Patents

Literature

149 results about "Foreign market" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foreign market Part of a nation's internal market, representing the mechanisms for issuing and trading securities of entities domiciled outside that nation. The market in one country for the trading of securities registered and based in another country.

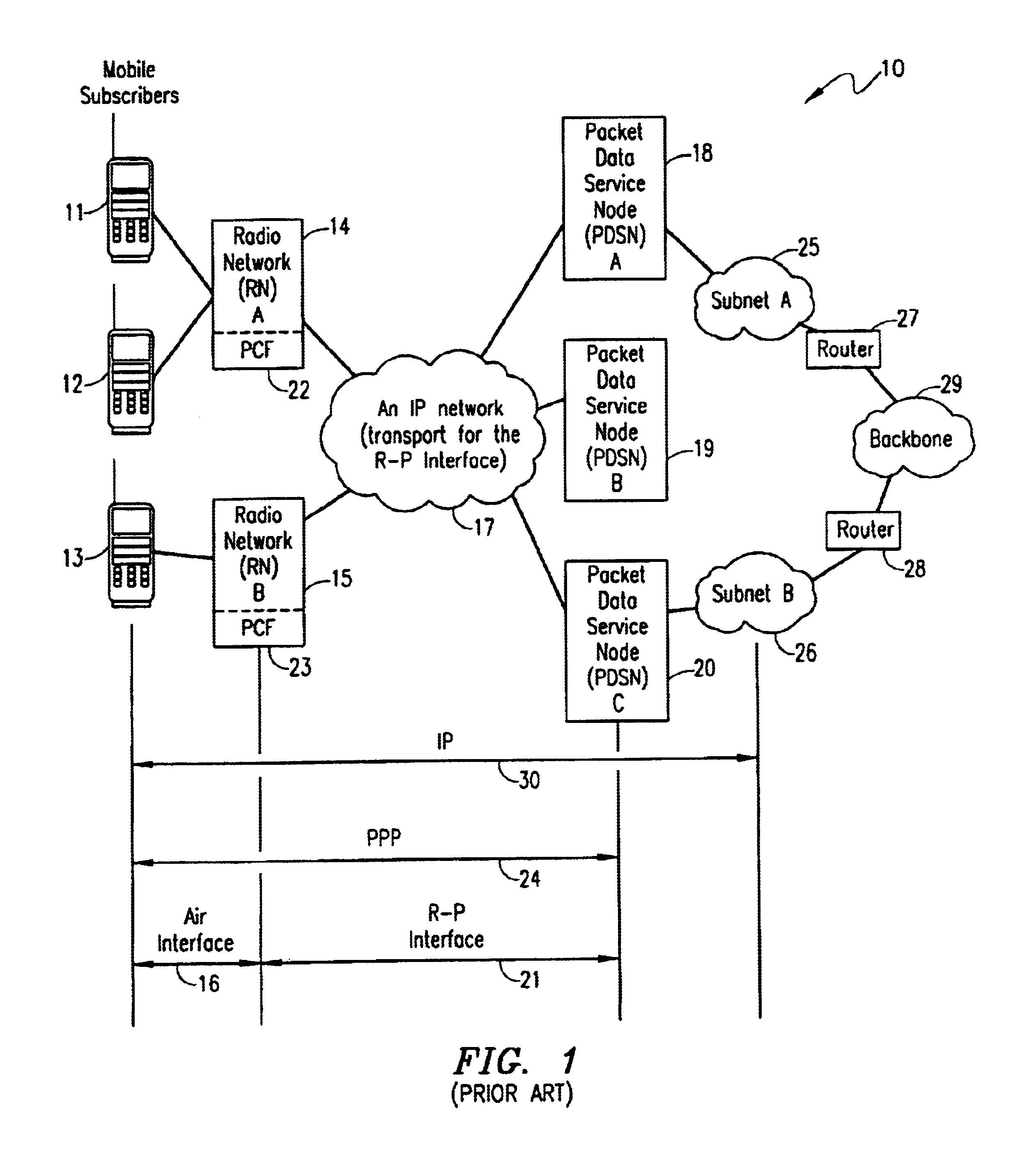

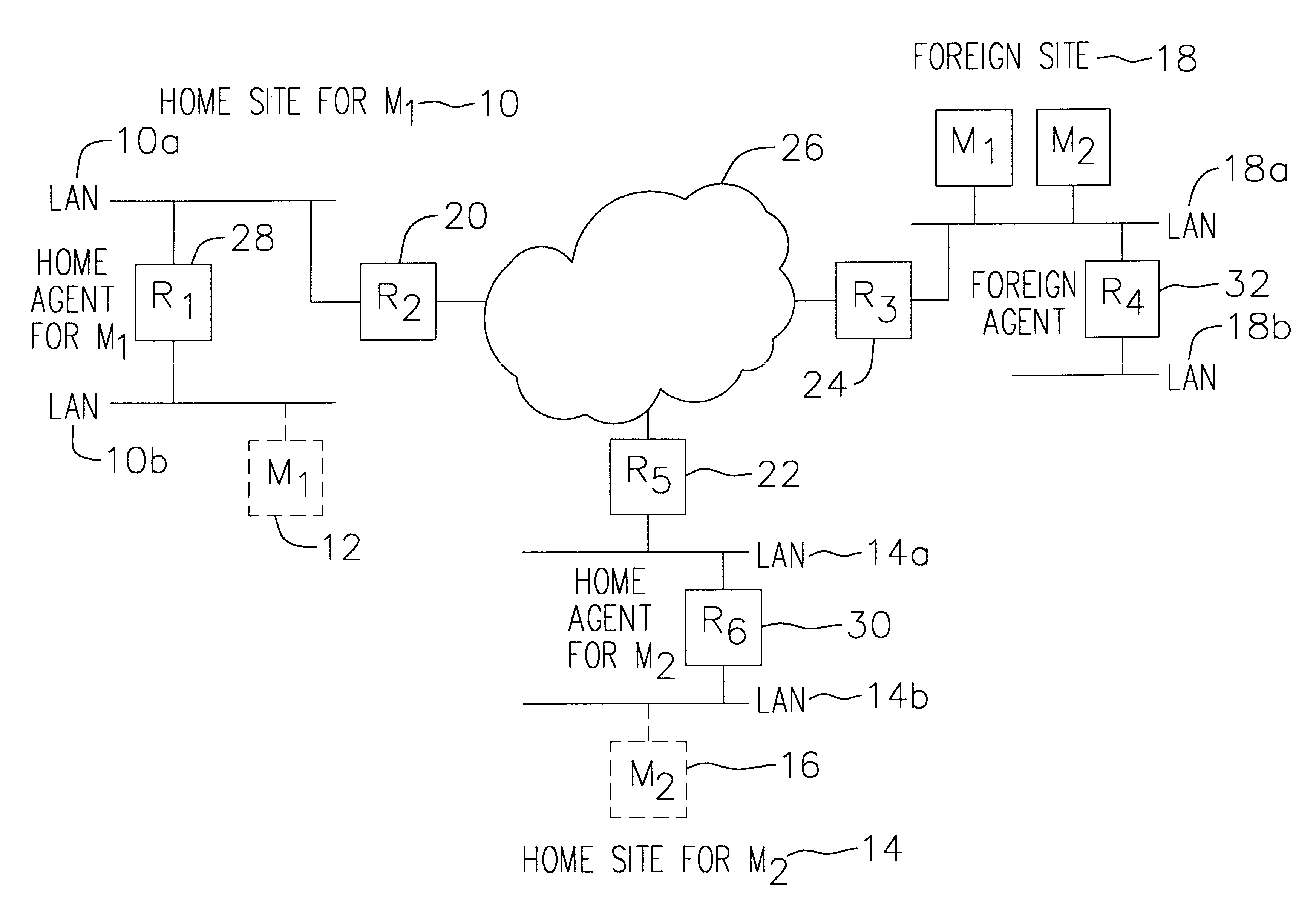

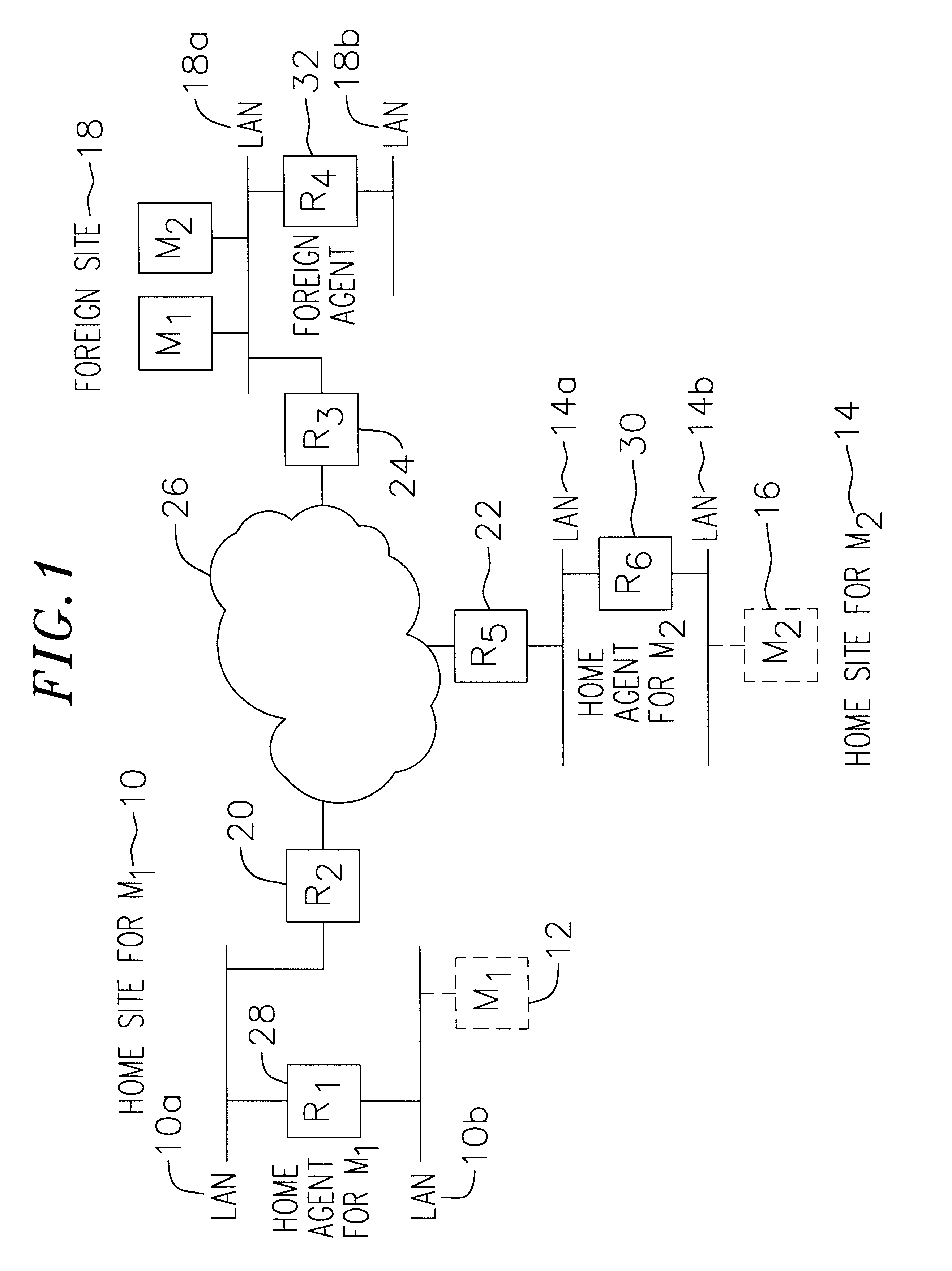

Simple multicast extension for mobile IP SMM

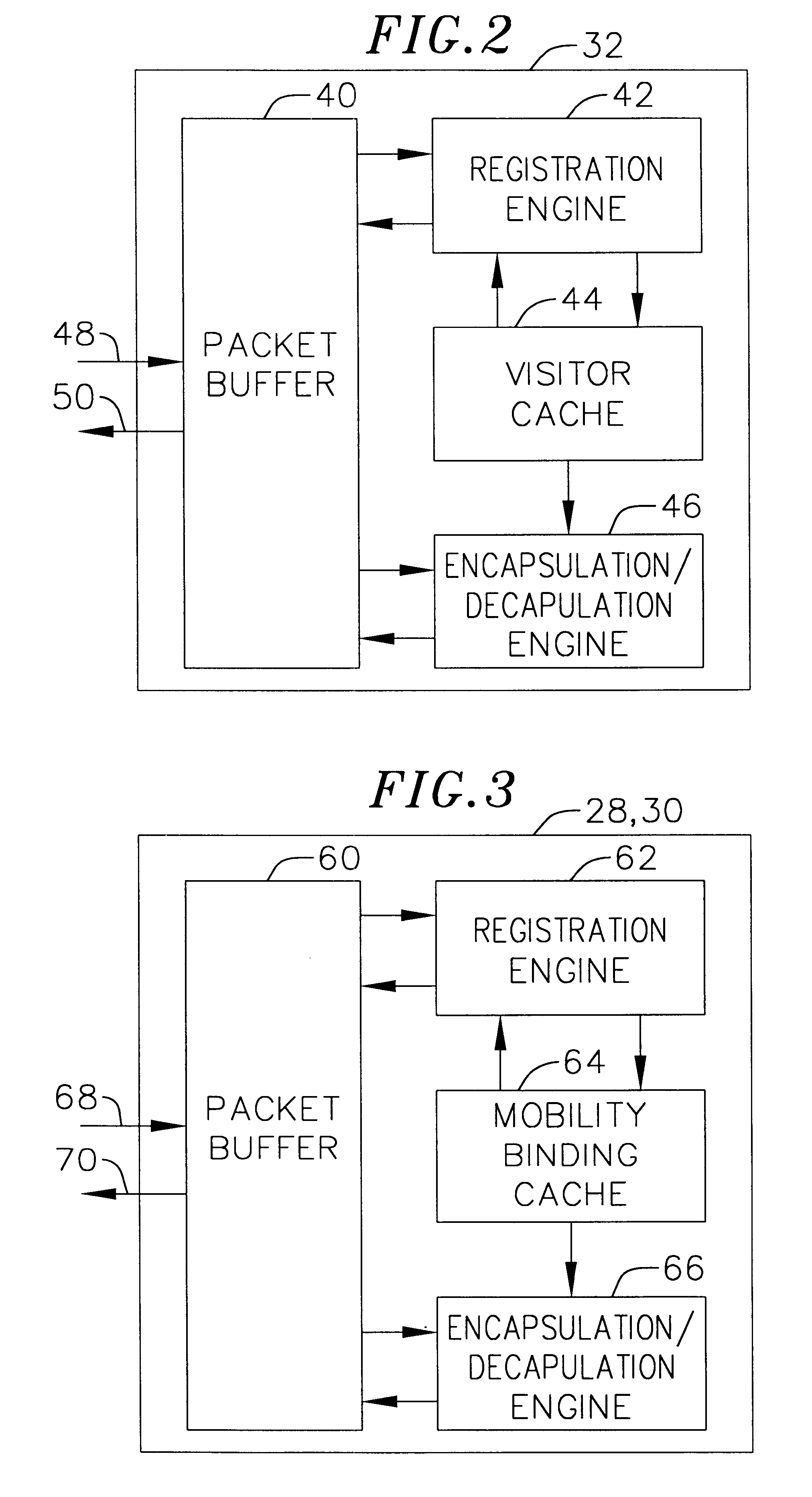

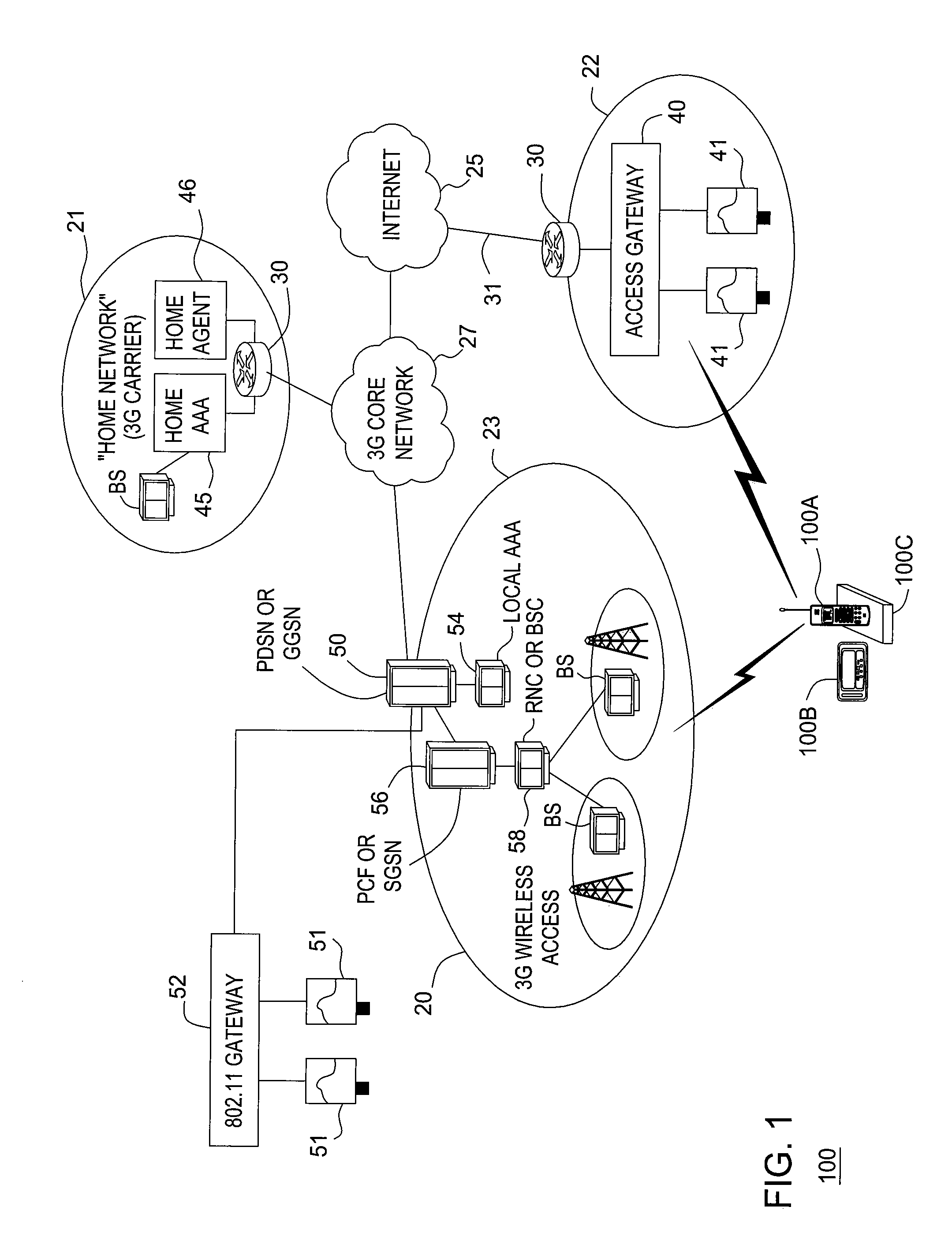

InactiveUS6988146B1Multiple digital computer combinationsWireless network protocolsComputer networkForeign agent

