Patents

Literature

126 results about "Poly(ethylene glycol) diglycidyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

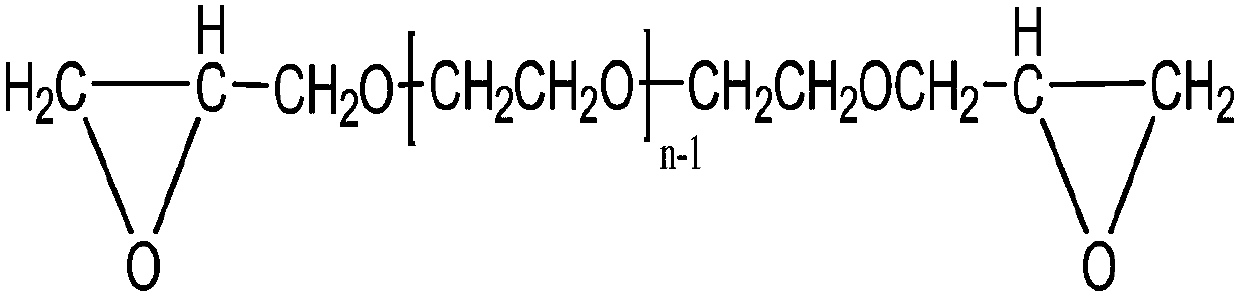

Poly(ethylene glycol) diglycidyl ether (PEGDGE) shows highly solubility in water. Hence, it easily undergoes hydrolysis followed by ring cleavage reaction in aqueous solution, yielding hydroxyl group. PEGDGE combines with proteins covalently or non-covalently. PEGDGE is widely used in chemical industries for cross linking and surface modifier.

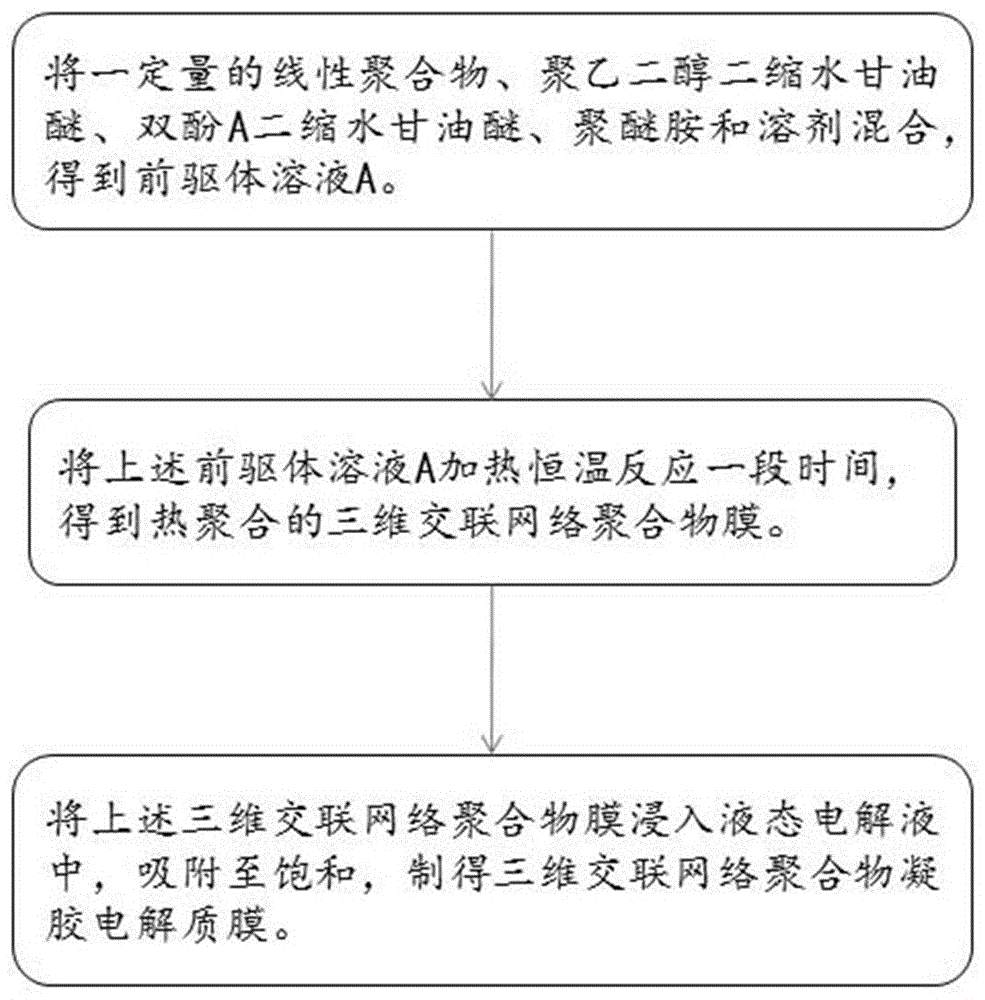

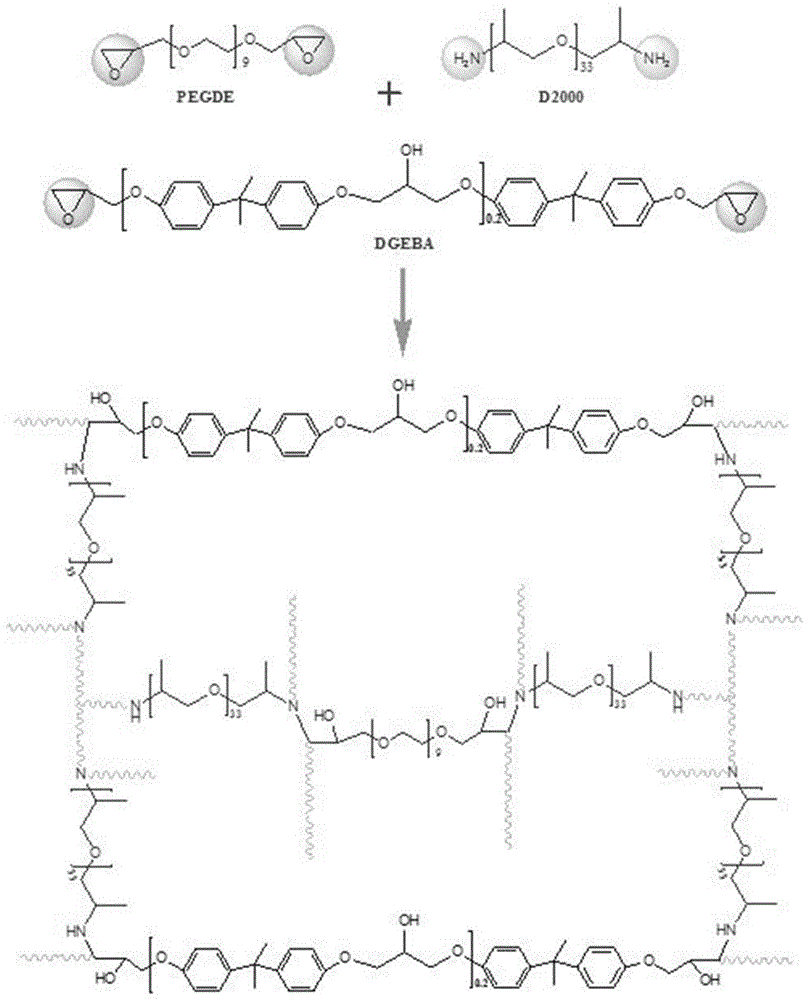

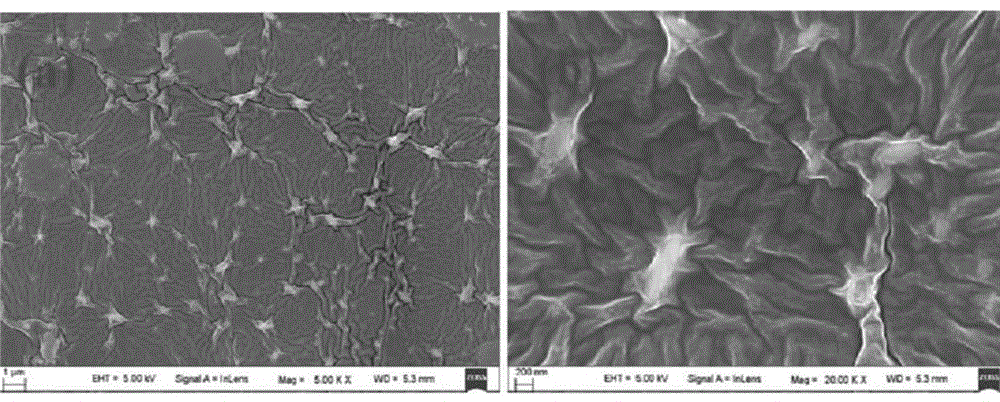

Three-dimensional crosslinked network polymer gel electrolyte membrane, preparation method and lithium-ion battery

ActiveCN105958122AImprove mechanical stabilityImprove interface compatibilityFinal product manufactureElectrolyte accumulators manufacturePolymer scienceLithium metal

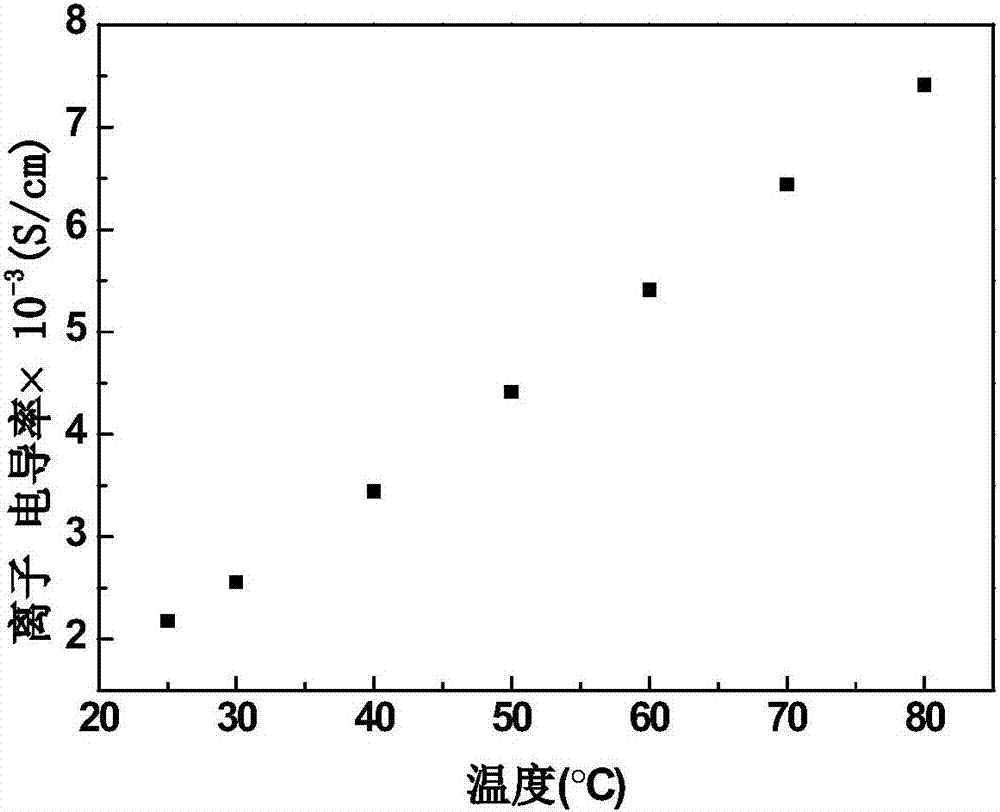

The invention provides a preparation method of a three-dimensional crosslinked network polymer gel electrolyte membrane. The method comprises the following steps of: (S1) mixing a linear polymer, polyethylene glycol diglycidyl ether, bisphenol A diglycidyl ether, polyether amine and a solvent to obtain a precursor solution; (S2) heating the precursor solution A for constant-temperature reaction for a period of time to obtain a three-dimensional crosslinked network polymer membrane; and (S3) immersing the three-dimensional crosslinked network polymer membrane into a liquid electrolyte for adsorption to saturation, thereby preparing the three-dimensional crosslinked network polymer gel electrolyte membrane. The three-dimensional crosslinked network polymer gel electrolyte membrane prepared by the method is good in mechanical stability, high in ionic conductivity and good in lithium metal interface compatibility. The invention further provides the three-dimensional crosslinked network polymer gel electrolyte membrane prepared by the preparation method, and a lithium-ion battery employing the three-dimensional crosslinked network polymer gel electrolyte membrane.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

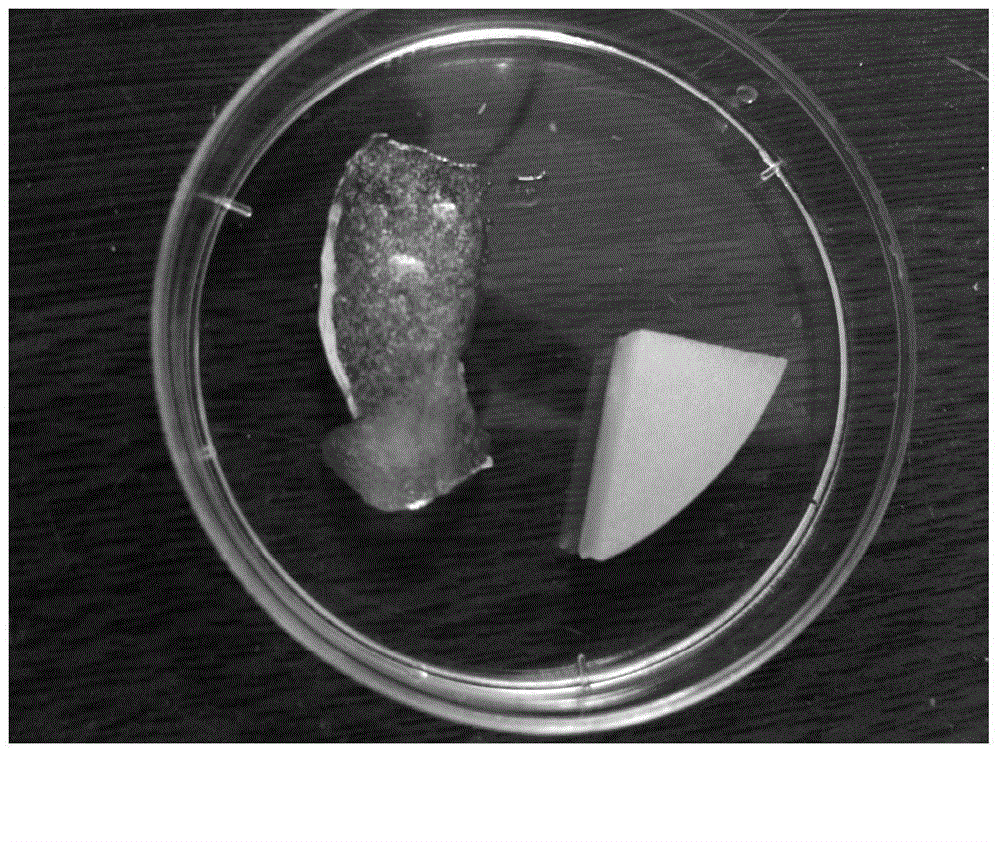

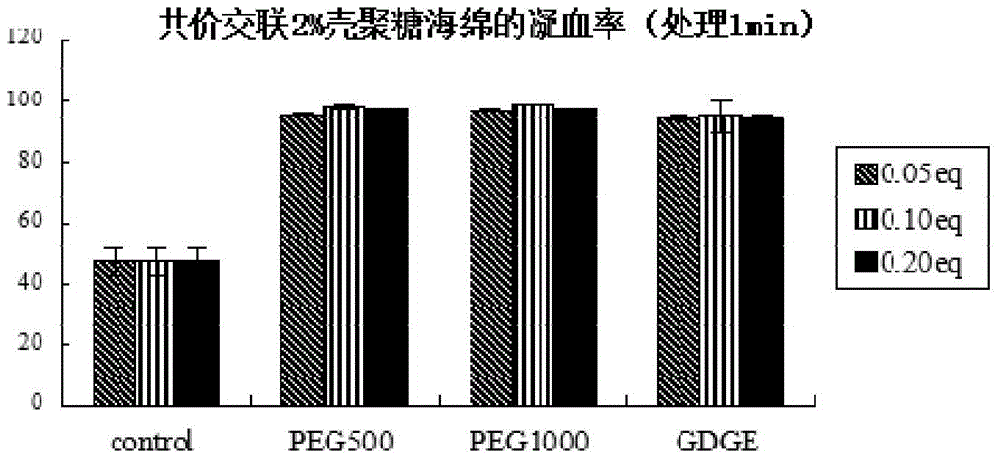

Chitosan hemostatic material formed through covalent crosslinking and preparation method thereof

ActiveCN104474575ASimple manufacturing processReduce manufacturing costAbsorbent padsBandagesCrosslinked chitosanPolymer science

The invention discloses a chitosan hemostatic material formed through covalent crosslinking and a preparation method thereof. The chitosan hemostatic material formed through covalent crosslinking is obtained by chemically crosslinking chitosan by utilizing a crosslinking agent via covalent bonds, wherein the crosslinking agent is polyethylene glycol diglycidyl ether. The preparation method of the chitosan hemostatic material formed through covalent crosslinking comprises the following steps: 1) preparing chitosan into a water solution; 2) adding the crosslinking agent to the chitosan water solution, fully stirring and mixing the materials, then pouring the mixture into a mold, and freeze-drying the product, thus obtaining the chitosan hemostatic material, wherein the crosslinking agent is polyethylene glycol diglycidyl ether. The chitosan hemostatic material and the preparation method have the beneficial effects that chitosan is crosslinked by polyethylene glycol diglycidyl ether under acidic conditions; an ethylene oxide group in polyethylene glycol diglycidyl ether carries out ring-opening reaction with hydroxyl on chitosan under acidic conditions to form the crosslinked product by generating ether bonds; the crosslinking agent used in the method is relatively safe; the preparation process is simple and practicable and is lower in production cost.

