Patents

Literature

50results about How to "With far infrared" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

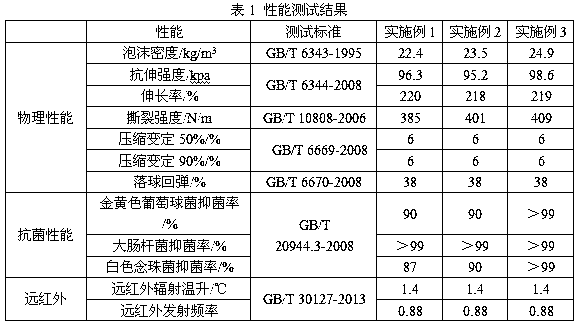

Graphene modified polyurethane foam and preparation method thereof

The invention relates to the technical field of graphene, in particular to graphene modified polyurethane foam and a preparation method thereof. Graphene is functionalized graphene with isocyanate groups; the isocyanate functionalized graphene is prepared from graphene oxide through modification; the graphene modified polyurethane foam is prepared from isocyanate, isocyanate modified graphene, polyether polyol, chain expanding agents, foaming agents, catalysts and organic silicon foam stabilizing agents through reaction under certain conditions. In order to improve the mutual action of graphene and polyurethane molecular chains, the graphene stably exists in the graphene foam; graphene oxide is subjected to isocyanate modification; isocyanate groups are introduced at the surface. The isocyanate groups can react with polyether polyol; the goal of modifying the polyurethane foam through graphene polymerization is achieved. The prepared graphene modified polyurethane foam has good mechanical performance, and simultaneously has functionality of bacteria resistance and bacteriostasis, far infrared function and the like.

Owner:江苏江山红化纤有限责任公司 +1

Bamboo carbon polyester fiber/chitin viscose fiber blended yarn and producing method

The present invention is blended yarn of bamboo carbon polyester fiber and chitin viscose fiber in the ratio of 45-55 %. The production process of the blended yarn includes the following steps: mixing and spinning bamboo carbon polyester fiber of linear density 1-3 D and chitin viscose fiber of chitin content not lower than 5 % and linear density2-3 D to form the blended yarn of bamboo carbon polyester fiber and chitin viscose fiber. The blended yarn of bamboo carbon polyester fiber and chitin viscose fiber is superior to available yarn of bamboo carbon polyester fiber, and has the has functions of adsorbing and eliminating bad smell, emitting far infrared ray, releasing negative ion, resisting bacteria, high hydroscopicity, soft hand feeling and comfort, and is suitable for making underwear.

Owner:DONGHUA UNIV

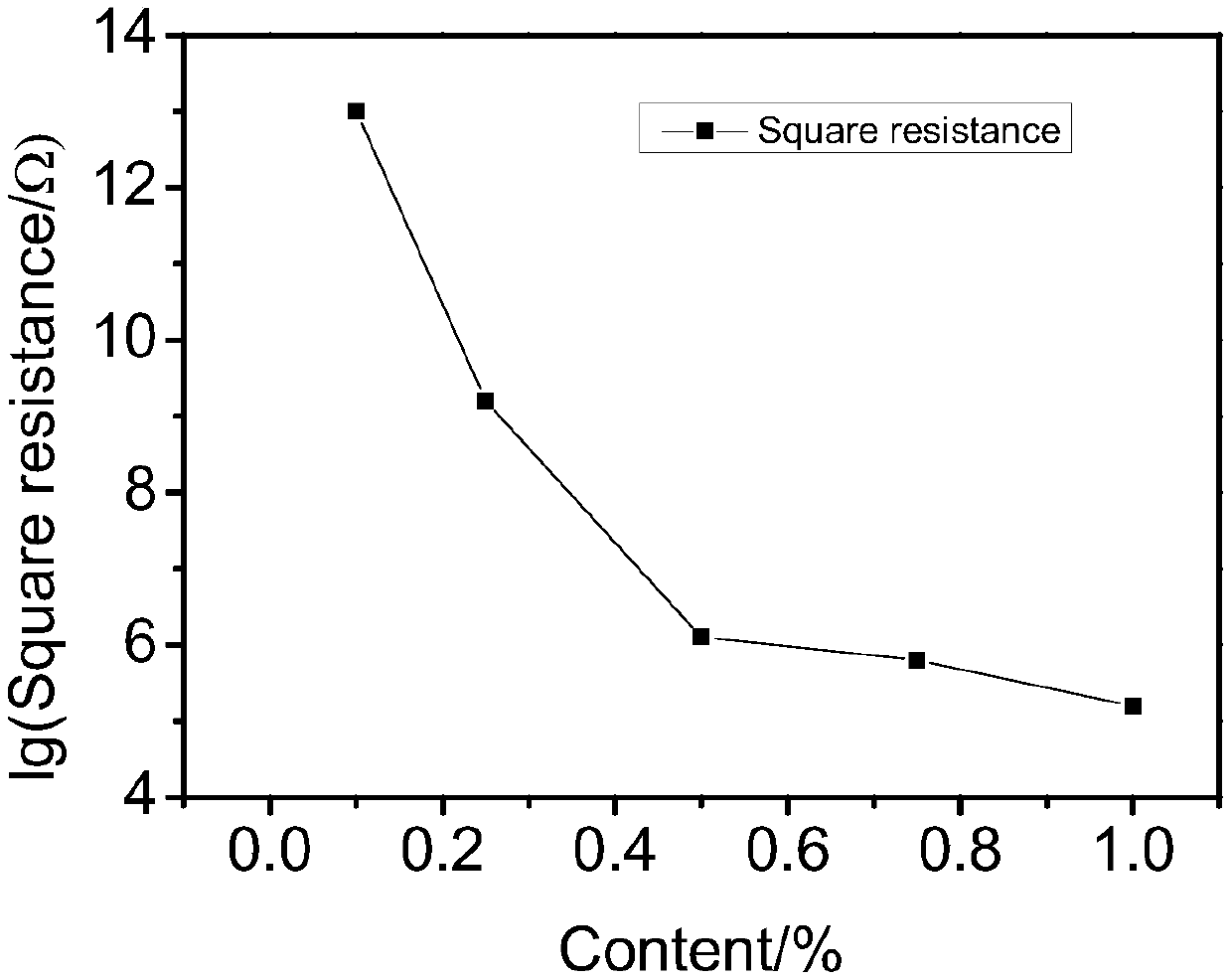

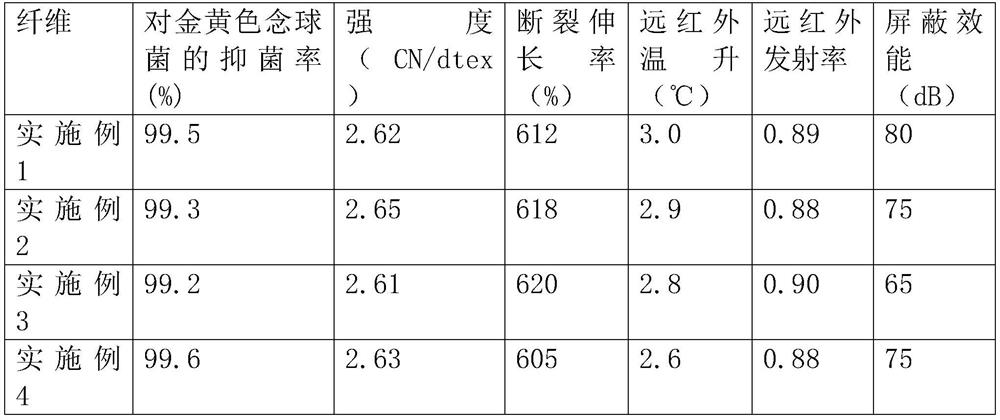

Modified white graphene and polyester composite fiber and preparation method thereof

InactiveCN110205702AImprove antibacterial propertiesGood far infraredMelt spinning methodsMonocomponent polyesters artificial filamentMasterbatchUltraviolet

The invention discloses a modified white graphene and polyester composite fiber and a preparation method thereof. The composite fiber is prepared from, by mass, 84%-99% of polyester chips, 0.1%-15% ofwhite graphene and 0.1%-1% of a modifying agent. The preparation method includes: step 1, weighing raw materials; step 2, drying the polyester chips and the white graphene, grinding the polyester chips into powder, adding the white graphene powder and the modifying agent into the polyester chip powder, mixing and stirring; step 3, adding the white graphene and polyester mixed powder into a twin-screw extruder, and performing extrusion granulation; step 4, drying modified white graphene and polyester masterbatch, adding into the twin-screw extruder, heating for melting, filtering through a spinning manifold, and spinning to obtain the modified white graphene and polyester composite fiber. The composite fiber prepared according to the method has advantages of antibacterial, far infrared andanti-ultraviolet functions, the added value of polyester can be increased, and a utilization range of polyester fibers is expanded.