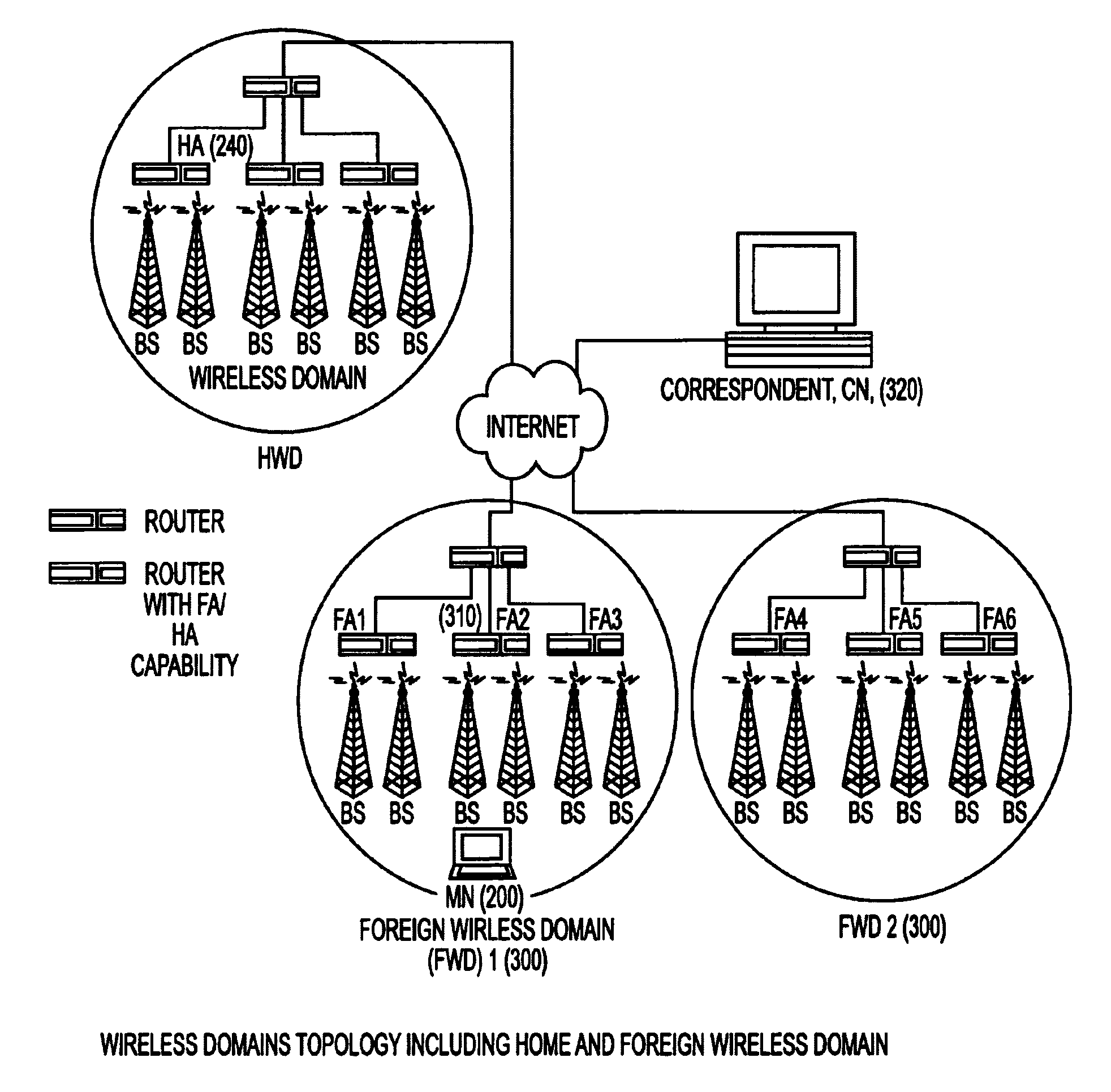

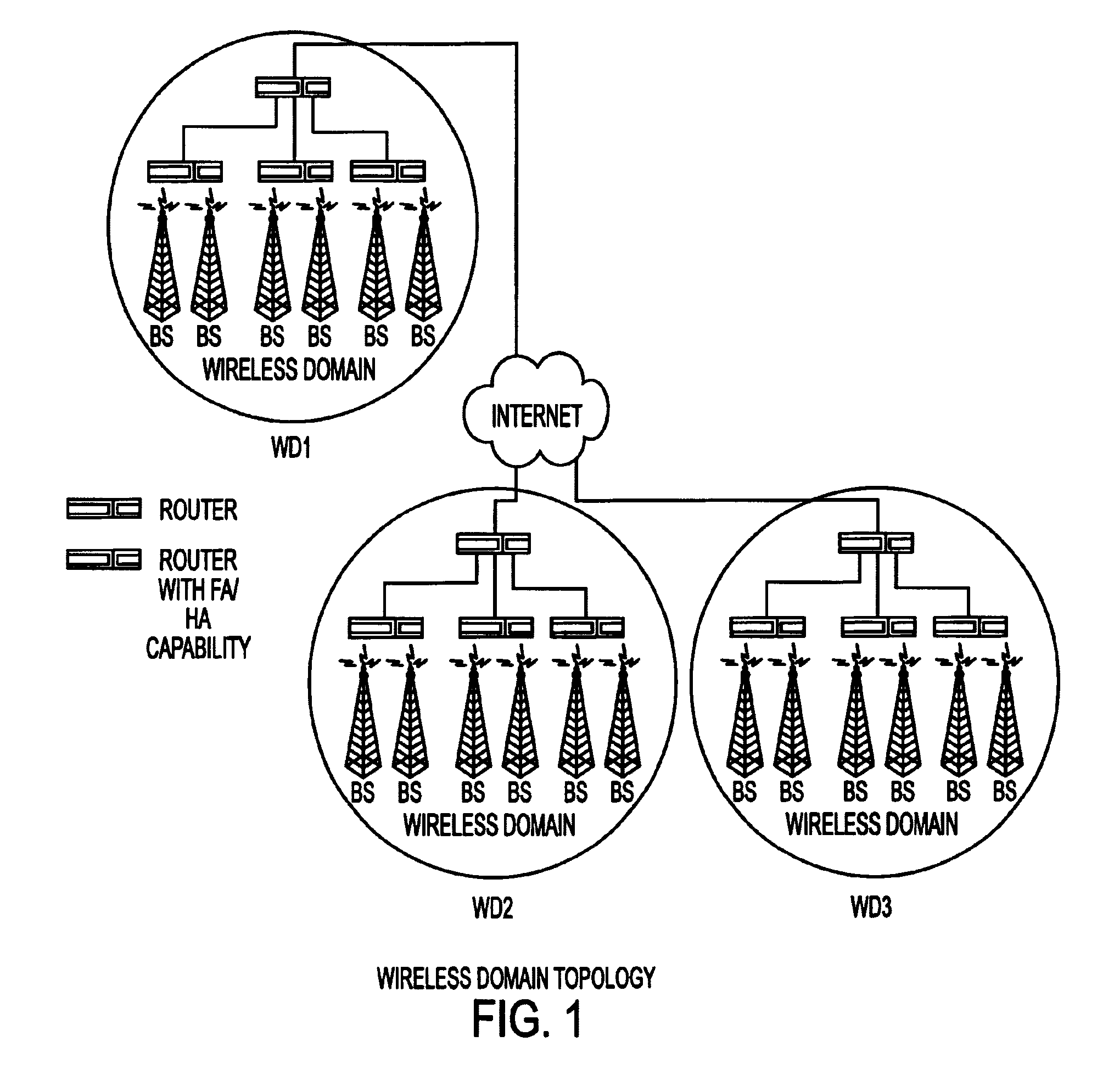

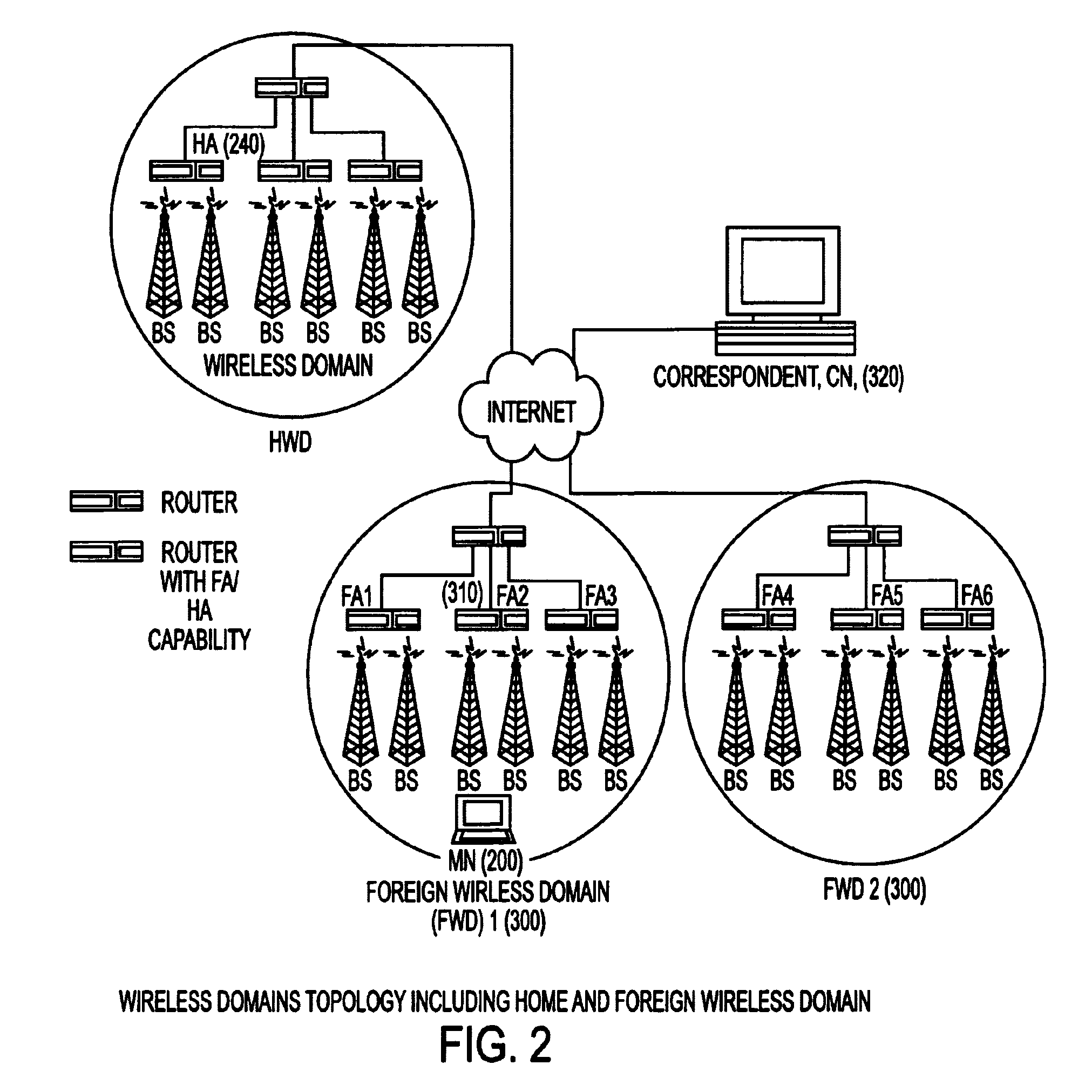

Under Simple Multicast Extension for Mobile IP, when a mobile node arrives at a foreign wireless domain, it listens for an agent advertisement sent by a foreign agent. The foreign agent attaches a network access identifier (NAI) extension to the agent advertisement. The mobile node uses the NAI extension to decide which action to take. If the mobile node determines that it is receiving an agent advertisement message from the same foreign agent it previously was in communication with, no action is required. If the mobile node discovers that it has entered a new foreign domain, it sends a registration request to the foreign agent. If the mobile node identifies that it is still in the same domain but has moved from a previous foreign agent to a new one, it sends a multicast subscription request to the new foreign agent.If a home agent supports the Simple Multicast Extension for Mobile IP, it allocates a source specific multicast address and inserts the address in a source specific multicast address extension after the registration reply. In addition, tunneling is used to route datagrams from correspondent nodes to the mobile node while the mobile node is in a foreign domain. The destination address of the tunnel is set to the source specific multicast previously allocated. Finally, update messages are used to inform correspondent nodes of a mobile nodes' new location.