Owner:LANZHOU KAIBO PHARMA

Polymer gel electrolyte membrane, preparation method and sodium ion battery

InactiveCN107154513AImprove mechanical stabilityStable interfacial compatibilitySecondary cellsElectrolyte immobilisation/gelificationPolymer sciencePolyethylene glycol

The invention discloses a preparation method of a polymer gel electrolyte membrane. The preparation method includes following steps: S1, mixing polyethylene glycol diglycidyl ether, polyether amine and solvent to obtain a precursor solution; S2, applying the precursor solution on a porous thin film, and heating for reaction to obtain a polymer membrane supported by the porous thin film; S3, soaking the polymer membrane in liquid-state electrolyte to adsorb the same to obtain the polymer gel electrolyte membrane supported by the porous thin film. The polymer gel electrolyte membrane is high in mechanical stability, ion conductivity and compatibility with a metal sodium interface. The invention further provides the polymer gel electrolyte membrane prepared by the method and a sodium secondary battery using the polymer gel electrolyte membrane.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Preparation method of biosensing film, biosensing film and monitoring device

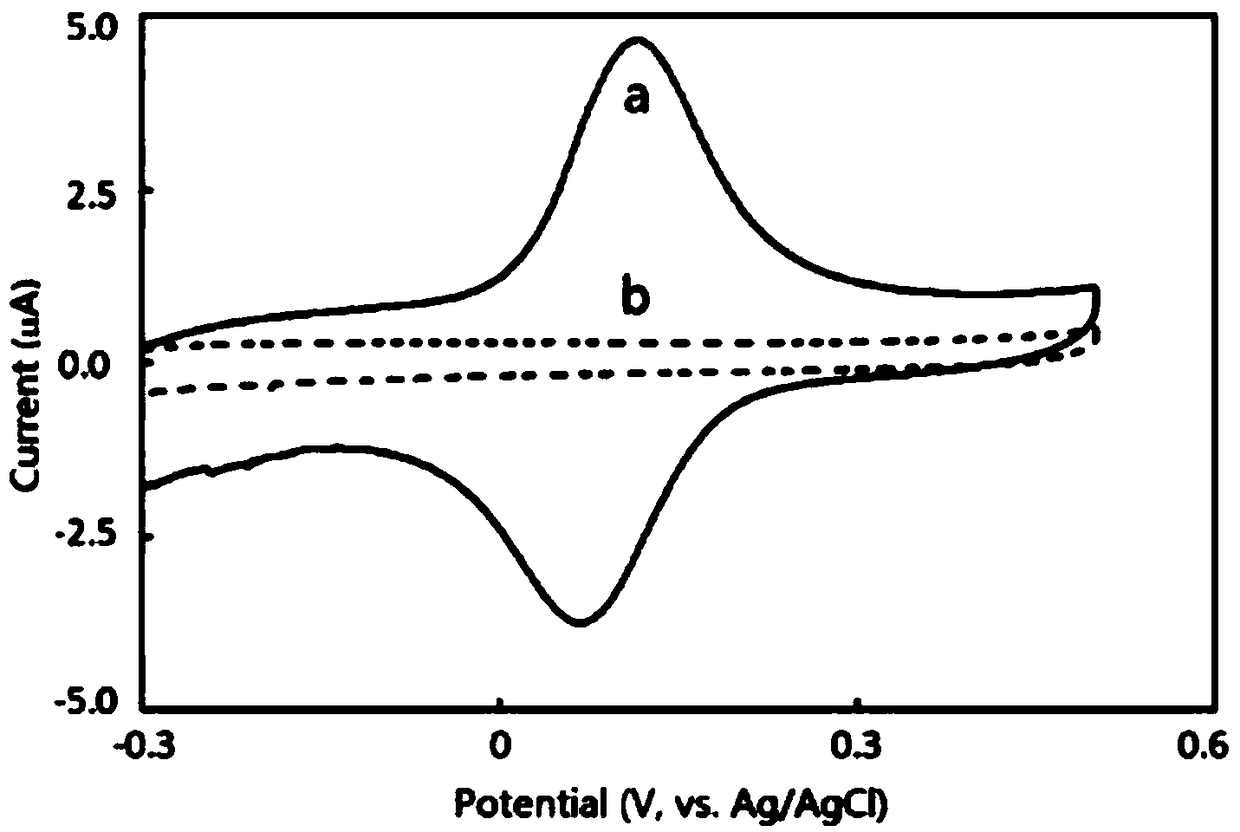

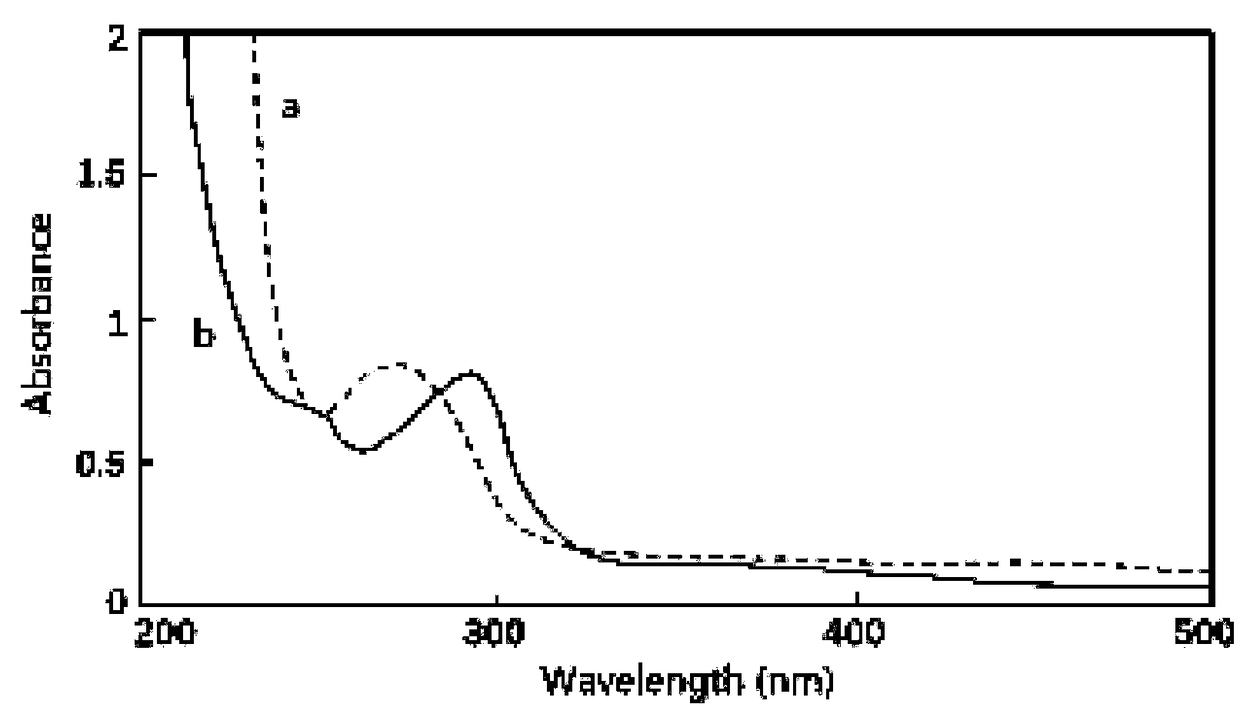

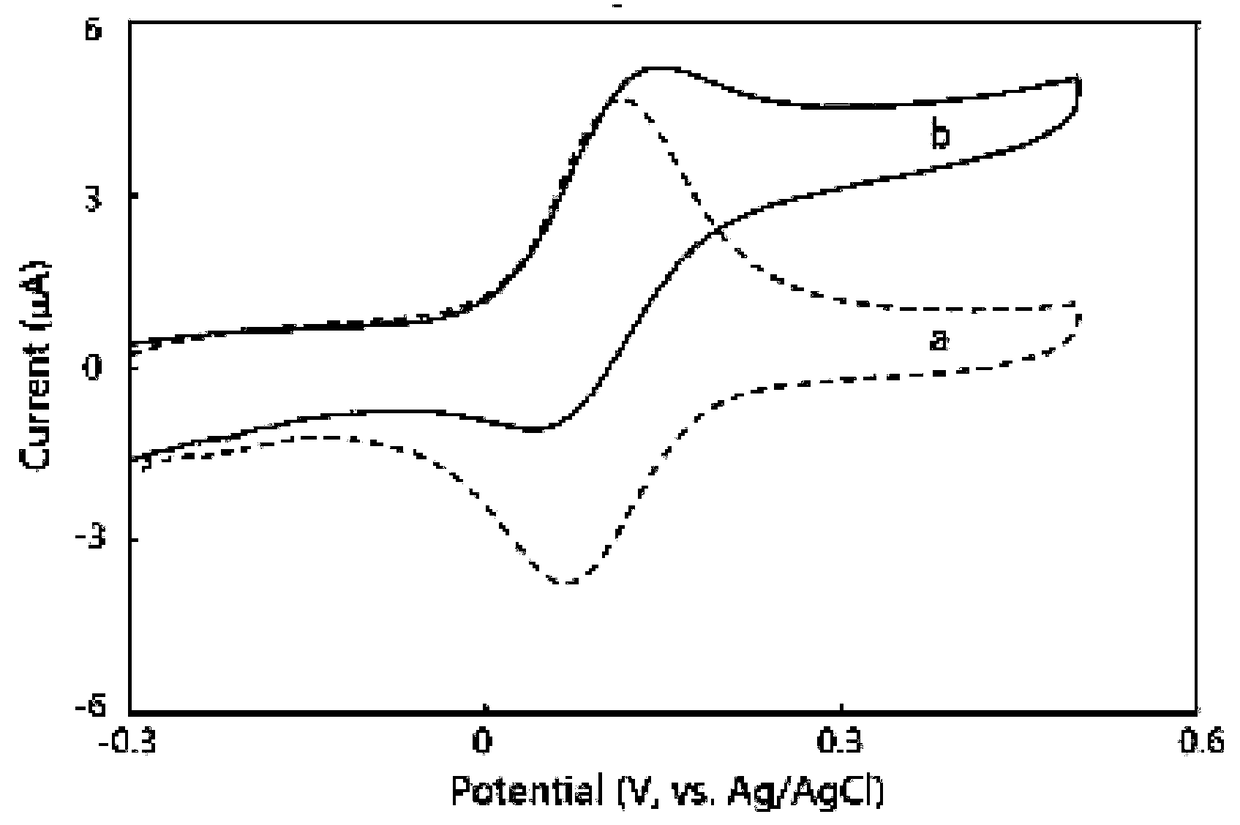

ActiveCN108918625AOxidoreductasesMaterial electrochemical variablesPoly(ethylene glycol) diglycidyl etherPolyethylene glycol

The application discloses a preparation method of a biosensing film, which comprises the steps of: after carrying out electrochemical activation modification on oxidordeuctase, carrying out cross-linking processing by using a chemical cross-linking agent; and coating the obtained product on the surface of an electrode to form the biosensing film, wherein the chemical cross-linking agent is glutaraldehyde or polyethylene glycol diglycidyl ether. The application further discloses a biosensing film prepared by the method and a monitoring device. The preparation method provided by the applicationor the biosensing film prepared by the preparation method and the monitoring device are stable and durable, can carry out repeated detection and are particularly applicable to a biosensing film used as a living body monitoring device.

Owner:SINOCARE

Waterborne epoxy emulsion, waterborne epoxy resin coating and preparation method thereof

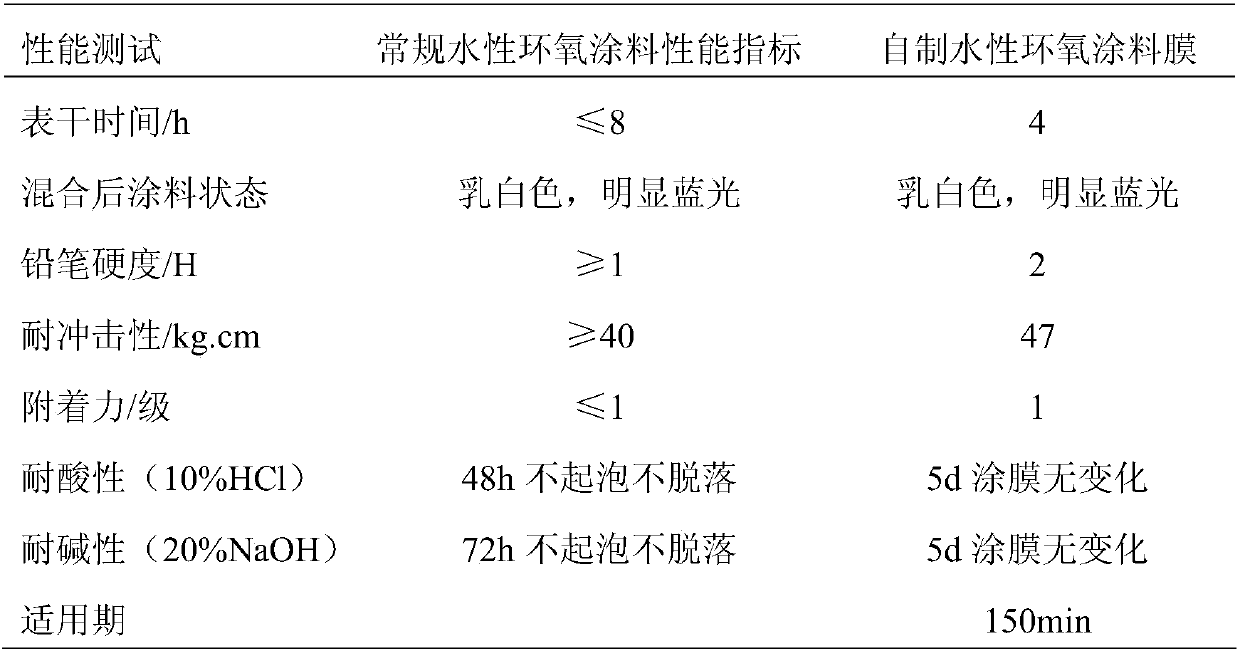

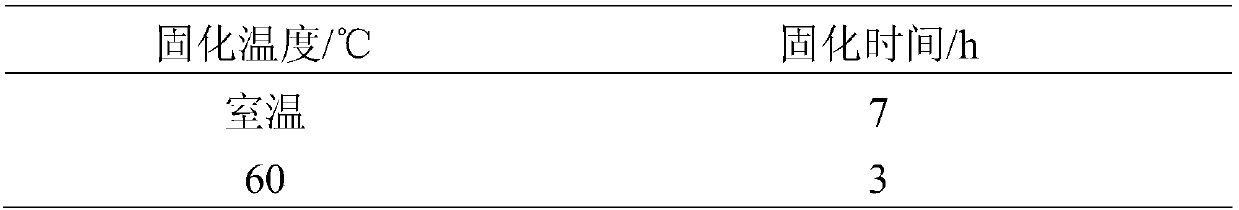

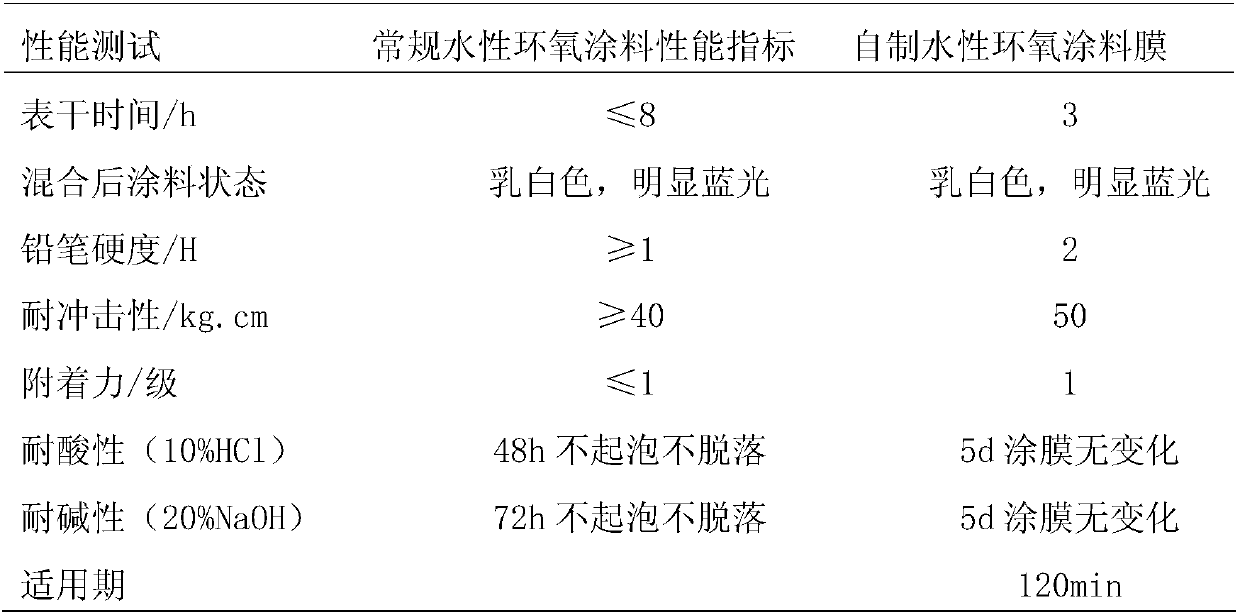

InactiveCN108047431AImprove stabilitySolve problems that require high-temperature energy-consuming curingEpoxy resin coatingsEpoxyPolyethylene glycol

The invention belongs to the technical field of epoxy coatings, and discloses a waterborne epoxy emulsion, a waterborne epoxy resin coating and a preparation method thereof. The preparation method ofthe waterborne epoxy emulsion comprises the steps that 1, polyethylene glycol and maleic anhydride are subjected to a heating reaction, then, epoxy resin is added for a continuous heating reaction, and an epoxy resin emulgator is obtained; 2, the emulgator and the epoxy resin are mixed, and the waterborne epoxy emulsion is obtained through the phase inversion technology. The preparation method ofthe waterborne epoxy coating comprises the steps that 1, an amine compound and epoxy resin are subjected to a heating reaction, polyethylene glycol diglycidyl ether is added for a continuous heating reaction, butyl vinyl ether is added for a continuous reaction, and a waterborne curing agent is obtained; 2, the waterborne curing agent and the waterborne epoxy emulsion are mixed, and the waterborneepoxy coating is obtained. The waterborne epoxy emulsion is good in stability; the waterborne epoxy coating is cured at the room temperature, the application period is long, and the formed coating has the good mechanical property, hardness and acid and base resistance.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +4

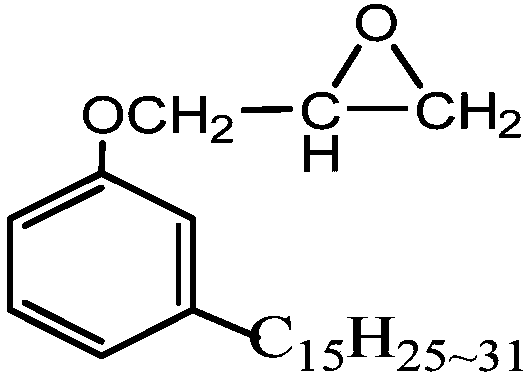

Cardanol modified waterborne epoxy curing agent and preparation method thereof

ActiveCN109517141ALow viscosityImprove mechanical propertiesEpoxy resin coatingsPolyethylene glycolFatty amine

The invention discloses a cardanol modified waterborne epoxy curing agent and a preparation method thereof. The cardanol modified waterborne epoxy curing agent is prepared by taking cardanol and polyethylene glycol as raw materials through the following steps: firstly, synthesizing polyethylene glycol diglycidyl ether and cardanol glycidyl ether respectively; then dropwise adding the polyethyleneglycol diglycidyl ether and fatty amine to react; and adding the cardanol glycidyl ether and carrying out reaction to prepare a product. The epoxy curing agent has water dispersibility and the viscosity is relatively low and is 1000 to 4000mpa.s, so that the epoxy curing agent can be stably stored under the condition that no diluting agent exists and is used for epoxy resin coating. According to the cardanol modified waterborne epoxy curing agent, the raw material cardanol is low in price, is easy to obtain and is a renewable biomass energy source; the structure contains a benzene ring rigid structure and a long-chain hydrocarbonyl substituent group, so that the thermal stability and mechanical properties of an epoxy resin cured product are improved; the curing agent which takes water as adispersion medium is convenient to use and can be constructed on a low-temperature and damp structure to form a film; and the content of VOC (Volatile Organic Compounds) is low and an energy-saving and environment-friendly development concept is met better.