Owner:常州兴烯石墨烯科技有限公司

Flame-retardant nanometer bamboo charcoal antibiosis filler fiber and manufacturing method thereof

InactiveCN102485981AWith flame retardant functionHas antibacterial functionHollow filament manufactureMelt spinning methodsSpinningBamboo charcoal

The invention provides a flame-retardant nanometer bamboo charcoal antibiosis filler fiber. The fiber comprises the following components, by mass, 1-20% of a nanometer bamboo charcoal antibiosis master batch and 80-99% of a sliced carrier. A manufacturing method of the fiber comprises the following steps: mixing the nanometer bamboo charcoal antibiosis master batch and the needed sliced carrier according to a certain ratio, uniformly stirring them, selecting a spinneret plate according to the fiber processing fineness and the section shape of the fiber, fusion-spinning, cooling, reeling, filament bunding, drafting, and spirally and curly cutting into short fibers to prepare the flame-retardant nanometer bamboo charcoal antibiosis filler fiber. The fiber of the invention has the advantages of substantial flame retardation and antibiosis, peculiar smell adsorption function possessing, soft handle, good elasticity, and wide application.

Owner:SHANGHAI JAROS NEW MATERIAL

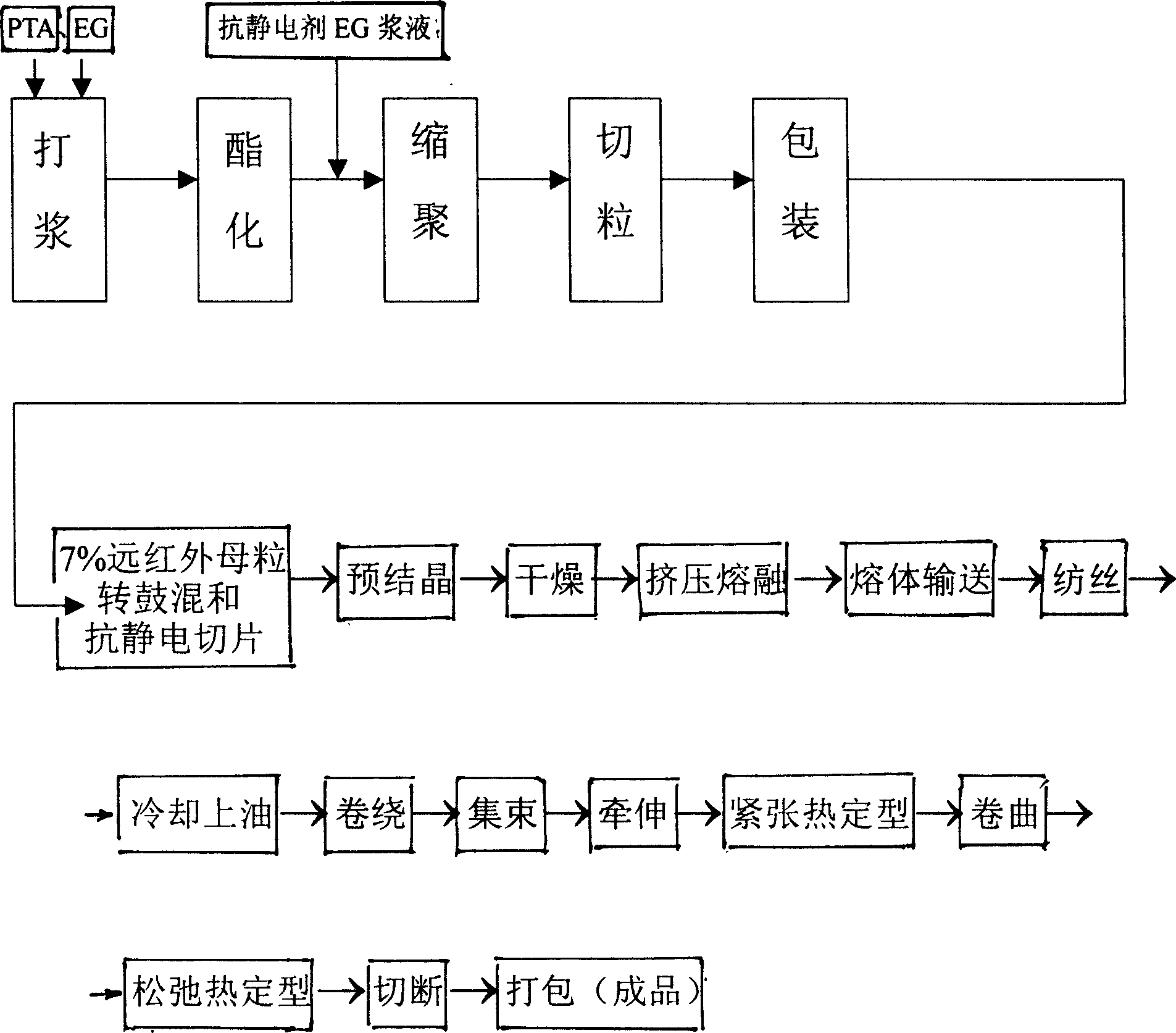

Method for manufacturing far infrared-antistatic polyester fiber

InactiveCN1763276AWith far infraredWith antistatic functionElectroconductive/antistatic filament manufactureHollow filament manufactureFiberPolymer science

The invention discloses a making method of far-infrared antistatic polyester fiber, which is characterized by the following: generating BHET terephthalic glycol ester monomer after the esterifying reaction of raw PTA terephthalic acid and EG glycol ester in the heating condition; leading the material into polyaxe; adding the preparing modulated functional additive of inorganic antistat EG glycol ester slurry in the atmospheric polycondensation reaction stage; starting pressure-relief reaction after a while; generating the polyester microtome section by cooling the fondant; textiling the far-infrared-and-antistatic compound function polyester short fiber after mixing the antistatic polyester microtome section and nanometer far-infrared ceramic powder. The technological program is mature and easy to operate, which can produce everlasting far-infrared-and-antistatic compound functional polyester short fiber.

Owner:天津石油化工公司化纤厂

In-situ polymerization modified graphene and polypropylene melt-blown nonwoven and preparation method thereof

PendingCN111334932AUV resistanceFunctionalMelt spinning methodsNon-woven fabricsPolypropyleneThermal bonding

The invention discloses an in-situ polymerization modified graphene and polypropylene melt-blown nonwoven and a preparation method thereof. The melt-blown nonwoven comprises the following raw materials: 0.1 to 30 percent of in-situ polymerization graphene and polypropylene master batch, 69 to 99 percent of polypropylene slices and 0.1 to 5 percent of a modifier. The preparation method of the melt-blown nonwoven comprises the following steps of 1, weighing the raw materials; 2, grinding and uniformly mixing the graphene and polypropylene master batch and the polypropylene slices; 3, putting themixed materials into a screw extruder for melt extrusion; 4, drafting melt, and then, performing cooling and shaping; 5, collecting fiber onto a collecting screen, and forming a nonwoven fabric by self heat through bonding; and 6, cutting the edge of the nonwoven fabric formed by a fiber screen by an edge cutting machine, winding the nonwoven fabric onto a winding roller to form a nonwoven fabricrolled according to the specification. The in-situ polymerization modified graphene and polypropylene melt-blown nonwoven prepared by the method provided by the invention has the characteristics of bacterium resistance, far infrared ray resistance and ultraviolet resistance; in addition, the graphene is uniformly dispersed and cannot easily fall off; and the functionality is durable.