Owner:ALCATEL LUCENT SAS

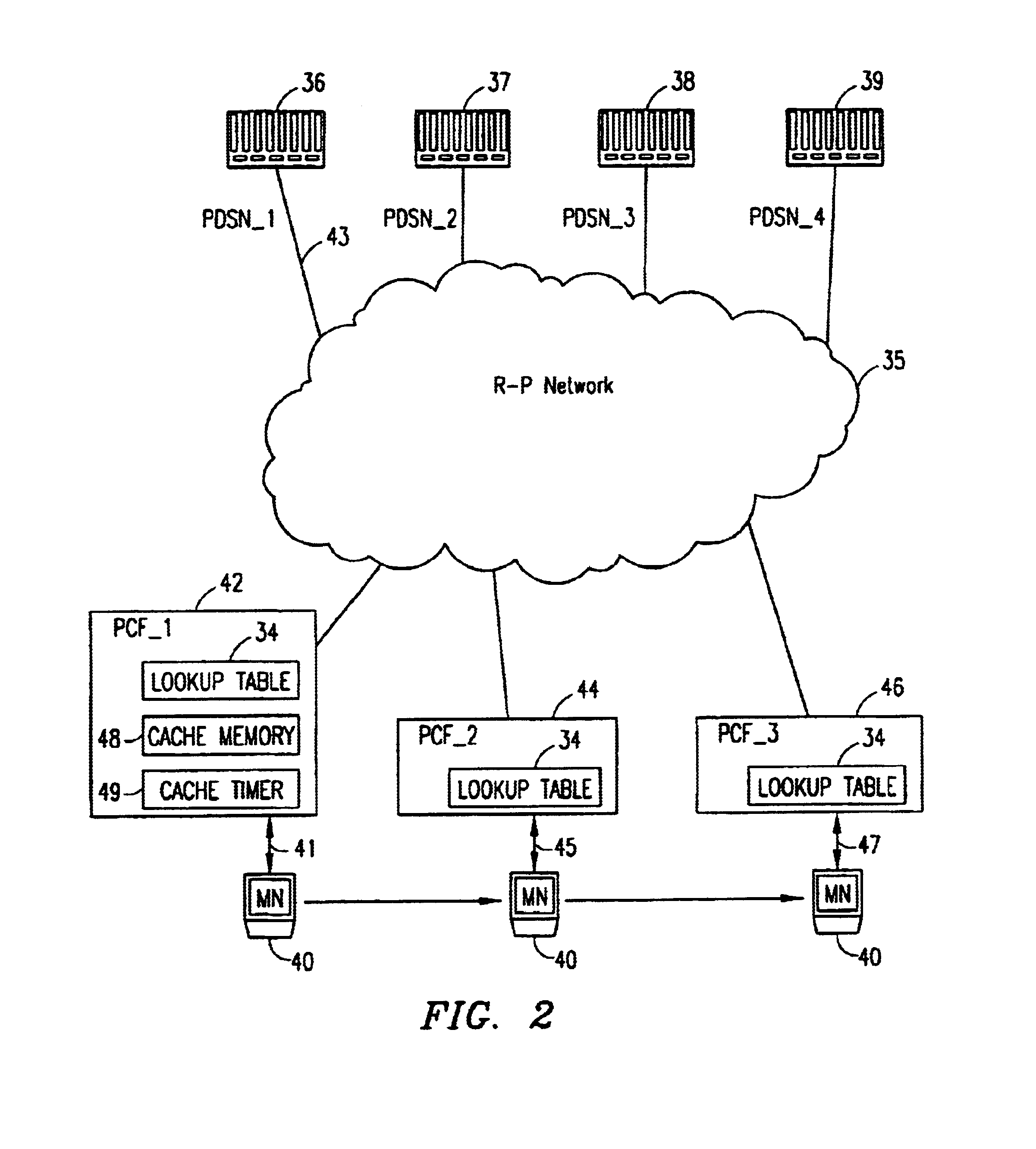

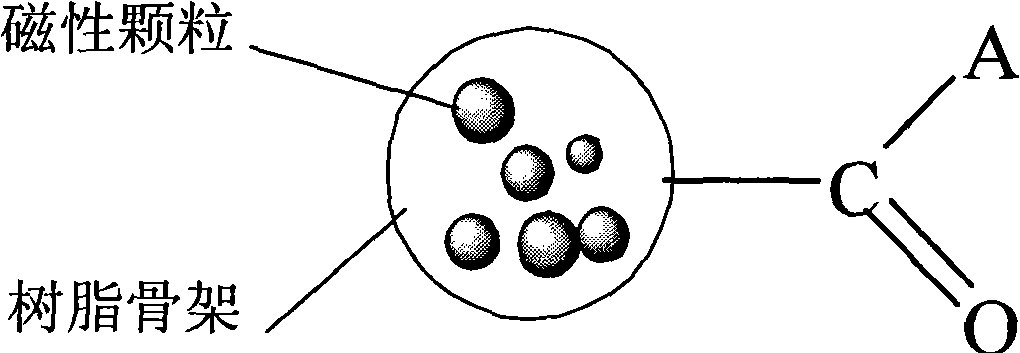

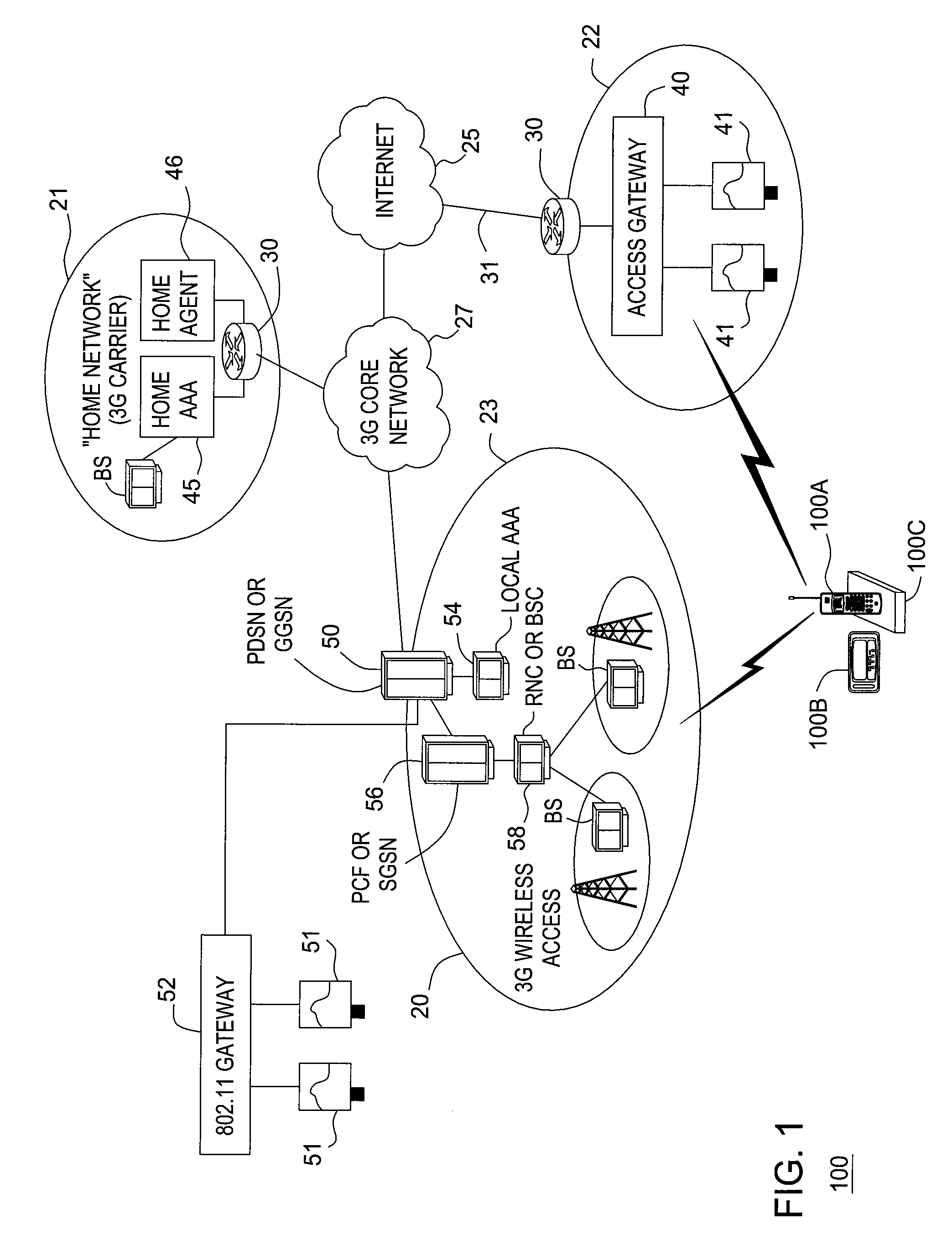

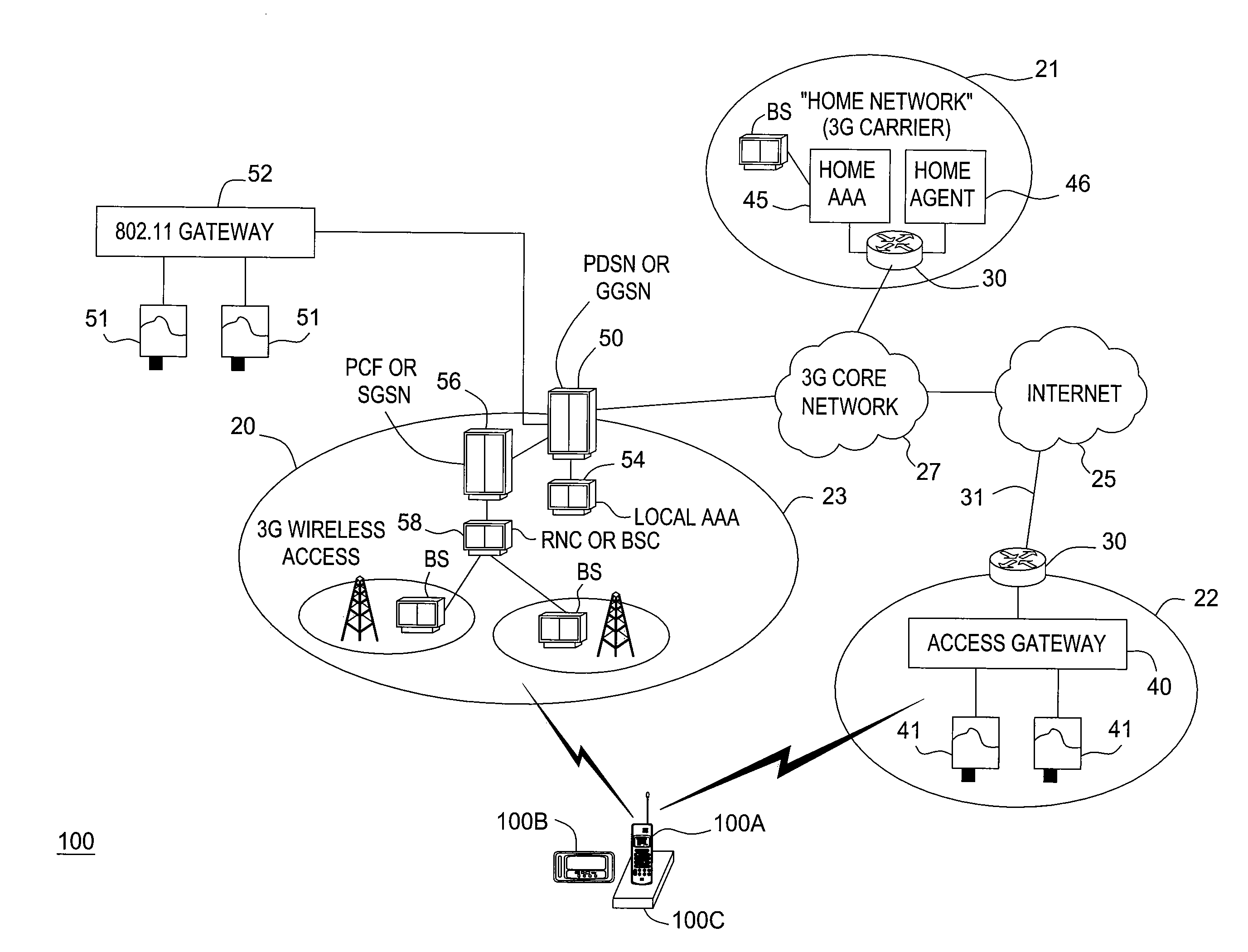

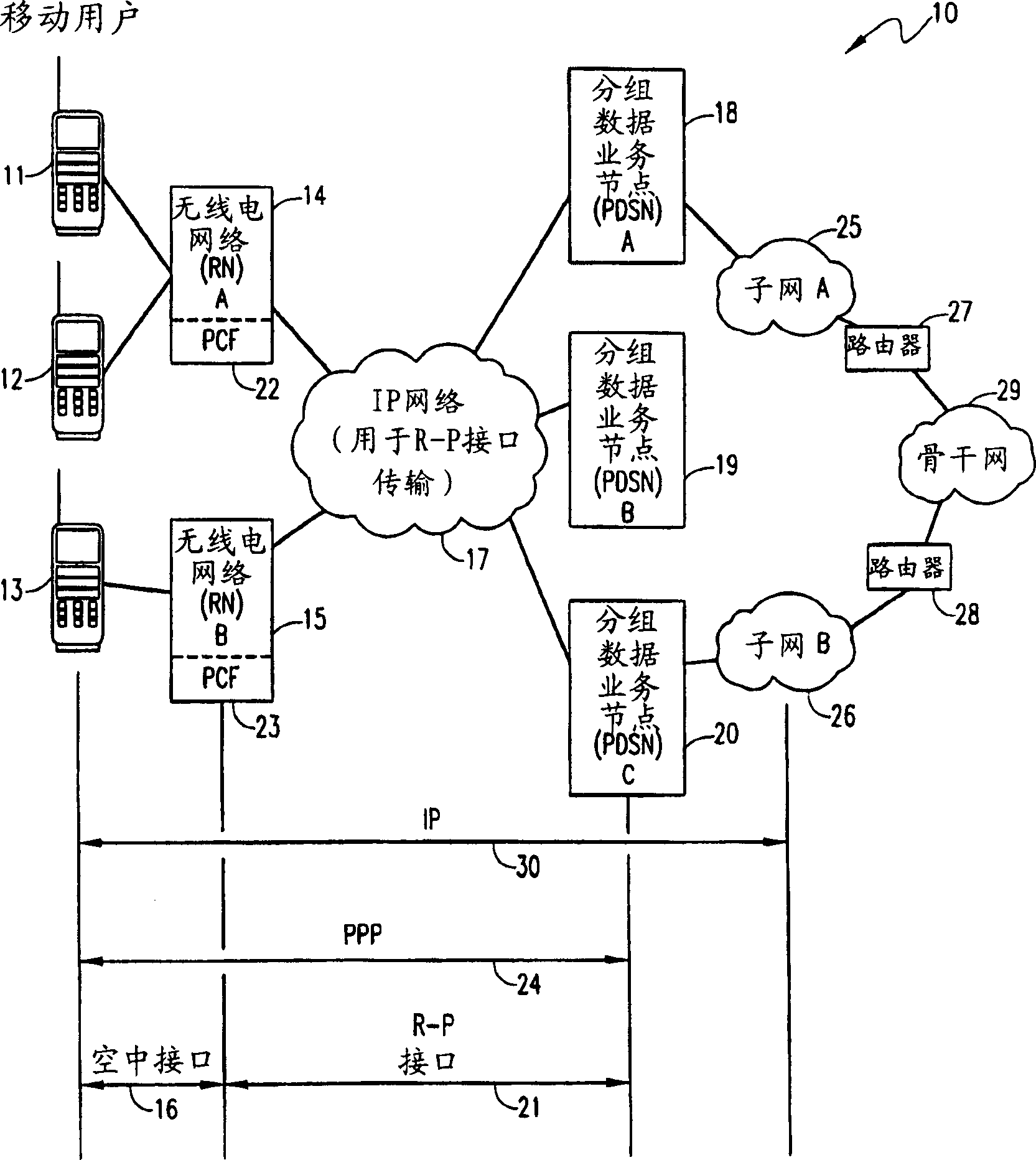

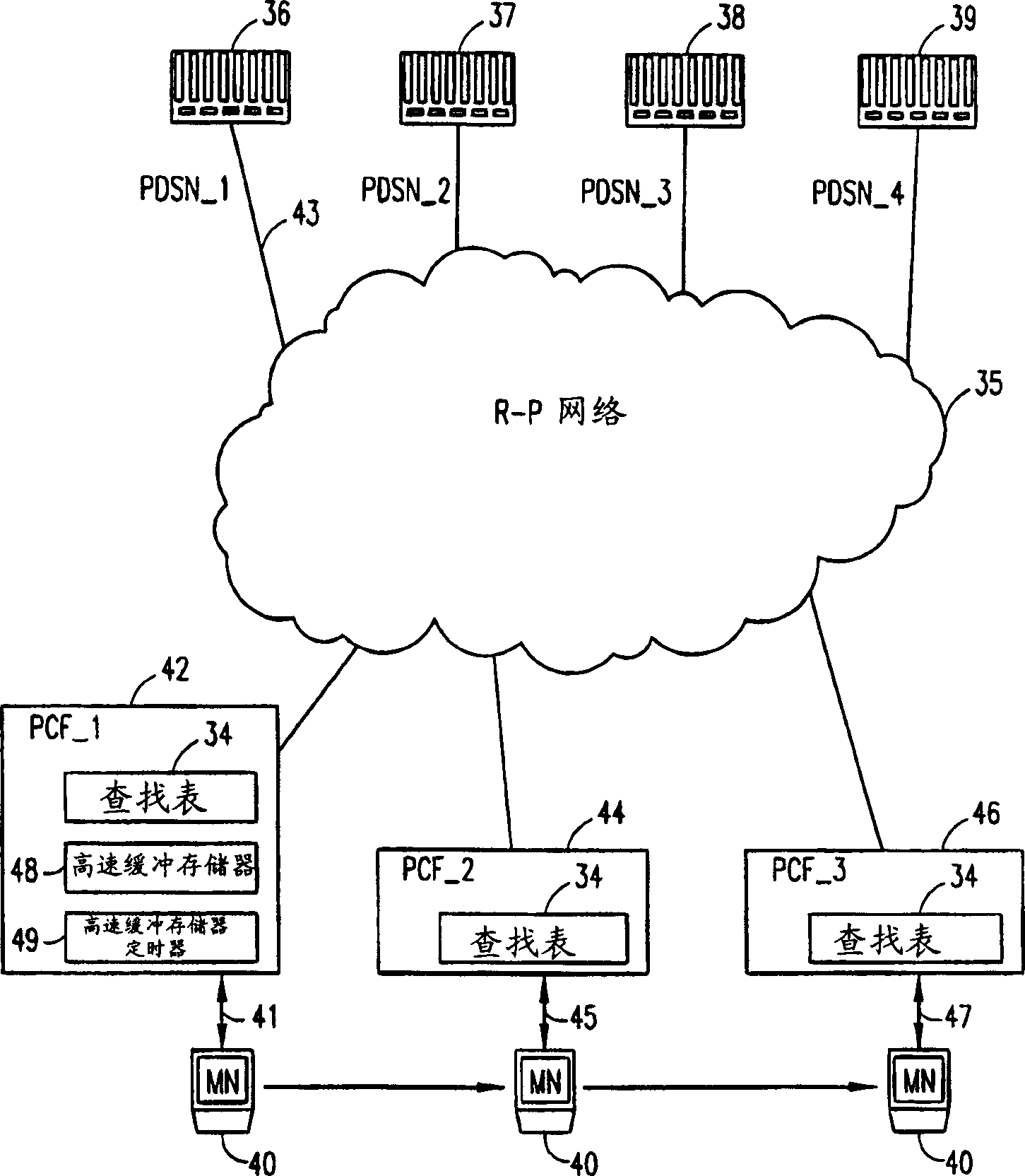

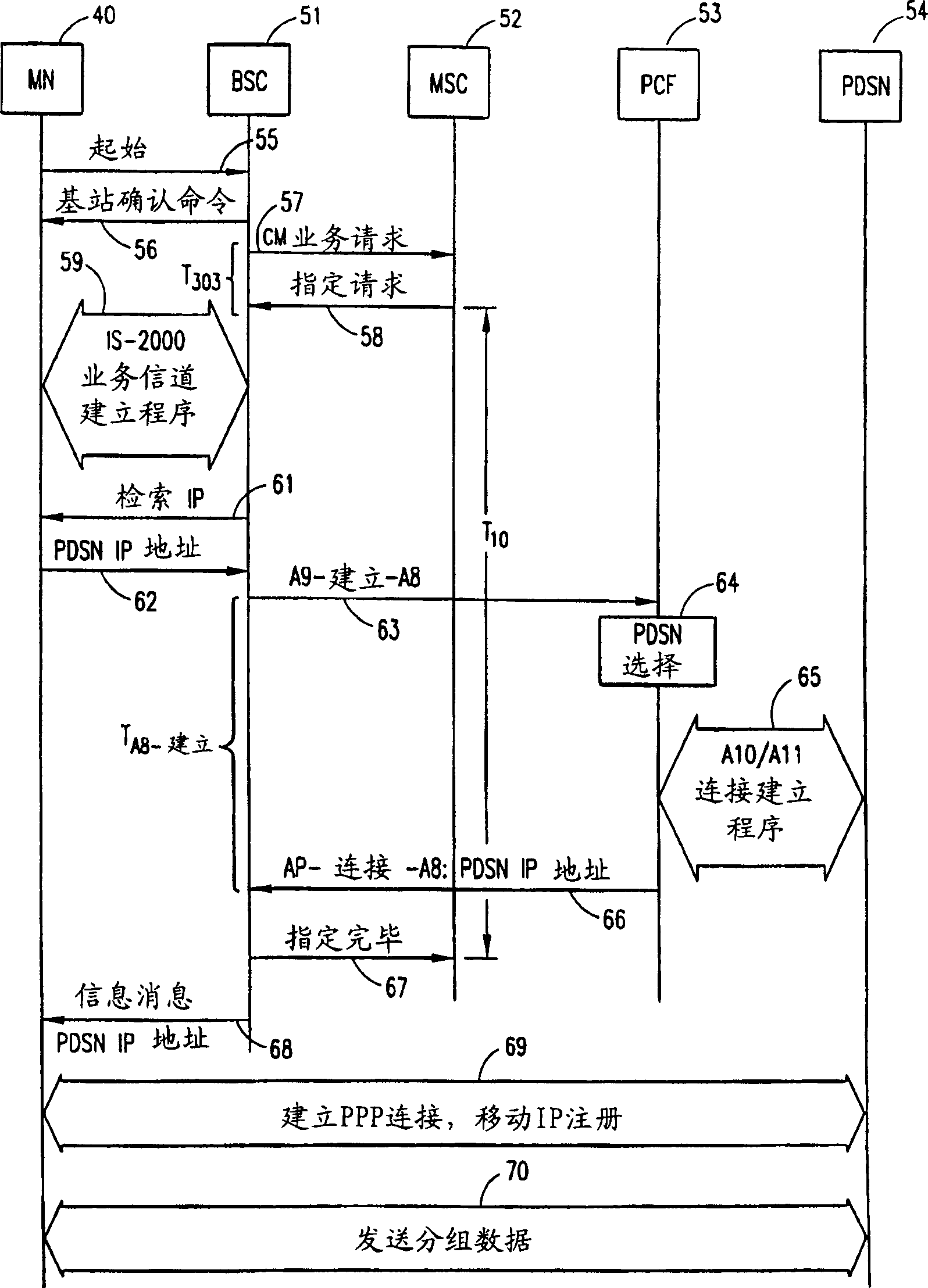

Packet core function and method of selecting a packet data service node/foreign agent in a packet data network

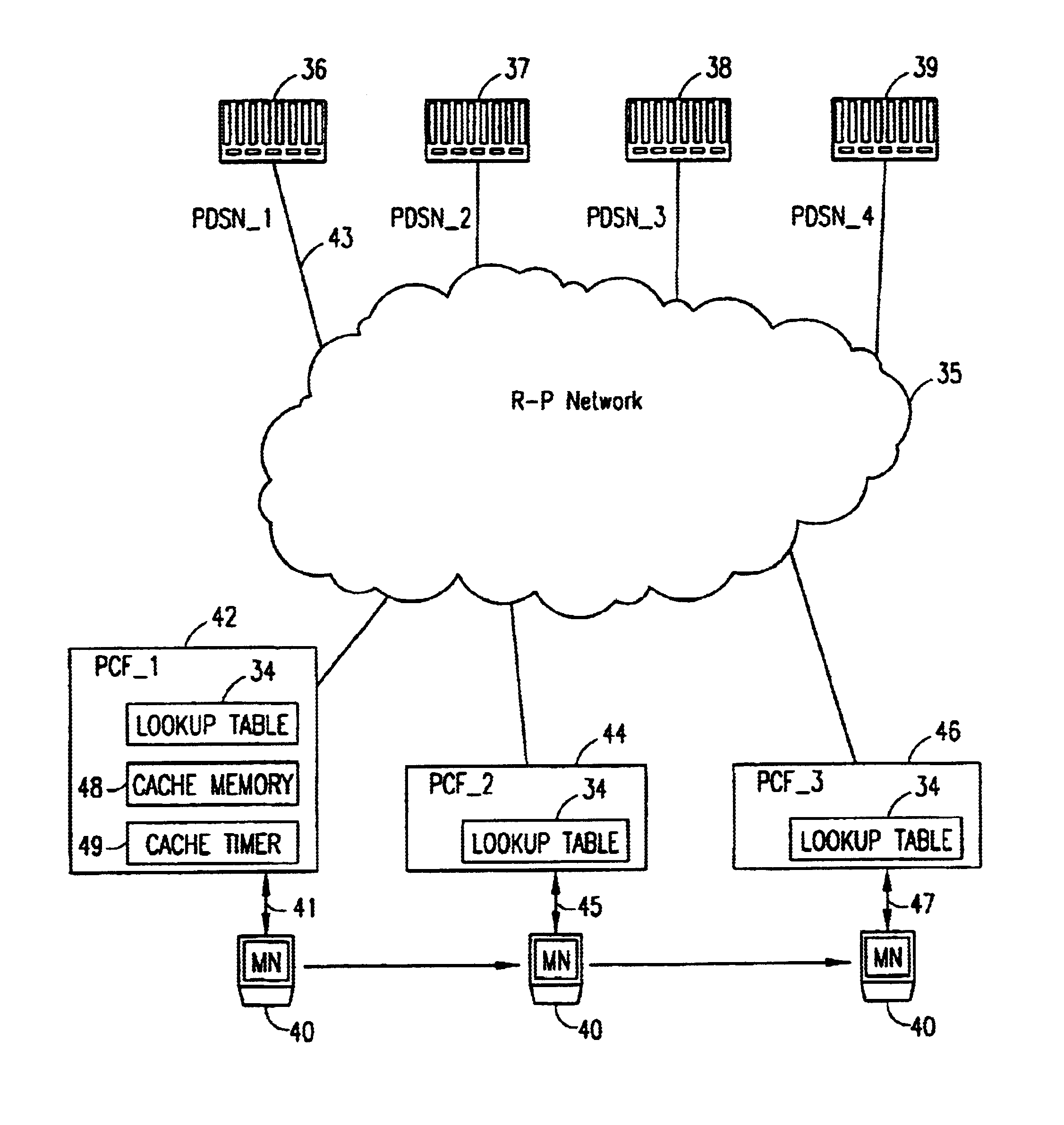

A Packet Core Function (PCF) and method of consistently selecting a Packet Data Service Node (PDSN) from a plurality of PDSNs in a packet data network to host a data session for a Mobile Node (MN). In a first embodiment, a static lookup table in the PCF is used to associate a list of identifiers for MNs and a list of the plurality of PDSNs in the network. The PCF obtains an identifier for the MN and utilizes the lookup table and a hash function to associate the identifier for the MN with a PDSN. The PDSN is then selected by the PCF to host the data session for the MN. In another embodiment, the PCF also includes a cache timer and a cache memory that stores the identifier for the MN and the IP address of the selected PDSN for a predetermined time period following the handoff of the MN to another PCF. If the MN returns to the PCF within the predetermined period of time, the PCF reselects the same PDSN to host the data session. In another embodiment, following the initial selection of a PDSN to host the data session, the EP address of the PDSN is sent to the MN which then passes the IP address of the PDSN to any subsequent PCFs where the MN roams. A PDSN zone ID may be utilized in lieu of the fill IP address.

Owner:TELEFON AB LM ERICSSON (PUBL)

Temporary unique private address

InactiveUS6856624B2Time-division multiplexData switching by path configurationPrivate IPTelecommunications

A communication network providing mobile IP services to mobile nodes sharing the same private IP address. A mobile node visits a foreign network from its home network and transmits a registration request including its private IP address to a foreign agent on the foreign network. If the foreign agent determines that another mobile node with a valid registration shares the same private IP address, the foreign agent requests the mobile node to use a temporary address. The temporary address is sent along with the registration request to the registering mobile node's home agent. When the home agent receives a packet addressed to its mobile node, it creates two tunnels. An outer tunnel is created using a care-of address associated with the foreign agent. An inner tunnel is created using the temporary address assigned to mobile node. The packet is then forwarded via the two tunnels. Upon receipt of the tunneled packet by the foreign agent, it de-tunnels the outer tunnel to uncover the inner tunnel, and forwards the inner tunnel to the mobile node. The mobile node de-tunnels the inner tunnel to recover the original packet.

Owner:ALCATEL LUCENT SAS

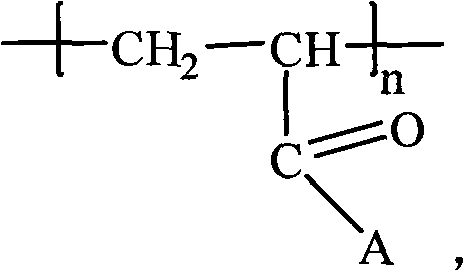

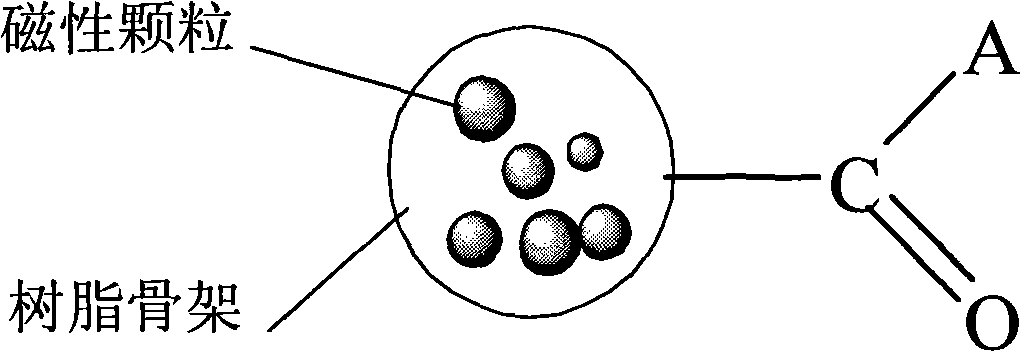

Magnetic acrylic acid series strongly basic anion exchange microballoon resin and preparation method thereof

ActiveCN101781437AIncrease switching capacityHigh base exchange capacityInorganic material magnetismAnion exchangersCross-linkIon exchange

The invention discloses a magnetic acrylic acid series strongly basic anion exchange microballoon resin and a preparation method thereof. The microballoon resin has the following structure: the resin skeleton is internally provided with magnetic particles, wherein A stands for a radical containing quaternary ammonium salt. The preparation method comprises the following steps: acrylic acid series substances serve as a monomer, the monomer is mixed with cross-linking agent and pore-forming agent to form oil phase; the oil phase is uniformly mixed with the magnetic particles and then suspension polymerization is carried out on the mixture; after going through amination and alkylation reaction, the polymerized magnetic polymer particles form the quaternary ammonium salt, namely the magnetic acrylic acid series strongly basic anion exchange microballoon resin. Exchange capacity of the resin is higher than any magnetic acrylic acid series strongly basic anion exchange microballoon resin ever found in existing literatures and reports and domestic market as well as foreign markets and can replace the traditional strongly basic anion exchange resin, thus being capable of being used for separating and removing soluble organisms in various water bodies, especially disinfection by-product precursor and multiple negative ions such as nitrate and phosphate.

