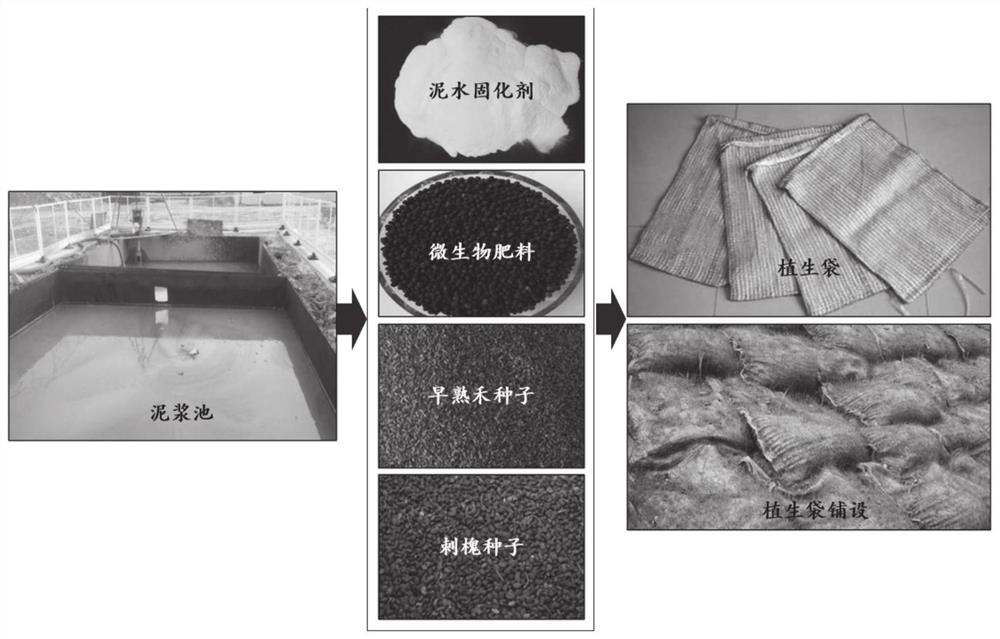

Muddy water curing agent for preparing plant-growing bag from engineering slurry, plant-growing bag and preparation method

A technology of curing agent and vegetable bag, applied in chemical instruments and methods, botanical equipment and methods, applications, etc., can solve limited problems, can only deal with the separated dregs, and there are few researches on the solidification of shield tunnel waste mud, which cannot be solved. Recycling and other issues to achieve the effect of increasing bonding efficiency, improving corrosion resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

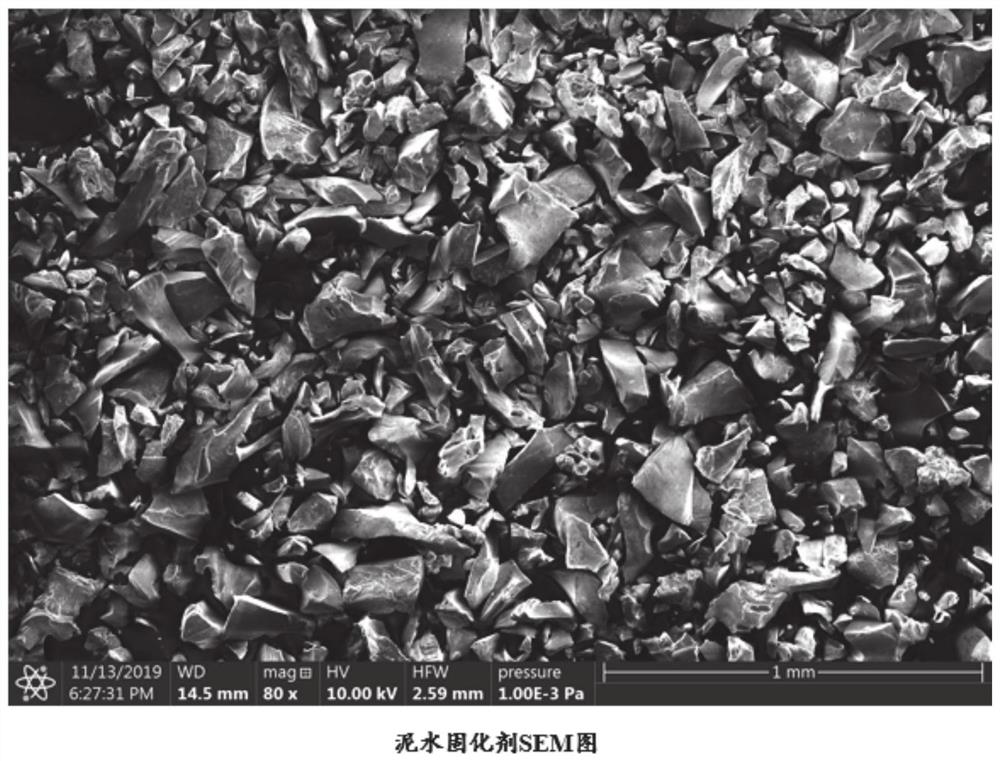

[0048] In the second aspect, the present invention provides the preparation method of the muddy water solidifying agent of the described engineering mud preparation plant growth bag, comprises the steps:

