Waterborne epoxy emulsion, waterborne epoxy resin coating and preparation method thereof

A water-based epoxy emulsion and water-based epoxy coating technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of reducing the curing temperature of coatings, poor stability, and reducing the VOC value of coatings, achieve good mechanical properties, and solve stability problems. Poor performance and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

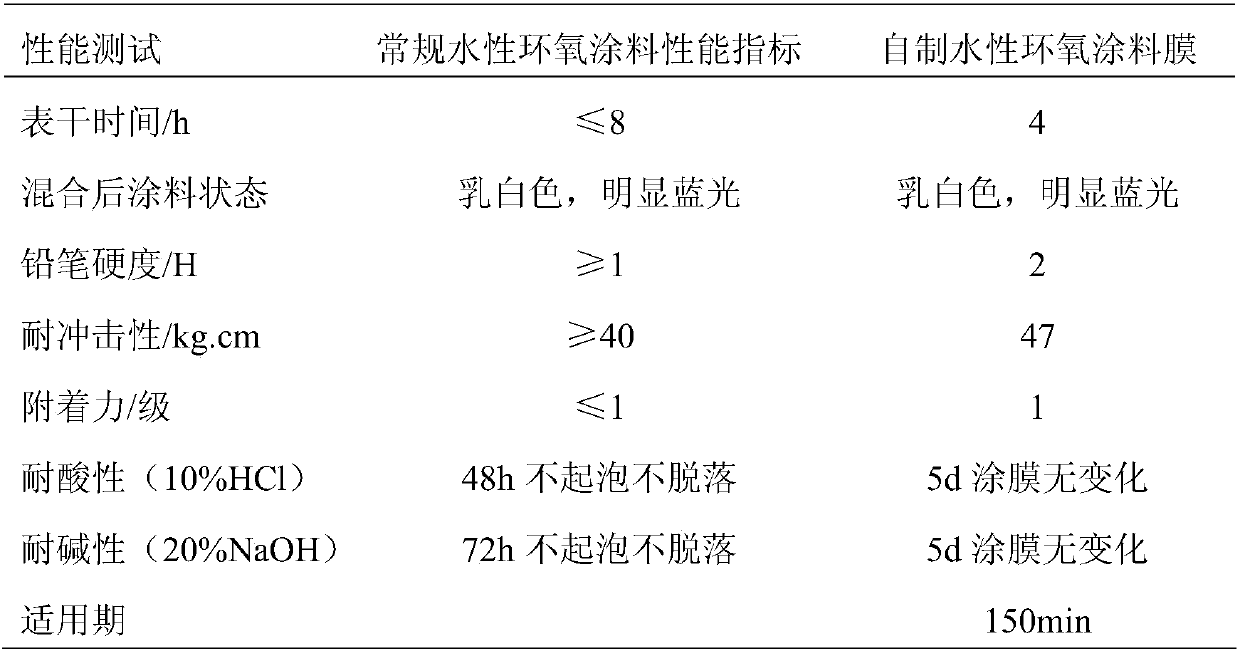

Embodiment 1

[0030] (1) Weigh 20g of polyethylene glycol (molecular weight 3000-4500) and 0.98g of maleic anhydride in a reaction vessel, heat up to 83°C under mechanical stirring, and react for 2.5h; add 3.92g of epoxy resin E -51 (the number average molecular weight is 392), rapidly warming up to 115 ℃, reaction 4h, obtains water-based epoxy emulsifier; (the molar ratio of polyethylene glycol / maleic anhydride / epoxy resin E-51 is 1 :2:2);

[0031] (2) Weigh 15g of water-based epoxy emulsifier and 83g of epoxy resin E-51 in a reaction vessel, under mechanical stirring, the rotating speed is 1200r / min, slowly add 100g of water by phase inversion technology to obtain water-based epoxy Lotion;

[0032] (3) Weigh 29.2g of triethylenetetramine into the reaction vessel, heat up to 55°C, add 29.4g of epoxy resin E-51 (number average molecular weight is 392), and react for 4h; then add 10g of polyethylene glycol dishrink Glyceryl ether (Guangzhou Jingwei Chemical Co., Ltd., molecular weight 500)...

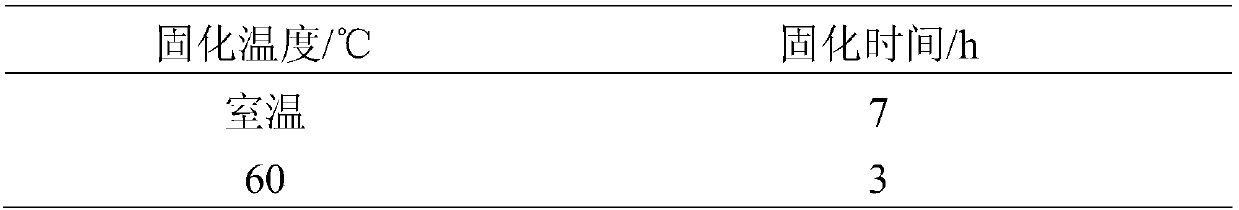

Embodiment 2

[0040] (1) Weigh 20.00g of polyethylene glycol (molecular weight 3000-4500) and 0.98g of maleic anhydride in a reaction vessel, heat up to 85°C under mechanical stirring, and react for 2h; add 3.92g of epoxy resin E -51 (the number-average molecular weight is 392), rapidly warming up to 120 ℃, reaction 3.5h, obtains water-based epoxy emulsifier; (the molar ratio of polyethylene glycol / maleic anhydride / epoxy resin E-51 is 1:2:2);