Owner:NANJING INNOVATION CENT FOR ENVIRONMENTAL PROTECTION IND

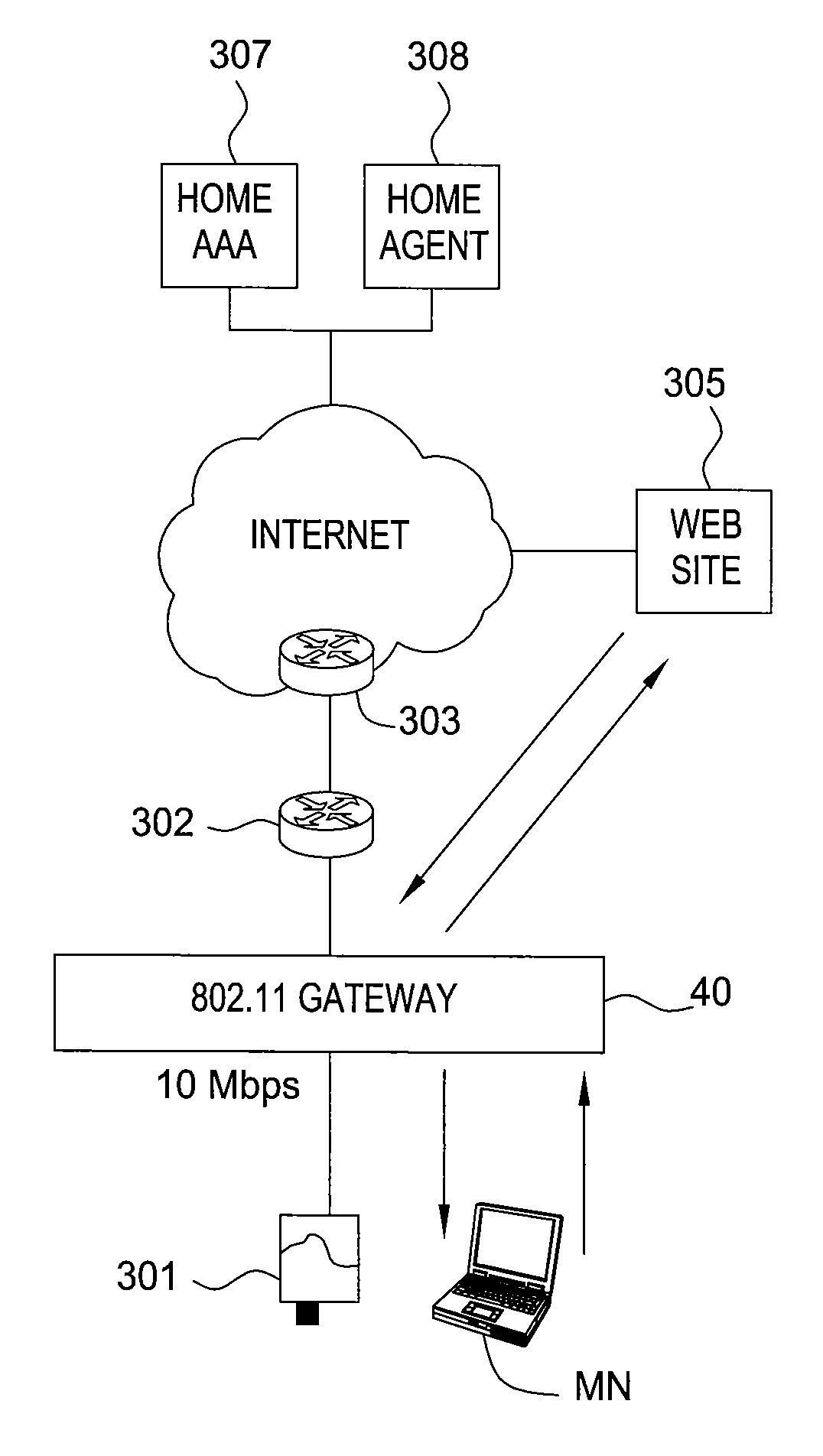

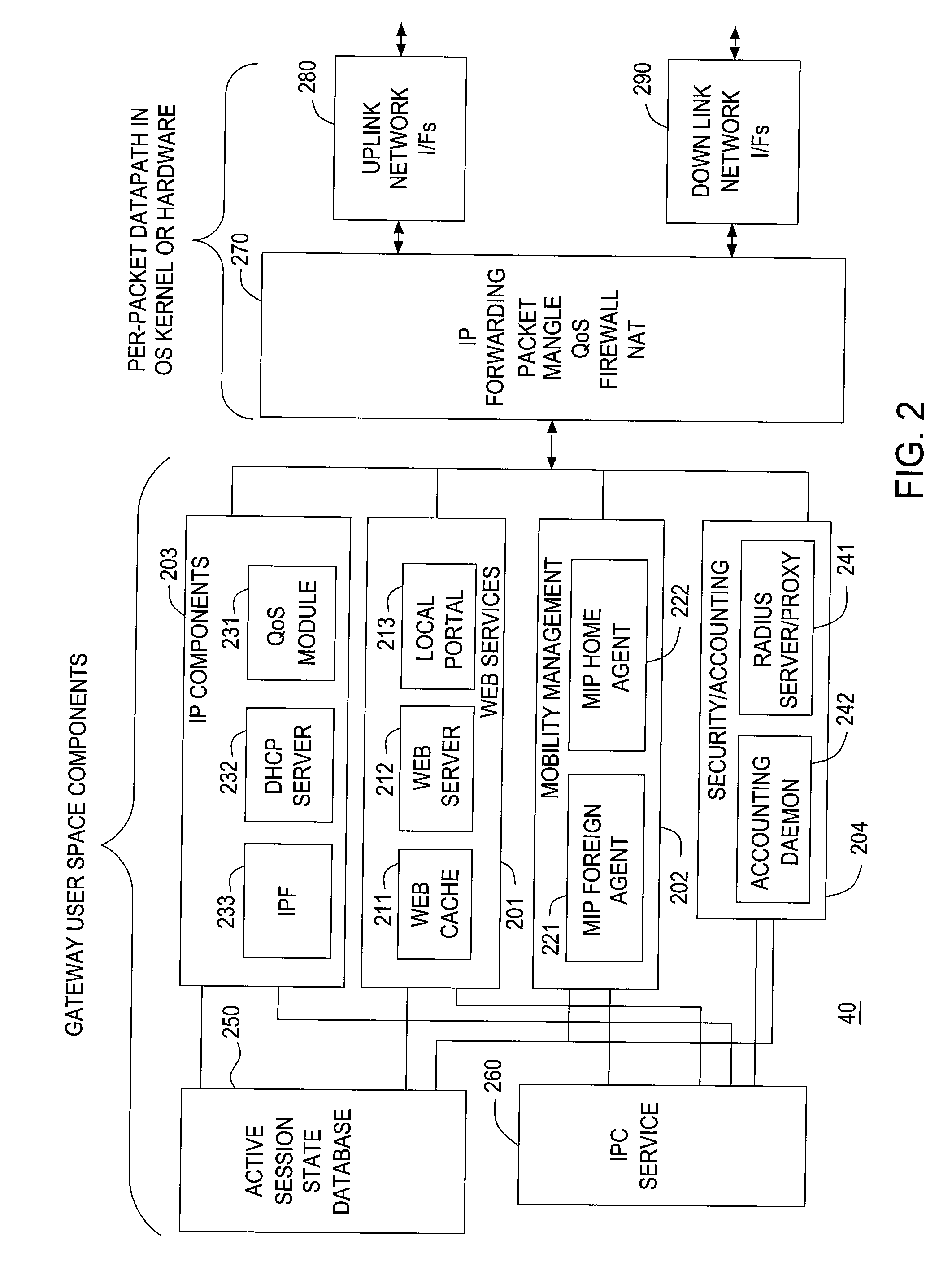

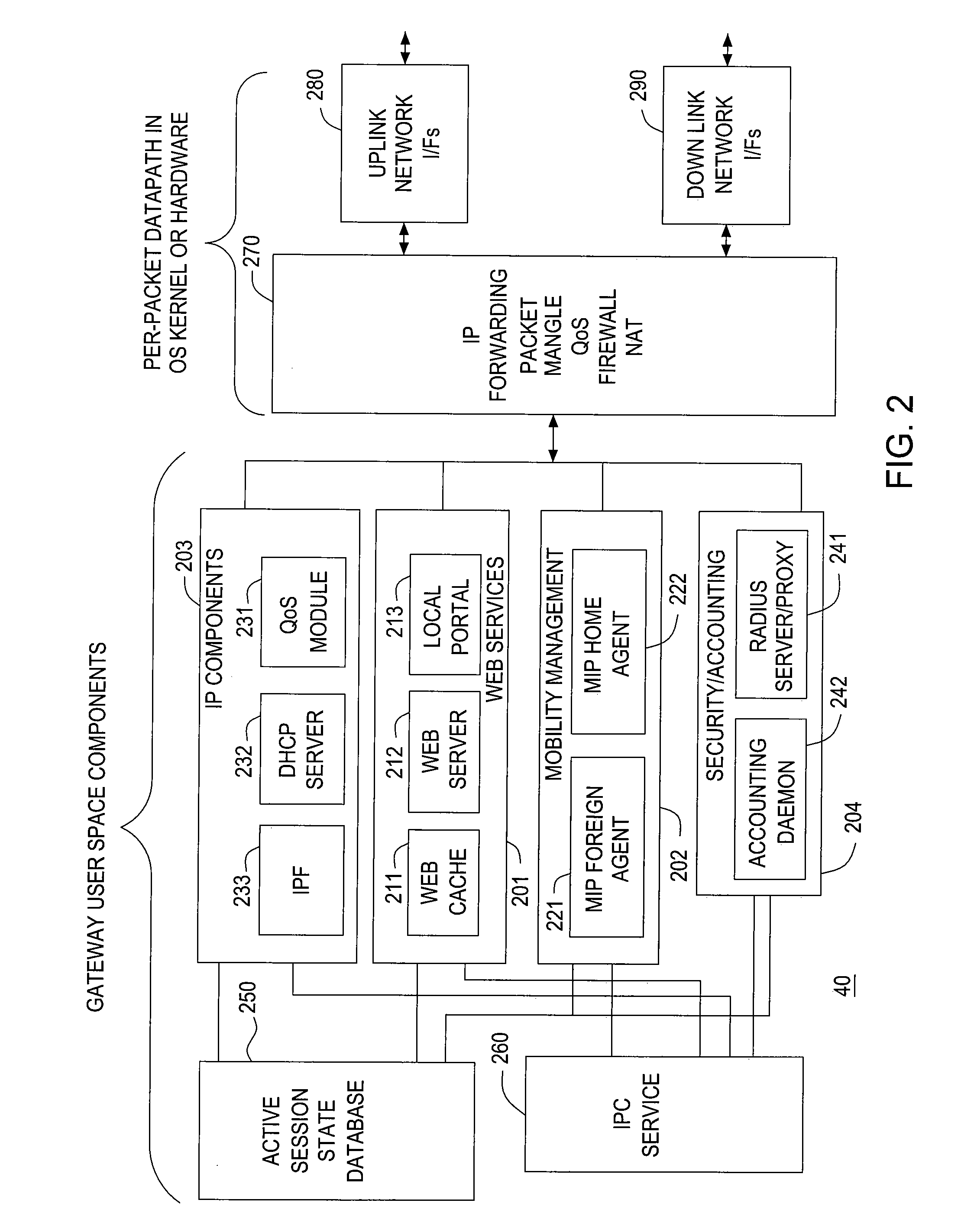

Integrated web cache

A gateway for mobile communications comprises a cache for storing network data recently downloaded from a network, a foreign agent, and a packet filter that directs requests for the network data from a mobile node to the cache. The packet filter directs the requested network data from the cache to the mobile node by way of the foreign agent, without forwarding the requested network data to a home agent of the mobile node.

Owner:SOUND VIEW INNOVATIONS

Integrated web cache

A gateway for mobile communications comprises a cache for storing network data recently downloaded from a network, a foreign agent, and a packet filter that directs requests for the network data from a mobile node to the cache. The packet filter directs the requested network data from the cache to the mobile node by way of the foreign agent, without forwarding the requested network data to a home agent of the mobile node.

Owner:SOUND VIEW INNOVATIONS

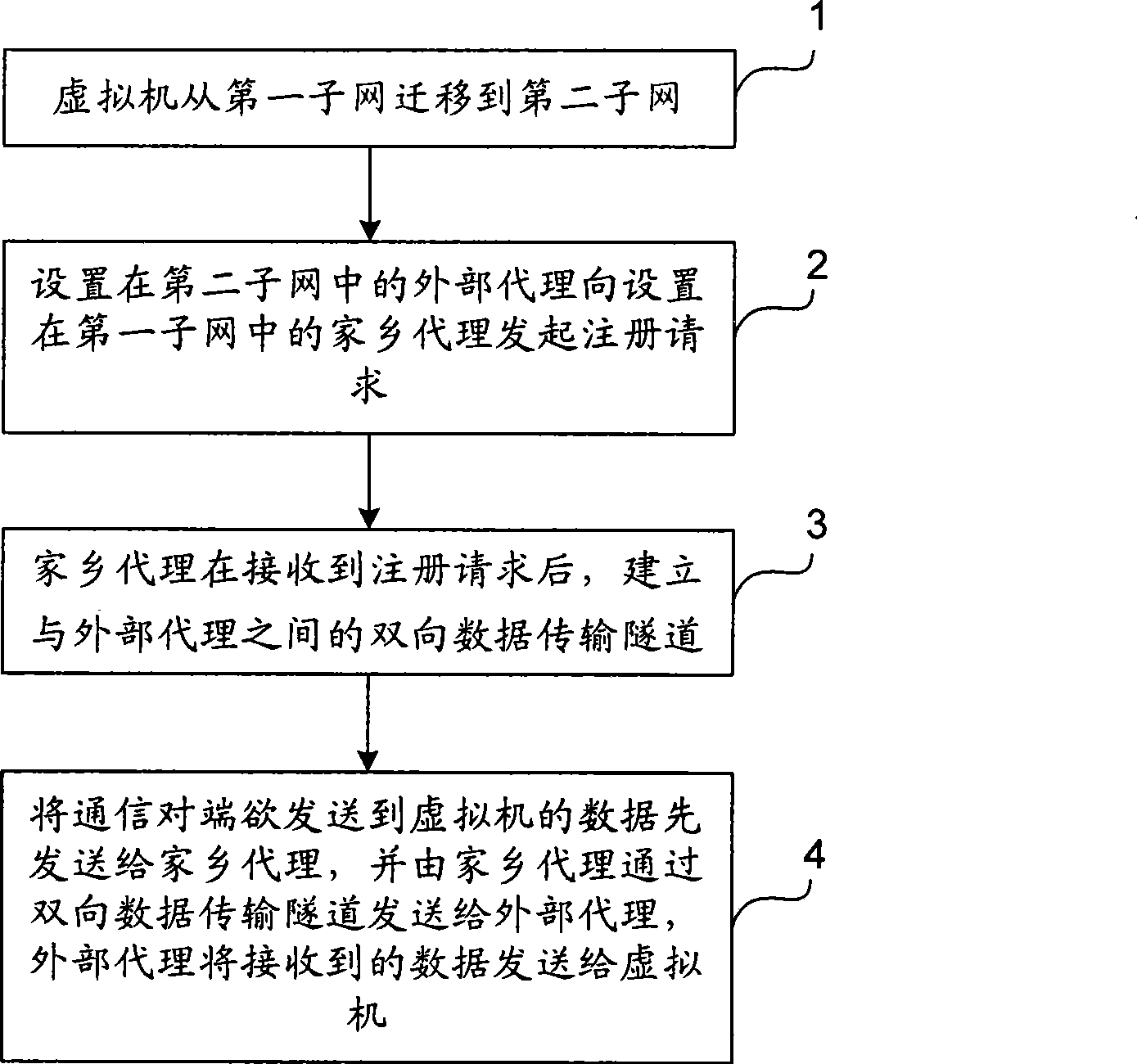

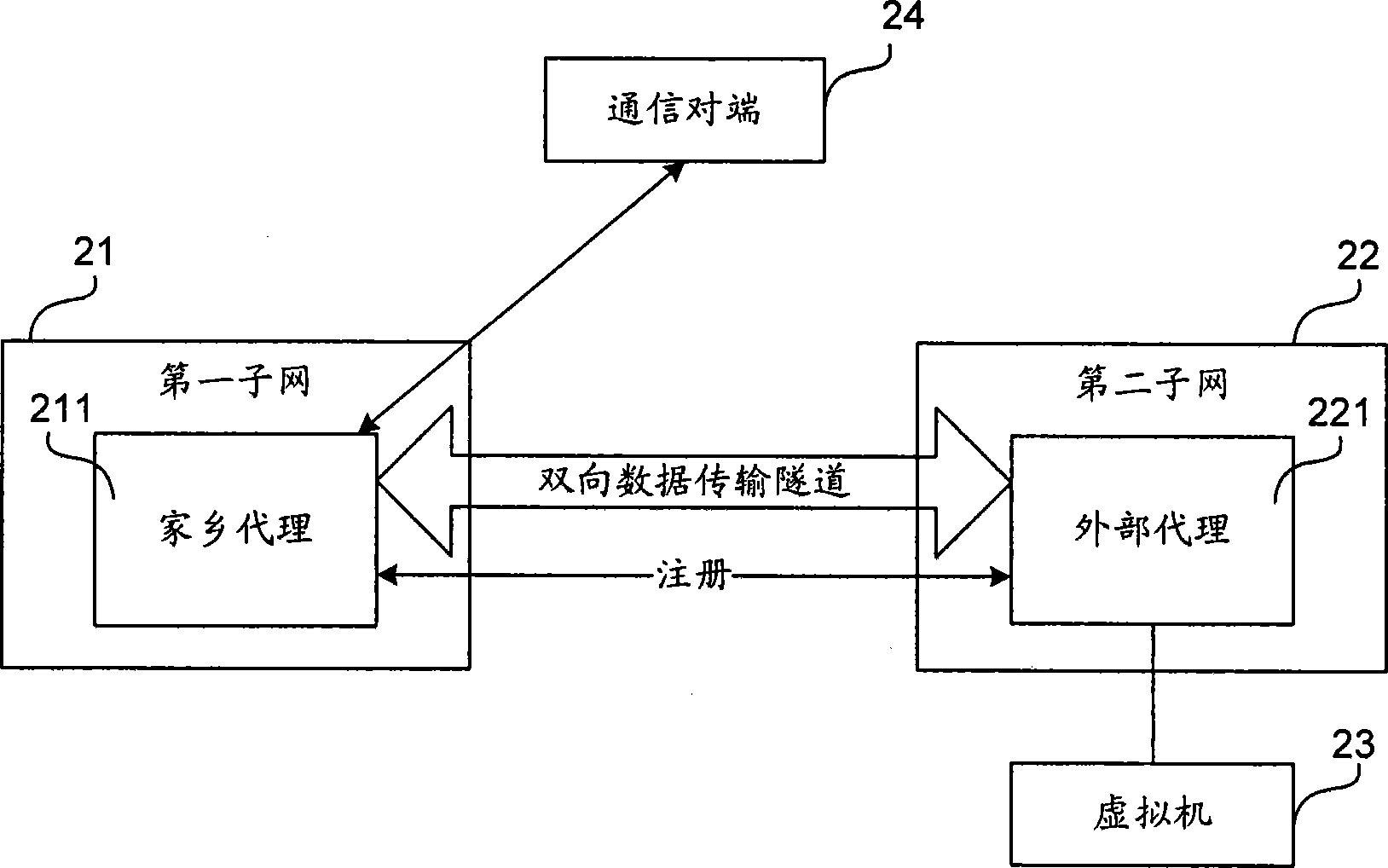

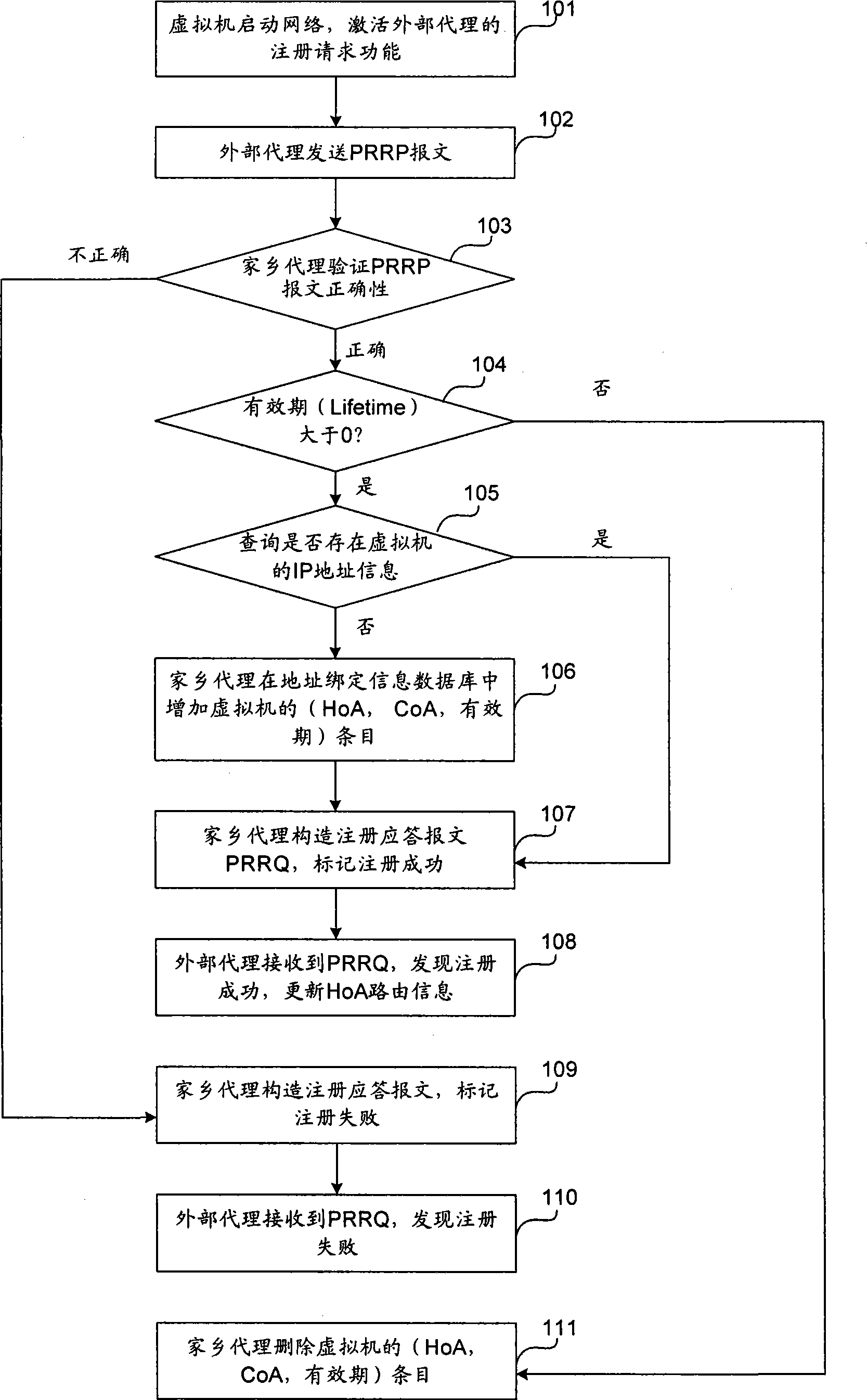

Redirection method for virtual machine network connection when on-line migrating striding sub network

InactiveCN101465812AEnsure transparencyOvercome the defect of increased loadNetworks interconnectionOperational systemNetwork connection

The invention relates to a method for redirecting network connection of a virtual machine when being transferred across subnets online, including the steps that: 1, the virtual machine is transferred from a first subnet to a second subnet; 2, a foreign agent arranged in the second subnet sends a registration request to a home agent in the first subnet; 3, after receiving the registration request, the home agent builds a bidirectional data transmission tunnel between the home agent and the foreign agent; 4, the data to be sent to the virtual machine by a communication counterpart terminal is first sent to the home agent and then is sent to the foreign agent by the home agent through the bidirectional data transmission tunnel, and the foreign agent sends the received data to the virtual machine. The method is unnecessary to change the operating system of the virtual machine, can ensure the transparency to the virtual machine in the network redirection process when transferring the virtual machine across the subnets, and can overcome the defect in prior art that data is forwarded between the communication counterpart terminal and the virtual machine through a source host, which leads to the increase of the load of the source host.

Owner:BEIHANG UNIV

Rose donkey-hide gelatin cake and preparation method thereof

The invention relates to the field of food, and in particular relates to a rose donkey-hide gelatin cake and a preparation method thereof. The rose donkey-hide gelatin cake is characterized in that the rose donkey-hide gelatin cake is prepared from the following raw materials in parts by weight: 8-25 parts of re-petal red rose fresh flowers, 5-15 parts of dry re-petal red roses, 10-35 parts of donkey-hide gelatin, 20-45 parts of black sesames, 10-35 parts of walnut kernels, 8-20 parts of crystal sugars, 28-100 parts of white granulated sugars and 10-30 parts of yellow wine. By the food, the rose petal in the product can be clearly seen, the color of the rose petals is reserved; the rose is organically combined with the donkey-hide gelatin, so that a new formulation of the rose and the donkey-hide gelatin is researched, and the donkey-hide gelatin drives the rose to develop so as to widen the domestic and foreign markets of Pingyin rose; and the food overcomes the defects of inconvenience in use of the rose and the donkey-hide gelatin, can be eaten after the package is opened, and is delicious and convenient to carry, transport and store, and solves the problems that the donkey-hide gelatin is difficultly boiled due to needs of being crashed and melted by heat, is inconvenient to orally take and is not good in taste.

Owner:济南紫金玫瑰股份有限公司

Producing method for bread freshwater lobster cake

The patent provides a preparation method of bread freshwater lobster cake and relates to a food processing method, specifically which is bread cake making method with freshwater lobster as material, wherein the procedure for making break includes, conventional blank-making, quick freezing, enveloping slurry, enwrapping breadcrumb, pre-frying, pre-cooling, packaging and warehousing. Bread freshwater lobster cake made with the method of invention has following advantages including, golden yellow appearance, testing crisp and tender, special flavor, which can be eaten by simple frying, portable and suitable to people of all ages. The present invention provides a making method of bread freshwater lobster cake to accord with common dietary of east and west people, which increases variety of freshwater lobster production, thus contributes to expand domestic and foreign markets of freshwater lobster production.

Owner:JIANGSU BAOLONG GROUP

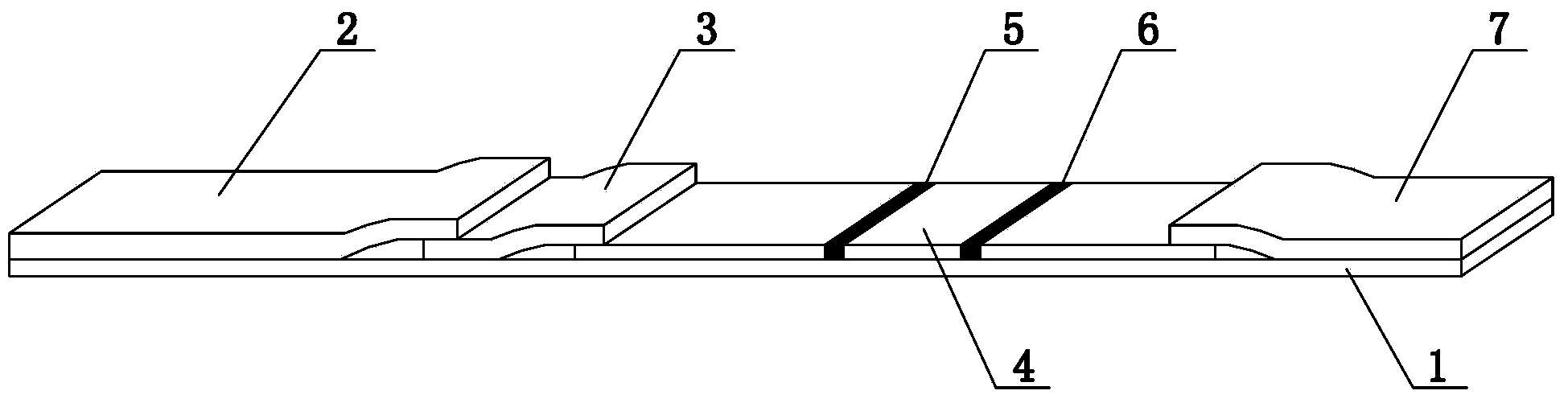

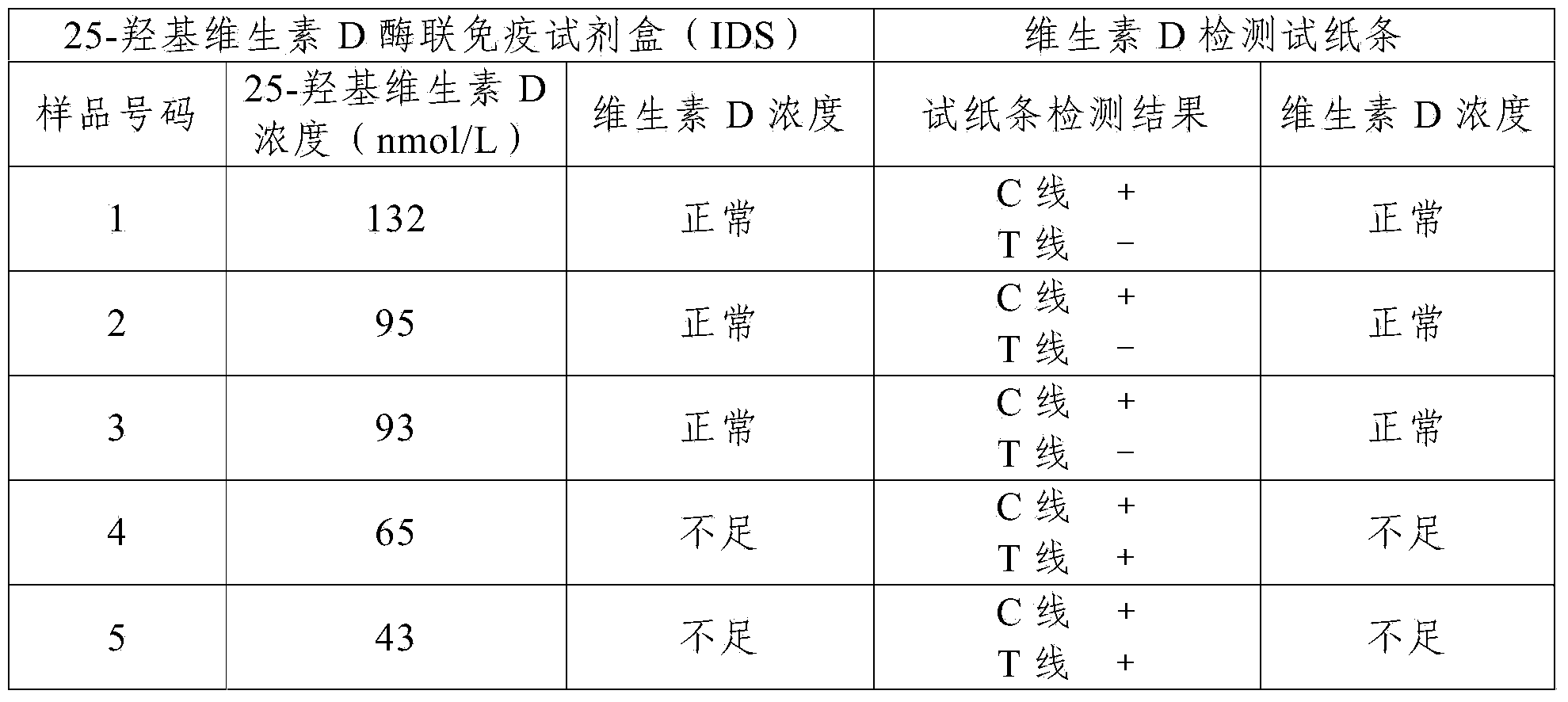

Test strip for rapidly detecting vitamin D

ActiveCN104062440AReduce testing costsThe detection method is simpleBiological testingMedical unitMedicine

The invention discloses a test strip for rapidly detecting vitamin D. The test strip comprises a supporting plate which does not absorb water. A sample pad, a combination pad, a chromatography film and an absorbent pad are arranged on the supporting plate in sequence. The combination pad is covered with a marker-marked conjugate of the vitamin D and carrier protein. The chromatography film is a nitrocellulose film and provided with a quality control line C and a detection line T, the detection line T is located between the combination pad and the quality control line C, the detection line T is covered with a vitamin D specific antibody, and the quality control line C is covered with a specific antibody capable of being combined with the carrier protein. The test strip is convenient to use, easy to operate, high in detection speed, and capable of being easily popularized in primary medical units, meeting market requirements, and filling gaps in domestic and foreign markets. A result of the test strip is easy to judge and is represented symbolically, and special requirements of vitamin D detection for equipment, instruments and personnel are eliminated.