Owner:北京盈创力和电子科技有限公司

Method of manufacturing modified white graphene and polyester composite fiber and fiber manufactured according to method

PendingCN111607839AGood dispersionAntibacterialMelt spinning methodsMonocomponent polyesters artificial filamentPolymer scienceSpinning

The invention discloses a method of manufacturing a modified white graphene and polyester composite fiber and the fiber manufactured according to the method. The method comprises the steps that the step 1, modified white graphene powder is manufactured; the step 2, white graphene and polyester mixed powder is manufactured; the step 3, modified white graphene and polyester masterbatches are manufactured; the step 4, the modified white graphene and polyester masterbatches are dried, then are added to a screw extruder to be heated and molten, are filtered by a spinning box and then are subjectedto spinning to form bundles. The invention further provides the modified white graphene and polyester composite fiber manufactured according to the method. According to the method, white graphene is preferentially modified to improve the dispersity of the white graphene in regenerated cellulose pulp, and the functionality of regenerated cellulose composite fibers is better achieved. The modified white graphene and polyester composite fiber manufactured according to the method has the advantages of antibacterial performance, far infrared resistance and ultraviolet resistance, and the white graphene in the white graphene and polyester composite fiber is evenly dispersed, is not prone to fall off and has the lasting functionality.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Graphene luminous chinlon composite fiber and preparation method thereof

PendingCN113005555ASimple processEasy to operateArtifical filament manufactureMonocomponent polyamides artificial filamentSpinningGraphene

The invention discloses a graphene luminous chinlon composite fiber and a preparation method thereof. The fiber comprises the following raw materials of 84%-99% of chinlon chips, 0.1%-15% of graphene, 0.1%-1% of a modifier and 0.1%-10% of luminous powder. The invention also provides a preparation method of the fiber. The preparation method comprises the following steps of step 1, weighing raw materials; step 2, preparing modified graphene powder; step 3, drying chinlon chips and luminous powder, grinding the chinlon chips into powder, adding the modified graphene powder and the luminous powder, and mixing and stirring in a high-speed mixer; step 4, adding the mixed powder into a double-screw extruder for extrusion and granulation; and step 5, drying the master batch, adding the master batch into a screw extruder for heating and melting, filtering by a spinning manifold, and spinning into bundles. The graphene luminous polyamide composite fiber prepared by the invention has antibacterial, anti-mite, anti-ultraviolet, far-infrared and luminous functions and the like, the added value of polyamide can be increased, and the application range of the polyamide fiber is expanded.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Hydrophobic modified antimicrobial cashmere fiber and manufacturing method of hydrophobic modified antimicrobial cashmere fiber

InactiveCN105088768ANot easy to fall offLow costFibre treatmentConjugated cellulose/protein artificial filamentsPolyesterCarbon nanotube

The invention discloses hydrophobic modified antimicrobial cashmere fiber. Chitosan fiber and cashmere are creatively blended, so that chitosan is uniformly distributed, cannot easily fall off and can be combined with saliva of bacterial microbe phospholipids; the chitosan is permeated and enters cell bodies to be adsorbed; the normal physiological activities of cells are disturbed, so that bacteria are killed; the bactericidal effect is durable; in addition, bamboo charcoal polyester fiber is adopted for replacing the partial cashmere fiber; the cost is reduced; various technical indexes of cashmere are also improved; added carbon nanotubes generate carboxyl and hydroxyl groups after being subjected to mixed acid oxidation modification; after the carboxyl and hydroxyl groups are added into raw materials, good dispersibility and good stability are realized. The prepared cashmere fiber adopts methacrylamide as a grafting monomer for surface grafting decoration modification; the prepared cashmere fiber has a hydrophobic antibiosis function, a far infrared function and a negative ion functions; the hand feeling of fabrics is soft; the heat insulation and comfort functions are good; the cashmere fiber is suitable for being made into casual clothes and underwears.

Owner:ANHUI TIANWEI CASHMERE PROD

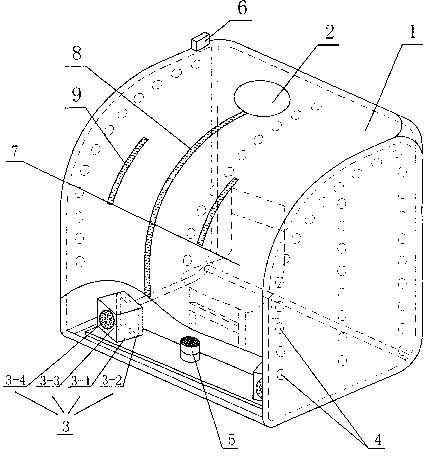

Health medical apparatus

InactiveCN102974043ADilated blood vesselsReduce humidityElectrotherapyMedical devicesHuman bodyRheumatism

The invention discloses a health medical apparatus. The health medical apparatus comprises a cabin body which is made from airtight materials and is capable of being opened and closed. A gap where the head of a human body can stretch out is arranged on the top face of the cabin body, a heater is arranged inside an inner cavity of the cabin body, and permanent magnets are distributed on the inner wall of the cabin body. A drug ionizer is placed inside the cabin body. The health medical apparatus has the advantages of combining far infrared, magnet therapy and medical therapy into a whole and being provided with various treatment and health functions of treating pain from rheumatism, detox, fat-drainage, strength training, health and the like.

Owner:国发科技(大连)有限公司

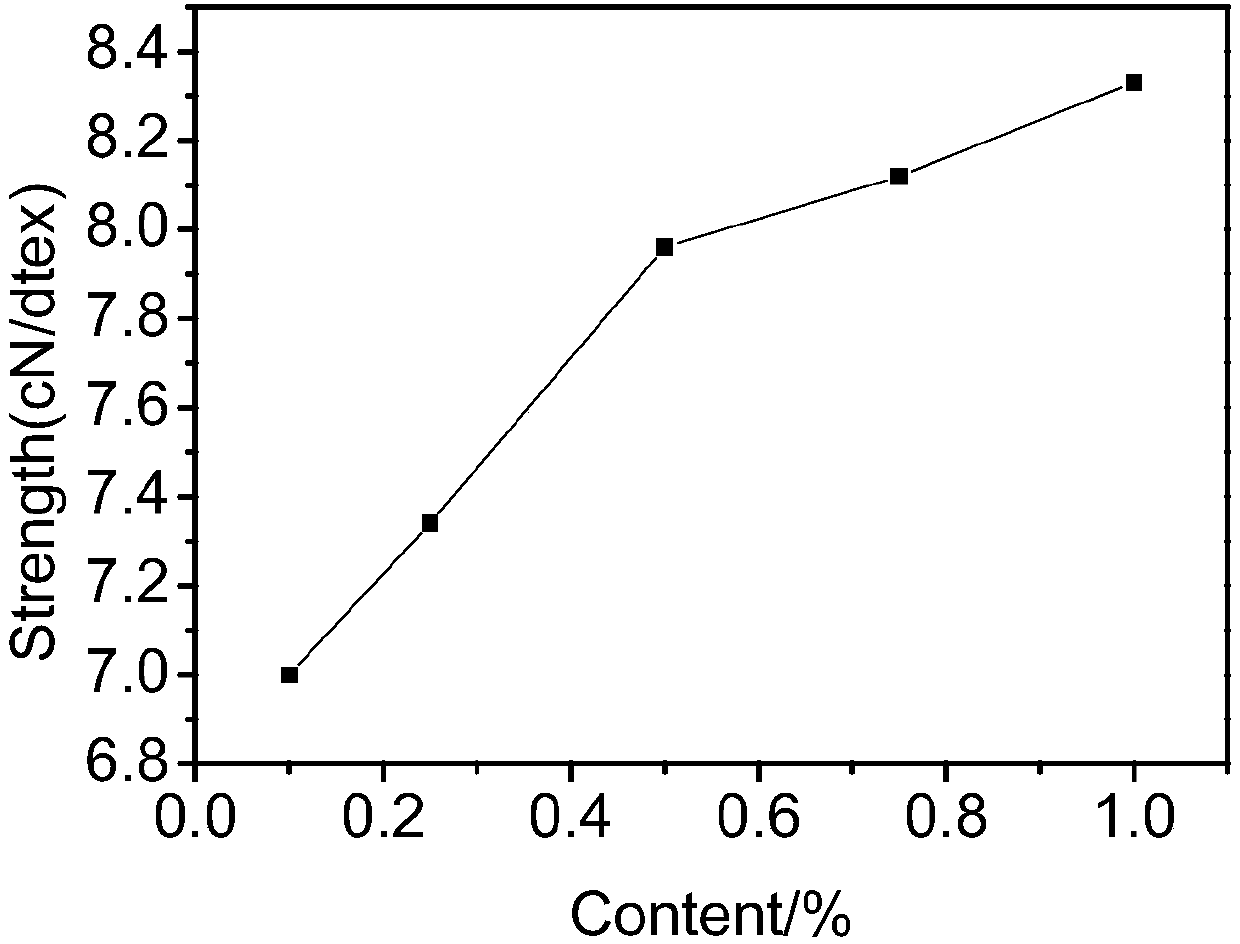

Production process of modified chinlon yarn

PendingCN112981588AEasy to prepareImproves sun aging propertiesElectroconductive/antistatic filament manufactureSynthetic polymer filament chemical after-treatmentYarnGraphene