Owner:ANHUI UNIVERSITY

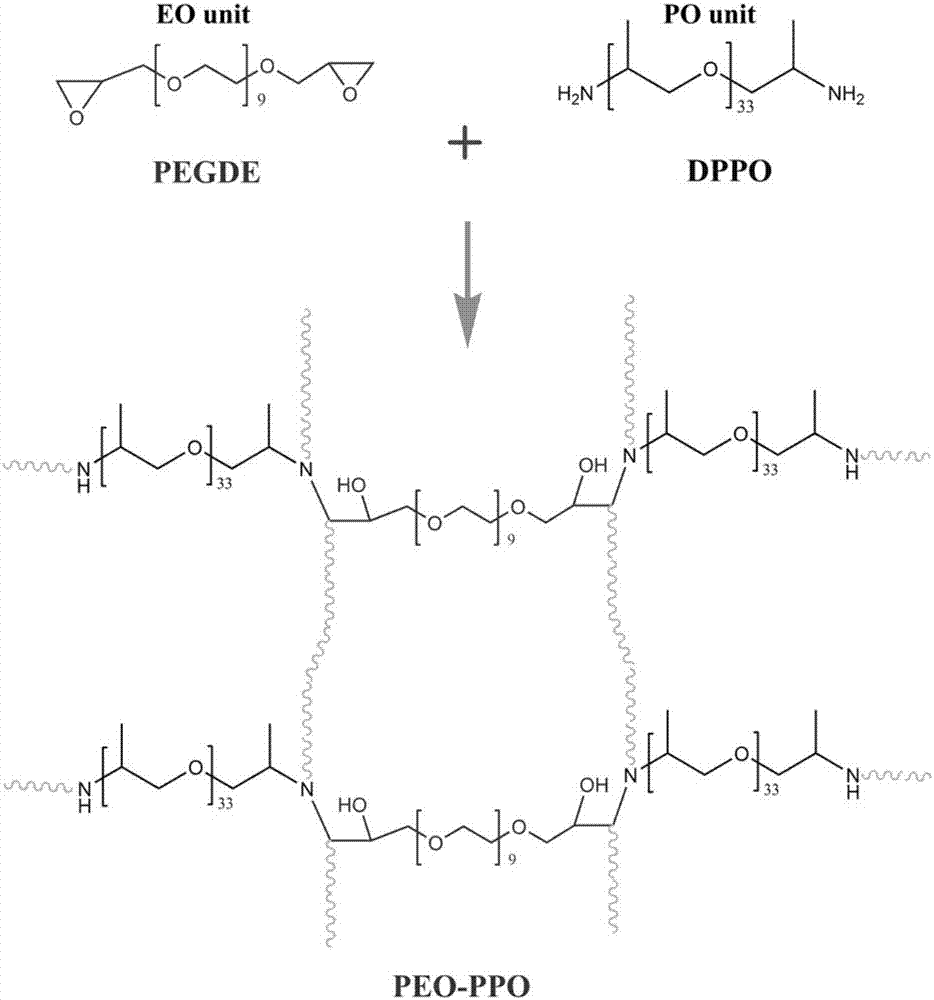

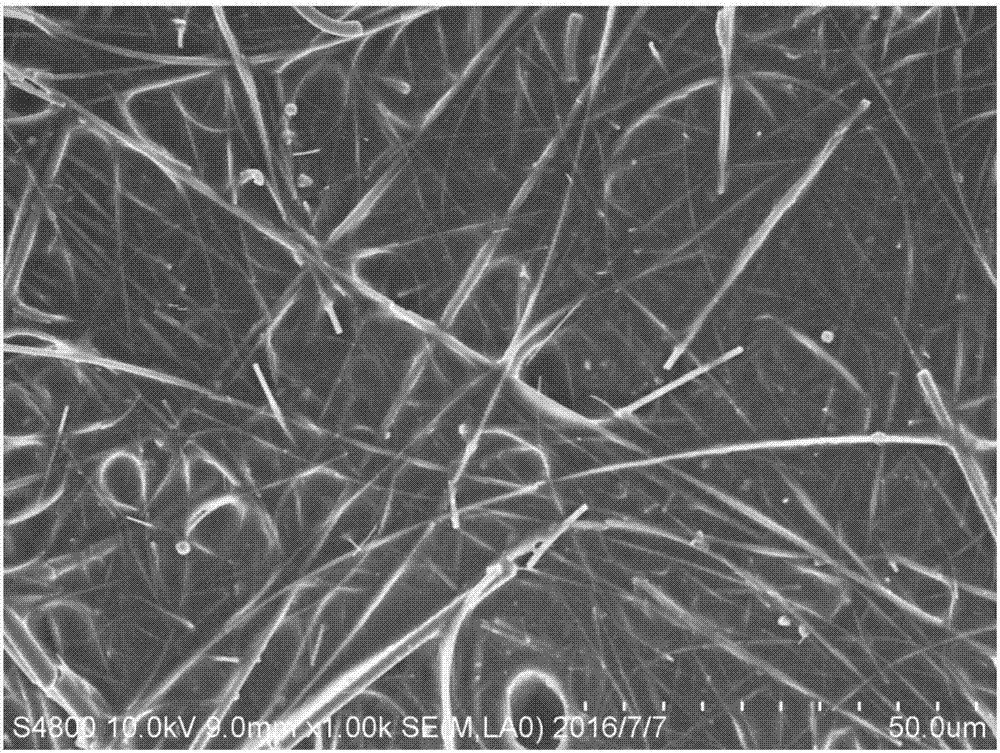

Preparation method of anti-coagulating composite tubular scaffold with good compliance

InactiveCN104524632AGood blood compatibilityImprove compliancePharmaceutical containersMedical packagingPoly(ethylene glycol) diglycidyl etherHaemodialysis machine

The invention provides a preparation method of an anti-coagulating composite tubular scaffold with good compliance. The tensile property of the tubular scaffold can be improved by the composite tubular scaffold by virtue of braided fabric; the tubular scaffold with sponge layers can be prepared by modification of silk fibroin and sulfated silk fibroin by polyethylene glycol diglycidyl ether; the compliance of the tubular scaffold is improved; the anti-permeability of the tubular scaffold can be improved by the silk fibroin and sulfated silk fibroin tubular scaffold with double sponge layers; meanwhile, the anti-coagulating property of the tubular scaffold can be improved by the sulfated silk fibroin; the composite tubular scaffold with good tensile property, compliance, anti-permeability and blood compatibility can be prepared by the combination; the pipe diameter is controllable; and the composite tubular scaffold can be applied to repair and reconstruction of a small-caliber blood vessel and building of hemodialysis vascular access. The preparation method is simple to operate and low in cost; and commercial production can be achieved.

Owner:BEIHANG UNIV

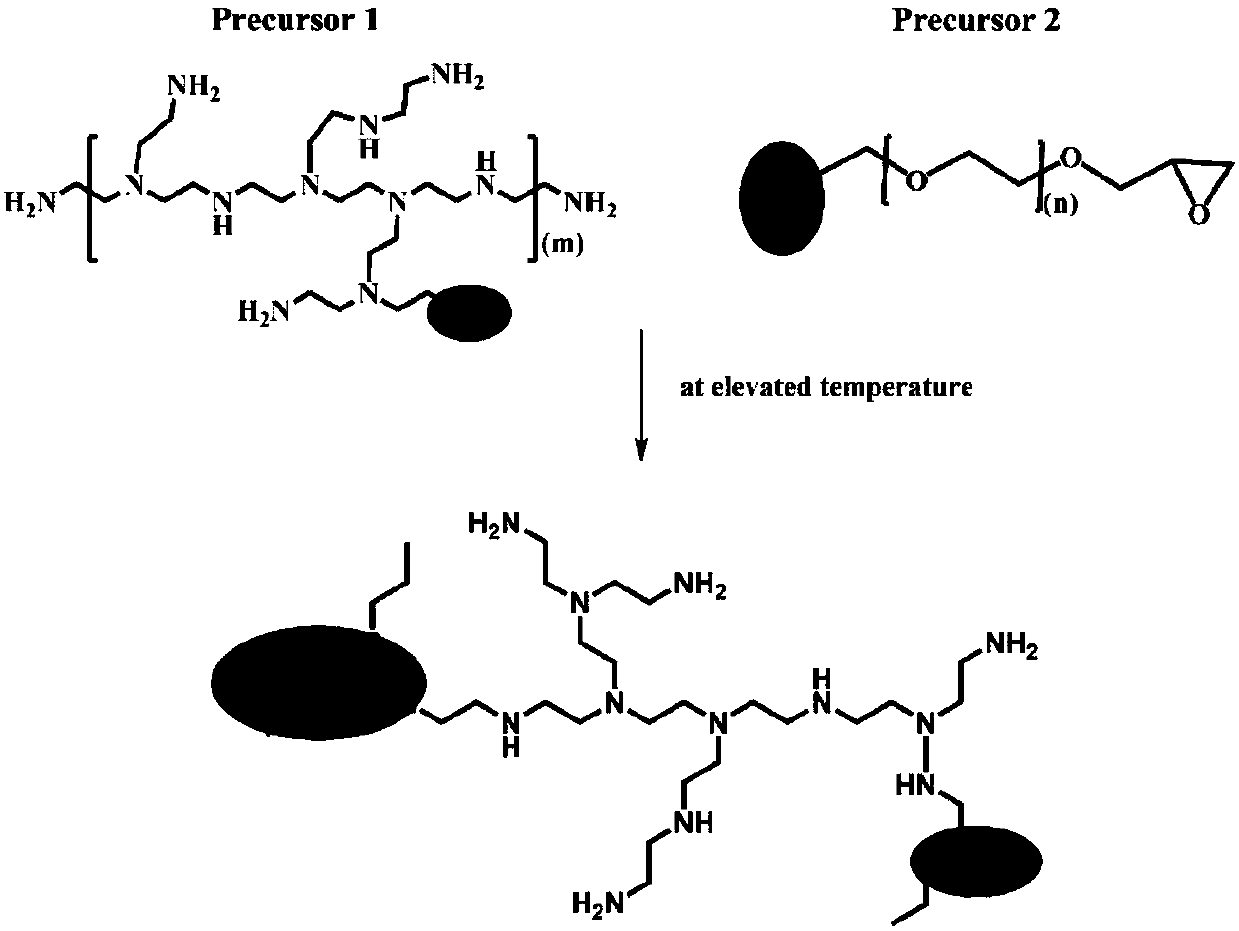

Polarity binding agent applied to lithium-sulfur battery and preparation method of polarity binding agent

InactiveCN107863534AStrong resistance to high pressure oxidationImprove cycle performanceFinal product manufactureElectrode collector coatingPoly(ethylene glycol) diglycidyl etherLithium–sulfur battery

The invention relates to a polarity binding agent applied to a lithium-sulfur battery and a preparation method of the polarity binding agent, and belongs to the technical field of a battery binding agent. The binding agent is a polymer obtained by performing reaction of polyethylenimine and polyethylene glycol diglycidyl ether for 3-6 hours under a temperature of 100-150 DEG C according to a moleratio being 1:(0.5-4), wherein the polyethylenimine and a polysulfide are polarly absorbed to form a bond by amino group or amide group of the polyethylenimine so as to achieve the purpose of preventing the polysulfide from being dissolved, and the polyethylene glycol diglycidyl ether is used for hinging the polyethylenimine to form a three-dimensional structure. A strong polar functional group (such as amino group, amide group and hydroxyl) is contained in the binding agent, a large amount of chemical bonds can be formed with the polysulfide under the condition that certain mechanical strength is maintained, the polysulfide is effectively prevented from being dissolved, and the cycle property of the lithium-sulfur battery is improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

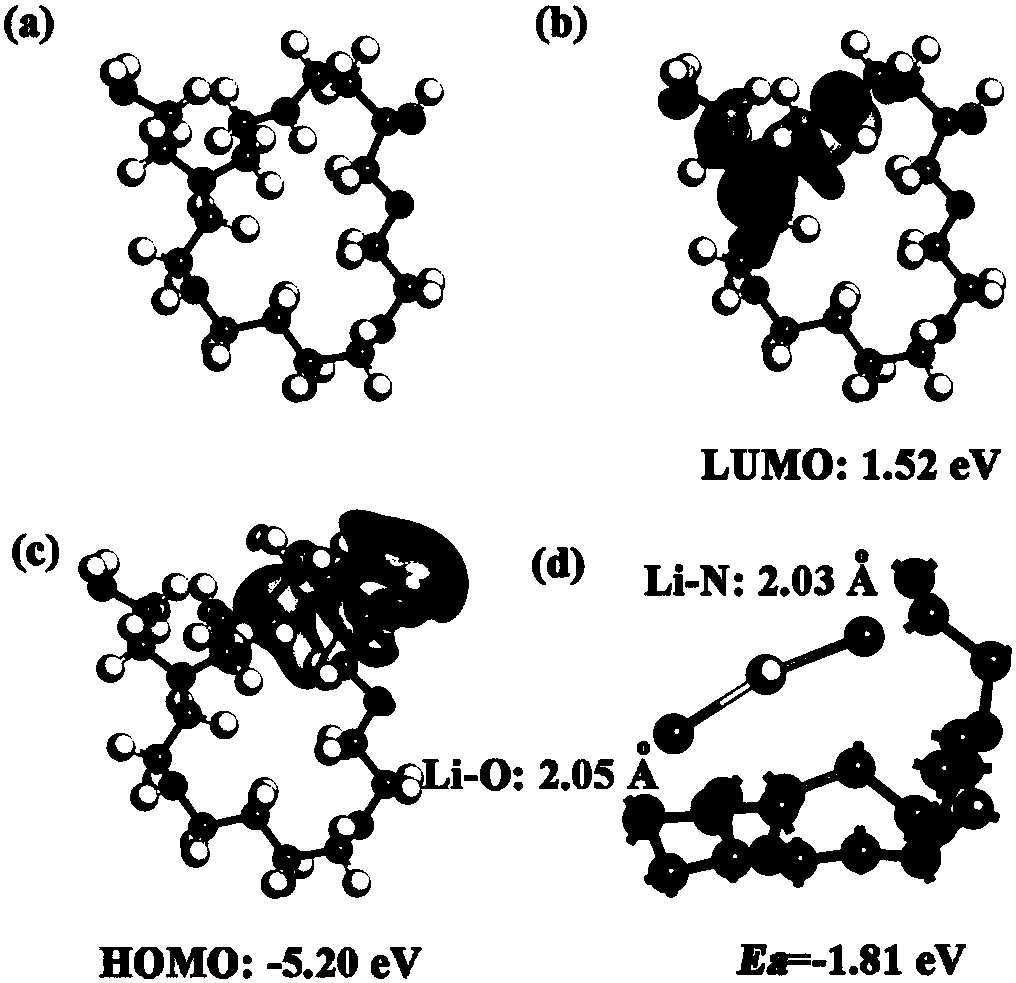

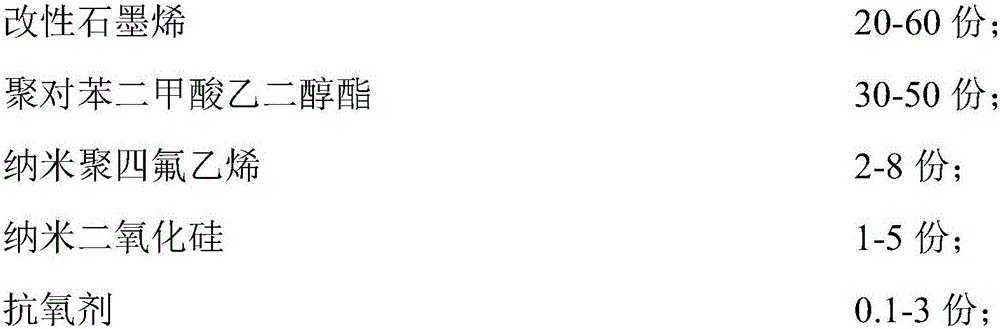

Polyester resin for low-gloss TGIC system powder coating and preparation method and application thereof

InactiveCN109320705AExcellent flatness and smoothnessImprove stabilityPowdery paintsPolyester coatingsEthylenediamineAntioxidant

The invention belongs to the technical field of resin production, and specifically relates to polyester resin for low-gloss TGIC system powder coating, a preparation method of the polyester resin, andapplication of the polyester resin. The polyester resin is mainly prepared from isophthalic acid, pyridine-2,6-dicarboxylic acid, 6-acetylaminocaproic acid, 3-hydroxy-4-aminobutyric acid, polyethylene glycol diglycidyl ether, neopentyl glycol, 2,4,6-trihydroxybenzoic acid, N-hydroxyethyl ethylenediamine tri-acetic acid, an esterification catalyst and an antioxidant. The molecules of the polyesterresin prepared by the method disclosed by the invention simultaneously contain active amino groups, hydroxyl groups and carboxyl groups, difference between the three kinds of base groups and epoxidegroups in TGIC molecules in curing reaction rate can be used for preparing low-gloss powder coating (gloss<20%), and the film coating properties can completely reach various requirements of powder coating.

Owner:周鹤洋

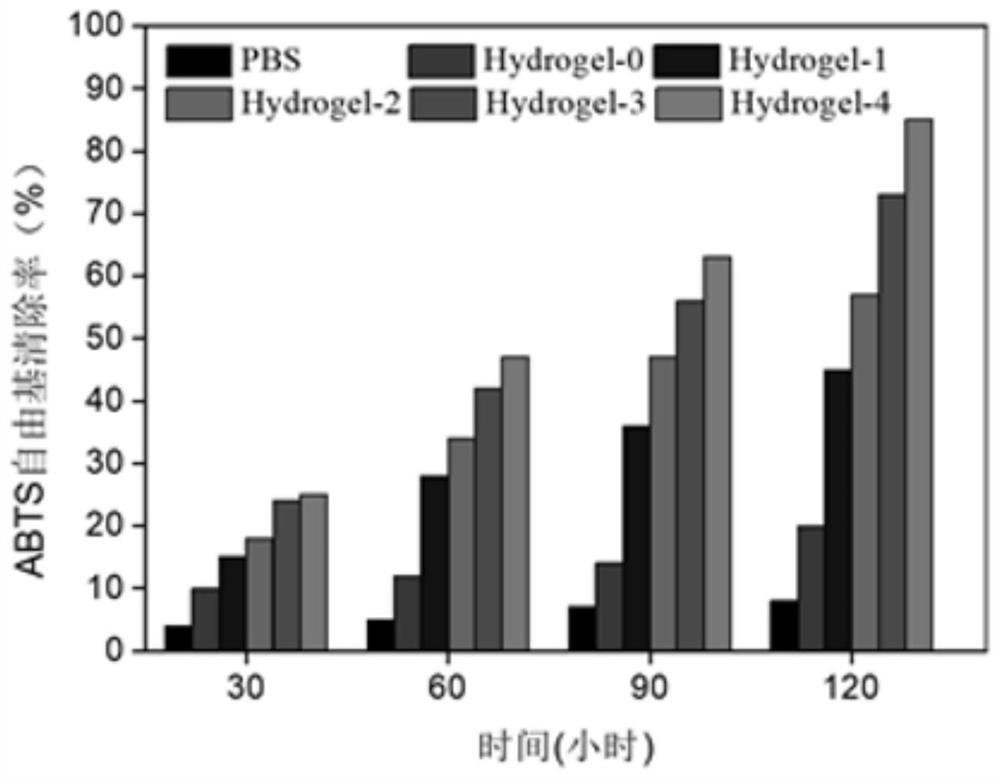

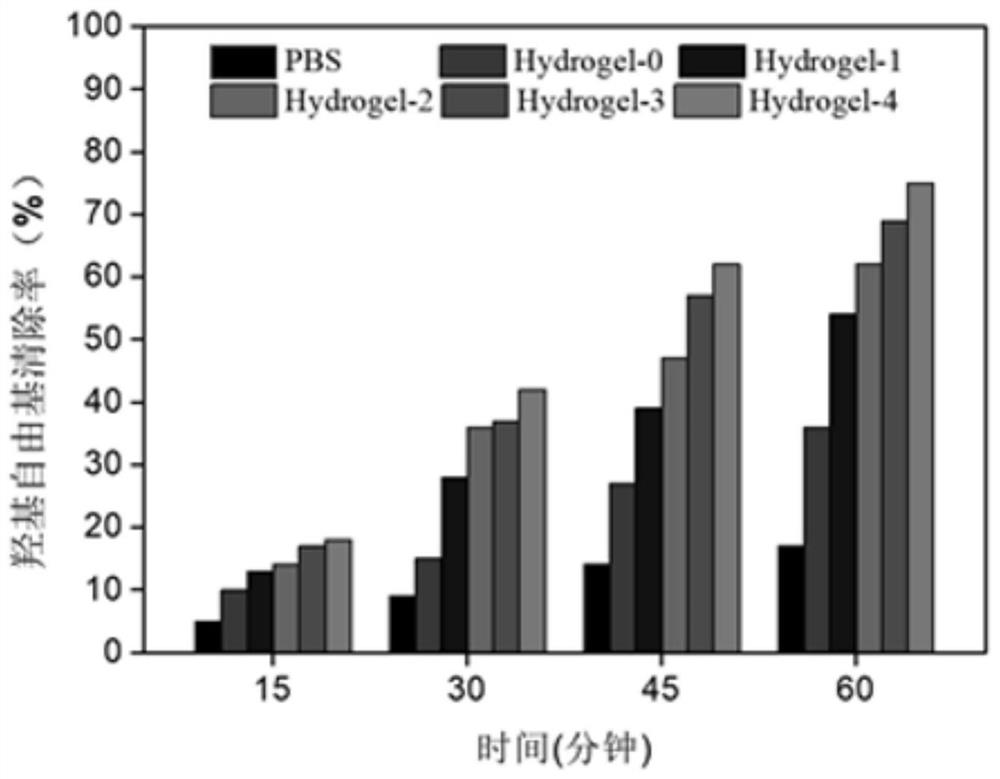

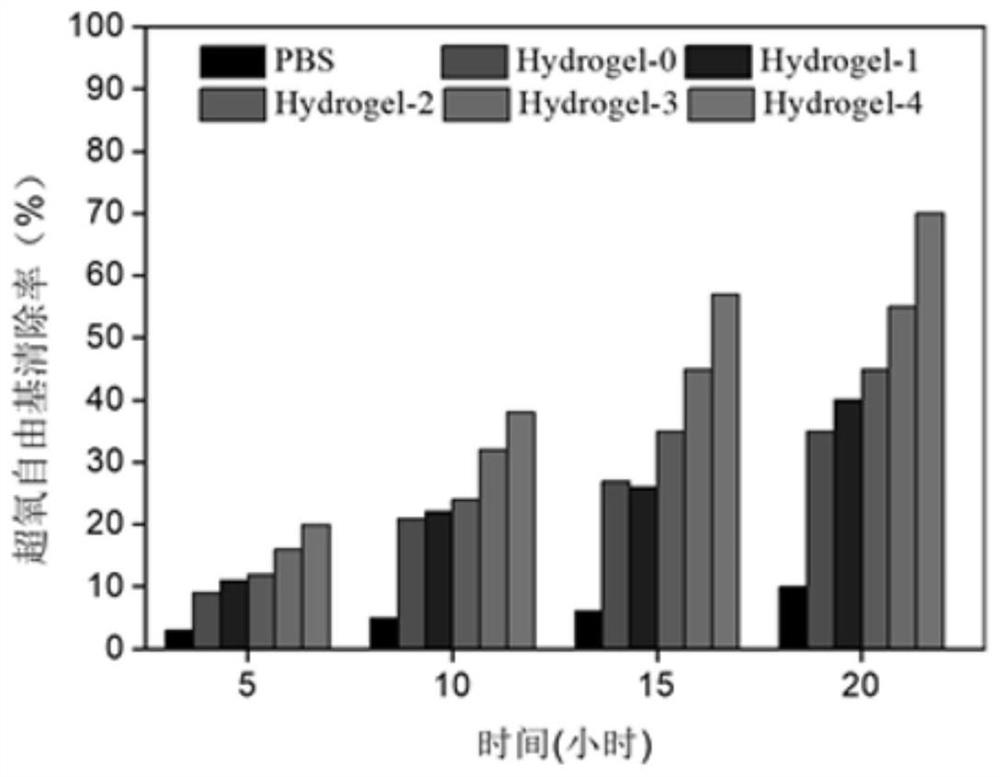

Copper metal organic framework nanoparticle functionalized hydrogel, preparation method and application thereof

ActiveCN112250887AGood mechanical propertiesLow cytotoxicityBandagesPolyethylene glycolMetal-organic framework

The invention discloses a copper metal organic framework nanoparticle functionalized hydrogel, a preparation method and application thereof. The preparation method comprises the following steps: dissolving carboxymethyl chitosan, and adding reduced glutathione and N-hydroxysuccinimide which are mixed and dissolved in deionized water; adding 1-(3-dimethylaminopropyl)-3-ethyl carbodiimide hydrochloride to prepare glutathione modified carboxymethyl chitosan; preparing copper metal organic framework nanoparticles; then mixing the copper metal organic framework nanoparticles with deionized water; and adding the glutathione modified carboxymethyl chitosan, acrylamide, polyethylene glycol diacrylate, polyethylene glycol diglycidyl ether and an initiator to prepare the copper metal organic framework functionalized hydrogel. According to the invention, the obtained hydrogel has the capabilities of slowly and controllably releasing copper ions, removing active oxygen of a wound surface, always keeping the wound surface free of hydrops and a wet 3D microenvironment, protecting the wound from external injury and promoting wound healing.