[0049] Mix the copolymer, crosslinking agent and acrylic acid for polymerization;

[0050] adding an initiator to the solution after the polymerization reaction, raising the temperature and stirring to obtain a hydrogel, and crushing the hydrogel to obtain gel particles;

[0051] Spray the surface cross-linking agent on the surface of the gel particles and dry to obtain the muddy water curing agent.

[0052] In some embodiments, the polymerization reaction time is 1-1.5h.

[0053] In some embodiments, the heating process for preparing the hydrogel is as follows: the reaction temperature is gradually increased from 0°C to 85°C. The initiator is a thermal decomposition initiator. At a certain temperature, the compound is thermally decomposed into free radicals, which are used ...

Embodiment 1

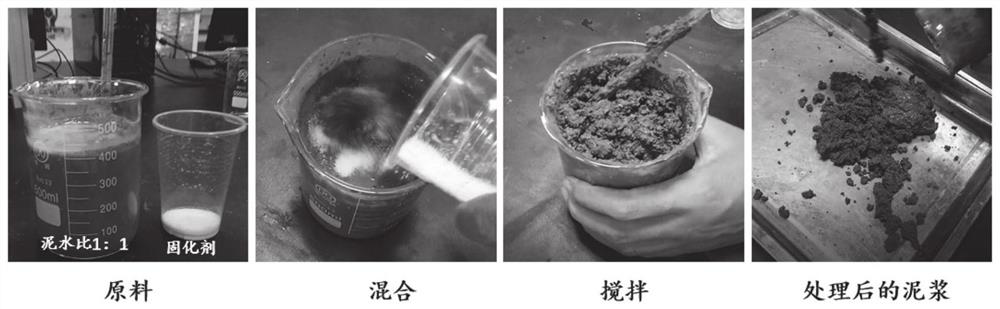

[0070] A mud water solidifying agent for preparing a vegetable bag from engineering mud, a vegetable bag and a preparation method thereof, comprising the following steps:

[0071] (1) Dilute the acrylic acid monomer with deionized water to obtain 500 g of acrylic acid solution with a concentration of 25%, then add 2.5 g of polyethylene glycol diglycidyl ether to the acrylic acid solution, stir with a magnetic stirrer for 10 min; then add 2.5 g Polyvinyl alcohol was polymerized for 1 hour to obtain solution A;

[0072] (2) Sodium persulfate: azobisisobutyronitrile: ammonium persulfate / sodium bisulfite is prepared according to the mass ratio of 5:1:1 to obtain an initiator, and 0.5g of this initiator is added to solution A, gradually Raise the temperature from 0°C to 85°C (at a rate of 2°C / min), stir to obtain a hydrogel, and grind the hydrogel to obtain gel particles B;

[0073] (3) Water: the ratio preparation of ethylene carbonate fat mass ratio 100:30, obtains surface cross...

Embodiment 2

[0077] A mud water solidifying agent for preparing a vegetable bag from engineering mud, a vegetable bag and a preparation method thereof, comprising the following steps:

[0078] (1) Dilute the acrylic acid monomer with deionized water to obtain 500 g of acrylic acid solution with a concentration of 45%, then add 2.5 g of polyethylene glycol diglycidyl ether to the acrylic acid solution, stir for 10 min with a magnetic stirrer; then add 2.5 g Polyvinyl alcohol was polymerized for 1 hour to obtain solution A;

[0079] (2) Sodium persulfate: azobisisobutyronitrile: ammonium persulfate / sodium bisulfite is prepared according to the mass ratio of 1:5:1 to obtain an initiator, and 0.5g of this initiator is added to solution A, gradually Raise the temperature from 0°C to 85°C (at a rate of 2°C / min), stir to obtain a hydrogel, and grind the hydrogel to obtain gel particles B;

[0080] (3) Water: the ratio preparation of ethylene carbonate fat mass ratio 100:30, obtains surface cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com