The invention discloses a production process of modified chinlon yarn. The production process includes the following steps: 1, mixing 7-8 parts of polyamide slices, 2-4 parts of graphene, 3-6 parts of far infrared ceramic powder, 6-9 parts of an antioxidant, 5-10 parts of a catalyst and 8-12 parts of a dispersing agent, feeding the above materials into a stock bin, mixing and melting to prepare functional master batch; 2, feeding the functional master batch and 70-80 parts of dried chinlon slices into a double-screw extruder to be extruded, then carrying out blended spinning at the temperature of 260-265 DEG C, and finally, carrying out oiling, winding and balanced stretching to obtain chinlon yarn; 3, soaking the chinlon yarn in the step 2 into a graphene solution through a compression roller, guaranteeing that the chinlon yarn makes full contact with graphene, after soaking is completed, feeding the chinlon yarn into a drying device for drying, and finally obtaining the novel modified chinlon yarn. The preparation method is simple, and the prepared modified chinlon yarn is good in use effect, good in antistatic performance, capable of keeping warm, convenient to use, safe and reliable.

Owner:海安海顺化纤有限公司

Multifunctional flame-retardant blanket and preparation method thereof

InactiveCN108754786AFlame retardant permanentPermanent antibacterial and anti-miteBlanketBed linenFiberFire retardant

The invention discloses a multifunctional flame-retardant blanket and a preparation method thereof. The multifunctional flame-retardant blanket is prepared by blending the following fiber materials inpercentage by weight: 20-50% of SOL FR fibers, 20-50% of polyimide fibers, 20-40% of flame-retardant acrylic and 1-3% of conductive fibers. The flame-retardant blanket produced in the invention has multiple functions of being comfortable, permanently flame retardant, antibacterial, anti-mite, far-infrared and the like.

Owner:SOL FLAME RETARDANT FIBER

Preparation method of high-performance PP fiber

InactiveCN108048936AIncreased oxygen-containing functional groupsEasy to functionalizeFlame-proof filament manufactureMonocomponent polyolefin artificial filamentAlkyl transferCoupling

The invention discloses a preparation method of a high-performance PP fiber. According to the method, hydroxylation and carboxylation are carried out on graphene oxide, oxygen-containing functional groups on the surface of the graphene oxide are increased, as many coupling agents KH570 as possible are chelated on the periphery of the graphene oxide, alkylation of graphene oxide is carried out, a special tangle with polypropylene is formed, melt spinning is carried out under the temperature of 250 DEG C-320 DEG C, and the high-performance PP fiber is obtained.

Owner:HANGZHOU GAOXI TECH CO LTD

In-situ polymerized and modified white graphene-polyester composite slice and preparation method thereof

InactiveCN109749374AImprove antibacterial propertiesGood far infraredMonocomponent polyesters artificial filamentArtifical filament manufactureIn situ polymerizationPolyvinyl alcohol

The invention discloses an in-situ polymerized and modified white graphene-polyester composite slice and a preparation method thereof. The n-situ polymerized and modified white graphene-polyester composite slice is prepared from the materials of 50-80% of terephthalic acid, 10-40$ of ethylene glycol, 0.1-10% of white graphene and 0.1-1% of modifier, wherein the modifier is composed one or more selected from polyvinyl alcohol, hydroxy propyl cellulose, polyethylene glycol, sodium lignin sulfonate, polyvinylpyrrolidone, sodium dodecyl benzene sulfonate, lauryl pyrrolidone, dimethylformamide andisopropanol. The preparation method of the in-situ polymerized and modified white graphene-polyester composite slice comprises, firstly, preparing a modified white graphene / ethylene glycol slurry; secondly preparing a terephthalic acid / ethylene glycol / modified white graphene slurry; thirdly, performing esterification reaction; fourthly, performing polycondensation reaction; fifthly, performing discharging and pelletizing. The prepared in-situ polymerized and modified white graphene-polyester composite slice has the advantage of resistance to bacteria, far infrared and ultraviolet; the white graphene is less prone to falling off and functionally durable.

Owner:常州兴烯石墨烯科技有限公司

In-situ polymerized modified hexagonal boron nitride nylon composite slice and preparation method thereof

ActiveCN109880169AImprove antibacterial propertiesGood far infraredIn situ polymerizationHexagonal boron nitride

The invention discloses an in-situ polymerized modified hexagonal boron nitride nylon composite slice and a preparation method thereof. The composite slice comprises the following raw materials: 80%-90% of caprolactam, 5%-10% of deionized water, 0.1%-10% of hexagonal boron nitride and 0.1%-1% of a modifier. The invention also provides the preparation method of the in-situ polymerized modified hexagonal boron nitride nylon composite slice, which comprises the following steps: step 1, preparing modified hexagonal boron nitride slurry: adding hexagonal boron nitride sheet powder and the modifierinto deionized water, stirring, heating, and carrying out ultrasonic dispersion treatment; step 2, preparing caprolactam / modified hexagonal boron nitride slurry: adding caprolactam into the modified hexagonal boron nitride slurry, and uniformly stirring and mixing; and 3, carrying out a polymerization reaction to obtain the in-situ polymerized hexagonal boron nitride nylon slice. The composite slice prepared by the invention has anti-bacterial, far-infrared and anti-ultraviolet properties, hexagonal boron nitride in the composite slice is uniformly dispersed and is not easy to fall off, and the function is durable.