Owner:SOUTH CHINA UNIV OF TECH

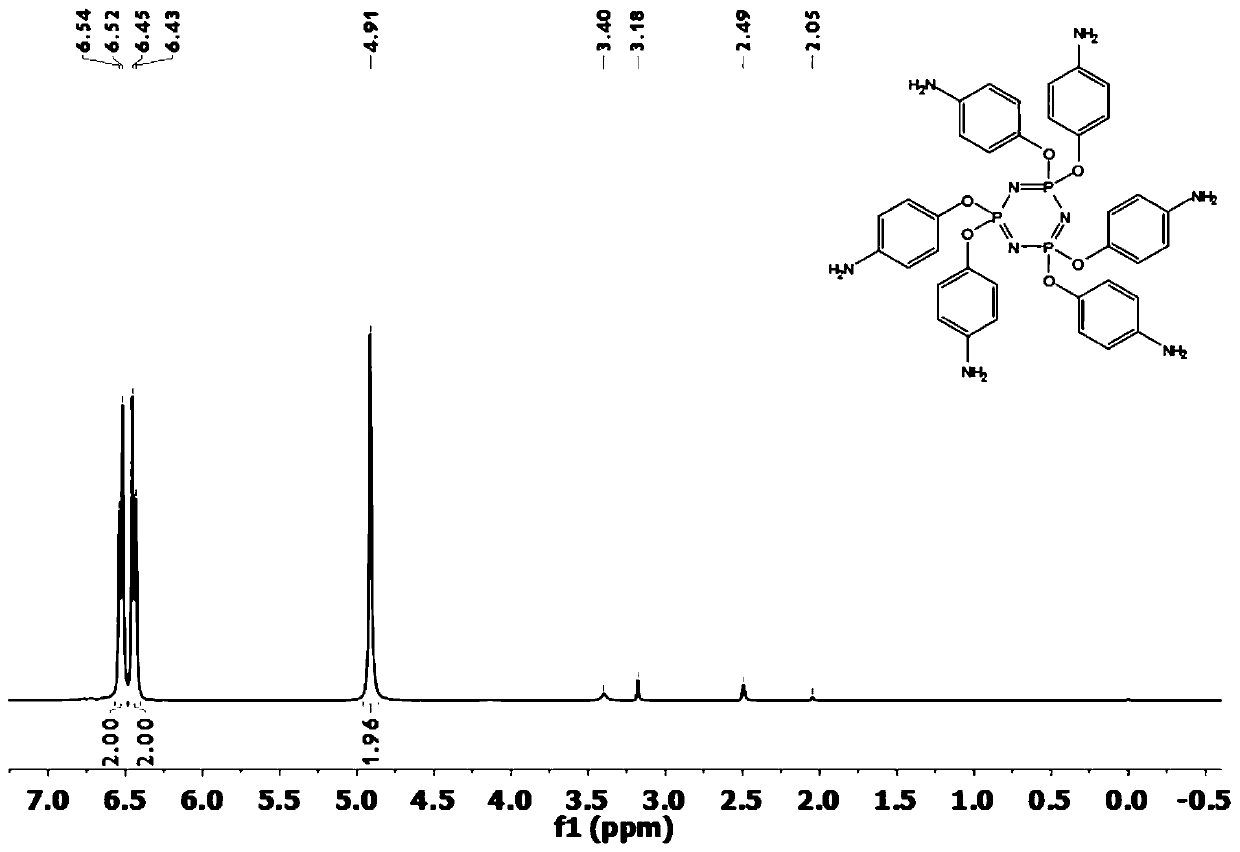

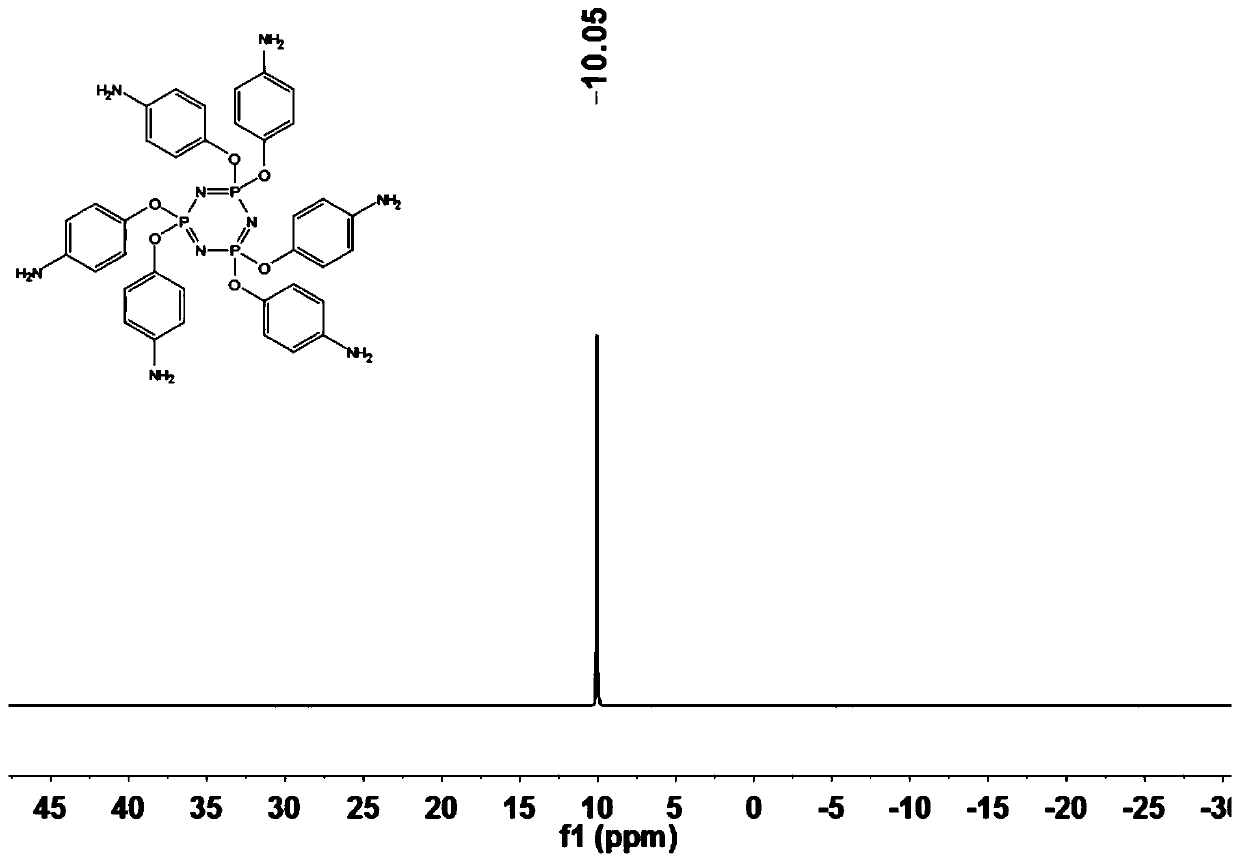

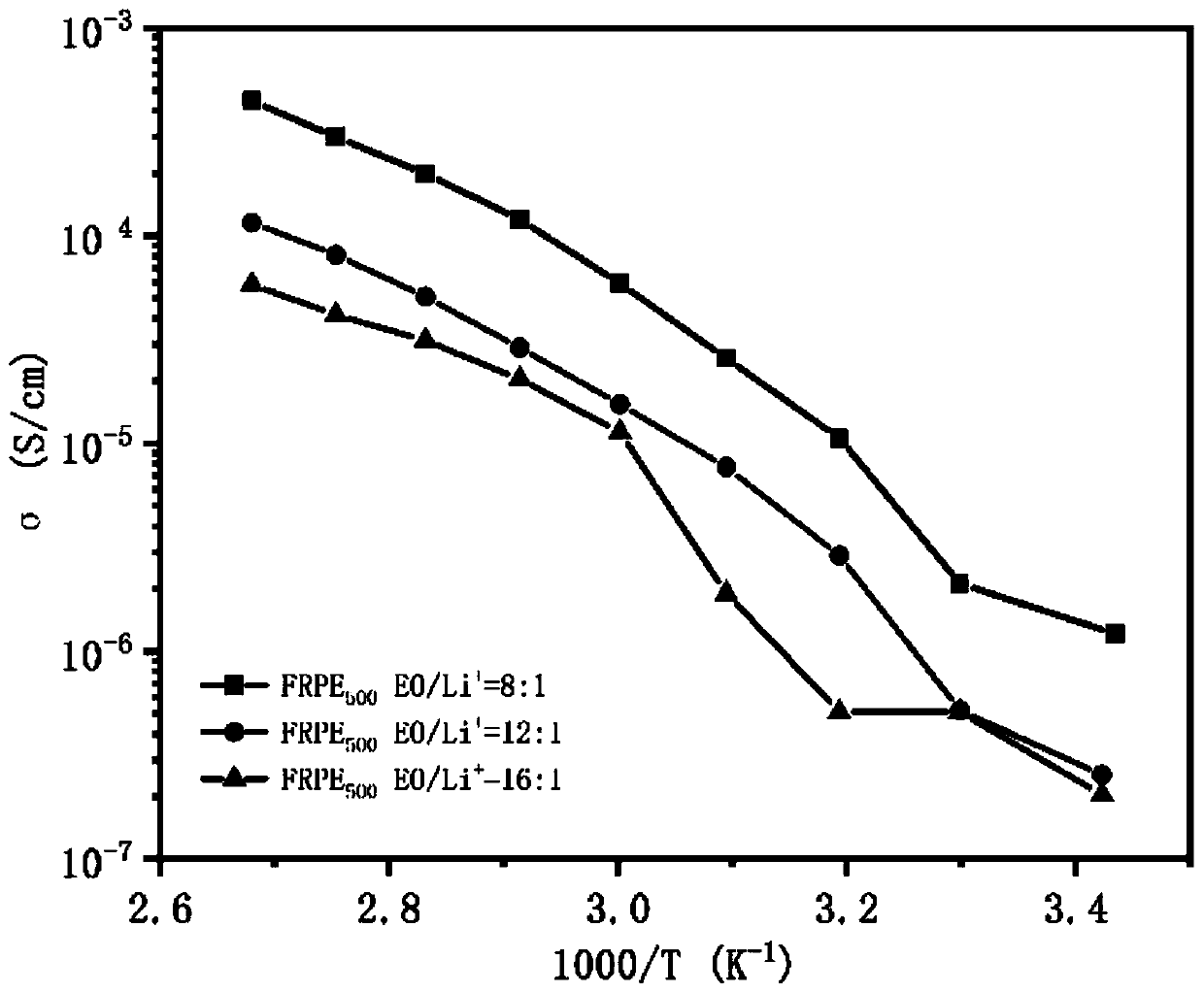

Polymer electrolyte with flame retardant function and preparation and application thereof

InactiveCN110380118AGood flexibilityImprove mechanical propertiesSolid electrolytesSecondary cellsCross-linkPolymer science

The invention belongs to the field of polymer electrolytes, and discloses a polymer electrolyte with a flame retardant function and preparation and application thereof. The polymer electrolyte comprises a metal salt and a cross-linked polymer formed by taking hexaphenol amino cyclophosphazene as an inner core and polyethylene glycol diglycidyl ether as a cross-linking arm, wherein the chemical structural formula of the cross-linked polymer is shown in the description, and n is an integer ranging between 4 and 113. By improving the key structure and composition of the polymer electrolyte and the overall process design of the corresponding preparation method, the polymer electrolyte which can be applied to metal ion batteries such as lithium-ion batteries and has the flame retardant functionis obtained. Compared with the prior art, the safety problems such as low ionic conductivity, poor mechanical performance and easy combustion and explosion of the polymer electrolyte can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

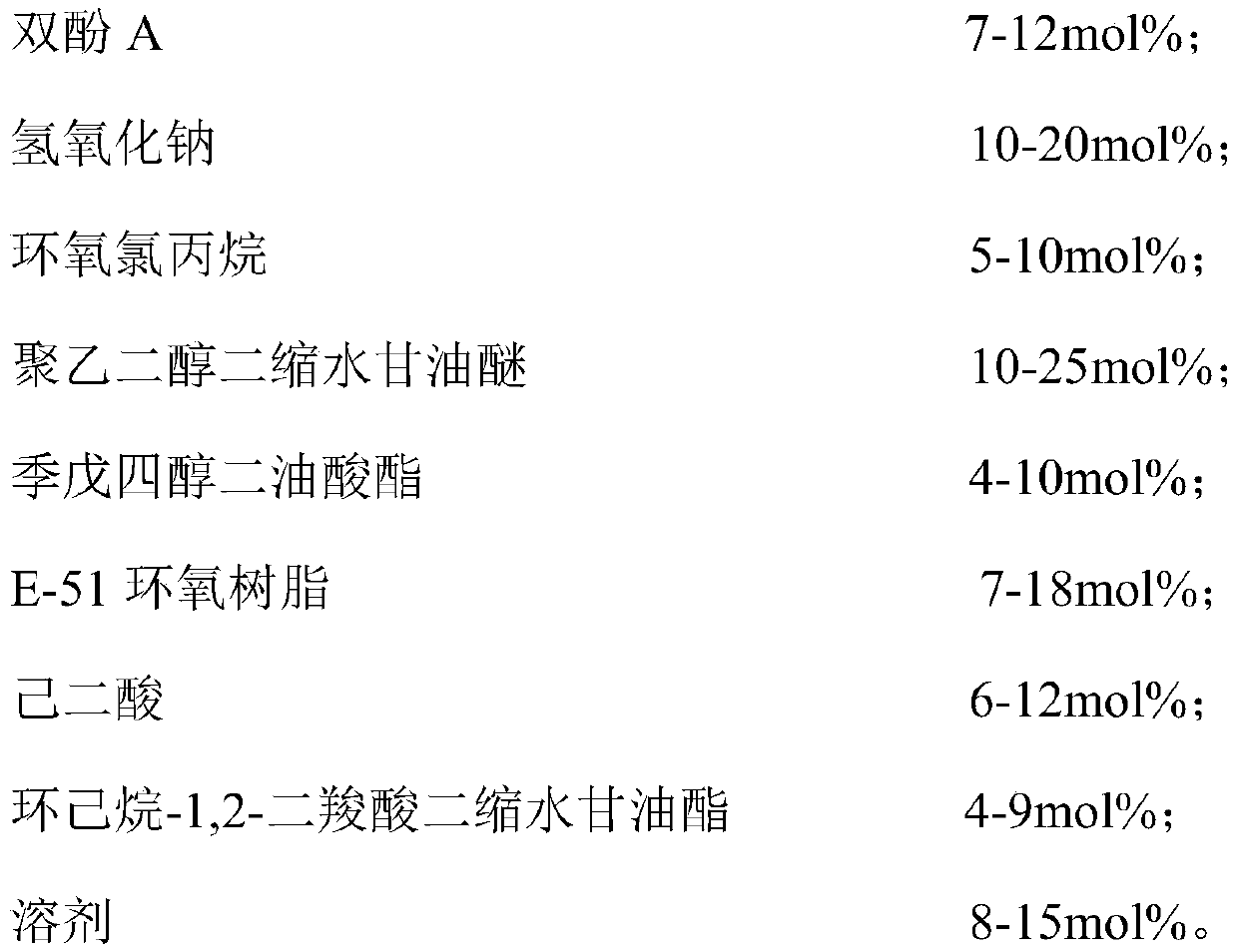

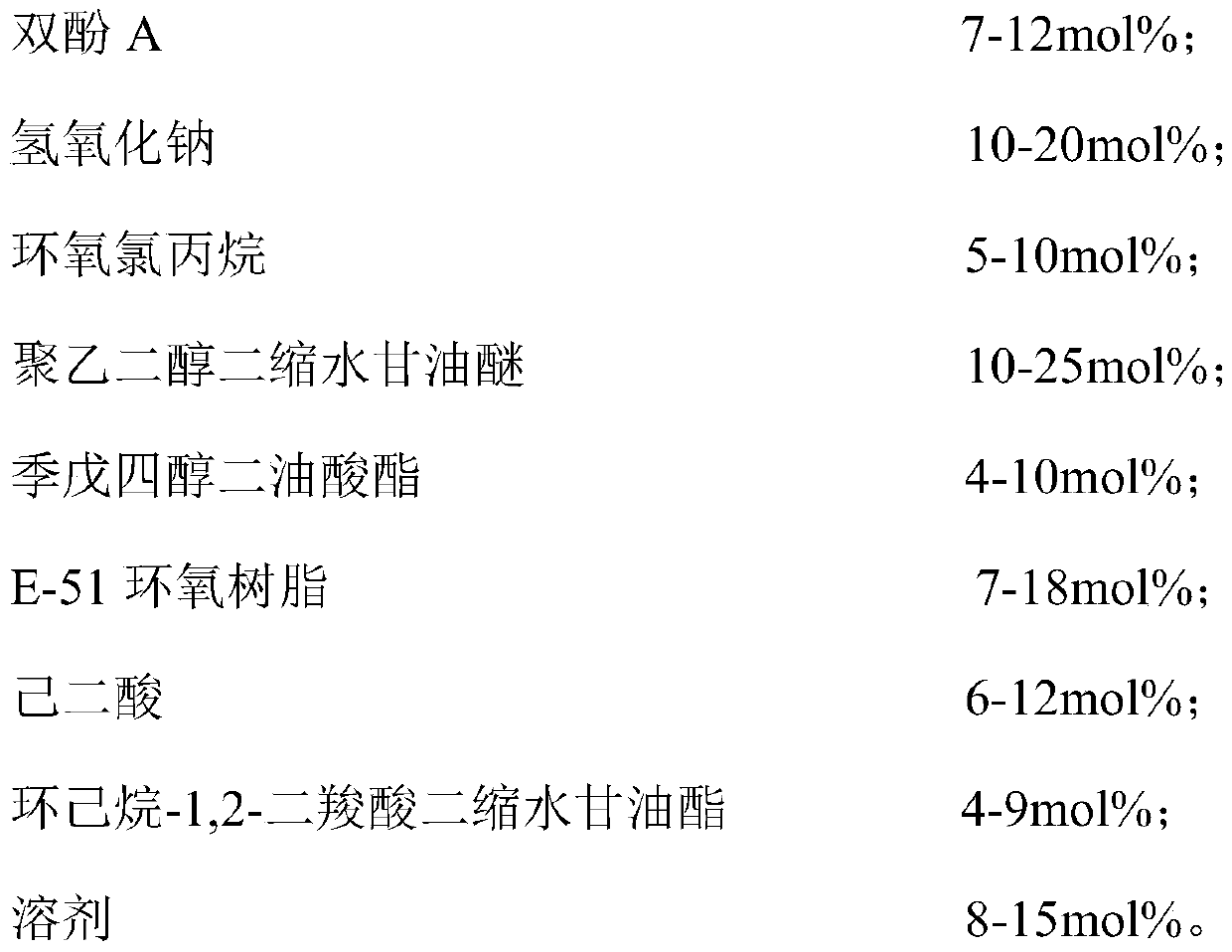

Epoxy resin for 50: 50 indoor powdery paint with high leveling grade, and preparation method thereof