Owner:西安良升生物科技有限公司

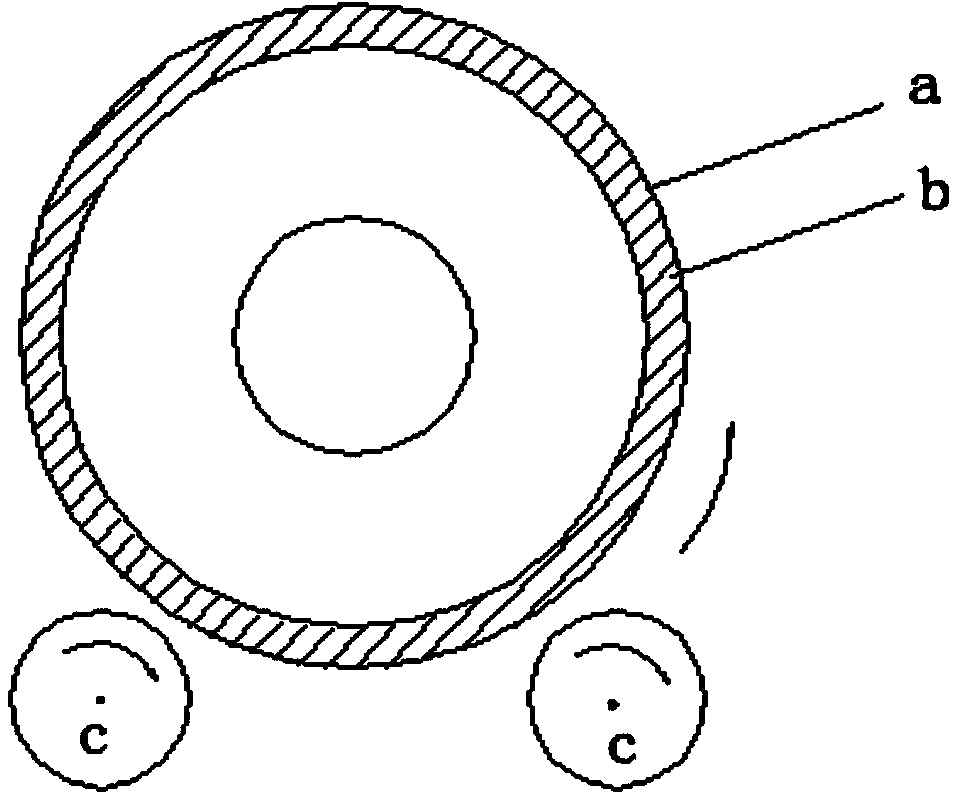

Manufacturing process for bi-metal composite roll collars

The invention discloses a manufacturing process for bi-metal composite roll collars and relates to the technical field of steel rolling industry. The manufacturing process comprises the following steps of manufacturing a centrifugal mold, arranging end covers at two ends of the centrifugal mold, brushing a coating on the centrifugal mold, covering a film on the centrifugal mold, baking at high temperature, and rotating on a centrifugal machine for casting preparation; smelting semisteel, spheroidizing a nodular cast iron material in a core, centrifugally casting a working layer material, covering a small amount of broken glass to prevent the working layer material form being oxidized, continuously rotating the centrifugal mold, ensuring that the working layer material is continuously cured, casting an inner layer material after a certain period of time, and completing the casting process in two times. In the manufacturing process, chemical compositions of a roll body are determined, a casting temperature, a cooling parameter, and parameters in an annealing process, a quenching process and a tempering process for heat treatment are controlled in certain ranges, large roll collars with reliable quality can be produced and are popular with domestic and foreign markets.

Owner:朝阳联强轧辊有限公司

Method for crystallizing cefixime trihydrate

The invention provides a method for crystallizing cefixime trihydrate. The cefixime trihydrate is obtained through hydrolyzing an aqueous solution of cefixime methyl ester by adding an alkali, adding at least one solvent, adjusting the pH value by an acid until the cefixime trihydrate is precipitated, heating, carrying out crystal growing for a certain time, and adjusting the pH value by the acid until a large amount of the cefixime trihydrate is precipitated. The method which allows at least one solvent to be added to water makes the impurity removal effect be very good and the cefixime trihydrate quality be high (equal to or more than 99.5%), and the obtained cefixime trihydrate has the advantages of granularity uniformity, good fluidity and very good stability, so the content is reduced by equal to or less than 0.2% after the cefixime trihydrate is disposed for 1 month at 40DEG C, thereby problems of bad quality and bad stability of the cefixime trihydrate in present domestic and foreign markets are solved, and the method is suitable for the industrialized production.

Owner:ZHEJIANG GUOBANG PHARMA

Production method for ultrafine raw silks of 7/9D specifications

The invention discloses a production method for ultrafine raw silks of 7 / 9D specifications. The method includes: processing high-quality ultrafine-denier cocoons with the fineness of 1 denier by hot air at the low temperature, drying the cocoons to dried cocoons by a dry method, cooking the dried cocoons for a short time at the low temperature to appropriately-cooked cocoons by the aid of steam and a cocoon cooking method, and reeling with 8 fixed cocoons by a small-aperture ceramic eyelet at a low speed to produce the ultrafine raw silks of the 7 / 9D specifications. The produced ultrafine raw silks of the 7 / 9D specifications are small in denier deviation and high in cleanliness, and a novel product woven by the raw silks is unique in gloss and flavor, crease-resistant, capable of improving dyeing property greatly and good in social and economic benefits. In addition, the traditional sericulture can be improved, and diversified demands of domestic and foreign markets can be met.

Owner:ZHEJIANG UNIV

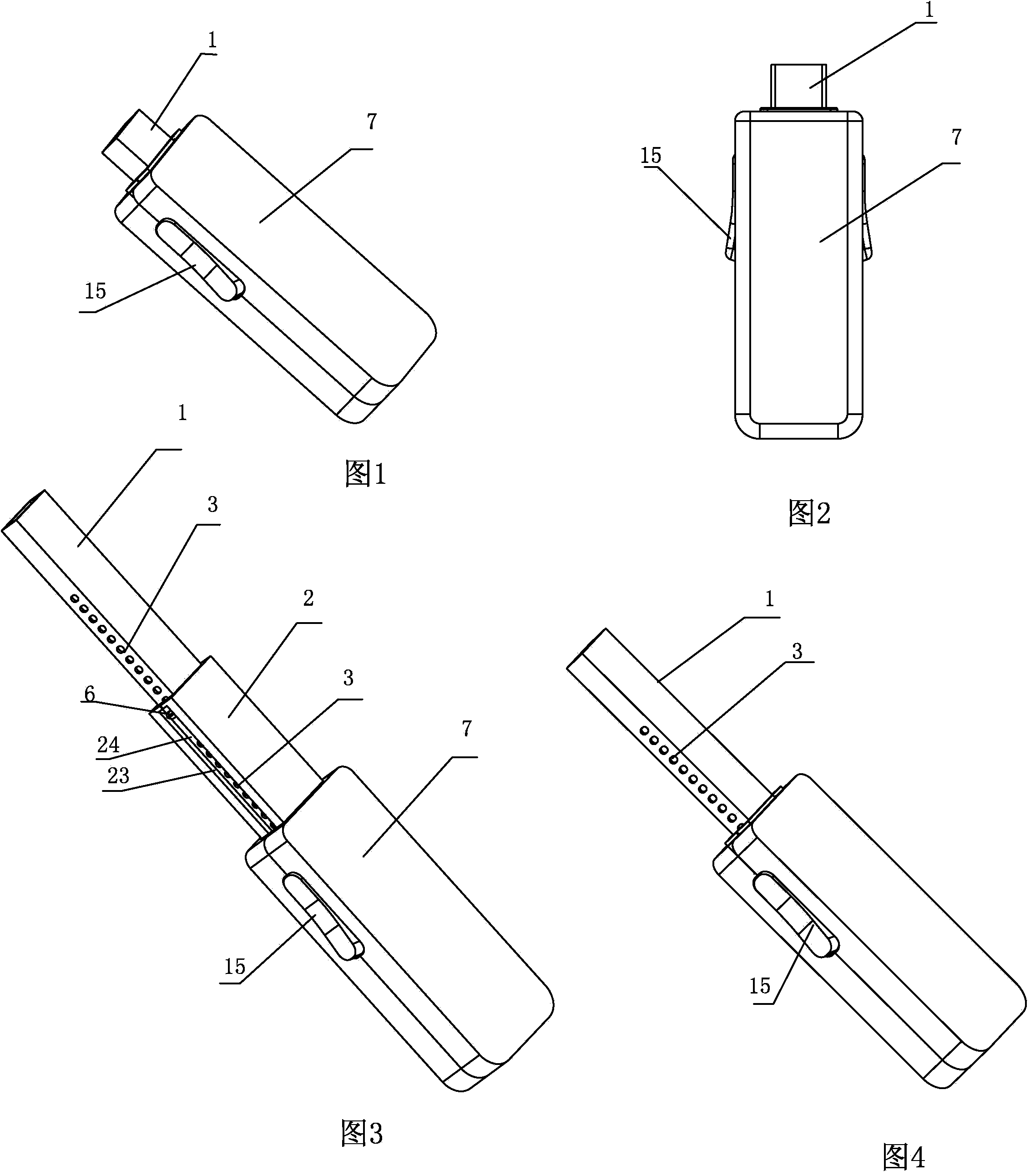

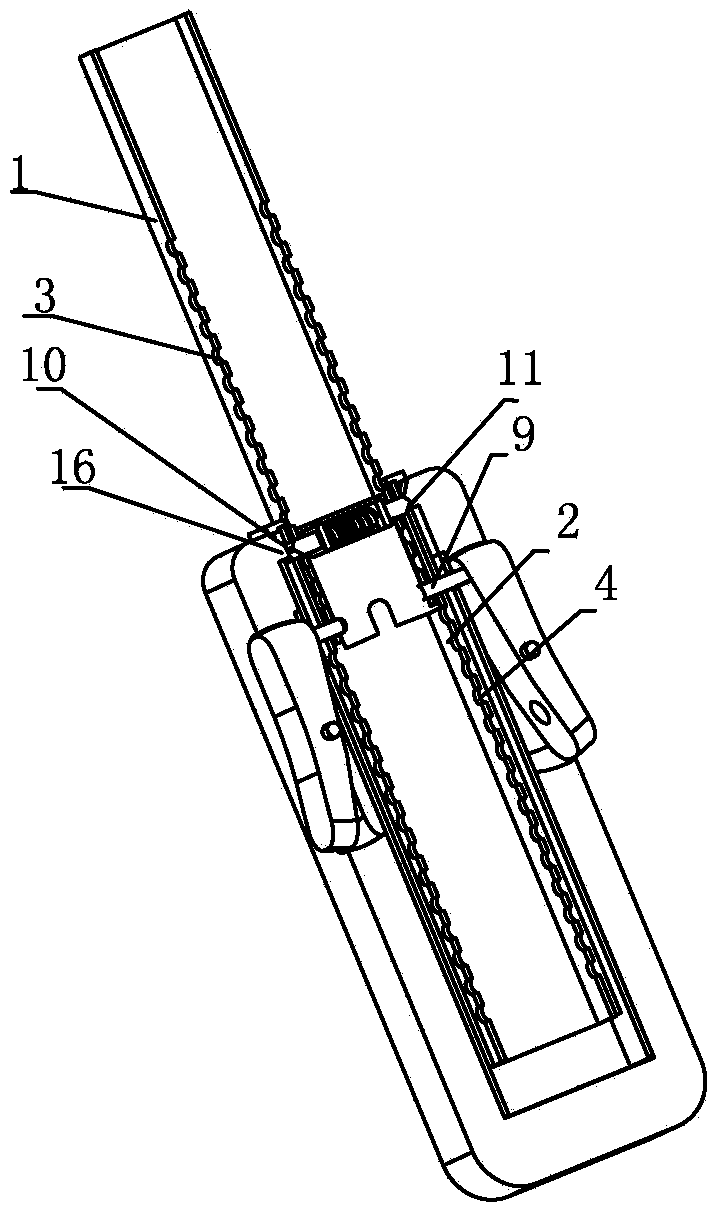

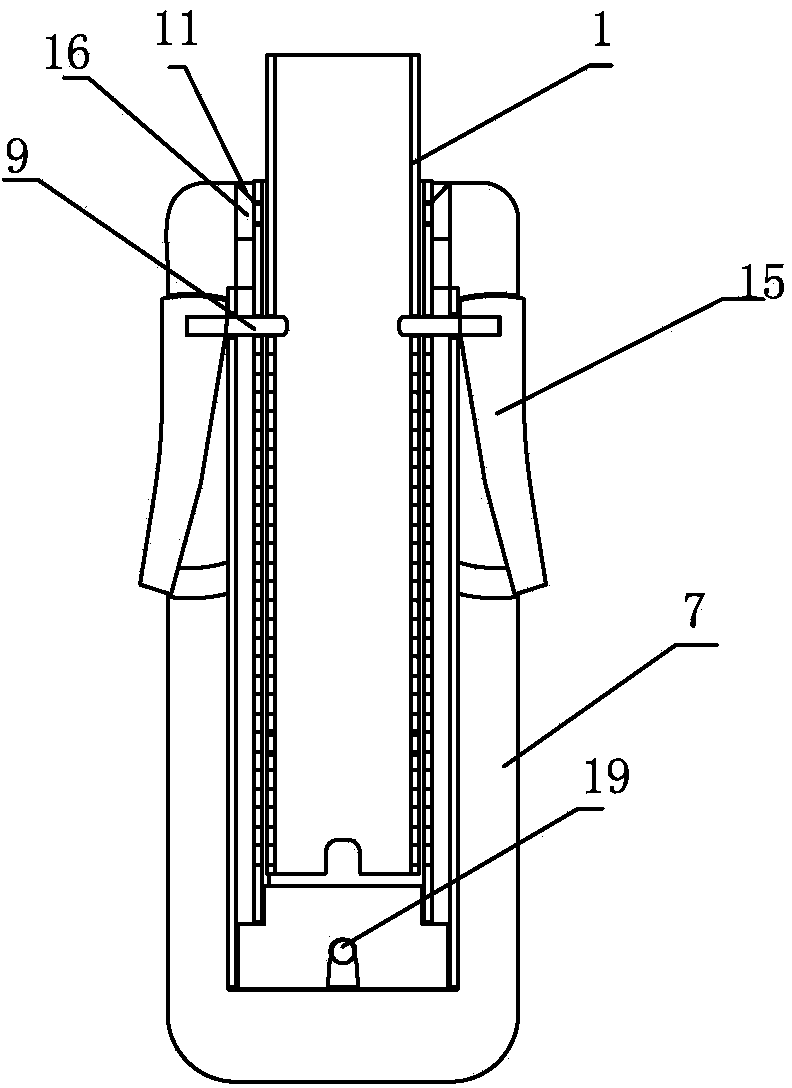

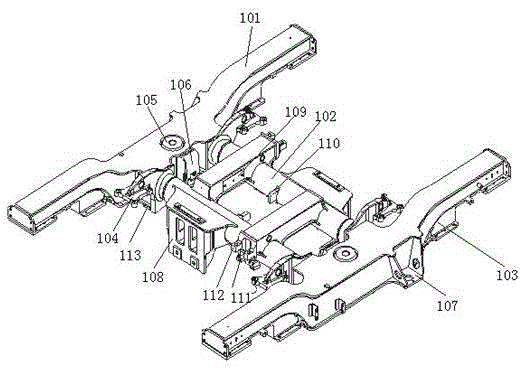

Supporting leg assembly of child safety seat

The invention discloses a supporting leg assembly of a child safety seat. A middle square pipe is sleeved with a supporting base which is supported by a vehicle bottom plate. An elastic locking mechanism is arranged on the supporting base and comprises hinge pins which are matched with a first locking hole and a second locking hole, a first inclined plane is arranged on the inner side of the supporting base, and a second inclined plane is arranged on the outer side of a locking block. When the first inclined plane of the supporting base presses the second inclined plane of the locking block, the front end of the locking block retracts into the inner wall of the middle square pipe. The supporting leg assembly has the advantages that a user can adjust the height of the supporting leg assembly only by pushing upwards or pulling downwards the supporting base with one hand, operation is convenient to conduct, the adjusting range of the height of supporting legs can be extended to 260 mm, and therefore the adaptability requirement of supporting legs of all vehicles with ISOFIX connectors on current domestic and foreign markets can be met.

Owner:NINGBO GLOBAL KIDS BABY PROD

High strength easy-to-cut aluminum alloy

ActiveCN101307403AExcellent machinabilityImprove mechanical properties5005 aluminium alloyMechanical property

The invention relates to a high-strength easy-cutting aluminium alloy. The invention is characterized in that the aluminium alloy is an aluminium-base alloy, containing bismuth, tin, copper, silicon and chromium as alloying elements, and other unavoidable impurity elements. A product produced by the alloy has good easy-cutting capability, excellent mechanical property, excellent corrosion resistance and excellent solderability. The aluminium alloy has low production cost and is equivalent to the prior leady aluminium alloy, so the aluminium has competitive advantages in domestic and foreign markets; The aluminium alloy product can replace partial leady aluminium alloys, thereby not only facilitating the reclamation when the product is consumed completely so as to reduce lead pollution, but also facilitating the expansion of the application field of aluminium alloy products. The aluminium alloy also can replace partial leady easy-cutting aluminium alloys, such as 2011 or 6262 leady aluminium alloy and so on.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