Owner:常州兴烯石墨烯科技有限公司

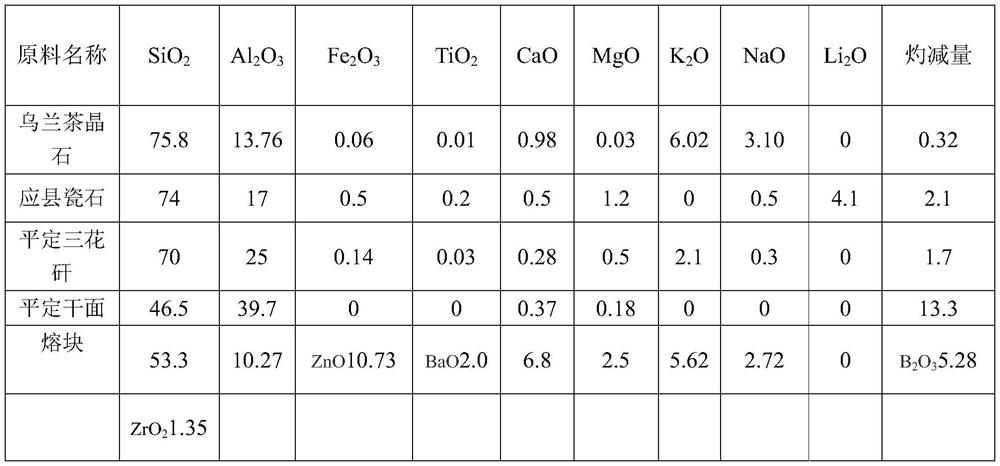

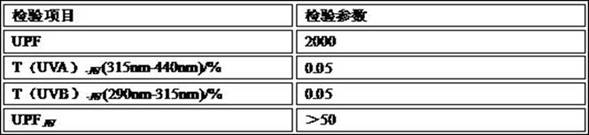

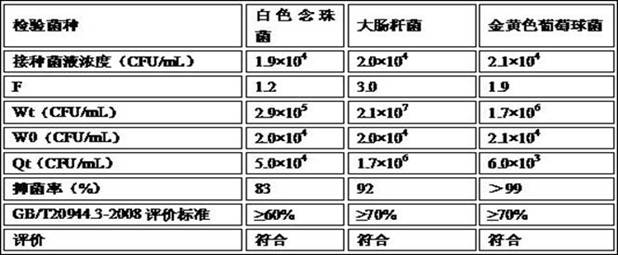

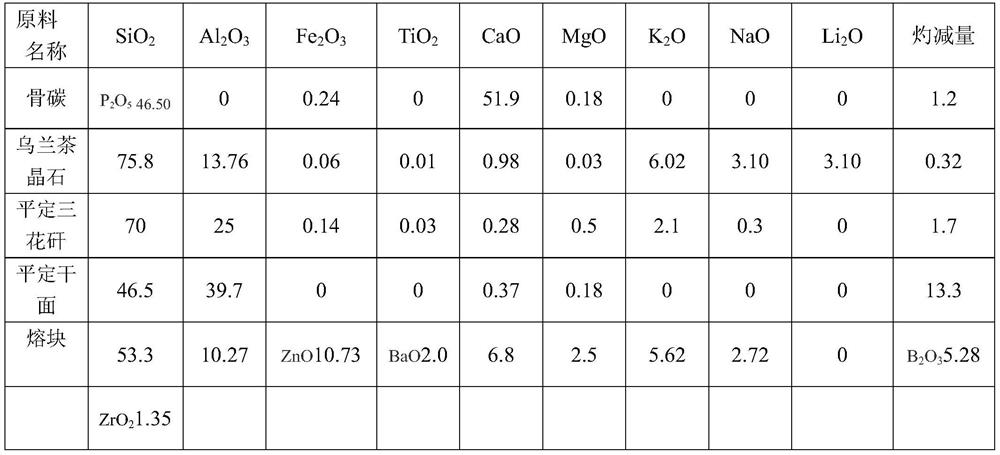

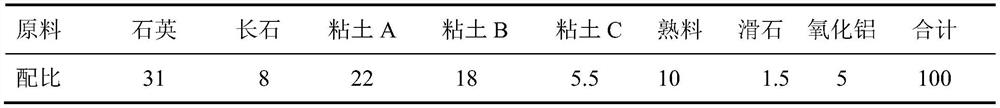

Antibacterial fantasy ceramic

ActiveCN112194476ALittle increase in costImprove antibacterial propertiesCeramic materials productionCelluloseFrit

The invention relates to ceramic production, in particular to antibacterial fantasy ceramic. The ceramic is made of blank and glaze, and is prepared from 18-28 parts of Wulan tea-coloured crystal, 20-30 parts of Jiangxian chinastone, 21-33 parts of Pingding three-flower gangue and 16-29 parts of Pingding dry surface. The glaze comprises the following components in parts by weight: 95 parts of frit, 3 parts of Pingding dry surface and 2 parts of cellulose. Wulan tea-coloured crystal is adopted as a main raw material of a ceramic body and glaze for formula design, special additives do not need to be added, domestic or imported antibacterial agents in the current market are basically 400,000-1,200,000 / ton, the cost is extremely high, the cost of ceramic ingredients is basically not increasedby the Wulan tea-coloured crystal, and a test result shows that the antibacterial effect is extremely good; the antibacterial fantasy ceramic has the function of emitting far infrared rays, and has the advantages of being easy to clean, bright in color, good in light transmittance and the like.

Owner:PINGDING YINGYU PORCELAIN

Thin stretch fabric

InactiveCN105747290AIncrease elasticityStrong water absorptionUndergarmentsProtective garmentPolyesterCarbon fibers

Components of a thin stretch fabric includes kapok fibers, blue modal fibers, viscose fiber, lycra spandex fibers, polyester bi-component fibers, bamboo carbon fibers, polyester fibers, elastic complex fibers, and soybean fiber. The obtained fabric by the formula is excellent in elasticity and water absorbing performance, and is soft in surface of the fabric. Through reasonable selection of fibers, the fabric has thin and flat characters and excellent wearability, has health functions of anion, far infrared ray, bacteria resistance, and deodorization, and is environment-friendly, safe and comfortable.

Owner:NANTONG JIANWEI YARN DYED CLOTHING CO LTD

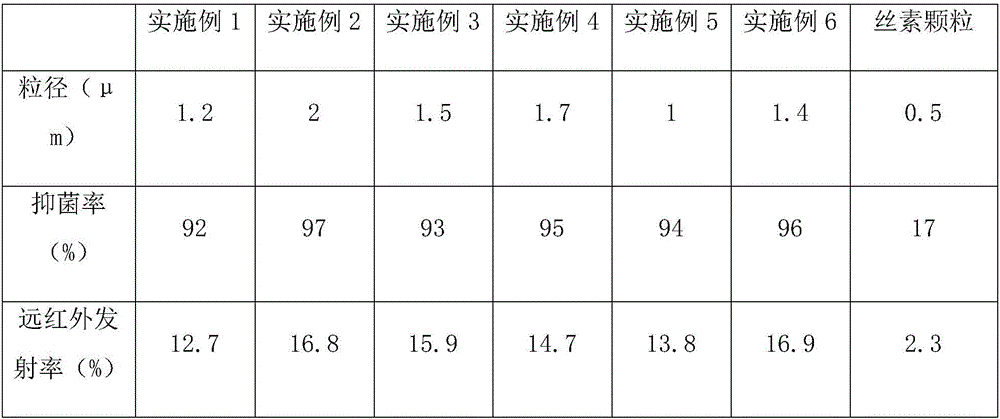

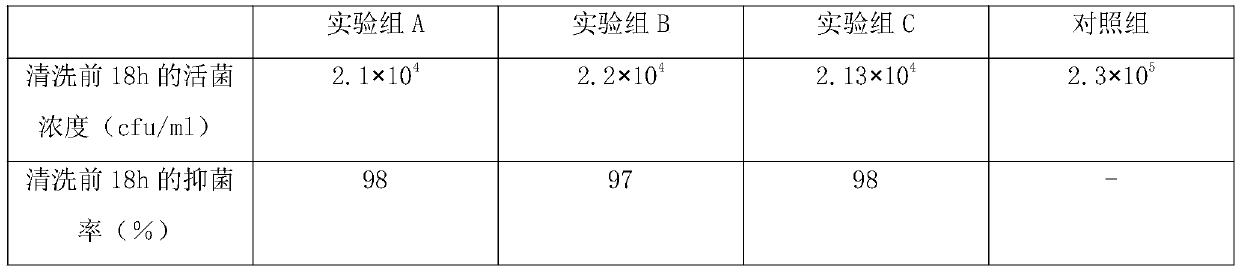

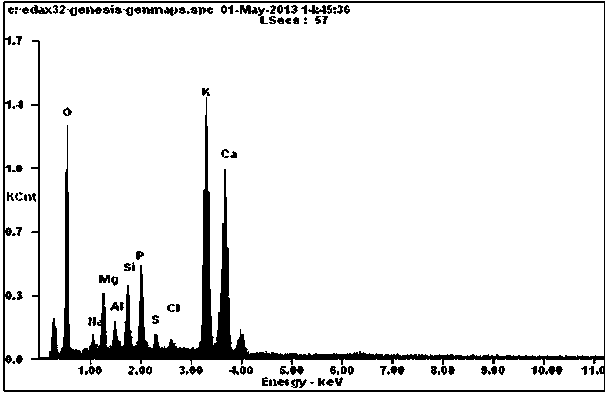

Fibroin containing antibacterial far-infrared microparticles and preparation method thereof

ActiveCN106009705AWell mixedImprove plasticityLight therapyCross-linkPoly(ethylene glycol) diglycidyl ether

The invention provides a preparation method of fibroin containing antibacterial far-infrared microparticles. The method comprises the following steps that nanogold particles and medical stone particles are added into a silk fibroin solution, the mixture is fully stirred, a film is formed through drying, and a fibroin-gold-medical stone mixed film is formed; then the fibroin-gold-medical stone mixed film is dissolved in hexafluoroisopropanol to form a solution A, and poly-l-lactic acid is dissolved in hexafluoroisopropanol to form a solution B; the solution A and the solution B are mixed to form a solution C, and ethylene glycol diglycidyl ether is added to serve as a cross-linking agent; heating and ultrasonic treatment are carried out, standing is carried out, and centrifugal treatment is carried out to remove precipitate; drying is carried out to obtain the fibroin containing antibacterial far-infrared microparticles. The microparticles prepared through the method are high in plasticity and stability and good in biocompatibility, and further has an antibacterial healthcare effect, a far-infrared healthcare effect and the like.