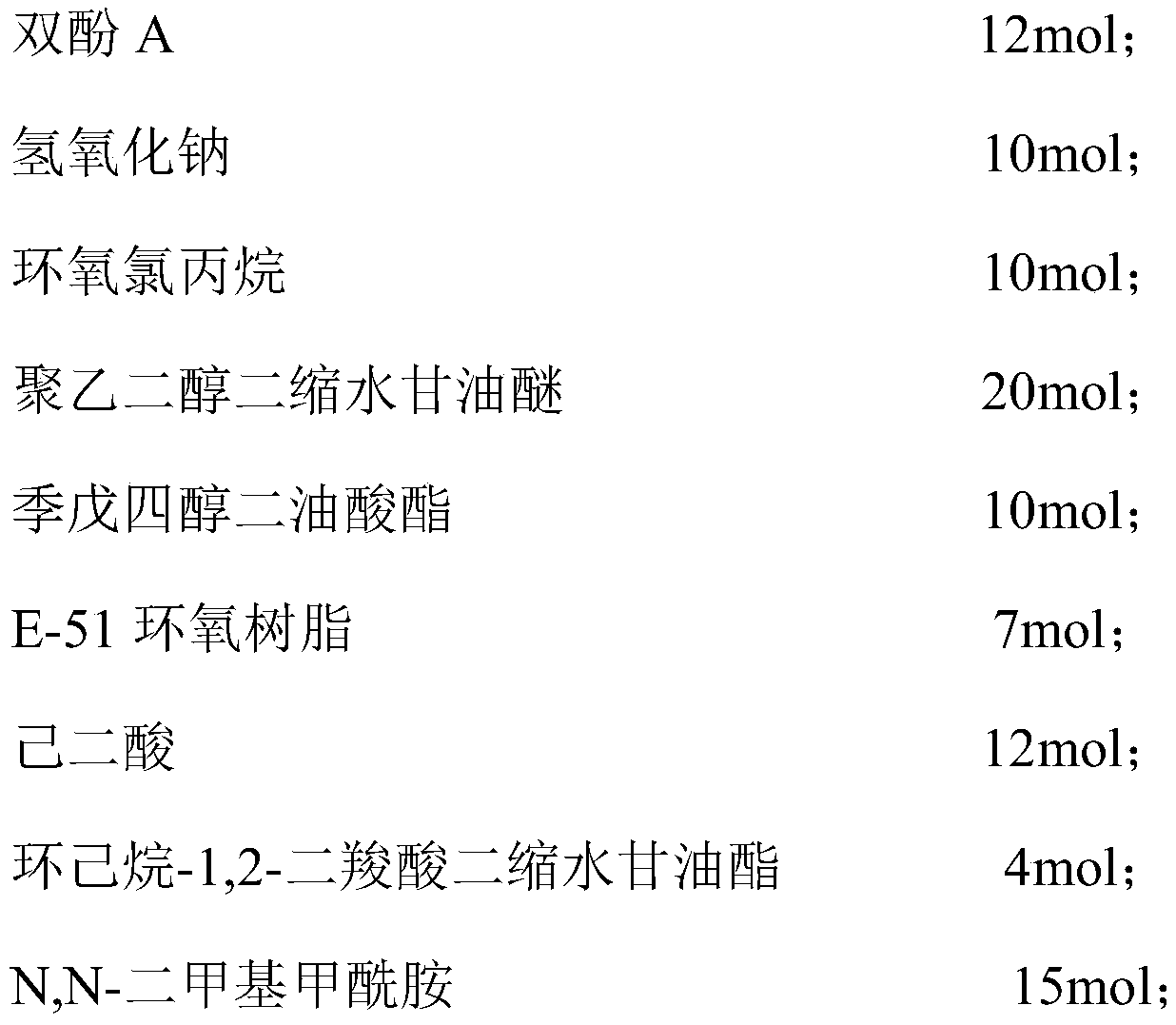

ActiveCN110423539AImprove the level ofSimple structurePowdery paintsEpoxy resin coatingsN dimethylformamideAdipic acid

The invention specifically relates to epoxy resin for a 50: 50 indoor powdery paint with a high leveling grade and further discloses a preparation method thereof, belonging to the technical field of powdery paints. The epoxy resin for the 50: 50 indoor powdery paint with a high leveling grade is prepared through polymerization of bisphenol A, epichlorohydrin, sodium hydroxide, polyethylene glycoldiglycidyl ether, pentaerythritol dioleate, E-51 epoxy resin, adipic acid, cyclohexane-1,2-dicarboxylic acid diglycidyl ester and N,N-dimethylformamide. The synergistic action among the raw materialsensures that the produced epoxy resin has excellent overall performance such as impact resistance, excellent adhesion, water resistance, etc. The epoxy resin is finally applied to the 50:50 indoor powdery paints and allows a coating with excellent comprehensive performance and a high leveling grade to be obtained.

Owner:黄山五环科技有限公司

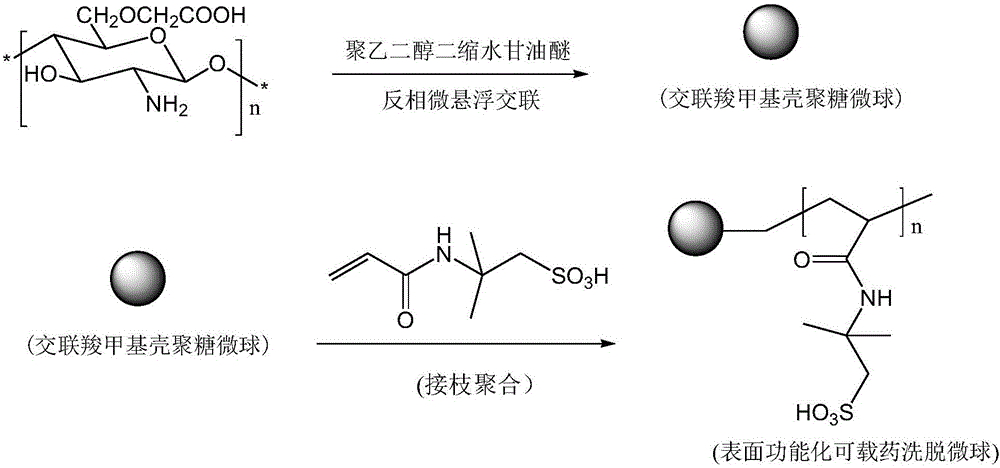

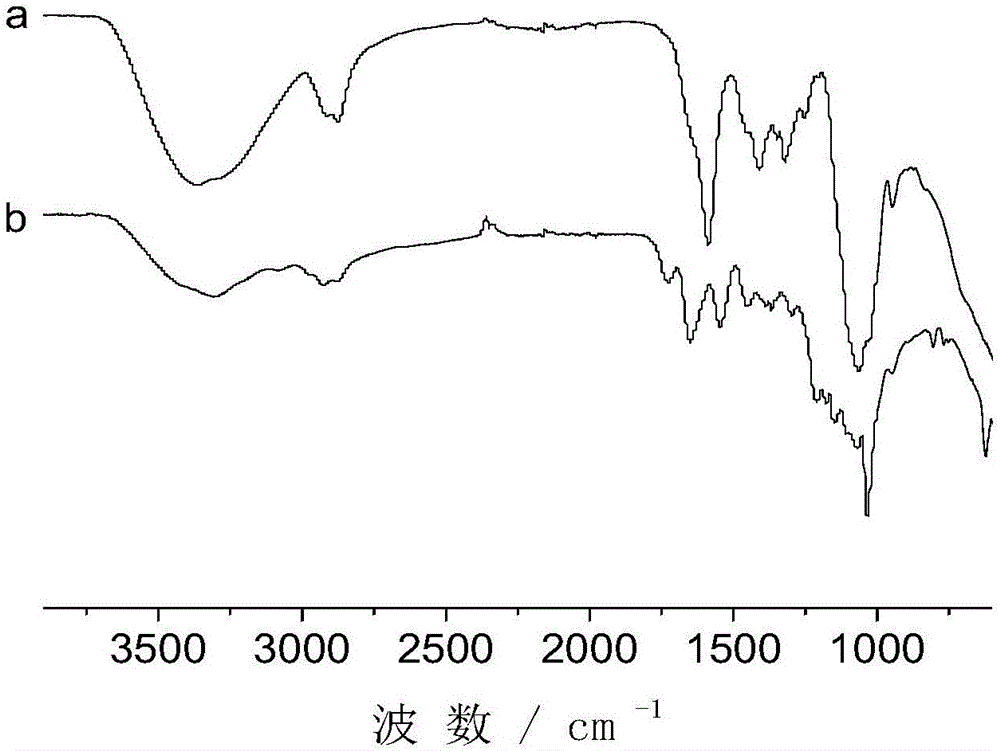

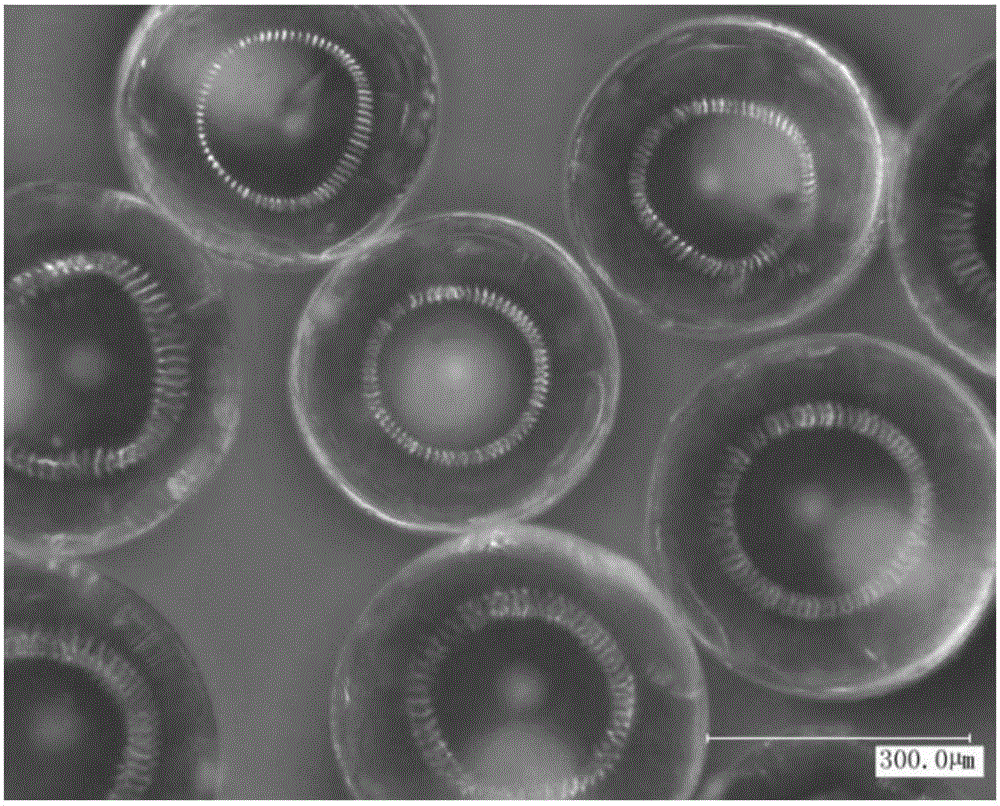

Preparation method of surface-functionalized elution micro-spheres capable of carrying drugs

ActiveCN106110334ALow priceEasy to getOrganic active ingredientsPharmaceutical non-active ingredientsCross-linkPolyethylene glycol

The invention discloses a preparation method of surface-functionalized elution micro-spheres capable of carrying drugs, relating to the field of bio-medical materials. The preparation method comprises the following steps: (1) by taking carboxymethyl chitosan as a raw material and polyethylene glycol diglycidyl ether as a cross-linking agent, preparing cross-linking carboxymethyl chitosan micro-spheres of which the particle sizes are mainly distributed in 300-400mu m by a reverse micro-suspension cross-linking method; and (2) putting the prepared dry cross-linking carboxymethyl chitosan micro-spheres into an aqueous solution of 2-acrylamide-2-methylpropanesulfonic acid for soaking, and carrying out graft polymerization on the 2-acrylamide-2-methylpropanesulfonic acid on the surfaces of the micro-spheres by taking ammonium ceric nitrate as an initiator, so as to modify the micro-spheres. As the surfaces of the micro-spheres, modified by graft polymerization, have a large number of sulfonic acid groups, drugs with positive charges, such as doxorubicin hydrochloride, can be effectively carried, so that the elution micro-spheres can be hopefully prepared.

Owner:CHANGSHA JINGYI PHARM TECH CO LTD

Preparation method of water-borne epoxy resin coating

InactiveCN107828311AHigh hardnessImprove impact resistanceEpoxy resin coatingsEpoxyPoly(ethylene glycol) diglycidyl ether

The invention relates to a preparation method of a water-borne epoxy resin coating, and relates to the coating preparation field, and particularly relates to the preparation method of the water-borneepoxy resin coating. The method includes steps of adding triethylene tetramine in a 250 mL four-opening flask; rising temperature to 65 DEG C and then stirring while slowly dropwise adding polyethyleneglycol diglycidyl ether under constant temperature; performing constant temperature reaction; slowly dropwise adding the solvent dissolved epoxy resin in a reaction product prepared in step one; after dropping completely, continuing the constant temperature reaction for 3 hours; dropwise adding end-capping reagent in a chain expanding reaction product; after dropping, performing the constant temperature reaction for 1 hour; adding distilled water, and stirring for 0.5 hour and then stopping reaction; preparing the self-emulsified water-borne epoxy resin curing agent. The preparation method issimple in technical flow, safe in operation, and gentle in reaction; the production efficiency and product quality are greatly improved, the production cost is reduced; the processed product has goodlead hardness, impact resistance, adhering property, water resistance and chemical goods resistance; moreover, the service life is long.

Owner:SHAANXI QIYUAN TECH DEV

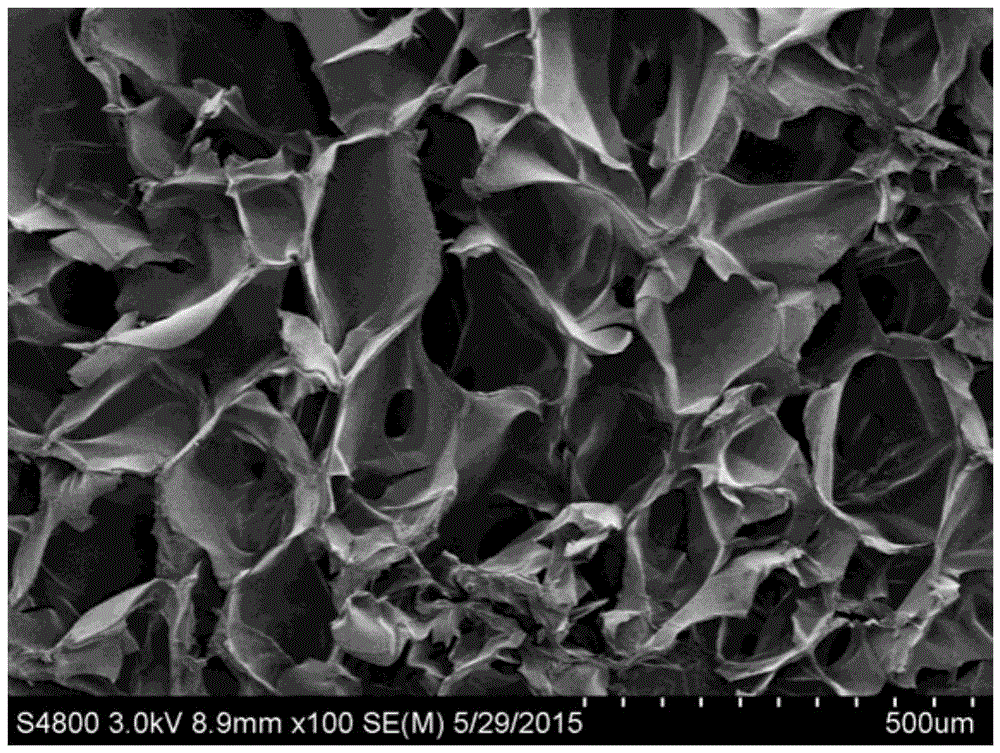

Graphene nano composite material and preparation method thereof

InactiveCN107245224ADifficult to uniform dispersion can be controlledSmall steric hindranceMaterial nanotechnologyAntifouling/underwater paintsDispersityGraphene nanocomposites

The invention discloses a graphene nano composite material. The preparation method of the graphene nano composite material comprises the following steps: (1) preparing a graphite oxide suspension; (2) performing a reaction on the graphite oxide suspension and a copper lysine complex, adding hydrazine hydrate and NaBH4, and performing reduction; (3) adding disodium EDTA to remover copper; (4) mixing the product obtained in the step (3), an E-42 epoxy resin, ethylene glycol diglycidyl ether, poly(ethylene glycol) diglycidyl ether, KH560 and nano boehmite, and performing ultrasonic dispersion; and (5) performing a reaction on the product obtained in the step (4), C12-C14 aliphatic glycidyl ethers, nano titanium dioxide, glass microspheres and camphor at 70-80 DEG C for 2-3 hours. The graphene nano composite material disclosed by the invention effectively solves the problem of dispersity in graphene; the adhesive force, wear resistance and antibacterial effect of the composite material are enhanced; and the graphene nano composite material can be used for preparing environment-friendly paints.

