Degumming method of flax and enzyme preparation for using in degumming

A degumming method and enzyme preparation technology, applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of long retting cycle, reduced quality of hemp, and low production rate of long flax fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

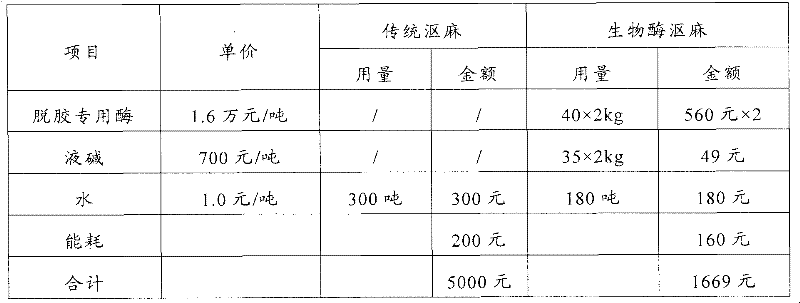

Image

Examples

Embodiment 1

[0033] Raw material selection: Winter flax produced in Anxiang, Hunan is used, stored for more than one year, and a small amount of mildew occurs.

[0034]Select full flax stems and bundle them into bundles. Inject water into the degumming tank, adjust the pH value of the water to 8.5, heat slowly to 32°C and keep warm, then inject 40kg of enzyme preparation into the degumming tank to obtain a mixed solution. Weigh 5000kg and put it into the degumming tank, so that the mixed solution is completely soaked into flax. The bath ratio of flax and water is 1:13, start retting and degumming. After 60 hours, the flax was fished out from the pool.

[0035] The flax that has been retting and degummed is dried to obtain dry stems. The dry stems are stacked together for 18h. After the dry stems are kept healthy, take a 100kg small sample and go on the machine to beat the flax fiber. The performance test of the obtained flax fiber is shown in sample 1 in Table 1.

Embodiment 2

[0037] The flax was degummed according to the degumming method of Example 1, the enzyme dosage was 60kg / pool, and the performance test of the obtained flax fiber was as shown in sample 2 in Table 1.

Embodiment 3

[0039] The flax was degummed according to the degumming method of Example 1, the enzyme dosage was 80kg / pool, and the performance test of the obtained flax fiber was shown in sample 3 in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com