Owner:广东凯迪服饰有限公司

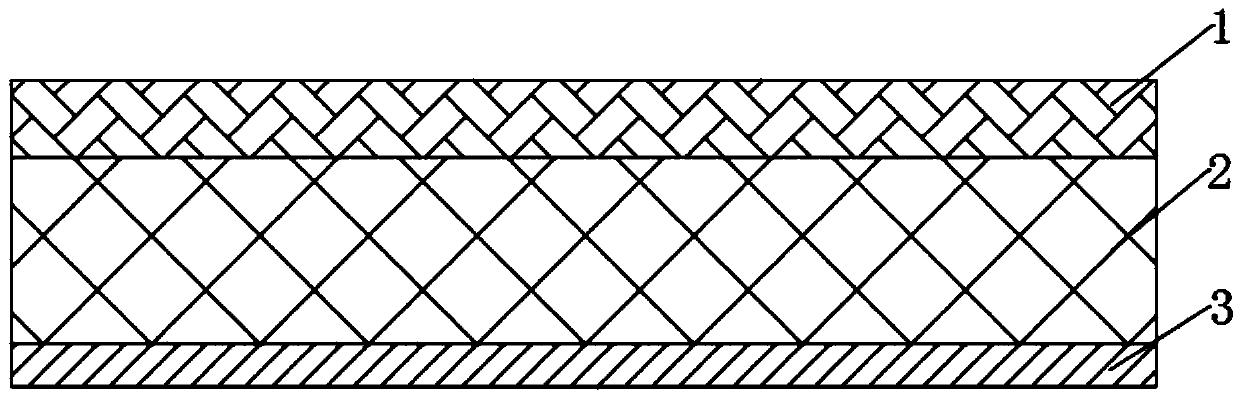

Graphene aerogel thermal fabric

PendingCN111058178AGood breathability and moisture permeabilityIncreased softness and comfortWarp knittingCellulose fiberHeat effect

The invention provides graphene aerogel thermal fabric. The graphene aerogel thermal fabric comprises an upper surface layer, a spacing layer and a lower surface layer, wherein the spacing layer is connected with the upper surface layer and the lower surface layer; the spacing layer is woven by aerogel yarns; the upper surface layer and the lower surface layer are woven together through the aerogel yarns; the upper surface layer is of a uniform breathable structure; the upper surface layer, the spacing layer and the lower surface layer are integrally woven and formed; the upper surface layer,the spacing layer and the lower surface layer are subjected to three-line yarn feeding through a 3D warp knitting machine; and the upper surface layer, the spacing layer and the lower surface layer are woven simultaneously. According to the graphene aerogel thermal fabric provided by the invention, fabric of the upper surface layer is woven by adopting cellulose fiber yarns, the middle spacing layer is woven by adopting aerogel yarns, and the lower surface layer is woven by adopting graphene pure-spun or blended yarns; the air permeability, moisture permeability, softness and comfort of the fabric are improved, and the fabric has excellent warmth retention property and the performances of light weight, quick drying and peculiar smell resistance; and fabric of the lower surface layer has far-infrared, antibacterial and antistatic health-care functions, a heat effect is generated, and blood circulation is promoted.

Owner:新正健(天津)家居有限公司

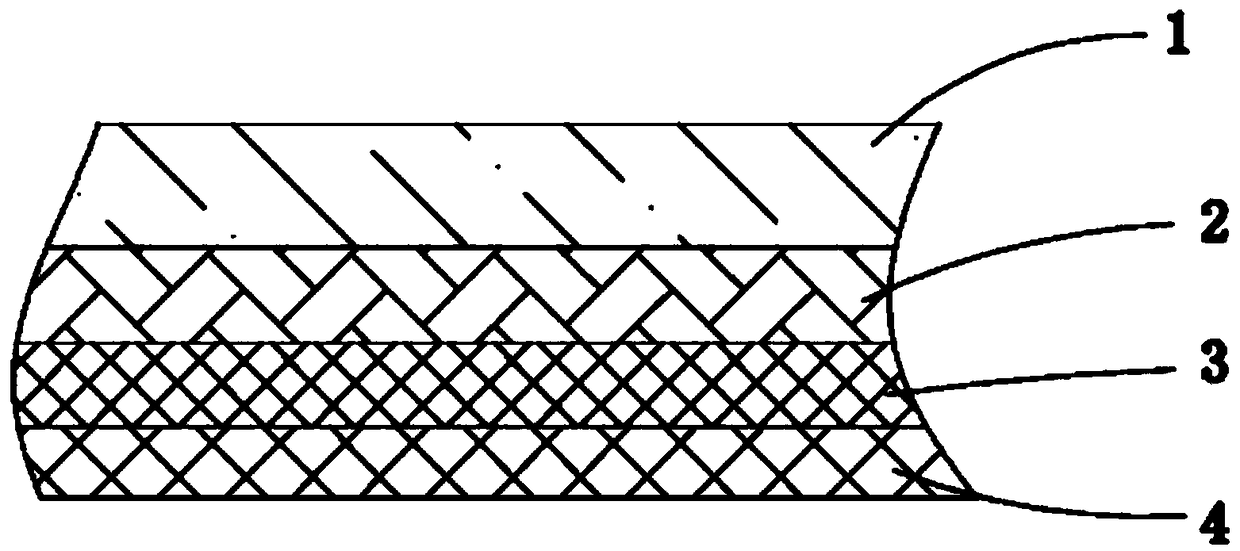

Antibacterial, antiviral, light and thin wool worsted fabric and production method thereof

PendingCN111304928APrevent intrusionSafe permanent antimicrobialLiquid/gas/vapor removalWoven fabricsFiberEmulsion

The invention discloses an antibacterial, antiviral, light and thin wool worsted fabric. The antibacterial, antiviral, light and thin wool worsted fabric is characterized by comprising an inner layer,an outer layer and an intermediate layer, wherein the inner layer is a graphene wool worsted woven fabric having 1 / 1 or 2 / 1 tissue, the intermediate layer is a high-molecular film barrier layer formed by functional aqueous polyurethane emulsion, the outer layer is a silver ion antibacterial and antiviral layer, and the graphene wool worsted woven fabric of the inner layer comprises 40-70% of woolfibers, 30-50% of graphene fibers and 0-20% of other fibers. The invention also discloses a preparation method of the antibacterial, antiviral, light and thin wool worsted fabric. The preparation method comprises the following steps of S1, preparing the graphene wool worsted woven fabric of the inner layer, and then processing the intermediate layer on the fabric; and finally, processing the outer layer outside the intermediate layer, wherein through interactions of a three-layer mechanism of the inner layer, the intermediate layer and the outer layer, the fabric not only has the advantages of safe and permanent antibacterial and antiviral functions, but also has the far-infrared and antistatic functions.

Owner:山东如意毛纺服装集团股份有限公司 +1

Tartarian buckwheat shell having health functions, and preparation method thereof

The invention discloses a tartarian buckwheat shell having health functions, and a preparation method thereof, and belongs to the functional material preparation field. A technical scheme adopted in the invention is characterized in that the tartarian buckwheat shell having health functions is directly synthesized in a high temperature reaction kettle by selecting a precipitating agent, a dispersant and a film forming agent and controlling technological conditions with a soluble inorganic metal salt as a base material and tartarian buckwheat shell as a carrier. The preparation method effectively overcomes the agglomeration problem of a nanomaterial in preparation and application, and also solves a problem of bad combination force of the nanomaterial and the tartarian buckwheat shell. The preparation method has the advantages of short process flow, low equipment requirements, light burden of sewage emission, and excellent and lasting antibiotic and mildew-resistant health functions of the tartarian buckwheat shell, and has very obvious economic benefits and industrial popularization values.

Owner:JIANGSU NADN SCI TECH CO LTD

Far infrared negative ion draw textured yarn

ActiveCN110257983AThe effect is long-lasting and stableWith far infraredYarnBio-packagingHollow fibreYarn

The invention discloses a far infrared negative ion draw textured yarn. The far infrared negative ion draw textured yarn comprises a hollow fiber core, porous polyester fibers, and a bamboo charcoal fiber web layer. An outer side face of the hollow fiber core is provided with a plurality of spherical bulges. The outer side face of the hollow fiber core is surrounded and covered by a plurality of the porous polyester fibers. An outer side face of the porous polyester fibers is successively dip-coated with a nano silver coating and a negative ion coating from inside to outside. The outer side face of the porous polyester fibers is covered and provided with the bamboo charcoal fiber web layer. The bamboo charcoal fiber web layer is dip-coated with a nano far infrared coating. The far infrared negative ion draw textured yarn is capable of enabling a draw textured yarn to has the far infrared and negative ion health efficacy, lasting and stable in effect, anti-bacterial and warm-keeping, comfortable in fabric wearing, and beneficial to popularization and application.