Owner:成都玺旺科技有限公司

High-transparency and low-cost polylactic acid composite material and preparation method thereof

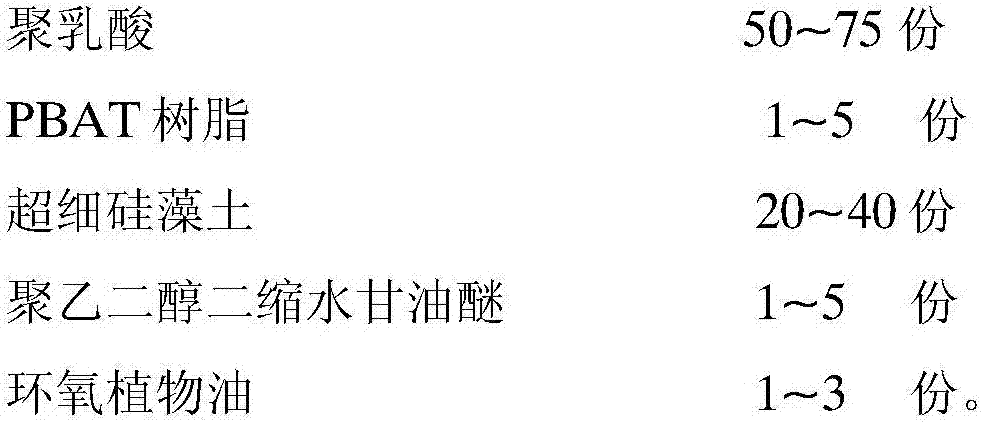

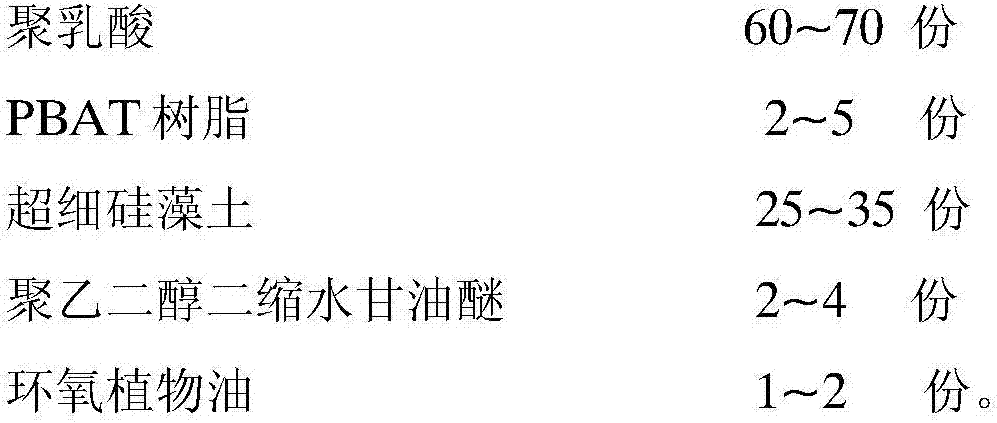

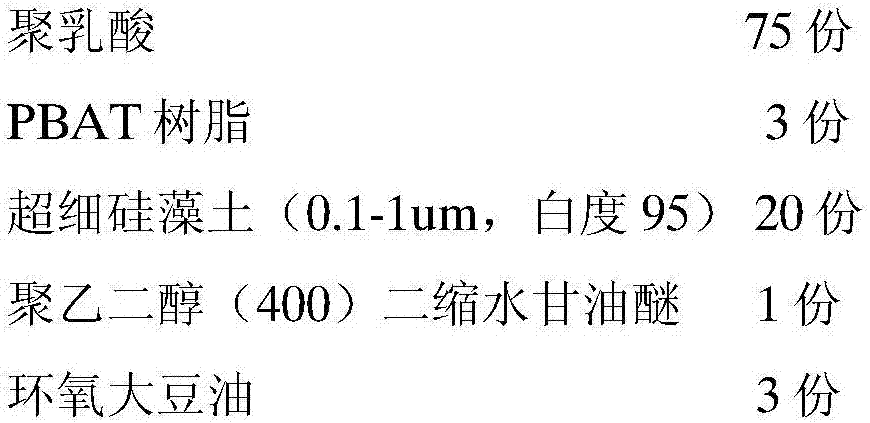

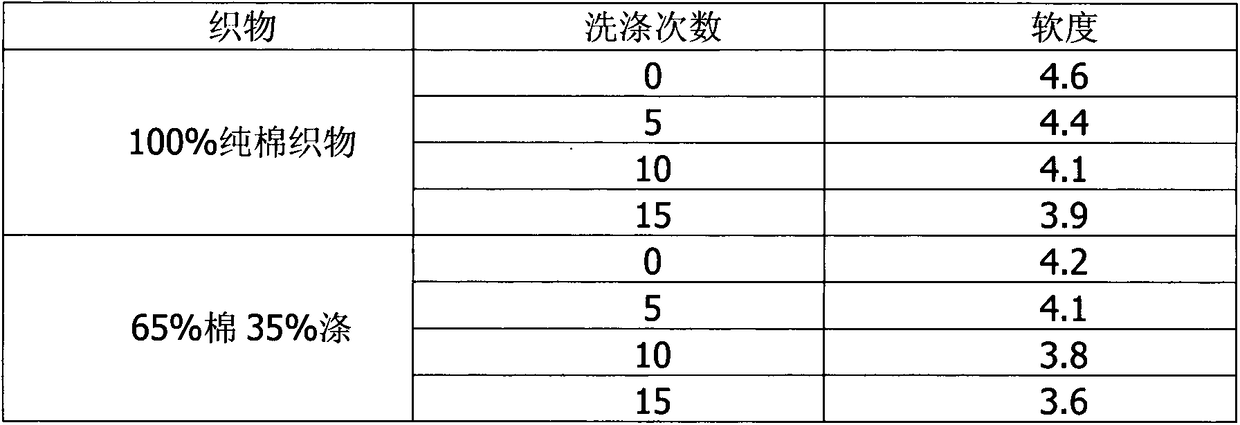

ActiveCN107312295AEvenly dispersedHigh transparencyVegetable oilPoly(ethylene glycol) diglycidyl ether

The invention relates to a high-transparency and low-cost polylactic acid composite material, which contains, by weight, 50-75 parts of polylactic acid, 1-5 parts of PBAT resin, 20-40 parts of ultrafine diatomaceous earth, 1-5 parts of polyethylene glycol diglycidyl ether, and 1-3 parts of epoxy vegetable oil. According to the present invention, the disclosed polylactic acid composite material can maintain the high transparency under the premise of the maintaining of the high proportion of the filler so as to reduce the application cost of the polylactic acid; and the polylactic acid composite material has advantages of excellent transparency, excellent mechanical property, high whiteness, environment friendliness, and simple preparation.

Owner:NINGBO HOMELINK ECO ITECH CO LTD

Method for manufacturing quaternary ammonium salt terminated hydrophilic block silicone oil

The invention discloses a method for manufacturing quaternary ammonium salt terminated hydrophilic block silicone oil. According to the method, an organic silicon annulus and an epoxy-terminated silicone oil chain extender are adopted, linear silicone oil with epoxy groups at both ends is prepared through an equilibration reaction in an alkaline catalyst, the linear silicone oil is then subjectedto block copolymerization with polyethylene glycol diglycidyl ether and 3-dimethylamino-1-propylamine in an isopropanol solvent to obtain tertiary amine-terminated block silicone oil, and glacial acetic acid is finally added to react with the tertiary amine-terminated block silicone oil to prepare quaternary ammonium salt-terminated hydrophilic block silicone oil. The method provided by the invention is simple to operate, the raw materials are simple and easy to obtain, and a finished fabric not only has a smooth hand feeling, but also has a permanent hydrophilic effect, and has a broad marketprospect.

Owner:SHEYANG TIANYUAN CHEM IND CO LTD

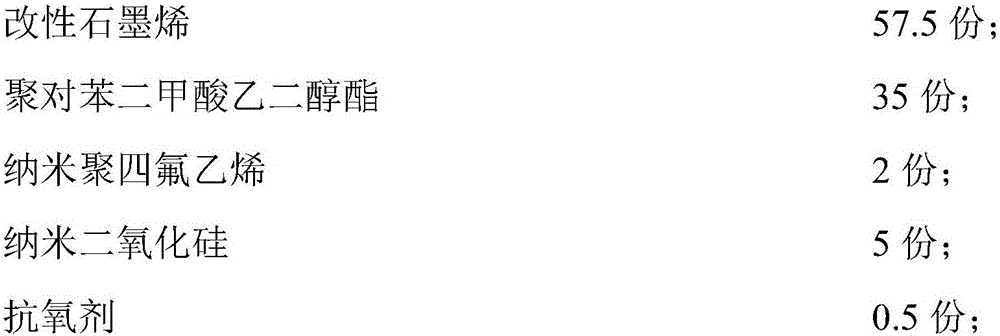

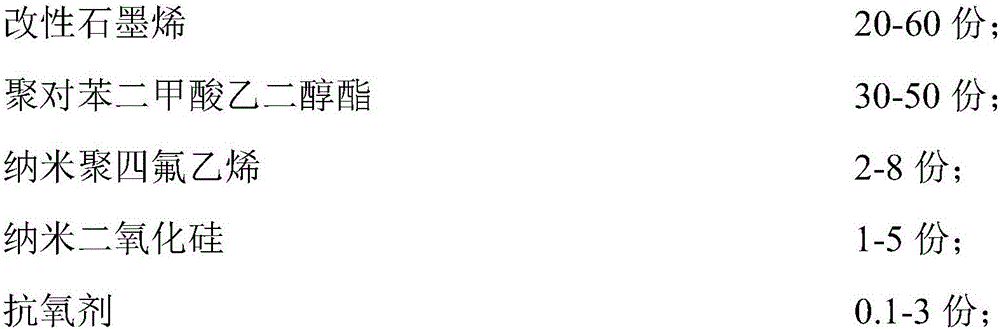

Graphene 3D printing material and preparation method thereof

ActiveCN106751587AGood flexibilityImprove mechanical propertiesAdditive manufacturing apparatusPoly(ethylene glycol) diglycidyl etherAntioxidant

Owner:深圳市明鑫高分子技术有限公司

Solvent-free flexible anticorrosion epoxy coating material, preparation method thereof and using method thereof

InactiveCN103788735AViscosity change rate is smallImprove flexibilityAnti-corrosive paintsGlycidyl methacrylatePoly(ethylene glycol) diglycidyl ether

The invention provides a solvent-free flexible anticorrosion epoxy coating material, a preparation method thereof and a using method thereof. The epoxy coating material comprises 45-60 parts by weight of epoxy resin, 10-15 parts by weight of a reactive diluent, 10-13 parts by weight of aluminium triphosphate, 7-10 parts by weight of glass flake, 2-3 parts by weight of wetting and dispersing auxiliaries and 10-14 parts by weight of a filling material, wherein the epoxy resin comprises 30-40 parts by weight of bisphenol A resin having an epoxide number of 0.54 and 15-20 parts by weight of bisphenol A resin having an epoxide number of 0.42, and the reactive diluent comprises 4-8 parts by weight of poly(ethylene glycol) diglycidyl ether and 6-7 parts by weight of glycidyl methacrylate. Compared with the prior art, the epoxy coating material has advantages of no solvent and zero VOC discharge, improves durability and brittleness of epoxy coatings and prolongs the durable time and anticorrosion age limit of the epoxy coatings, and therefore the epoxy coating material is environmental-friendly, flexible, long-acting and anticorrosion.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Preparation method of adsorbing material based on natural polysaccharides

InactiveCN105457604AHigh mechanical strengthImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionPoly(ethylene glycol) diglycidyl etherHydrogen

The invention relates to a preparation method of an adsorbing material based on natural polysaccharides. According to the method, nano clay particles and hemicellulose polysaccharides separated from agricultural waste cornstalks are used as raw materials and have chemical crosslinking with polyethylene glycol diglycidyl ether under the mild alkaline condition, the adsorbing material adopting a three-dimensional net structure is prepared, and the adsorbing material based on the natural polysaccharides is obtained. Compared with the prior art, the method has the advantages that the material has the efficient adsorbing effect on methylene blue dye ions in water, and the adsorbing capacity can be adjusted through factors such as the adsorbing temperature, pH (potential of hydrogen), initial concentration of dye ions, the usage amount of nano clay and the like. The source of the raw materials adopted by the adsorbing material is wide, the cost is low, the preparation technology is simple and reliable, and the adsorbing material has broad application prospect in the field of dye wastewater treatment.

Owner:TONGJI UNIV

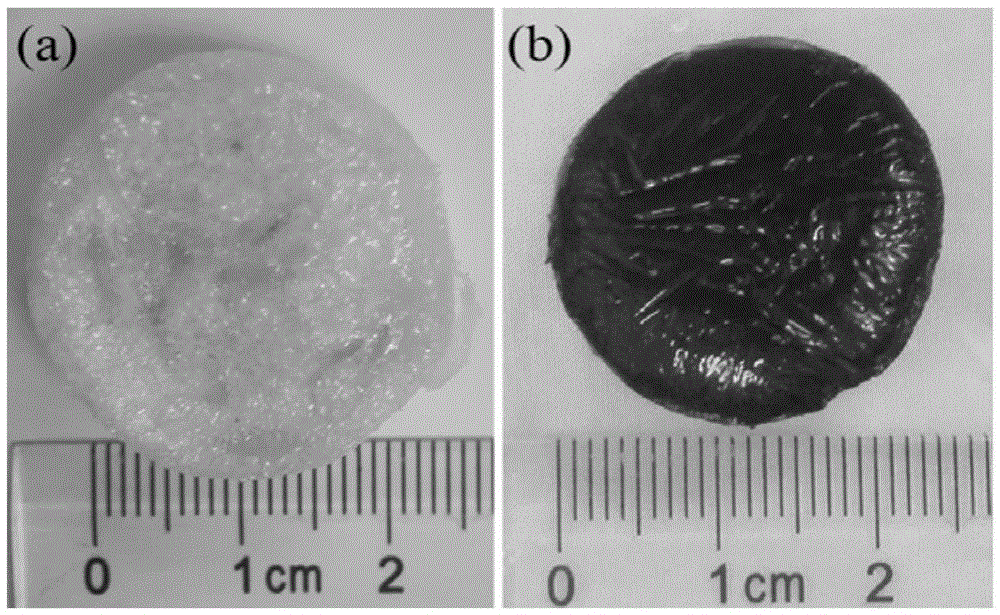

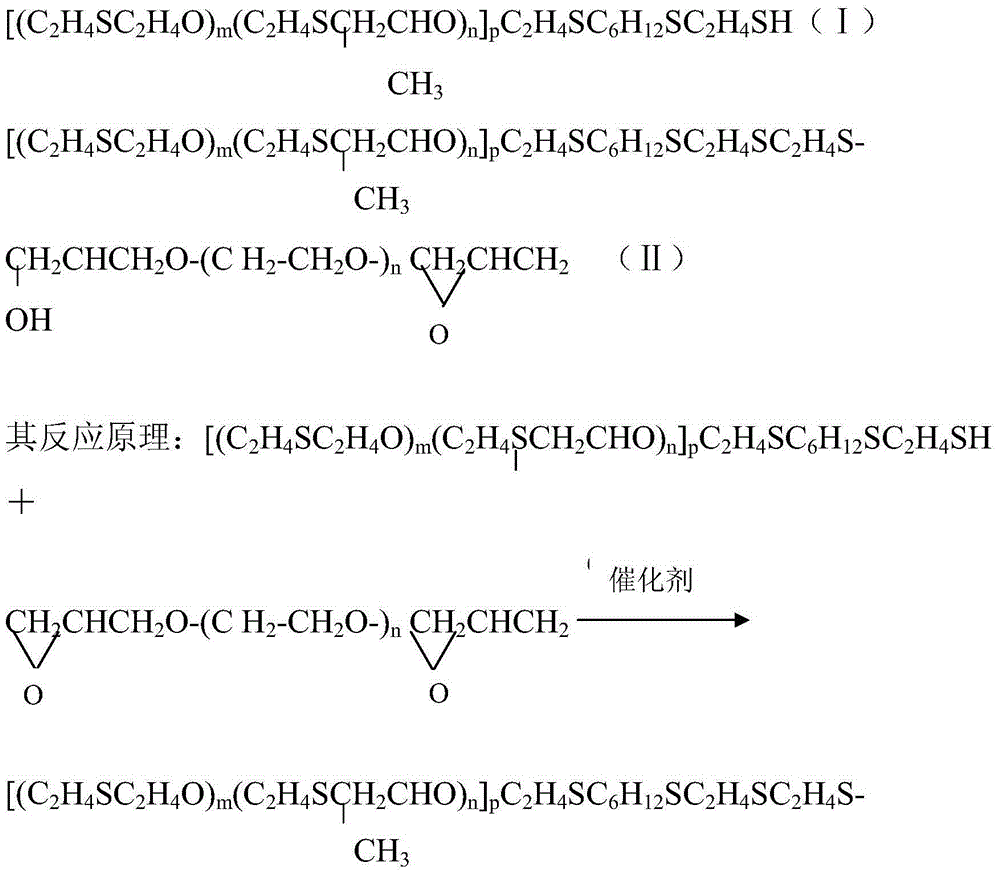

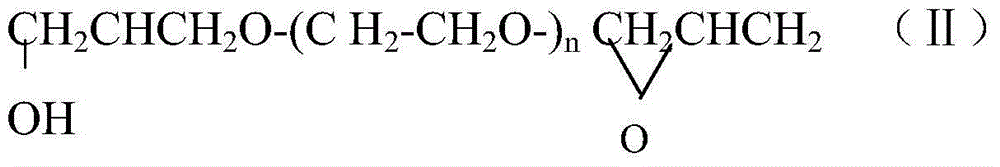

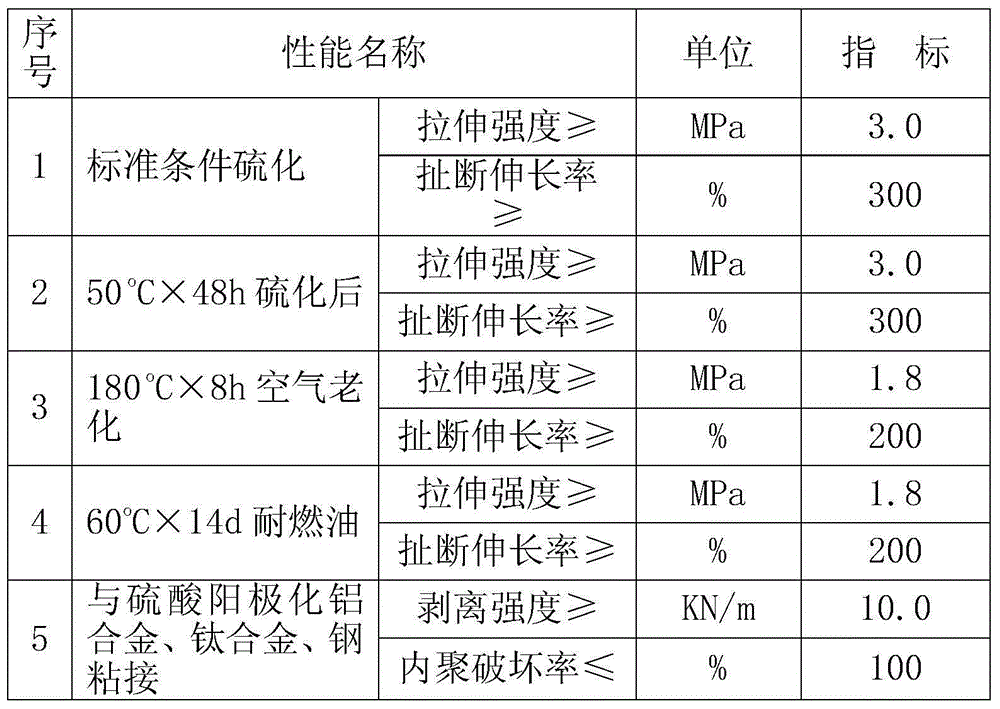

Synthetic method for epoxy end group polythioether liquid rubber

ActiveCN104558584AModerate viscosityGood adhesionPoly(ethylene glycol) diglycidyl etherHeat resistance

The invention discloses a synthetic method for epoxy end group polythioether liquid rubber. The method comprises the following steps: synthesizing sulphydryl end group polythioether liquid rubber by using thiodiglycol, hydroxyethyl-2-hydroxypropyl thioether and the like as main monomers; then using polyethylene glycol diglycidyl ether resin as a transforming agent so as to transform a sulphydryl end group into an epoxy end group so as to finally generate the end group polythioether liquid rubber. The technology has the advantages that the polyethylene glycol diglycidyl ether resin is adopted as the transforming agent of the end group, the defects that the viscosity of a sulphydryl in traditional epoxy modification technology is high, solvents of toluene, butanone and the like are needed to perform dilution, the reaction exotherm is violent, and a side effect is easy to generate are overcome; reactions are smooth, the product quality is easy to control, the viscosity of the generated epoxy end group polythioether liquid rubber is moderate, and the stability is good; the strength of epoxy resin and the toughness and the heat resistance of polythioether rubber are reserved after the end group is transformed, so that the brittleness of the epoxy resin is improved, and the adhesive property of materials is improved.