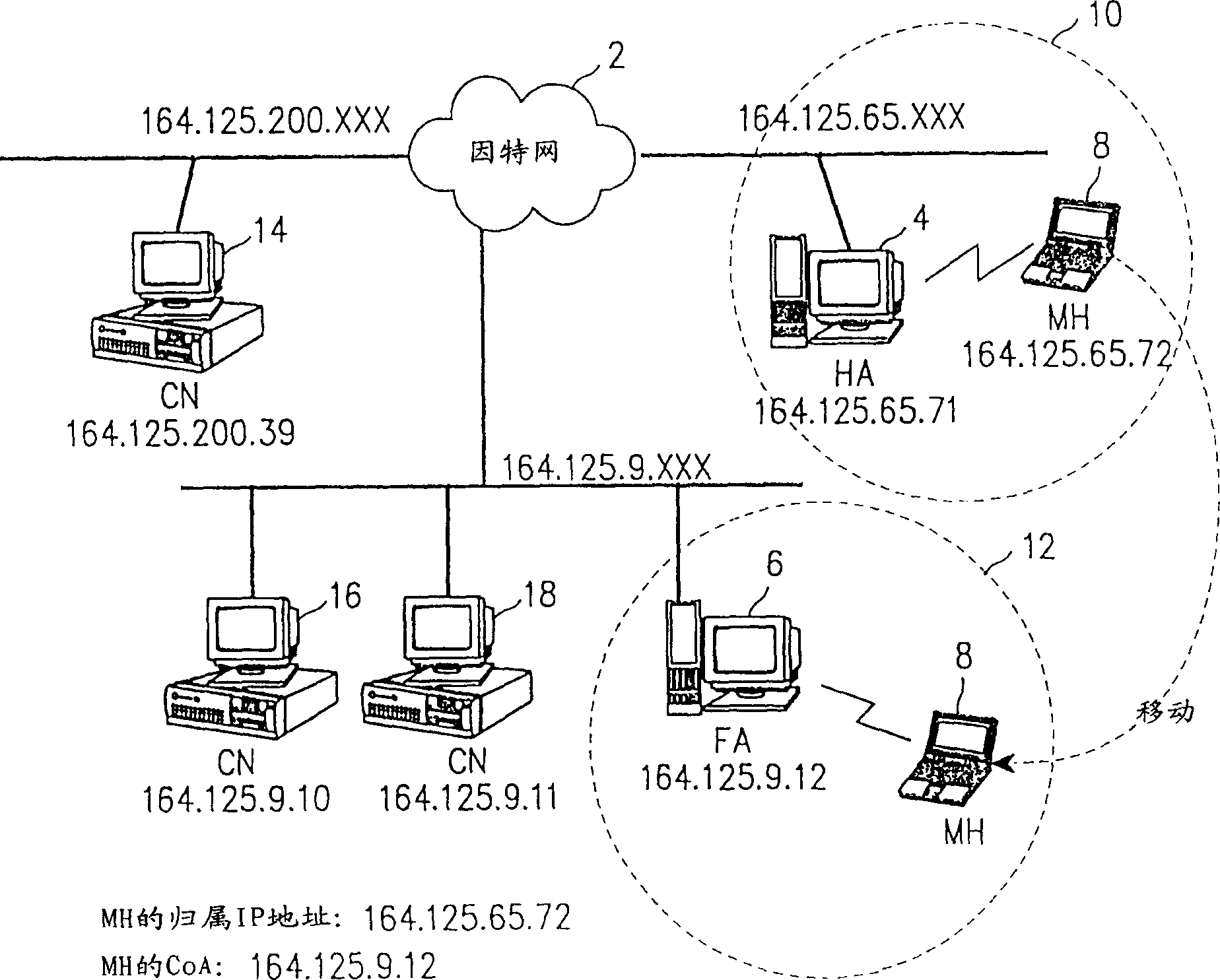

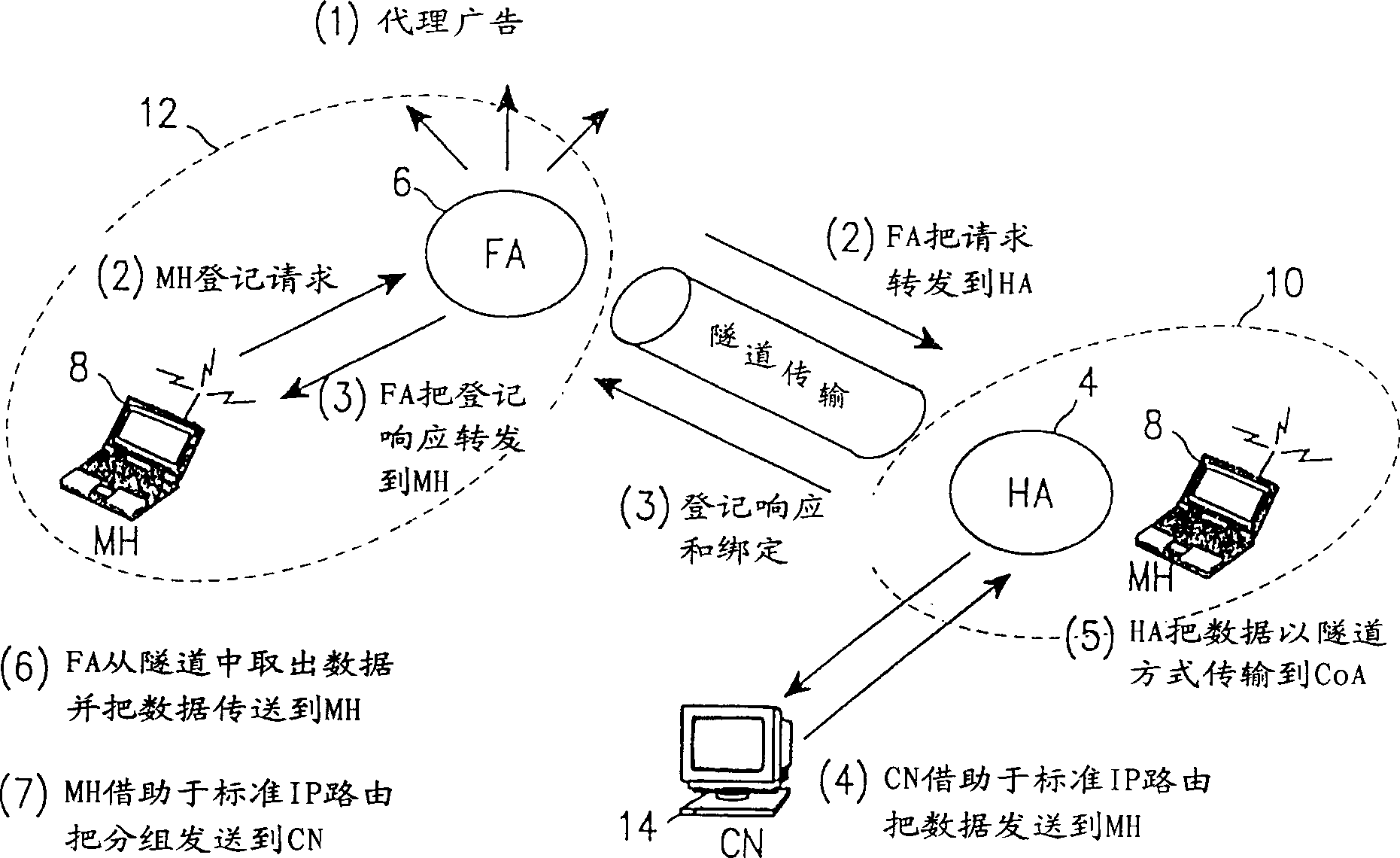

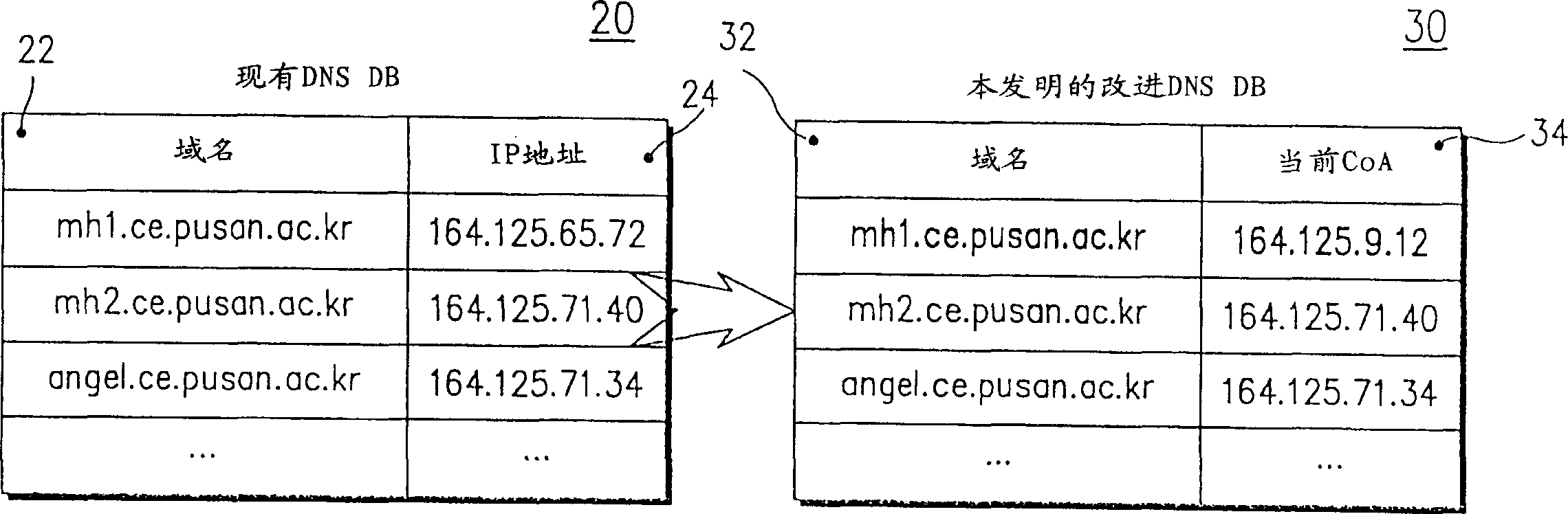

Moboile internet protocol system and its route optimizing method

InactiveCN1402493AData switching by path configurationWireless network protocolsDomain nameComputer network

There is provided a route optimization method in a mobile Internet Protocol (IP) system using a mobile Internet Protocol. When a mobile host (MH) moves over the Internet and is assigned to a care-of-address (CoA) corresponding to a changed point of attachment to the Internet, it sends a registration request message containing the care-of address to a home agent (HA) via a foreign agent (FA). The home agent stores the care-of address in relation to a domain name of the mobile host in an internal domain name server database. Upon receipt of a query about the mobile host by domain name from a correspondent node (CN), the home agent sends the care-of address corresponding to the domain name of the mobile host together with caching prevention information to the correspondent node. The caching prevention information is set to prevent the correspondent node or another domain name server from caching the care-of address of the mobile host. The correspondent node communicates with the mobile host using the care-of address.

Owner:SAMSUNG ELECTRONICS CO LTD

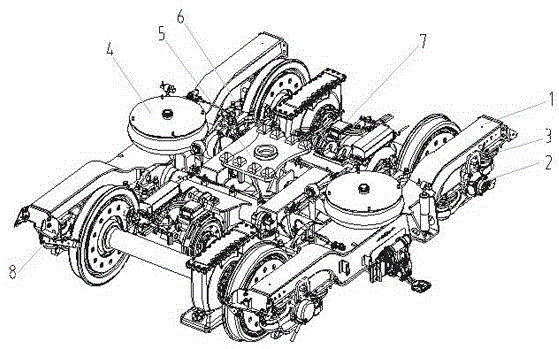

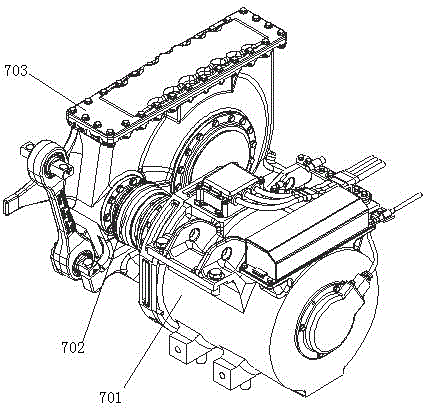

Bogie for A-type broad-gauge metro vehicle

The invention discloses a bogie for an A-type broad-gauge metro vehicle. The bogie comprises a frame, a wheelset and axle box device, a primary suspension device, a secondary suspension device, a central traction device, a foundation brake device, a driving device and a rim lubrication device. The bogie is characterized in that the frame has a large lateral span, the primary suspension adopts a rubber spring, the secondary suspension adopts an air spring, a secondary vertical damper and a horizontal damper to reduce vibration and impact, so that a passenger sits more conformably, two traction rods are adopted between a vehicle body and the bogie for transferring traction and braking force, and the foundation brake device adopts a wheel mounted type disc brake unit. The bogie meets requirements for a Brazil 1A metro project contract, and the bogie for the A-type broad-gauge metro vehicle, which meets requirements for a dual-mode signal system, is researched for the first time; the gauge is 1600 mm and the axle load is 17.5 tons; the bogie has the advantages of high operation quality and convenience for maintenance and can be widely applied to the foreign market.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

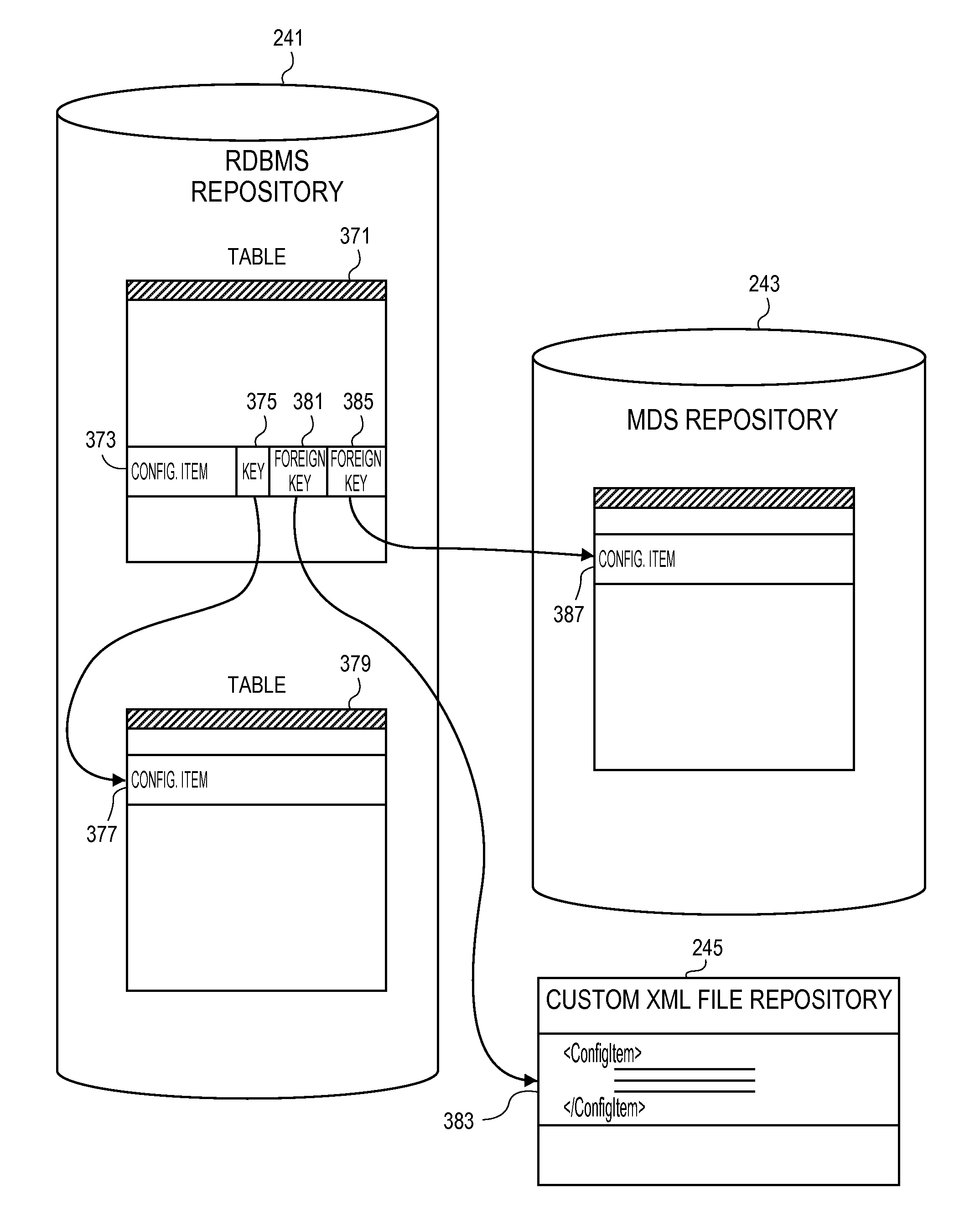

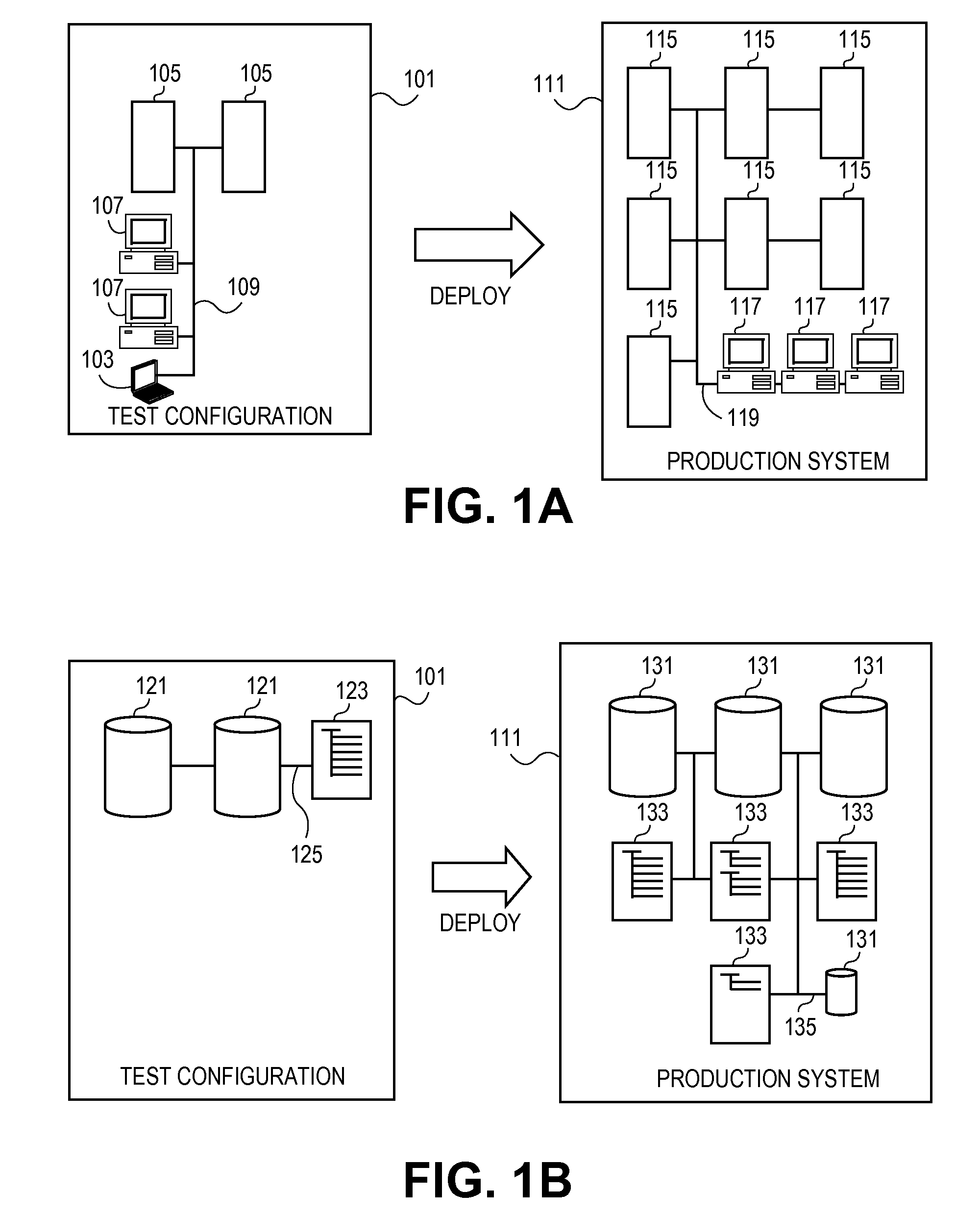

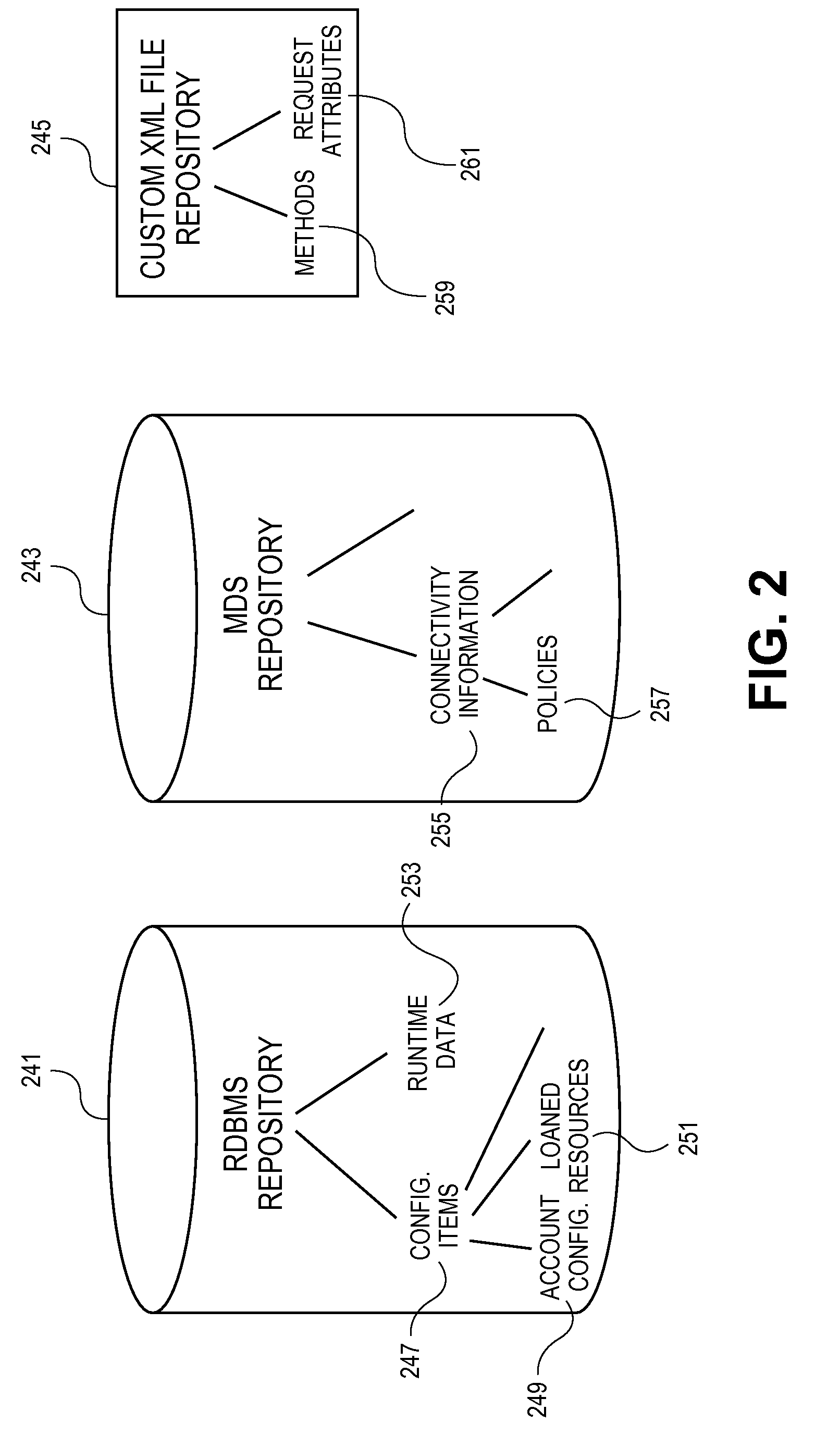

Configuration deployment management

ActiveUS20100100870A1Database management systemsDigital data processing detailsCode moduleMeta Data Services

Applications, code modules, and other such software objects are able to be deployed and / or ported even when the corresponding configuration data is spread between a relational database management system (RDBMS) database and a meta data services (MDS) database, even where the configuration data is spread across any disparate databases. Configuration data also can be stored in a custom repository, such as an custom extensible markup language (XML) file. One approach involves detecting foreign keys, creating logical references to replace the foreign keys, and resolving the foreign keys to new references in the deployed environment by using the logical references. Code can be stored in the databases in order to help resolve the foreign keys.