Owner:浙江天祥新材料股份有限公司

Golden graphene oxide regenerated cellulose complex fiber and preparation method thereof

InactiveCN110172747AVisibly goldenBeautiful colorArtificial filaments from viscoseAdditional valuesUltrasonic dispersion

The invention discloses a golden graphene oxide regenerated cellulose complex fiber and a preparation method thereof. The golden graphene oxide regenerated cellulose complex fiber comprises the following raw materials: 60%-84.9% of regenerated cellulose complex pulp, 0.1%-10% of a graphene oxide solution, 0.1%-5% of a surfactant, 0.1%-5% of an alkaline reagent, and the balance of water. The preparation method comprises the following steps of 1, weighing the raw materials; 2, preparing graphene oxide powder; 3, preparing the graphene oxide solution, adding the surfactant and the alkaline reagent, and performing ultrasonic dispersion; 4, weighing the regenerated cellulose complex pulp, mixing the regenerated cellulose complex pulp with a sodium hydroxide solution, extruding the mixture, ageing the mixture, and yellowing the mixture; 5, heating a graphene oxide mixing solution, mixing with the pulp, and stirring the mixture; and 6, performing spinning. The prepared golden graphene oxide regenerated cellulose complex fiber has the functions of being anti-bacterial, anti-mite, resistant to ultraviolet rays and far infrared rays and the like, the additional value of the golden graphene oxide regenerated cellulose complex fiber can be increased, and the application range of the golden graphene oxide regenerated cellulose complex fiber is extended.

Owner:常州兴烯石墨烯科技有限公司

Functional spandex fiber preparation method

PendingCN113584631AExcellent performanceGood antibacterial propertiesElectroconductive/antistatic filament manufactureFilament/thread formingPrepolymerOrganosolv

The invention discloses a functional spandex fiber preparation method. The preparation method comprises the following steps: using an organic solvent, a part A graphene or carbon nanofiber material, polyether glycol and diisocyanate to obtain a prepolymer solution; and reacting the prepolymer solution with a chain extension solution, filtering melt, and conducting spinning by spinning equipment to prepare functional spandex fiber. The spandex fiber is multifunctional, has the characteristics of far infrared, bacteriostasis, high elasticity, high strength, static resistance and the like, and is wider in application field.

Owner:张家港市昌源氨纶制造有限公司

Chinese herbal medicine aromatic apocynum venetum fiber composite health-care fabric and preparation method thereof

InactiveCN106564233AHigh strengthImprove wear resistanceSynthetic resin layered productsLaminationSurface layerApocynum venetum

Chinese herbal medicine aromatic apocynum venetum fiber composite health-care fabric and a preparation method thereof belong to the field of textile fabrics. The Chinese herbal medicine aromatic apocynum venetum fiber composite health-care fabric comprises a surface layer, an intermediate layer and an internal layer. The surface layer is composed of 50-55 parts by weight of acrylic fibers and 30-35 parts by weight of viscose fiber. The intermediate layer is composed of cotton cloth which is impregnated with a Chinese herbal impregnation liquid and sprayed with a fragrant finishing agent. The internal layer is composed of 50-55 parts by weight of apocynum venetum fiber and 30-35 parts by weight of silk fiber. The fabric of the invention has good health-care performance, good drug adhesion and durability and good medication performance, and has natural aroma so as to effectively cover the smell of traditional Chinese medicines.

Owner:ANHUI YICAINI FIBER MATERIALS TECH

A functional core-spun yarn and its spinning process

ActiveCN108456962BStrong water vapor absorption capacityPromote moisture absorption and heat generation functionYarnYarnTextile technology

The invention relates to the technical field of spinning, in particular to functional covered yarn and a spinning technology thereof. The functional covered yarn is prepared by mixing, by weight, 10-30% of EKS fiber and 70-90% of ultrafine acrylic fiber to form core yarn, and the core yarn is wrapped by taiji stone viscose as yarn skin. The spinning technology of the functional covered yarn comprises the steps of 1 spinning a yarn core, 2 spinning the yarn skin and 3 combining the yarn skin and the yarn core, namely spinning the covered yarn. The functional covered yarn can lower the risk thata white part of a cloth cover is leaked due to the fact that EKS fiber is leaked out of the cloth cover, the functional covered yarn has the good anti-pilling effect and high water absorbability, hasthe effect of promoting the moisture absorption and heating function, meanwhile has the far infrared effect and further has the anti-ultraviolet and antibacterial advantages, and the spinning technology of the functional covered yarn has the advantages of being simple, low in production cost and suitable for large-scale production.