[0041](2) Weigh 15.00g of water-based epoxy emulsifier and 90.00g of epoxy resin E-51 in the reaction vessel, under mechanical stirring, the rotating speed is 1300r / min, slowly add 105.00g of water by phase inversion technology, to obtain Water-based epoxy emulsion;

[0042] (3) Weigh 29.20g of triethylenetetramine into the reaction vessel, raise the temperature to 65°C, add 24.5g of epoxy resin E-51 (the number average molecular weight is 392), react for 3 hours, then add 12.50g of polyethylene glycol Glycidyl ether (Guangzhou Jingwei Chemical Co....

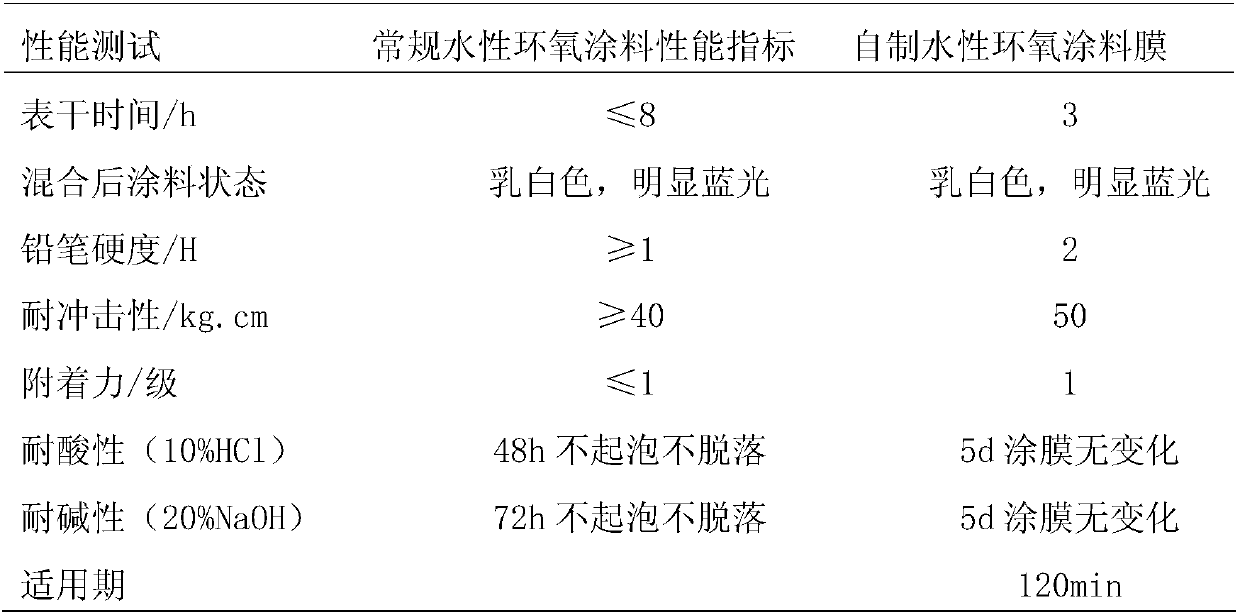

Embodiment 3

[0050] (1) Weigh 20.00g of polyethylene glycol (molecular weight 3000-4500) and 0.98g of maleic anhydride in a reaction vessel, heat up to 88°C under mechanical stirring, and react for 2h; add 3.92g of epoxy resin E -51 (the number-average molecular weight is 392), heat up rapidly to 125°C, react for 3 hours to obtain a water-based epoxy emulsifier; the molar ratio of polyethylene glycol / maleic anhydride / epoxy resin E-51 is 1: 2:2;

[0051] (2) Weigh 15.00g of water-based epoxy emulsifier and 90.00g of epoxy resin E-51 in the reaction vessel, under mechanical stirring, the speed is 1400r / min, slowly add 105.00g of water by phase inversion technology to obtain water-based epoxy emulsion;

[0052] (3) Weigh 29.20g of triethylenetetramine into the reaction vessel, raise the temperature to 65°C, add 34.30g of epoxy resin E-51, react for 3.5h, then add 6.25g of polyethylene glycol diglycidyl ether (Guangzhou Wei Chemical Co., Ltd., wherein the number-average molecular weight of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com