Owner:ORACLE INT CORP

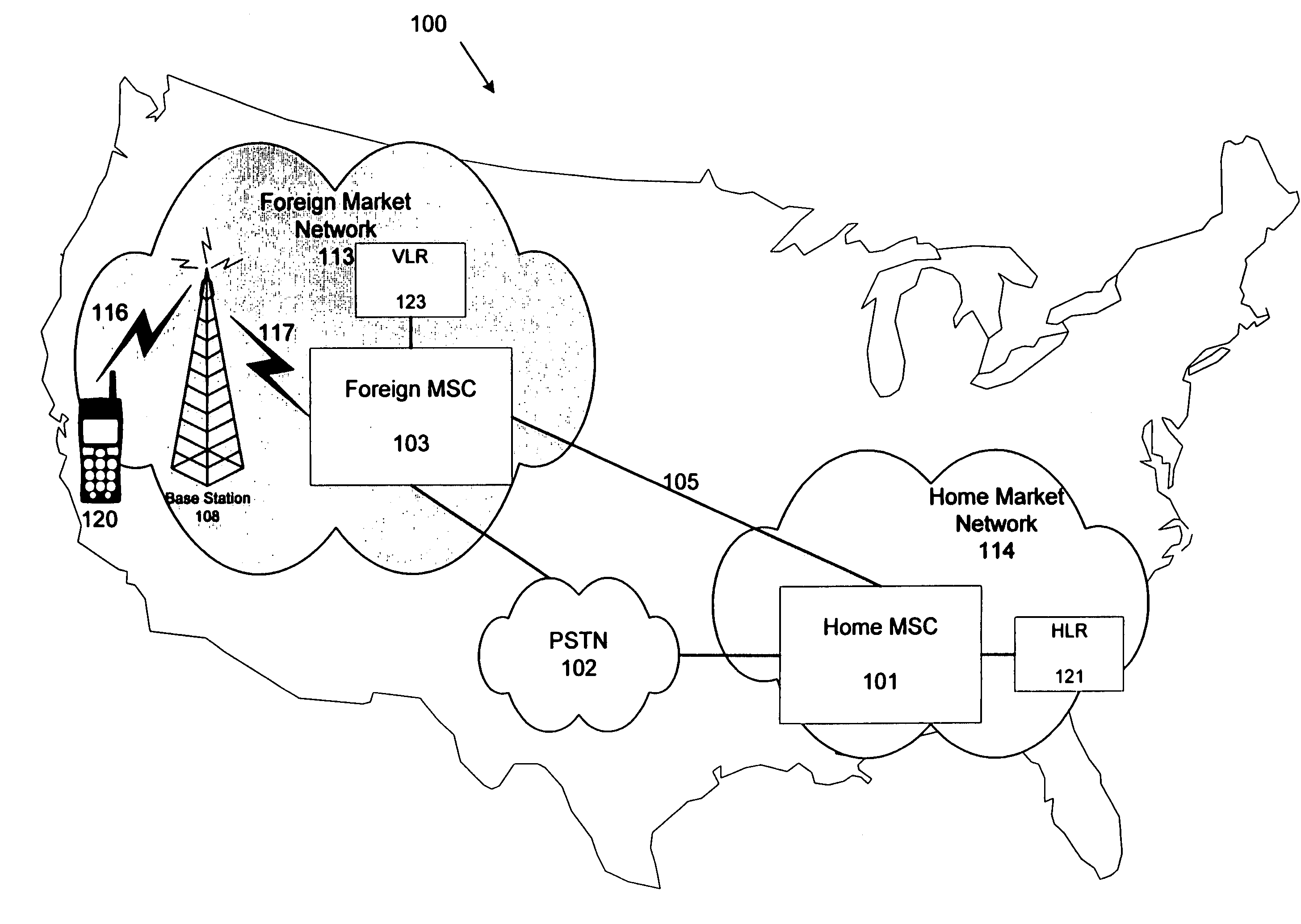

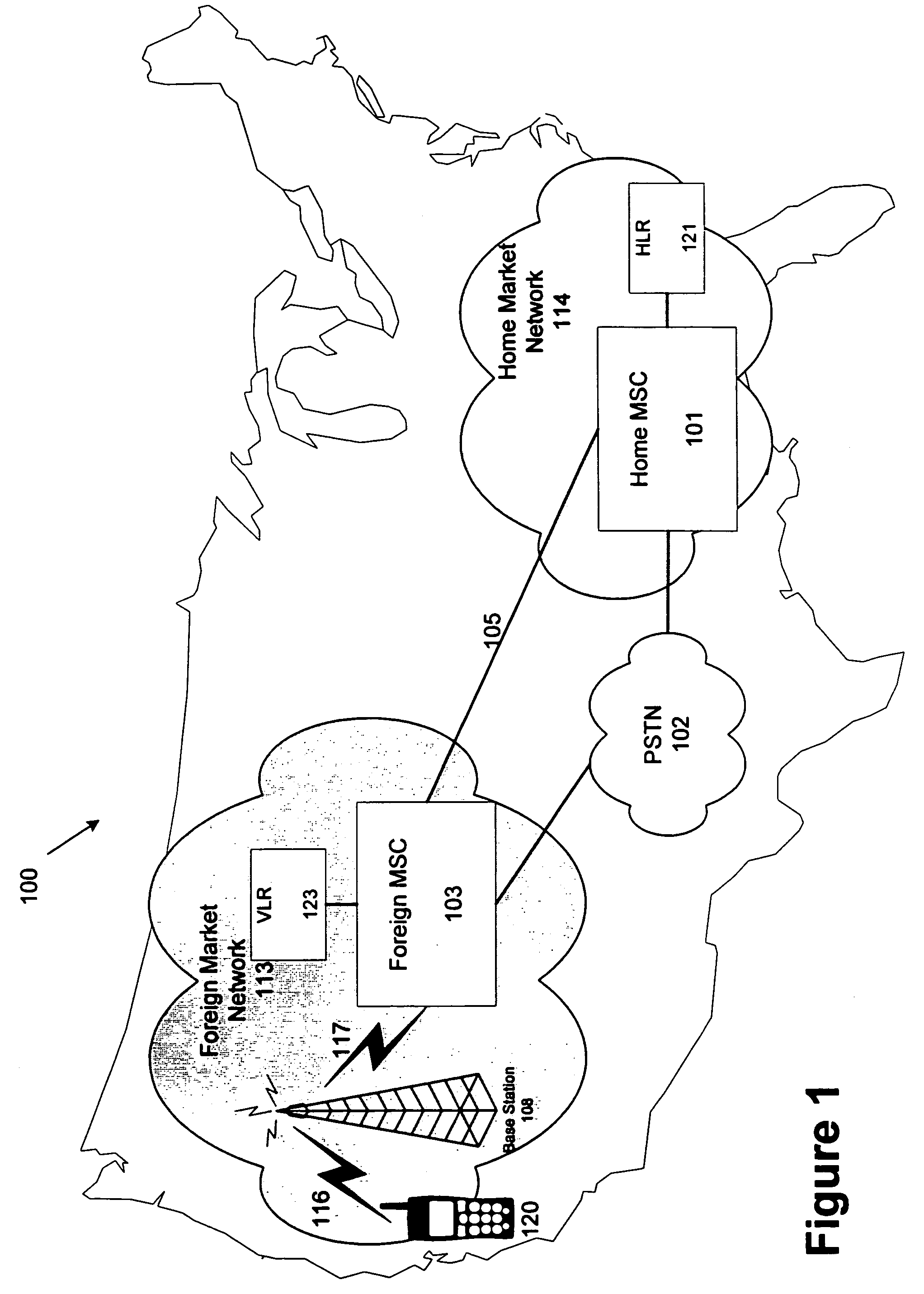

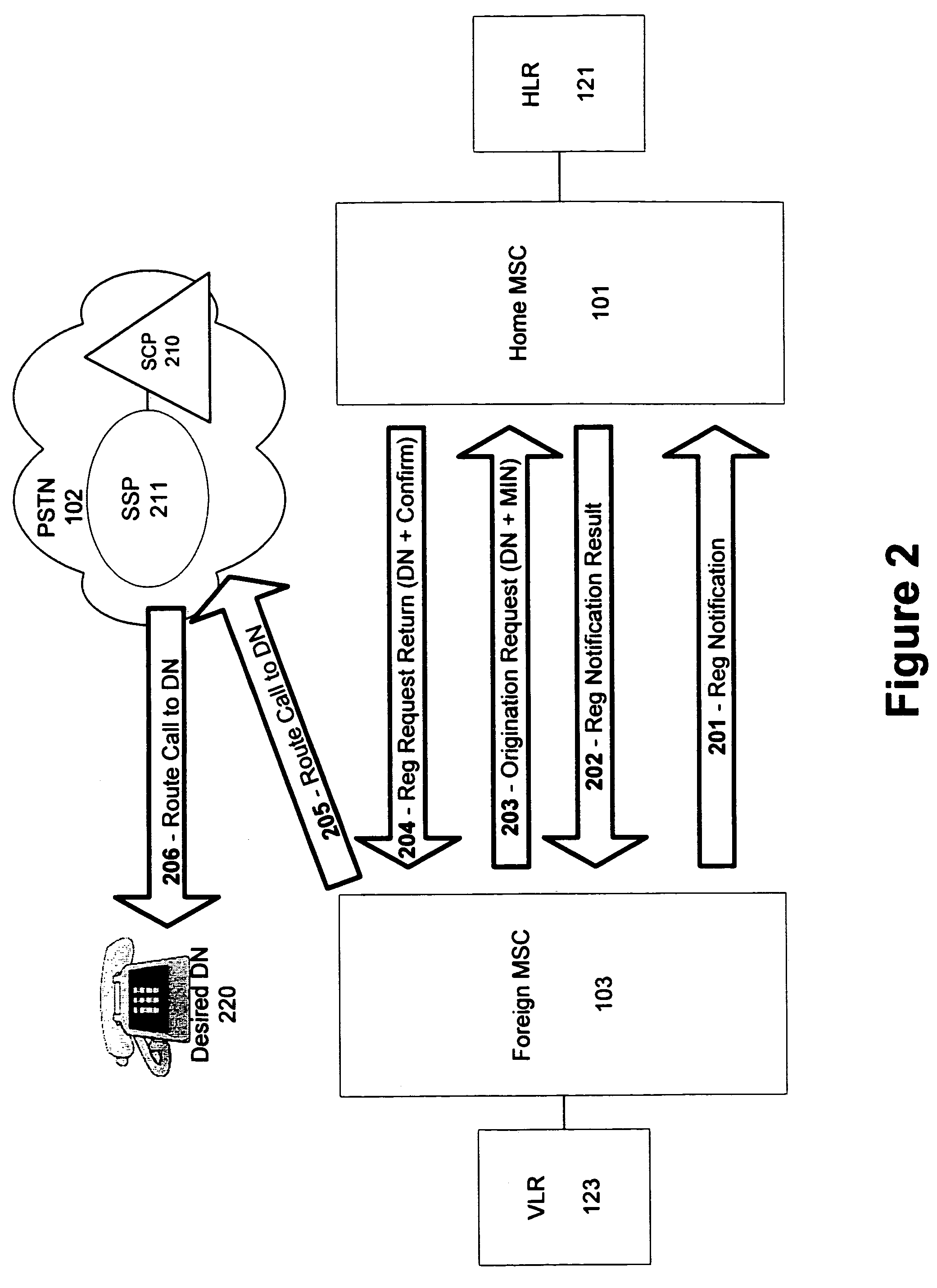

Roaming virtual long distance

InactiveUS7082300B1Interconnection arrangementsSpecial service for subscribersMobile identification numberTelecommunications

The invention provides a system and a method for connecting an out-of-market customer to a desired telephone number. The method comprises receiving a customer validation request from a foreign market provider and, in return, providing a random or designated toll-free telephone number to the foreign market provider. Upon receiving a call request from the foreign market provider, the call request is directed to the desired telephone number. The customer validation request may include the desired telephone number and / or a mobile identification number. The call request is based on the provided toll-free telephone number, which is owned by a home market provider.

Owner:BELLSOUTH INTPROP COR

Antibody, and coding gene and application thereof

The invention discloses an antibody, and a coding gene and application thereof. An amino acid sequence of a heavy chain variable region of the antibody is shown in the sequence 2 in a sequence table, while the amino acid sequence of a light chain is shown in the sequence 3 in the sequence table. Experimental results prove that the antibody of the invention has high binding activity (affinity is 2.7*10-8 mol / L) and high tumor cell growth and migration suppression capacity; and the affinity of an anti-epidermal growth factor receptor (EGFR) human-mouse chimeric antibody Cetuximab in foreign markets is 1.1*10-9 M. The humanized antibody of the invention can be better bound with an EGFR so as to ensure anti-tumor effect thereof. An anti-body preparation method of the invention has the advantage of simultaneously expressing the light chain and the heavy chain variable region. After all, the antibody and the preparation method thereof have vast application prospect in the field of the prevention and / or treatment of tumors.

Owner:INST OF BIOENG ACAD OF MILITARY MEDICAL SCI OF THE CHINESE

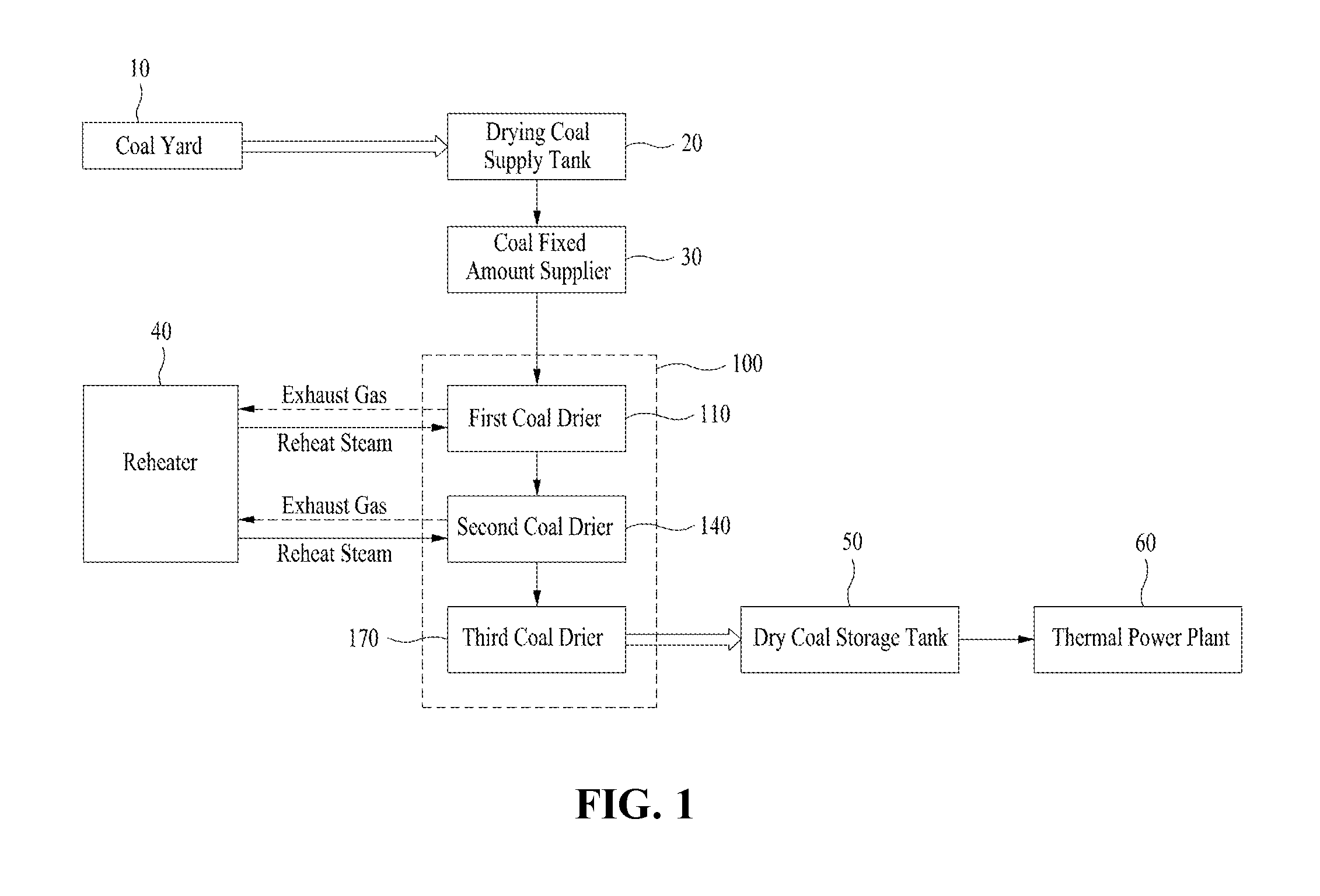

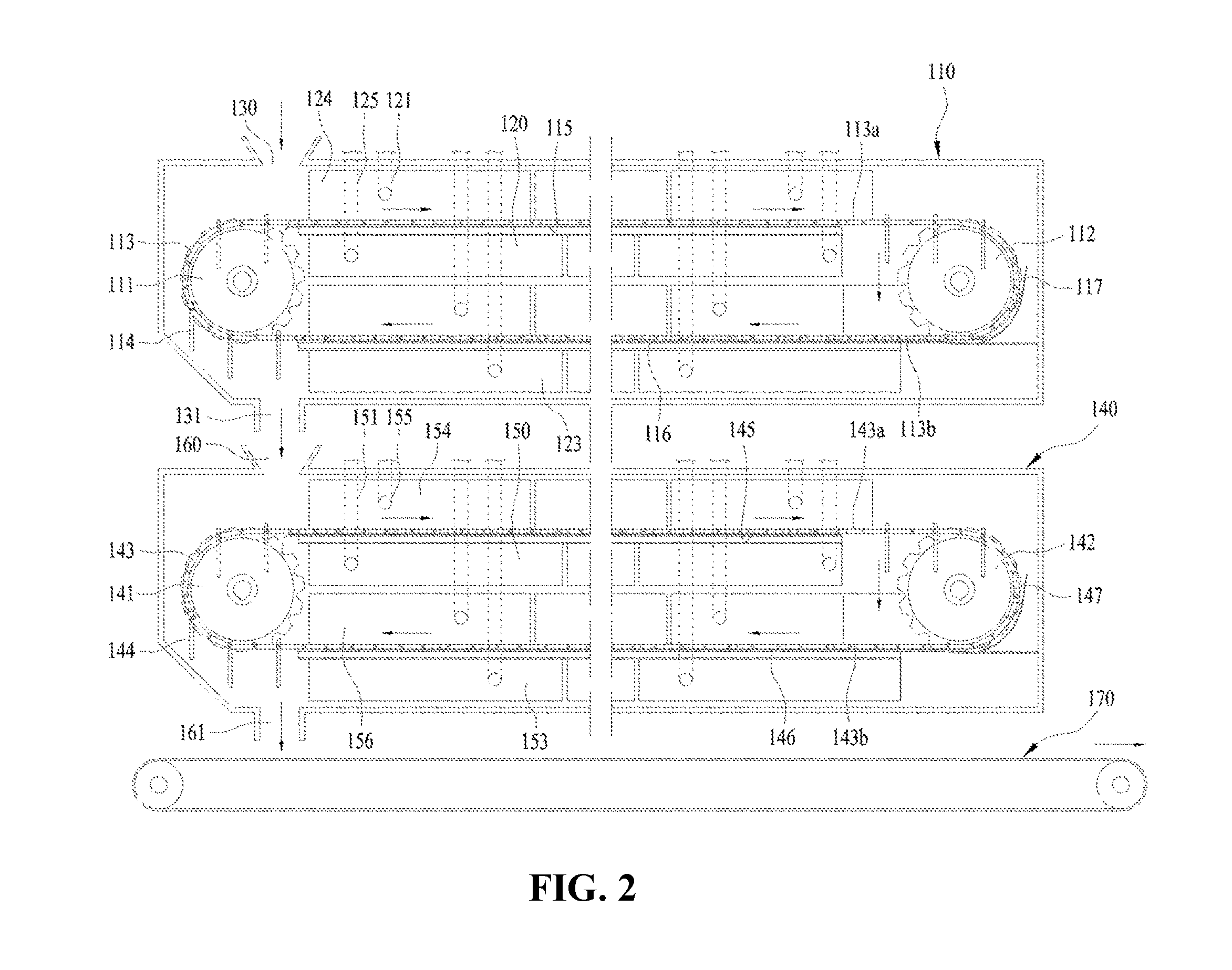

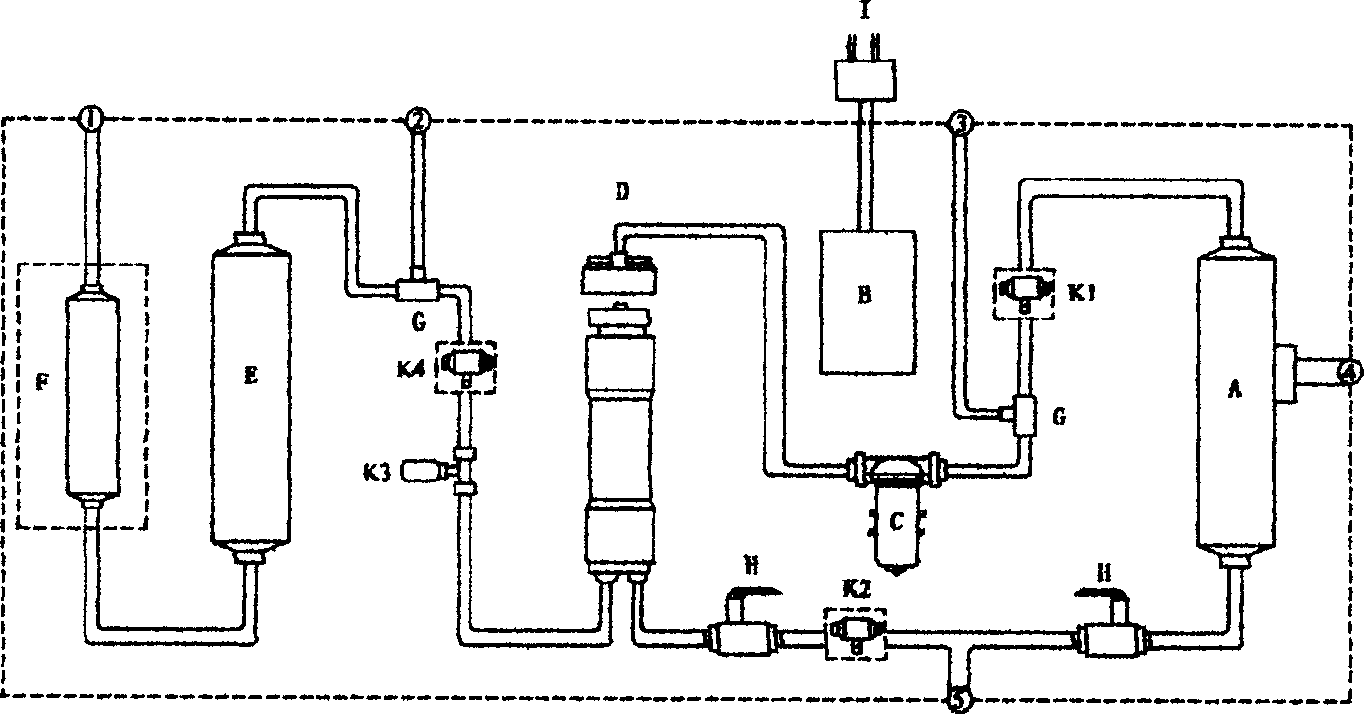

Apparatus for drying coal using reheat steam

InactiveUS20160264896A1High calorific valueCorrosion of the system is preventedDrying solid materials with heatSolid fuelsSpontaneous combustionForeign technology

The present comprises: a first coal dryer; a second coal dryer; and a third dryer, by removing moisture remaining inside and outside of coal, which is used for fueling thermal power plants, in the multiple coal dryers using reheat steam at a high temperature, incomplete combustion of coal can be prevented, thereby enhancing heat capacity of the coal, minimizing release of pollutants, preventing corrosion and enhancing the durability of a system, reducing the rate of spontaneous combustion due to reduced moisture, improving crushing efficiency of a coal pulverizer and heat distribution of a power boiler when coal is combusted, resolving the issue of clogging of a moving pathway when coal is transported, and improving coal supply stability by increasing utilization of low-quality coal for which demand is low. Furthermore, the following advantages can be provided: use of low heat capacity coal which is more affordable than high heat capacity coal; savings in fuel cost and manufacturing cost by reduced coal importation; reduction of waste, pollutants, and carbon dioxide generated from exhaust gas by relative reduction of coal consumption, and the advantages of replacement of foreign technology and exportation of equipment to foreign markets could be anticipated.

Owner:HANKOOK TECH

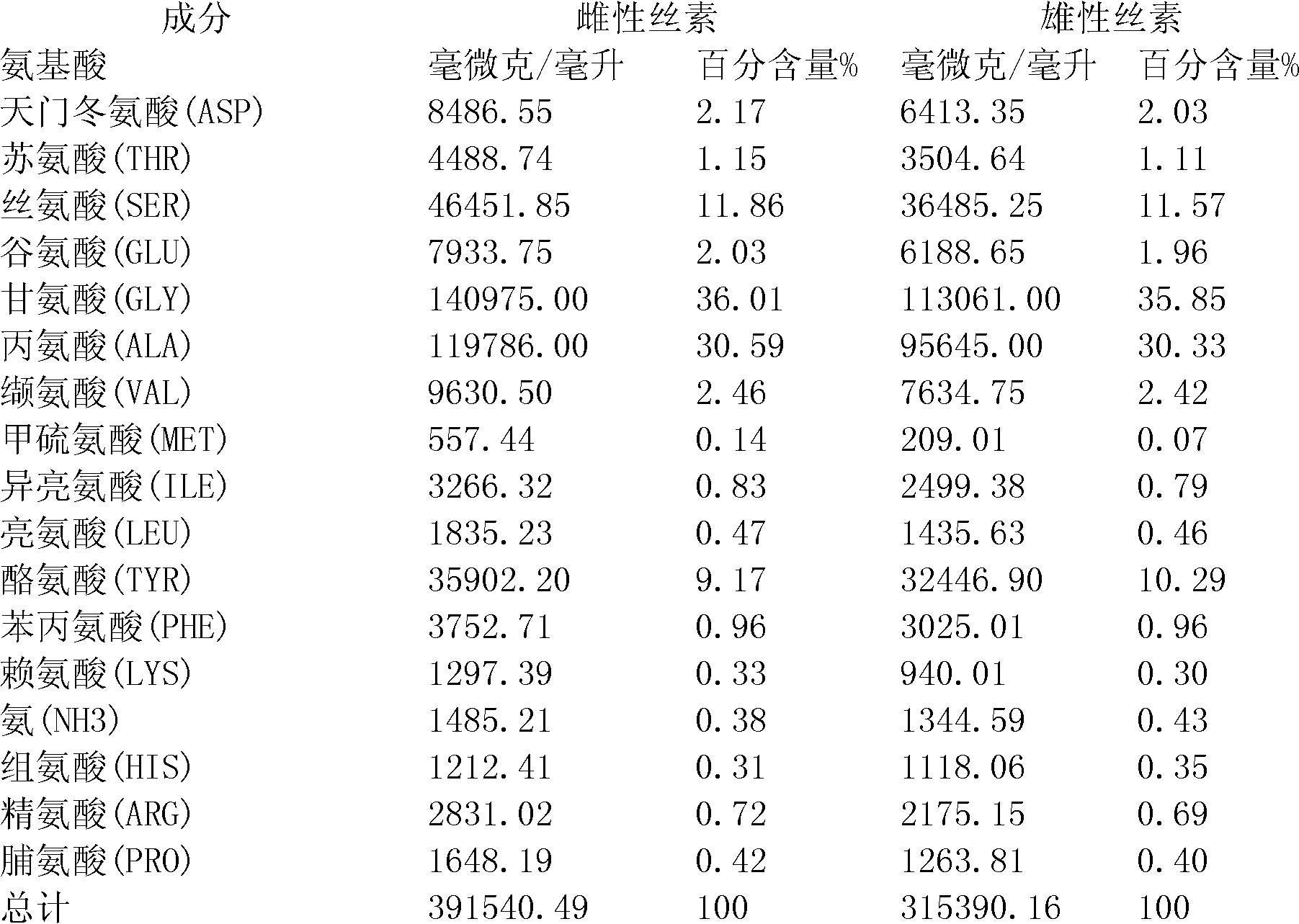

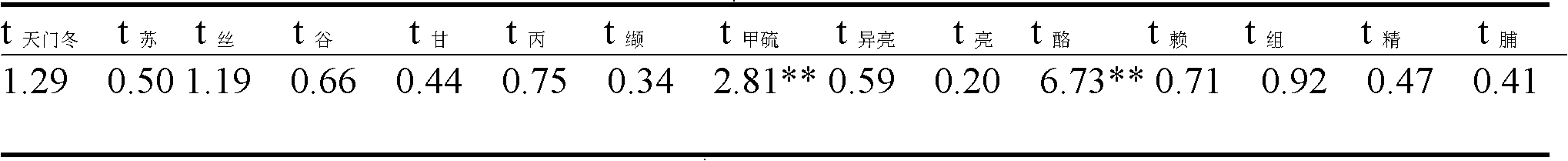

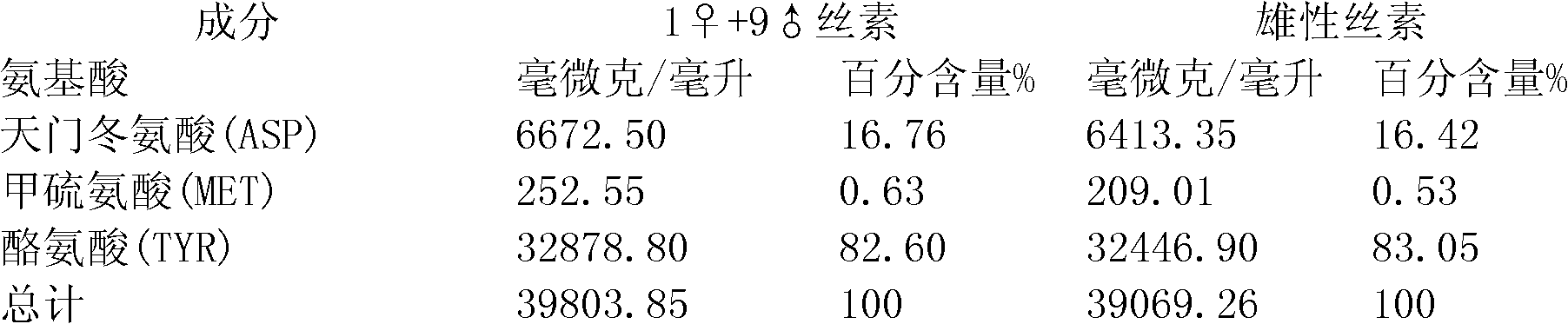

Method for identifying male silk of mulberry silkworm

InactiveCN102590482AThe method is simpleThe result is accurateTextile testingTyrosineMethionine biosynthesis

The invention discloses a method for identifying male silk of mulberry silkworm, and belongs to the technical field of silk production of textile engineering. The method comprises the following steps of: degumming tested silk to obtain pure silk fibroin and preparing into a powdery sample; testing content values of three amino acids, i.e., tyrosine, methionine and aspartic acid, in the sample in the unit of milligram / milliliter; obtaining chi-square X2 by using a chi-square test method based on the content values of the three amino acids in the silk fibroin of the standard male silk; and judging the tested silk as the male silk if X2 is less than 4.61 under the condition of significance level alpha being equal to 0.10. The content values of the three amino acids in the silk fibroin of the silk are used as a judgment basis; the chi-square test is adopted for processing; and the method is simple and convenient, has an accurate result and has a positive effect on promotion of high-grade male silk and products thereof on domestic and foreign markets.