Owner:锦西化工研究院有限公司

Functionalized quantum dot composite solid electrolyte membrane and preparation method and application thereof

ActiveCN110504486AImprove mechanical propertiesEasy to makeSolid electrolytesLi-accumulatorsSolid state electrolytePolyethylene oxide

Owner:河南景创新能源科技有限公司

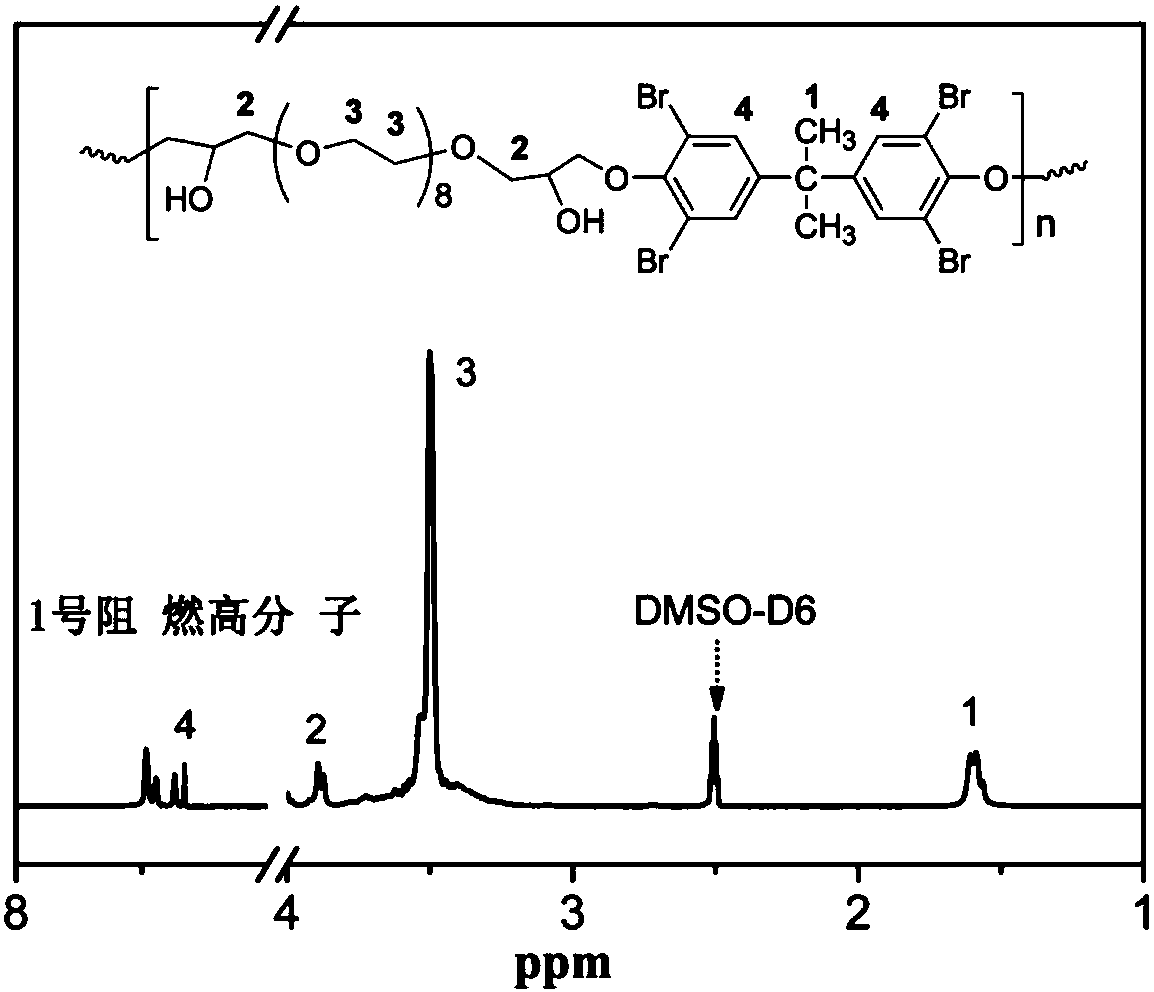

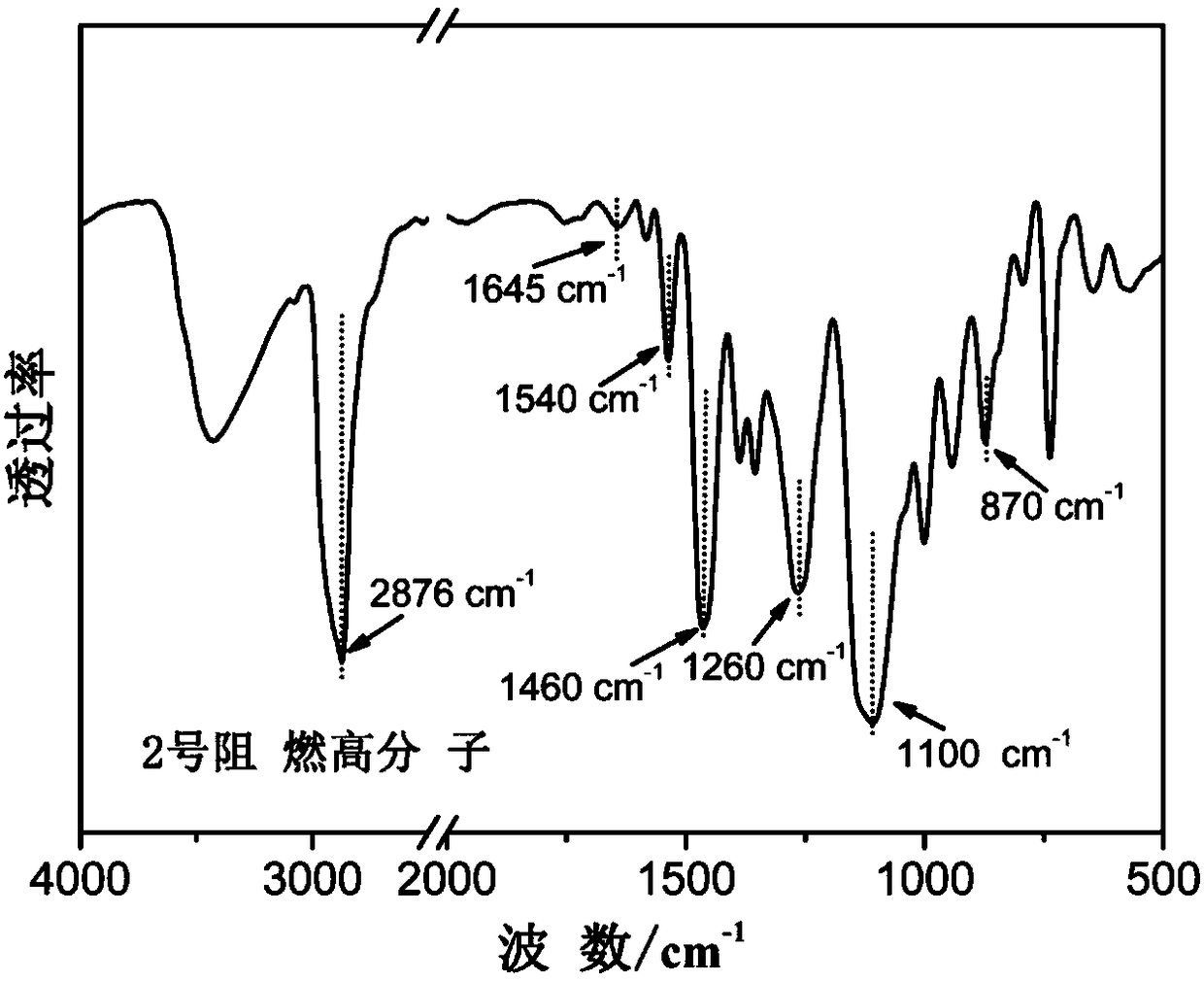

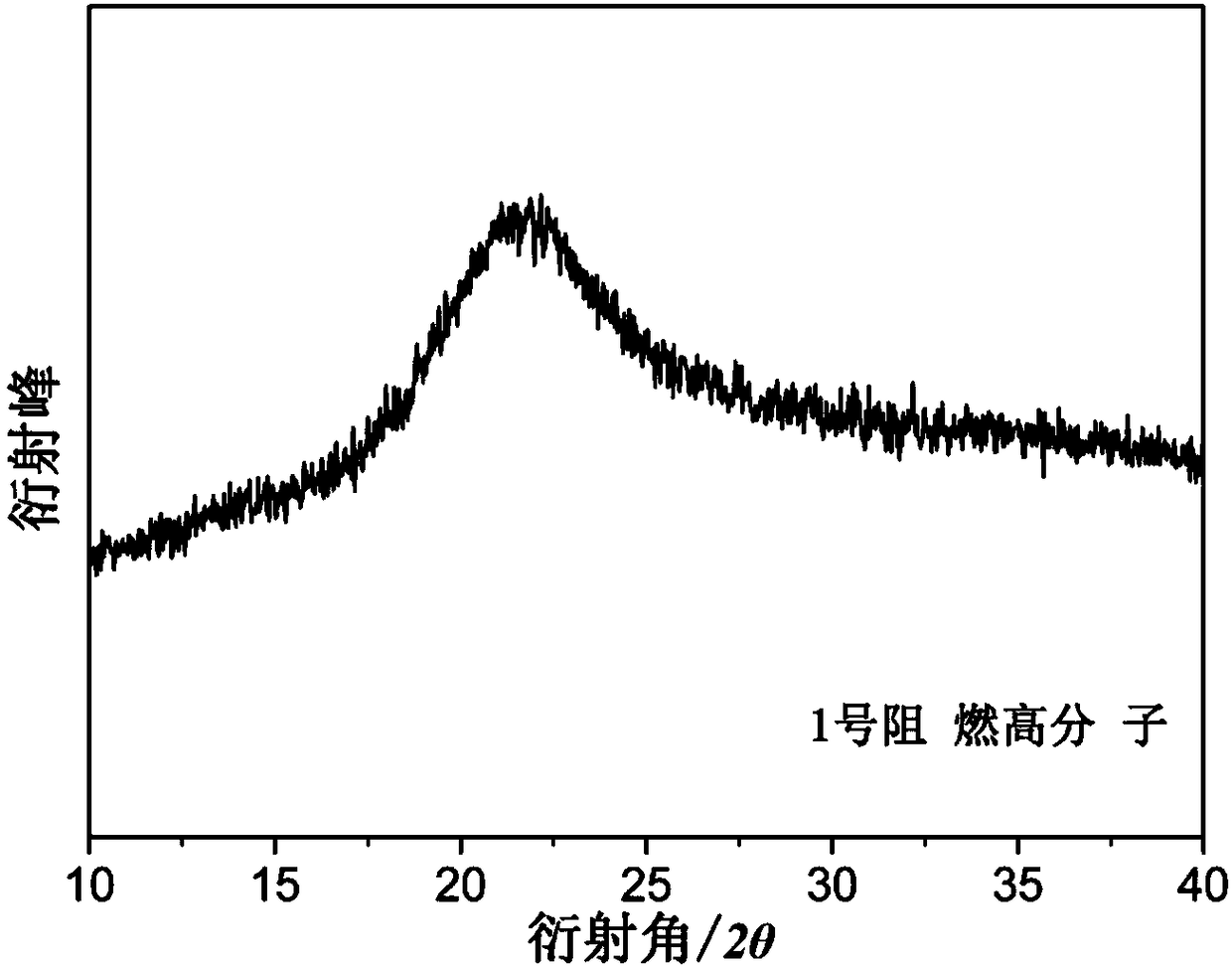

Flame-retardant gel electrolyte, preparation method and application of flame-retardant gel electrolyte in lithium ion battery and supercapacitor

ActiveCN108598567AReduce the possibility of leaksFacilitate conductionSolid electrolytesHybrid capacitor electrolytesTetrabromobisphenol APolyethylene glycol

The invention relates to an organic flame-retardant gel electrolyte, a preparation method and an application of the flame-retardant gel electrolyte in a lithium ion battery and a supercapacitor, and belongs to the technical field of electrolyte preparation. The gel electrolyte comprises the following components in parts by mass: 1 part of organic solvent, 0.1 to 1 part of electrolyte lithium saltand 0.1 to 3 parts of flame-retardant macromolecules. The flame-retardant macromolecules are obtained through heating open-loop polymerization reaction of tetrabromobisphenol A or tetrabromobisphenolA (bis(2-hydroxyethyl)ether) with a flame-retardant function and polyethylene glycol diglycidyl ether with a lithium ion conduction function and the number-average molecular weight being 500, 2000 or6000, and a reaction molar ratio is 1 to 1. The gel electrolyte prepared by the method has a better flame-retardant effect and ionic conductivity comparable to that of a liquid organic electrolyte, the electrolyte is gelled through the addition of the flame-retardant macromolecules, and the risk of electrolyte leakage is reduced, so that the use safety of the lithium ion battery and the supercapacitor is greatly improved, and the application prospect is wide.

Owner:JILIN UNIV

Preparation method of redox-sensitive reversible crosslinked nano micelle with reversible charges

ActiveCN106750376AMild and efficient responseImprove adsorption capacityPharmaceutical non-active ingredientsEmulsion deliveryProtonationCross-link

The invention relates to the technical field of biomedical materials. The method comprises the steps of firstly synthesizing a yellow gelatinous compound thiocinamide from lipoic acid and ethylenediamine under an N,N'-carbonyl diimidazole catalyst; carrying out polymerization by using thiocinamide, ethylene glycol diglycidyl ether and lysine through a nucleophilic addition mechanism to prepare a poly(lysine-co-ethylene glycol diglycidyl ether-co-thiocinamide) terpolymer, and then forming a zwitter-ion nano micelle in a selective solvent through self-assembly. The micelle can be endowed with excellent anti-protein nonspecific adsorption and enhanced cell uptake property through protonation / deprotonation action under different pH conditions; a disulfide bond in lipoyl can form a linear polydisulfide structure under the action of 1,4-dithiothreitol, so that a micelle core is crosslinked and a cross-linked structure is destroyed in the cell, and controlled release of a drug can be achieved. The nano micelle is expected to be a drug carrier for treating cancers.

Owner:JIANGNAN UNIV

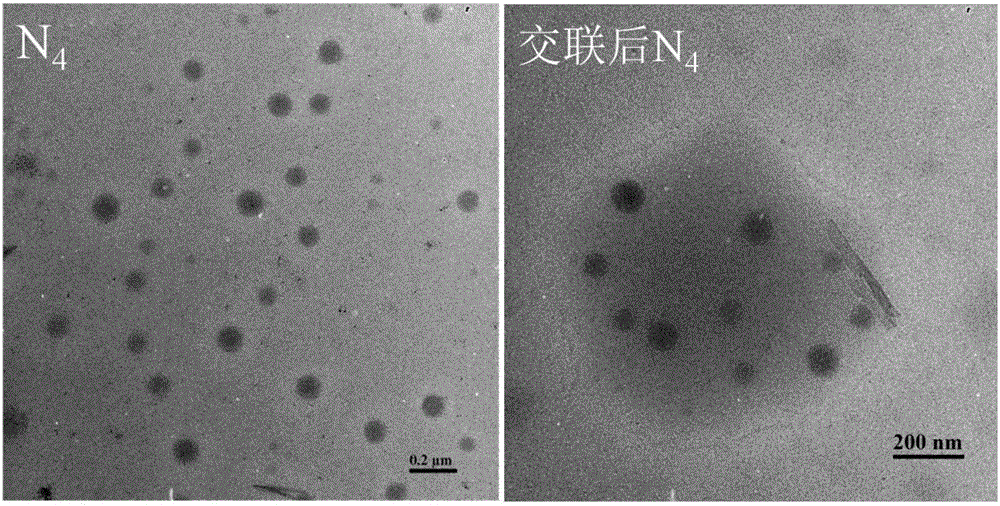

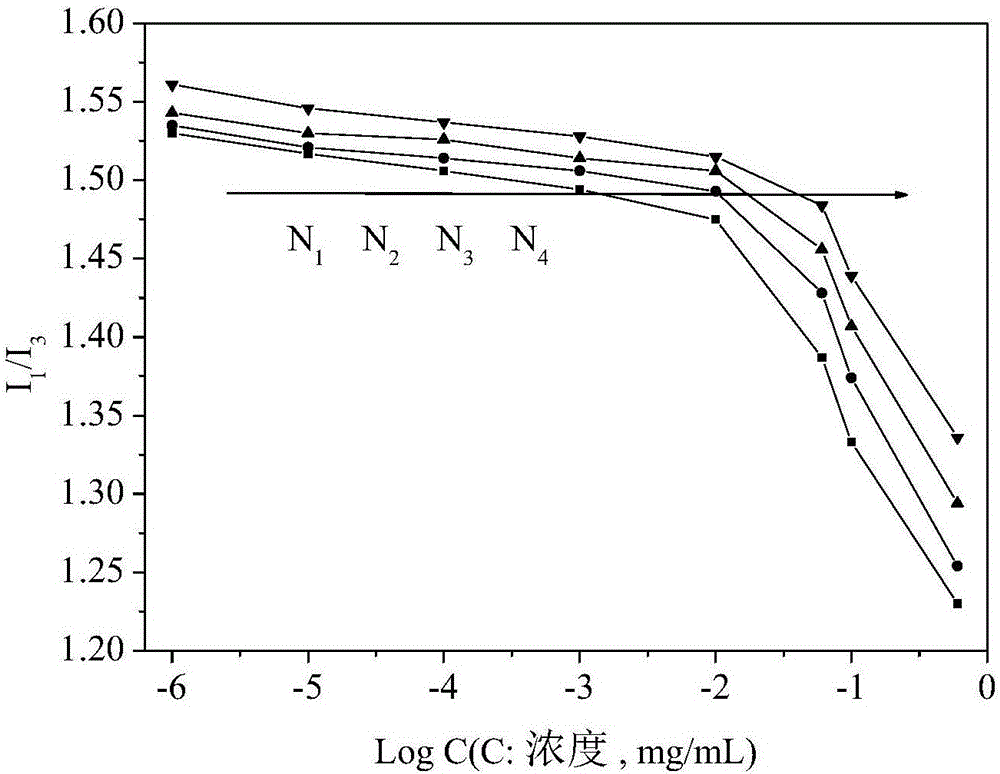

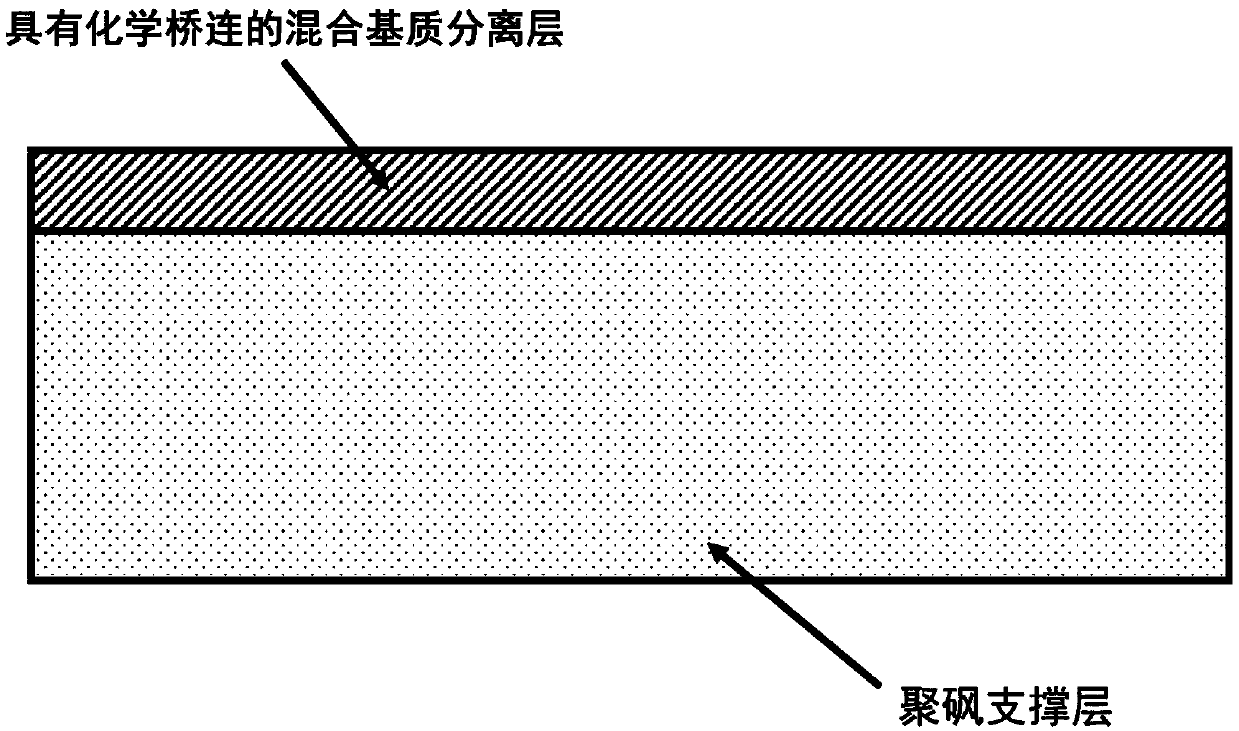

Method for preparing mixed matrix membrane for carbon dioxide separation through chemical bridging

ActiveCN109248571AExcellent permeation selectivityEasy to makeGas treatmentDispersed particle separationSeparation factorPoly(ethylene glycol) diglycidyl ether

The present invention relates to a method for preparing a mixed matrix membrane for carbon dioxide separation through chemical bridging. According to the present invention, nanoparticles and a polymerare bonded with a bridging agent polyethylene glycol diglycidyl ether through a chemical method to enhance the interfacial action force of UIO-66-NH2 and polyvinylamine, and by enhancing the interfacial action force, the interfacial compatibility of the nanoparticles UIO-66-NH2 and the polymer PVAm is improved to reduce the interface defect so as to obtain the mixed matrix membrane with high permeation selectivity, wherein the CO2 permeation rate reaches 1000 GPU under 0.11 MPa, and the CO2 / N2 separation factor reaches 70; and the preparation method has characteristics of simple preparation process, short operation time, easy implementation and low cost; and after the chemical bridging, the interface compatibility of the two phases is substantially improved while the gas separation membrane with excellent permeation selectivity is obtained.

Owner:TIANJIN UNIV

Antistatic anticorrosion paint for petroleum pipelines

InactiveCN102453359AStrong adhesionImprove anti-corrosion performanceAnti-corrosive paintsEpoxyPoly(ethylene glycol) diglycidyl ether

The invention discloses an antistatic anticorrosion paint for petroleum pipelines. The antistatic anticorrosion paint is prepared by stirring the following raw materials of: by weight, 50-55 parts of an epoxy resin, 36 parts of polyaspartic ester, 26 parts of an static conductive auxiliary agent, 20 parts of di-n-butyl, 12 parts of polyethyleneglycol diglycidylether, 23-25 parts of methyl methacrylate, 2-5 parts of acetone, 14 parts of styrene, and 2.5 parts of a thickening agent. The invention is long-acting and antistatic, has strong adhesive force and excellent anticorrosion performance, and requires no special spraying equipment for construction.