Owner:GUANGDONG SMART TEAM TEXTILES TECH

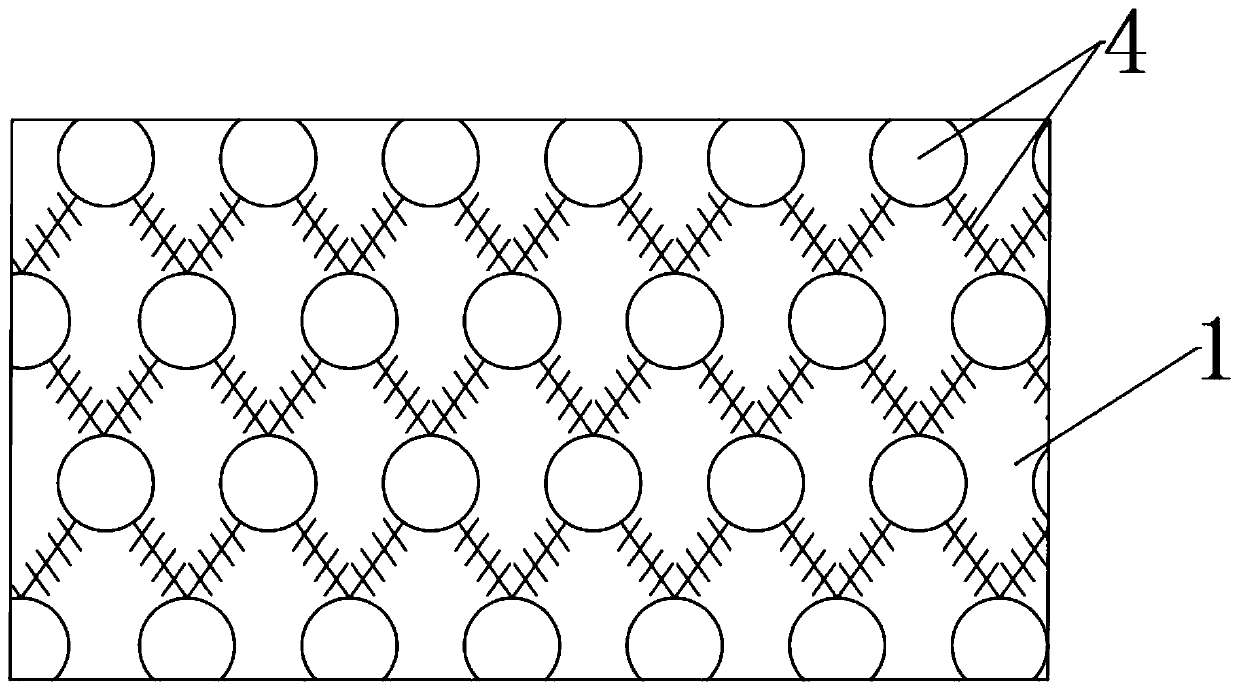

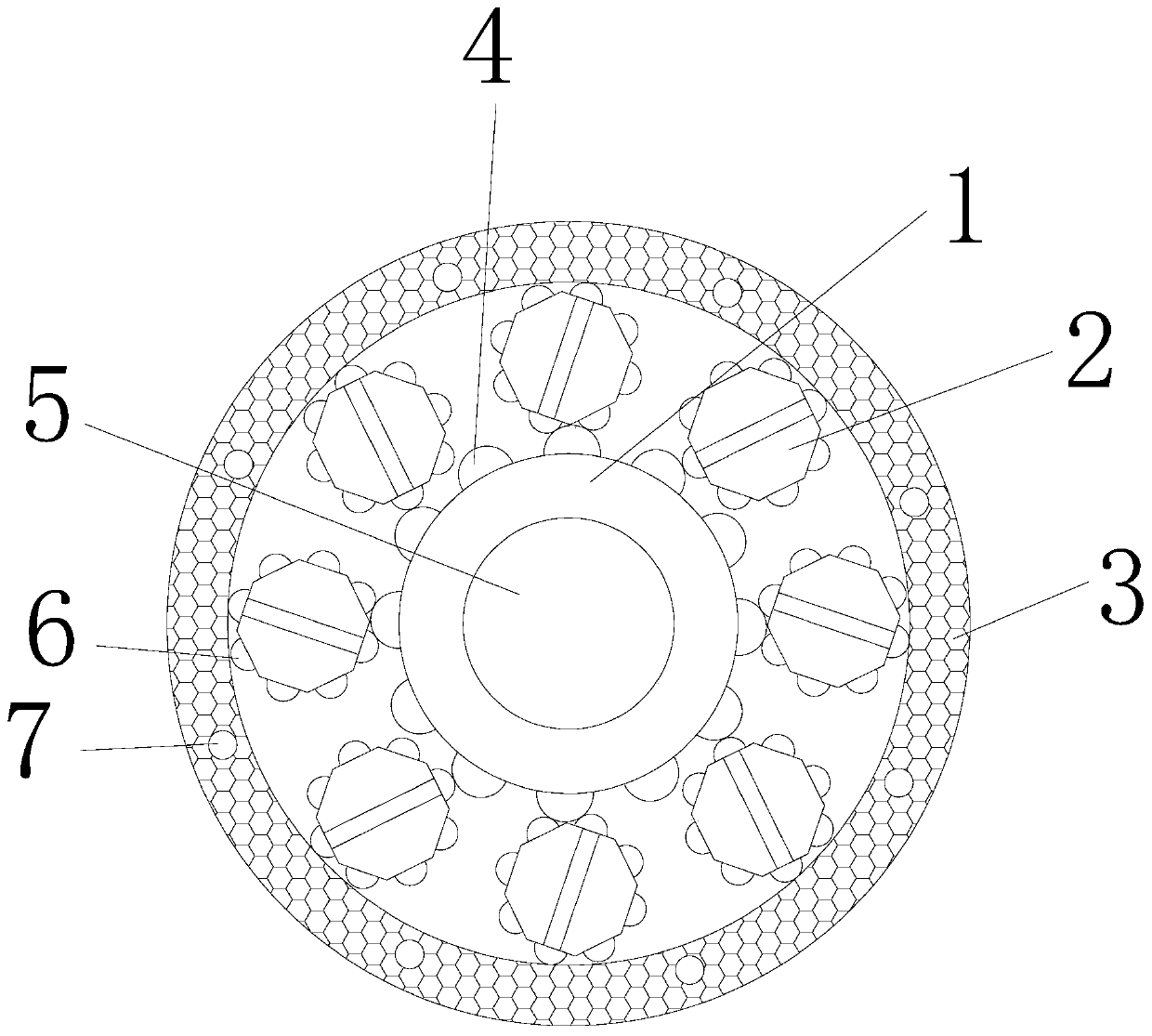

Health-care underwear

InactiveCN108903066AWith negative ionsWith far infraredHollow filament manufactureSynthetic resin layered productsPolyesterEngineering

The application relates to a health-care underwear, which comprises an underwear body. The underwear body is formed by an underwear fabric, the underwear fabric is provided with an external layer, a functional layer, an internal sublayer and an internal layer sequentially from the outside to the inside, the external layer is a hydrophilic layer, the internal layer is a hydrophobic layer, the internal sublayer is a moisture transfer layer, the functional layer is a polyester fiber layer, air holes which run through the functional layers along the thickness direction are evenly distributed in the functional layer, the aperture of the air hole is not greater than 0.1mm, the number of the air holes per square meter is not less than two millions, and the polyester fiber is prepared with polyester as substrate and filler A, filler B and filler C as additives by melt blending.

Owner:FOSHAN NANHAI DISTRICT JIAYAN UNDERWEAR CO LTD

Preparation method of natural fiber graphene composite material

ActiveCN112176746AEvenly distributedImprove bonding fastnessLiquid/gas/vapor removalDyeing processYarnNatural fiber

The invention relates to a preparation method of a natural fiber graphene composite material. The preparation method comprises the following steps that S1, natural fiber yarns enter a pretreatment tank containing a pretreatment solution for padding, and the pretreatment solution comprises the following components of, in percentage by mass, 2%-20% of biological enzyme, 0.5%-5% of sodium carbonate,1%-10% of sodium hydroxide, 0.5%-2% of leveling agent peregal, 1%-5% of penetrant JFC and the balance of deionized water; S2, the padded and baked natural fiber yarns are enabled to enter an ultrasonic tank containing the graphene solution for pad dyeing, and the graphene solution comprises the following components of, in percentage by mass, 3%-6% of a graphene material, 20%-40% of waterborne polyurethane, 1%-5% of a leveling agent peregal, 0.5%-1% of a penetrating agent JFC and the balance of deionized water; and S3, after the pad-dyed natural fiber yarns are pre-dried, steaming and color fixing are carried out. The preparation method of the natural fiber graphene composite material has the advantages of high production efficiency, high binding strength of graphene and natural fibers, anduniform distribution of graphene.

Owner:常州森彩新材料科技有限公司

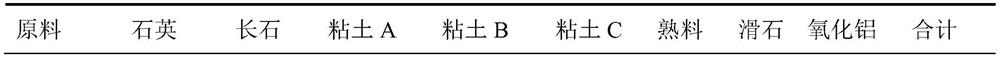

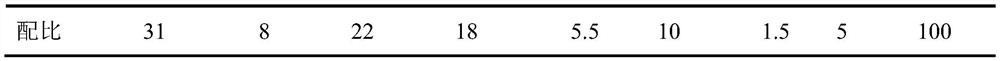

Antibacterial reinforced bone china

ActiveCN112159229ALittle increase in costImprove antibacterial propertiesCeramic materials productionBone chinaAnti bacterial

Owner:PINGDING YINGYU PORCELAIN

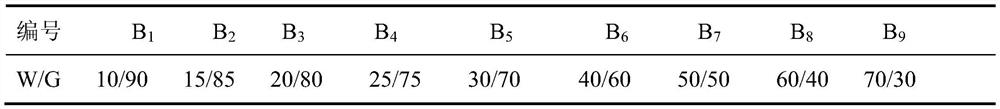

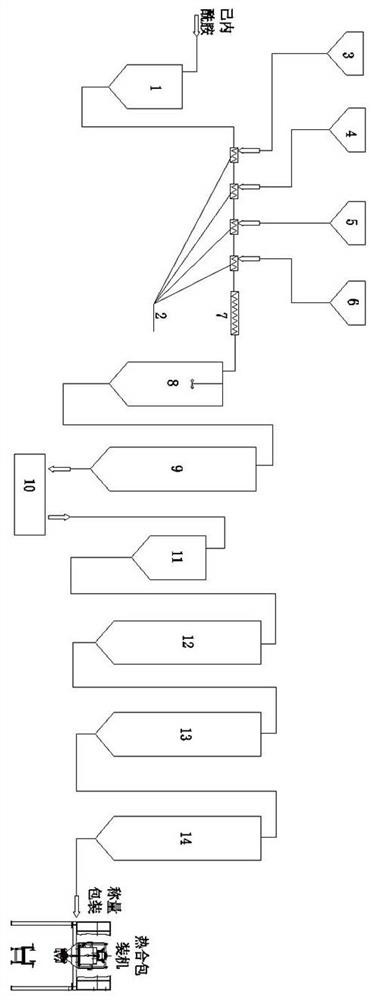

Production device and process of in-situ polymerization colored graphene modified polyamide-6 slices

PendingCN112724398AAvoid reunionImprove spinnabilityPigment addition to spinning solutionMonocomponent polyamides artificial filamentYarnPolymer science

The invention discloses a production device and process for in-situ polymerization colored graphene modified polyamide-6 slices. The production device comprises a raw material storage tank, a static mixer, a refined terephthalic acid preparation tank, a modifier preparation tank, a graphene preparation tank, a coloring agent preparation tank, a dynamic mixer and the like. According to the invention, graphene modified polyamide-6 colored slices are directly prepared by adopting an in-situ polymerization method, the prepared slices can be directly spun to obtain functional colored yarns required by customers, and due to the fact that the particle size of the coloring agent is nanoscale, the service cycle of a spinning assembly is prolonged, and the spinning assembly can be used for 3-6 months generally, so that the production cost of spinning can be greatly reduced; and after treated graphene is added, the polyamide colored slice has multiple functions of antibiosis, high strength, far infrared and the like.

Owner:HAIYANG TECH (JIANGSU) RES INST CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com