken as compound and a sweetener is taken as a main accessory for manufacturing the tablet candy. After infantile anorexia action principle is fully researched, according to the characteristics, such as the immature growth and development of children, and the like, the medical and edible dual-purpose raw materials, namely, the hawthorn, tuckahoe, grist, endothelium corneum gigeriae galli and zinc-rich material are reasonably proportioned, thereby synergizing. The anorexia symptom is efficiently relieved and the tablet candy is especially suitable for children. The conventional pelletizing drying process flow is improved according to the invention, and the manufacturing method is suitable for the formula containing a large amount of sugar powder and traditional Chinese medicine extracts. The stickiness of soft material is higher, so that screen is easily plugged by over-swinging pelletizing. According to a semi-drying pelletizing method, a subsequent pelletizing process is omitted. The interiors of grains are still wet and soft, so that the big grains can be excellently broken and the yield is increased by 3-5%.

Owner:ZHEJIANG CONBA HEALTH PROD

Preparation method of composite antistatic agent for fiber fabric

The invention discloses a preparation method of a composite antistatic agent for a fiber fabric. The composite antistatic agent for the fiber fabric in the preparation method comprises the following components: a butanol phosphate ester antistatic agent, a terminal hydroxyl hyperbranched antistatic agent, a terminal carboxyl hyperbranched antistatic agent and a terminal quaternary ammonium salt hyperbranched antistatic agent; and the preparation method comprises the following steps: firstly, respectively preparing the butanol phosphate ester antistatic agent, the terminal hydroxyl hyperbranched antistatic agent, the terminal carboxyl hyperbranched antistatic agent and the terminal quaternary ammonium salt hyperbranched antistatic agent; and mixing the four antistatic agents to prepare the composite antistatic agent for the fiber fabric. The preparation method is simple and feasible; and the prepared antistatic agent has a good antistatic effect, good heat resistance and good acid and alkali resistance.

Owner:SUZHOU CHENHENG WEAVING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com