Owner:WUJIANG LONGJING HONGBEI INTERIOR DECORATION

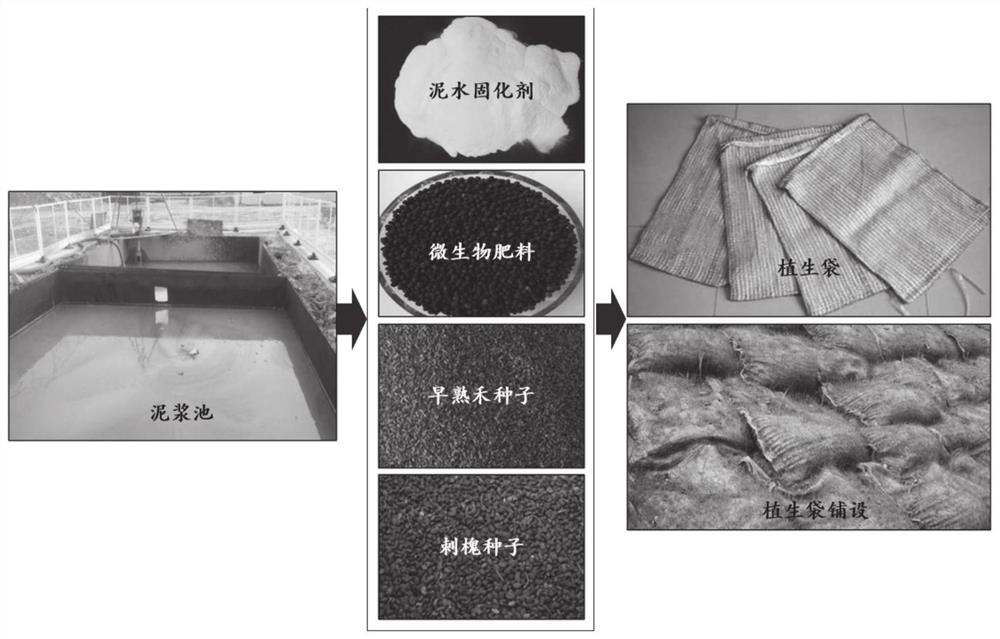

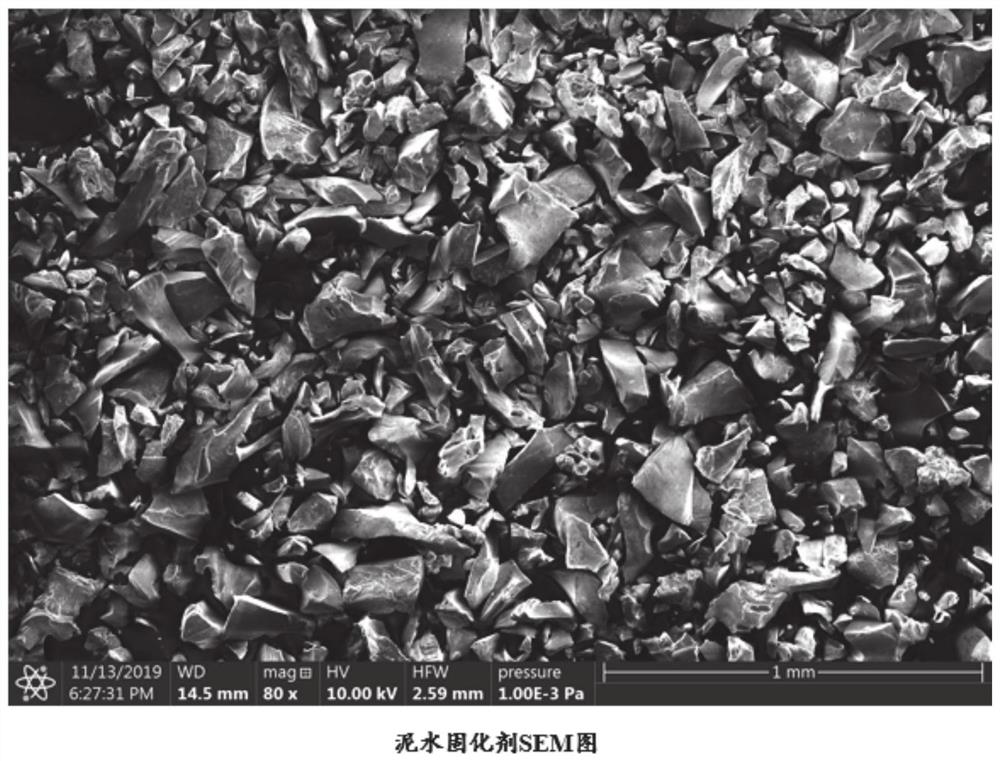

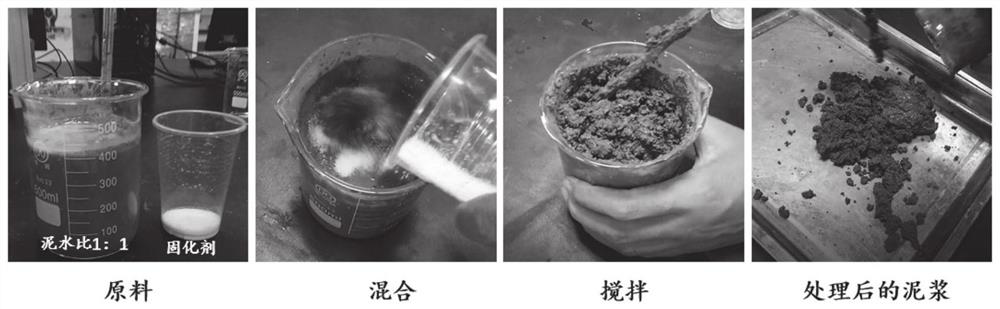

Muddy water curing agent for preparing plant-growing bag from engineering slurry, plant-growing bag and preparation method

PendingCN112980449ASave resourcesLow costAgriculture tools and machinesOrganic fertilisersMeth-Polyvinyl alcohol

The invention discloses a muddy water curing agent for preparing a plant-growing bag from engineering slurry, the plant-growing bag and a preparation method. The muddy water curing agent is prepared from the following raw materials: a copolymer, a cross-linking agent, acrylic acid, an initiator and a surface cross-linking agent, wherein the copolymer is polyvinyl alcohol, acrylamide, methacrylamide or acrylonitrile; the cross-linking agent is selected from one or more of polyethylene glycol diglycidyl ether, ethoxylated glycerol triacrylate and ethylene glycol dimethacrylate; mixing the copolymer, the cross-linking agent and the acrylic acid, and carrying out polymerization reaction; adding the initiator into the solution subjected to the polymerization reaction, heating and stirring to obtain hydrogel, and mincing the hydrogel to obtain gel particles; and spraying the surface cross-linking agent onto the surfaces of the gel particles, and drying to obtain the muddy water curing agent. The muddy water curing agent can effectively modify mud and other waste sludge and make the mud and other waste sludge into the plant-growing bag so that resources are saved, the environment is protected, the cost is low, and the transportation cost is saved.

Owner:SHANDONG UNIV

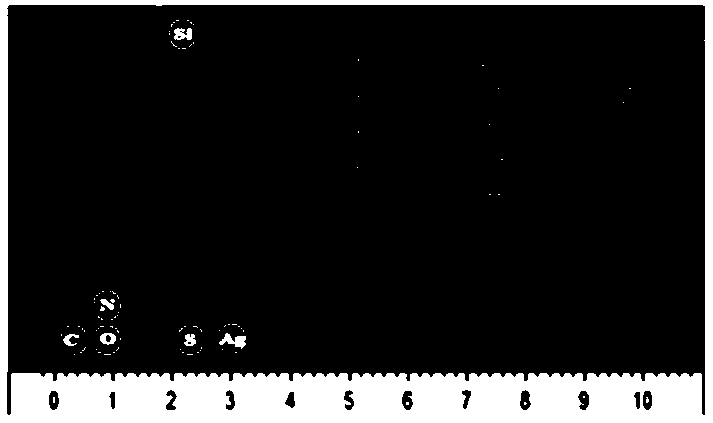

Janus-structured polyether/Ag particle and preparation method and application thereof

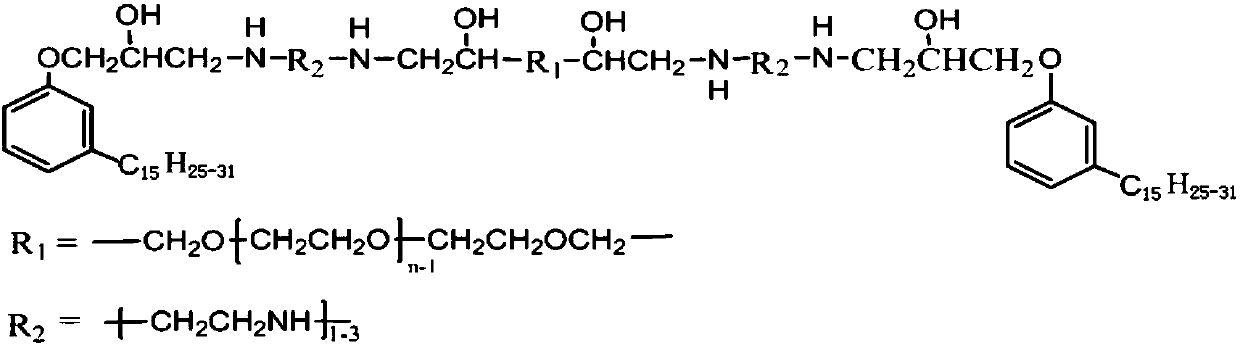

ActiveCN107823142AMild reaction conditionsEasy to operateAntibacterial agentsInorganic active ingredientsBiocompatibility TestingStructural formula

The invention relates to a preparation method of a Janus-structured polyether / Ag particle. Sulfydryl polyether amine and soluble silver salt are dissolved in water, so that a solution A is obtained, and after sunlight or ultraviolet irradiation, separation and drying, the Janus-structured polyether / Ag particle is obtained; sulfydryl aliphatic amine and poly(ethylene glycol) diglycidyl ether undergo nucleophilic addition-ring-opening polymerization, so that the sulfydryl polyether amine is obtained, a structural formula of a constitutional unit of the sulfydryl polyether amine is shown in the description; in the formula, m is equal to 2 to 4, n is equal to 5 to 250, and both m and n are integers. The method disclosed by the invention has the characteristics of mild reaction conditions and rapid, simple and environment-friendly operation process; the prepared Janus-structured polyether / Ag particle has the characteristics of small grain size, narrow size distribution and good biocompatibility, and can be used as an antibacterial agent, and moreover, the surface of an Ag phase of the Janus particle can be further functionalized, so that the application range of the Janus-structured polyether / Ag particle can be broadened.

Owner:HENAN UNIVERSITY

Castor oil sourced aqueous epoxy curing agent, and preparation method thereof

InactiveCN110105543AImprove hydrophilicityHigh value-added utilizationEnvironmental resistanceGreen environment

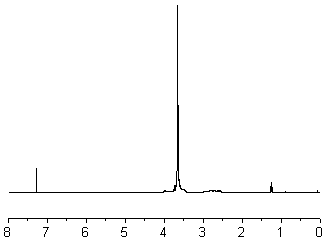

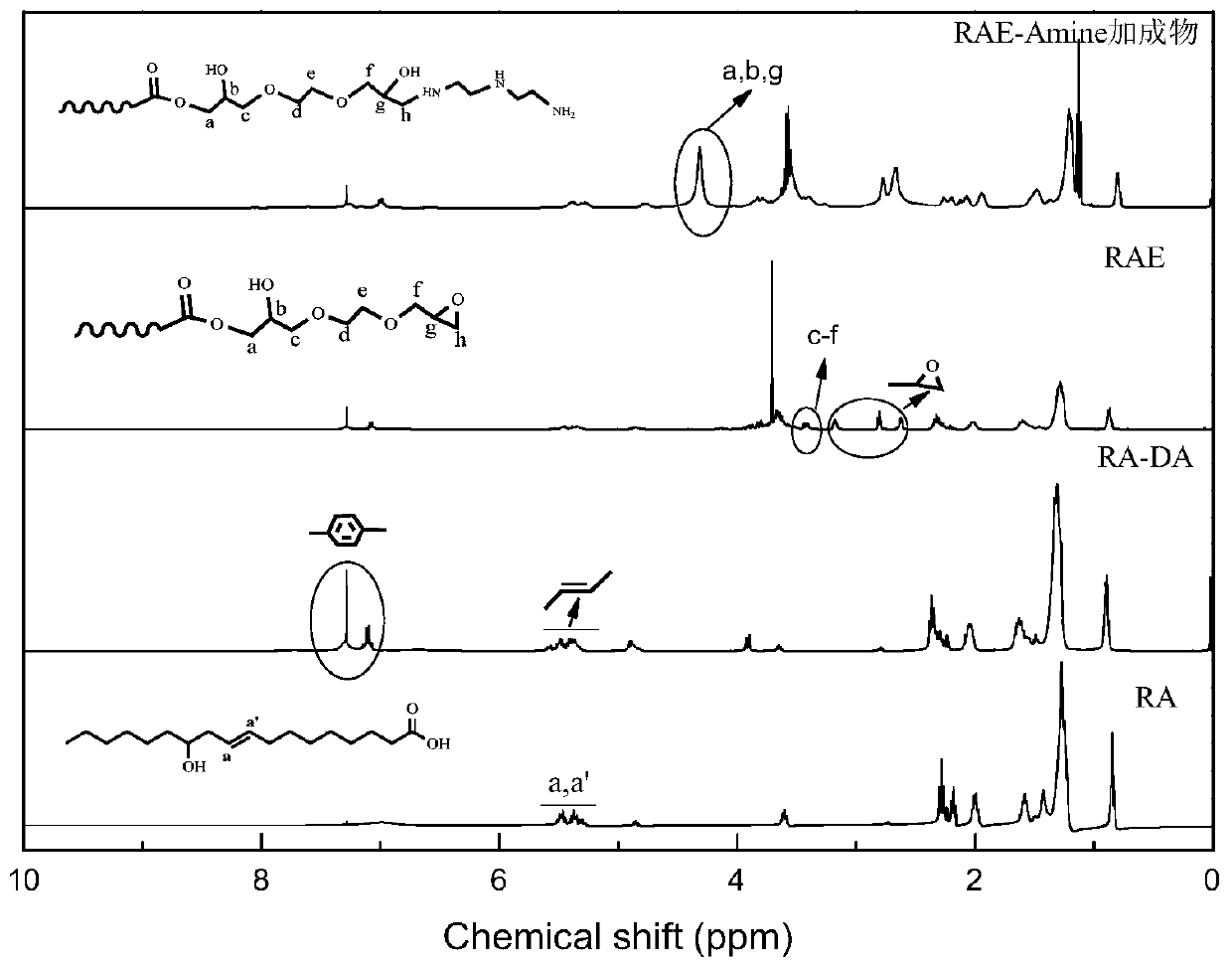

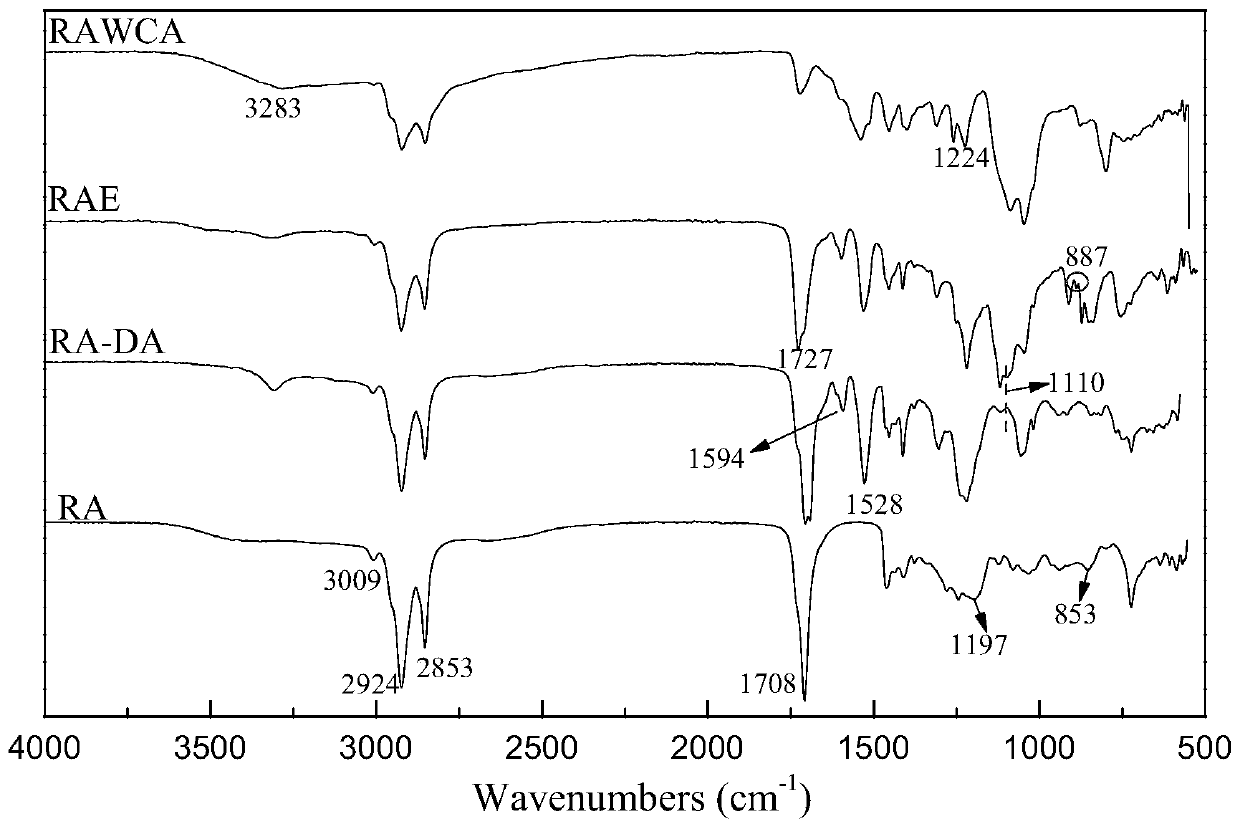

The invention discloses a castor oil sourced aqueous epoxy curing agent, and a preparation method thereof. The preparation method comprises following steps: diisocyanate, ricinoleic acid (RA), and dibutyltin dilaurate are mixed to be uniform, the temperature is controlled to be 60 to 85 DEG C, and reaction is carried out for 2 to 4h so as to obtain a ricinoleic acid sourced diacid (RA-DA); RA-DA is reacted with ethylene glycol diglycidylether (or polyethyleneglycol diglycidylether) so as to obtain a ricinoleic acid sourced epoxy active intermediate RAE; and RAE is subjected to polyamine chainextansion and single epoxy end-capping agent end capping so as to obtain the ricinoleic acid based aqueous epoxy curing agent (RAWCA). RAWCA can be prepared into an aqueous solution with a solid content of 40 to 60% for using. According to the preparation method, natural renewable castor oil derivative is taken as a raw material to prepare the aqueous epoxy curing agent product, so that it is helpful in promotion of green renewable forest and grass resource high added value utilization, and satisfying of green environment protection and sustainable development requirements.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Protein modification method of polyester fabric

ActiveCN107938315AImprove coolnessGood flexibilityDry-cleaning apparatus for textilesGrip property fibresFiberCross-link

The invention provides a protein modification method of polyester fabric. The method comprises the following steps: performing desizing treatment on the polyester fabric, so as to obtain desized fabric; treating the desized fabric with sodium hydroxide, and washing the fabric, so as to obtained fabric subjected to alkali treatment; soaking the fabric subjected to alkali treatment into cross-linking agent solution, and ensuring that the fabric is mixed and reacted with silk fibroin with the molecular weight being 1000 to 5000Da; ensuring that a cross-linking agent comprises polyethylene glycoldiglycidyl ether. The modification method ensures that the fabric subjected to desizing treatment is treated through sodium hydroxide, and alkali treatment ensures that reaction sites are released onpolyester fiber molecular chains; meanwhile, the fabric subjected to alkali treatment is modified by the silk fibroin with the molecular weight being limited to 1000 to 5000Da, the silk fibroin with specific small molecular weight is firmly led to the fiber surface of the polyester fabric through a principle of covalent binding, the coolness, softness and antistatic property of polyester fabric are improved, meanwhile the mechanical property is good, and the silk protein is good in stability.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com