Owner:SUZHOU UNIV

Packet core function and method of selecting packet data service node/foreign agent in packet data network

A packet Core Function (PCF(53, 75, 88, 89)) and method of consistently selecting a Packet Data Service Node (PDSN(54, 81, 90)) from a plurality of PDSNs in a packet data network to host a data session for a Mobile Node (MN(40)). In a first embodiment, a static lookup table (34) in the PCF (42, 44, 46) is used to associate a list of identifiers for MNs and a list of the plurality of PDSNs in the network. The PCF obtains an identifier for the MN and utilizes the lookup table and a hash function to associate the identifier for the MN with a PDSN. The PDSN is then selected by the PCF to host the data session for the MN. In another embodiment, the PCF also includes a cache timer (49) and a cache memory that stores the identifier for the MN and the IP address of the selected PDSN for a predetermined time period following the handoff of the MN to another PCF. If the MN returns to the PCF within the predetermined period of time, the PCF reselects the same PDSN to host the data session. In another embodiment, following the initial selection of a PDSN to host the data session, the IP address of the PDSN is sent to the MN which then passes the IP address of the PDSN to any subsequent PCFs where the MN roams. A PDSN zone ID may be utilized instead of the full IP address.

Owner:TELEFON AB LM ERICSSON (PUBL)

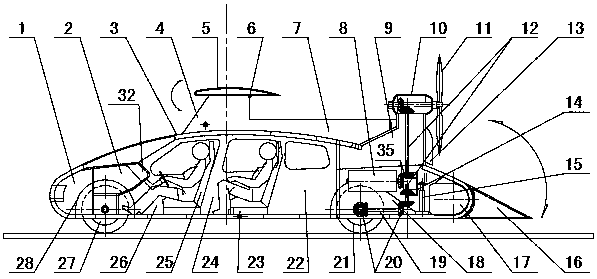

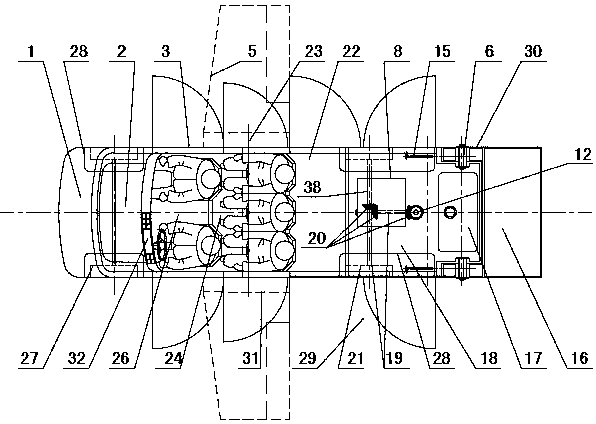

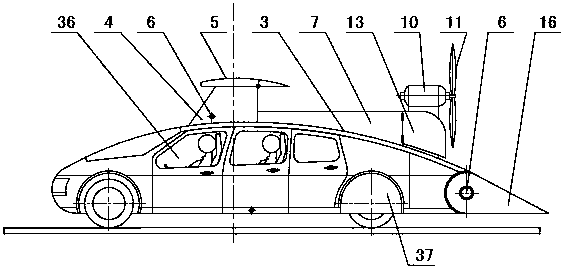

Flying car

ActiveCN103770589AEasy to liftReduce approach speedConvertible aircraftsAircraft convertible vehiclesPropellerEngineering

A flying car comprises a body, a cockpit, a passenger cabin, a baggage cabin, an equipment cabin, a body tail, wheels, airfoils and a propeller which are sequentially combined. As the combined longitudinal section of the body and the body tail is in the shape of an airfoil section, the body can generate lifting force when the flying car runs on a road surface and flies in air, the areas of the airfoils and spans can be relatively decreased under the same loading condition, the airfoils are mounted on hollow flat columns on two sides of the top face of the body, a distance is reserved among the airfoils and the arc top face of the body, and the length, the width and the height of the shape of the flying car are smaller than those of a bus when two ends of each airfoil are folded downwards, so that the flying car can safely and freely take off, land and run on an expressway. At present, cars are popular, urban streets and expressways are frequently jammed, and the flying car can relieve the contradiction and is conveniently, rapidly and safely used for private families and businesses, so that the flying car has wide domestic and foreign markets.

Owner:WUHAN LANTIANXIANG AVIATION TECH

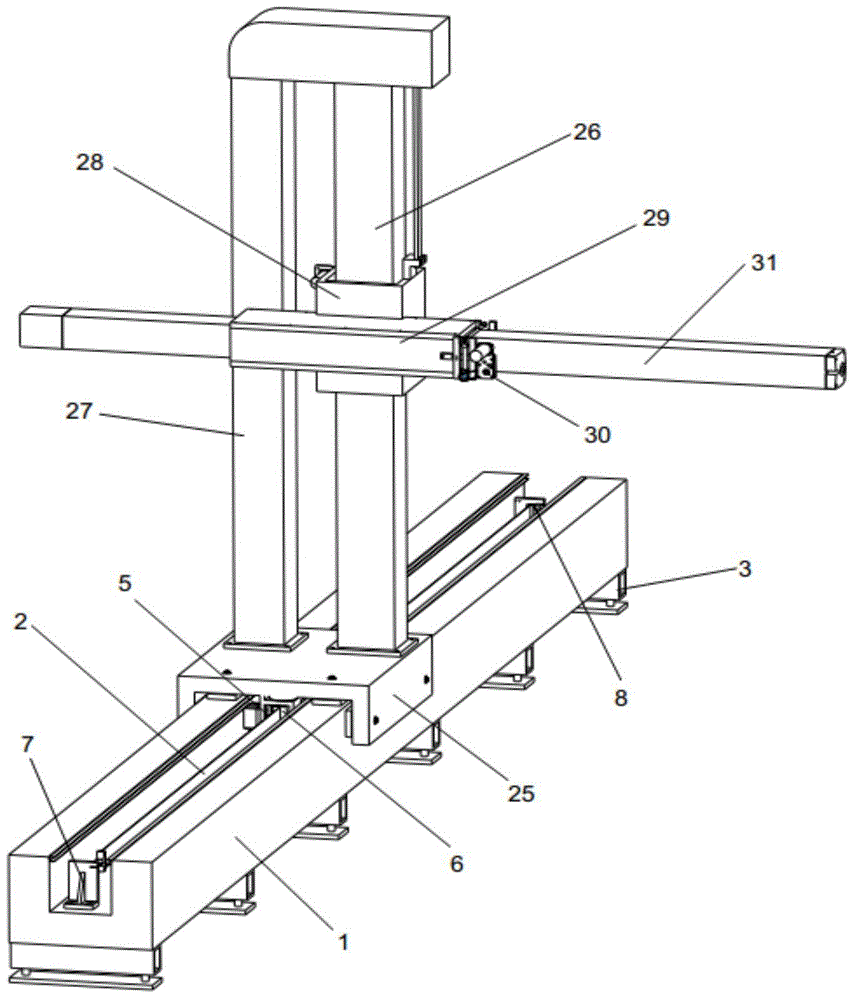

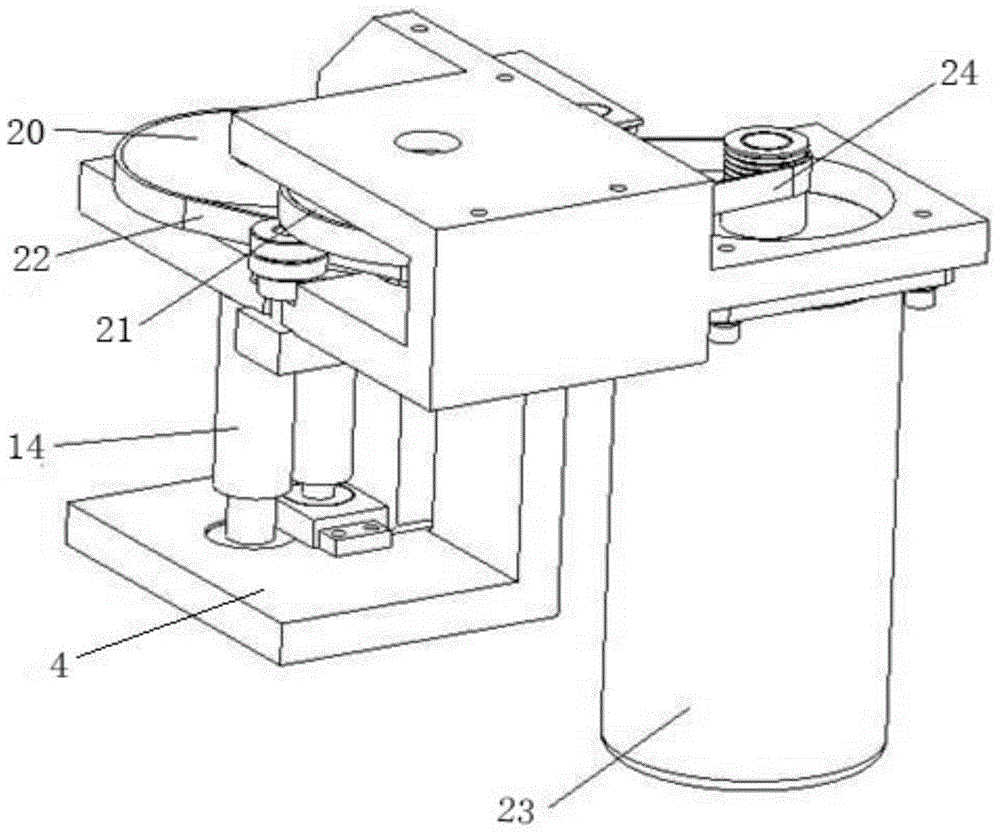

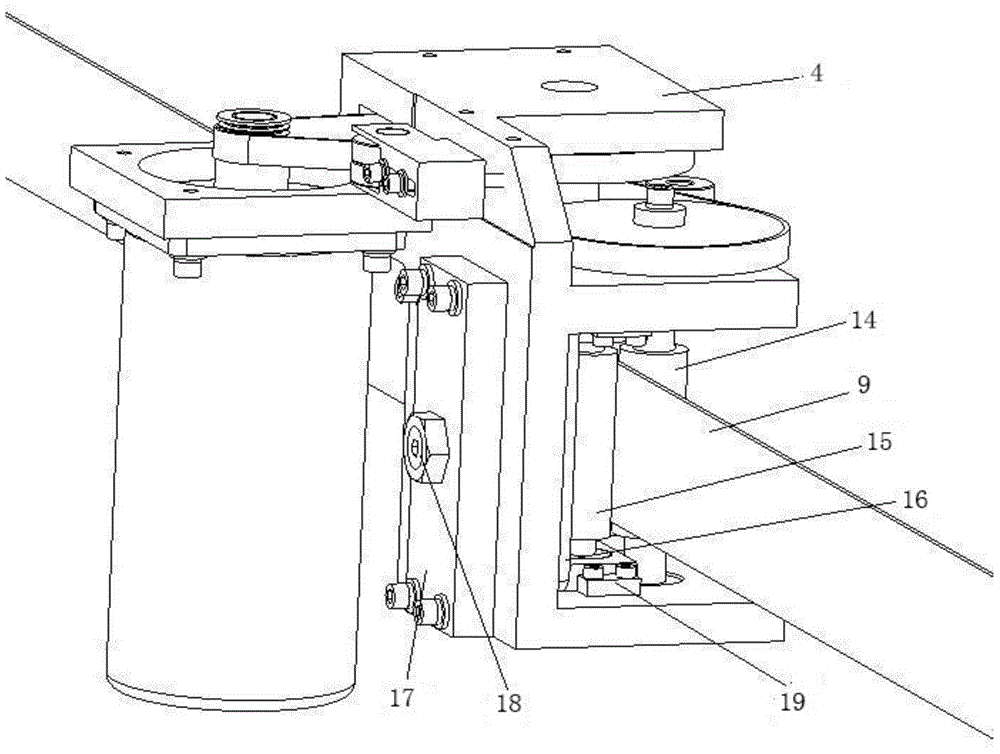

High-stability long cantilever type coordinate measuring machine

ActiveCN103557820AImprove motion stabilityHigh measurement accuracyMeasurement devicesAir bearingSlide plate

A high-stability long cantilever type coordinate measuring machine comprises a Y-direction guiding track, a transmission device and a supporting component. A Y-direction sliding plate is fixed on the transmission device. A stand column is arranged on the Y-direction sliding plate. A Z-direction sliding plate is arranged on the stand column in a sleeved mode. The Z-direction sliding plate is fixedly provided with a horizontal X-direction sliding plate which comprises four long guiding track air bearing devices connected to form a long cube box structure. An X-direction transmission device is arranged at one end of the X-direction sliding plate. A horizontal cantilever beam is arranged in the X-direction sliding plate. The machine moves in the X direction by driving of the X-direction transmission device which contains a clamping and guiding leather roller. The high-stability long cantilever type coordinate measuring machine improves moving stability and the straightness and the rigidness of the cantilever beam and the stand column, the innovative design of a transmission mechanism, a supporting mechanism, a cantilever structure and a stand column structure is determined, measuring accuracy can be greatly improved to 7 + 5 L / 1000microns, the high-stability long cantilever type coordinate measuring machine belongs to high-accuracy long cantilever measuring machines in domestic and foreign markets, and the measuring accuracy index is in a leading level.

Owner:青岛弗尔迪测控有限公司

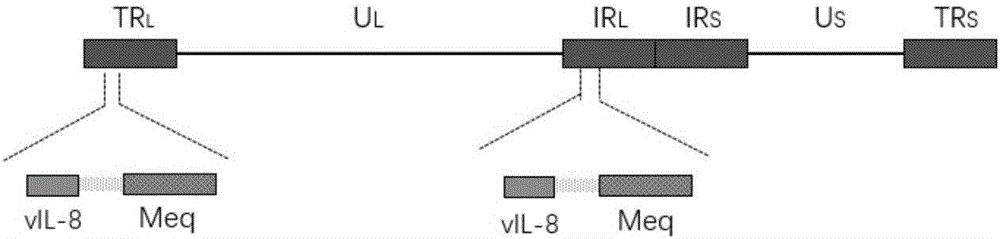

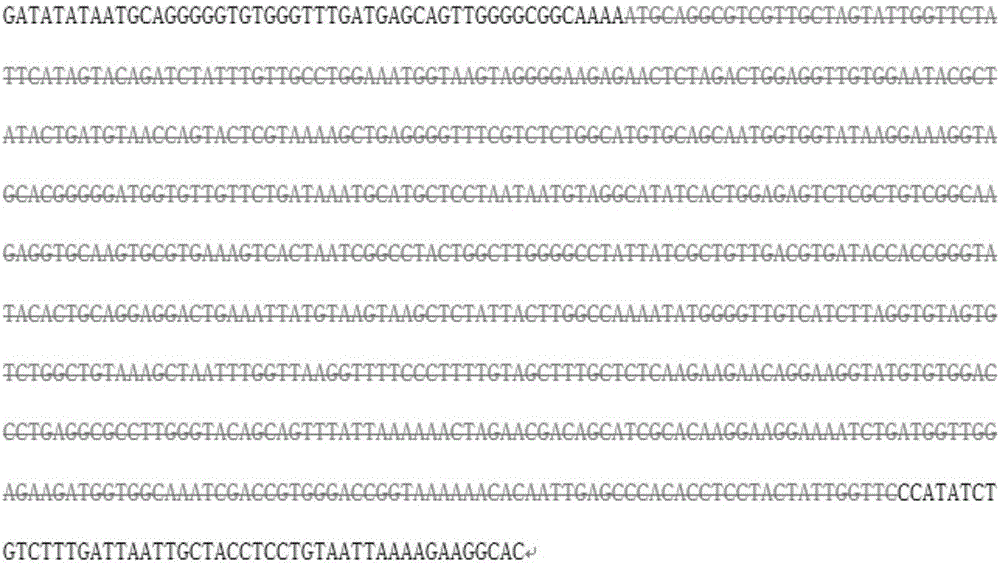

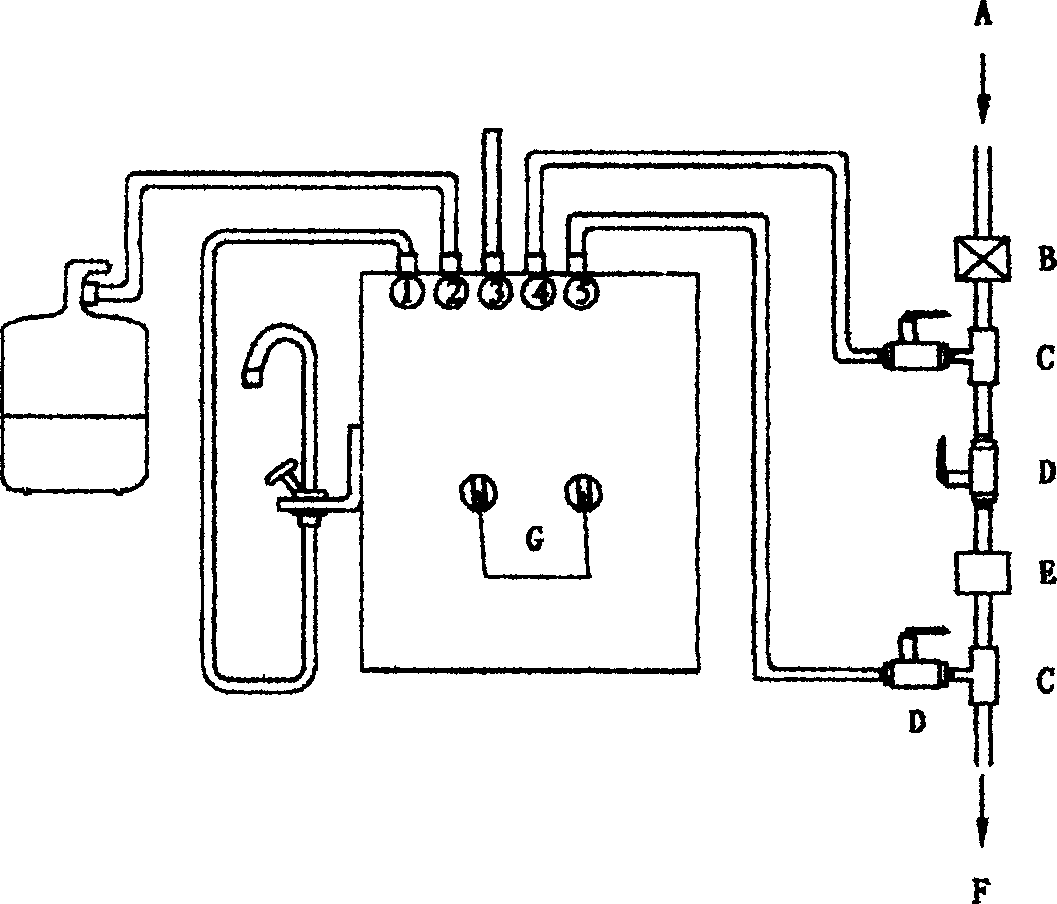

Construction of recombinant MDV (Marek's Disease Virus) and vIL-8 (Viral Interleukin 8) double-gene deleted strain and application thereof

ActiveCN106754761AGood immune protectionViral antigen ingredientsVirus peptidesImmune effectsSerum ige

The invention provides a recombinant serum I type MDV (Marek's Disease Virus) (a BZ-1 strain). The recombinant serum I type MDV is actually characterized in that pathogenic associated genes (meq and vIL-8 (Viral Interleukin 8) genes) of an isolated MDV virulent strain BJ07 are knocked out at the same time, and a constructed MDV gene deleted strain (the BZ-1 strain) has no pathogenicity, cannot induce tumor of chicken and has no immunosuppressive action on chicken flocks; the BZ-1 strain is used as a vaccine prepared by a strain produced by MD (Marek's Disease) live vaccine, chicken MD induced by a very virulent MDV can be prevented, and the protective immune effect is superior to that of a CVI988 / Rispens strain vaccine which is most widely applied in domestic and foreign markets at present.

Owner:北京邦卓生物科技有限公司

Method for breeding scorpions

InactiveCN102812926ALong-lasting hypotensive effectHigh nutritional valueAnimal husbandryLitterMesobuthus martensii

Disclosed is a method for breeding scorpions. Domesticated buthus martensii karsches serve as female parents and wild eastern Asian king scorpions serve as male parents to be hybridized, and litters reproduced by pregnant scorpions are first-generation eastern Asian king scorpions. The first-generation eastern Asian king scorpions serve as female parents, the wild eastern Asian king scorpions serve as male parents to be hybridized, and litters reproduced by pregnant scorpions are second-generation eastern Asian king scorpions. The second-generation eastern Asian king scorpions serve as female parents, the wild eastern Asian king scorpions serve as male parents to be hybridized, and litters reproduced by pregnant scorpions are third-generation eastern Asian king scorpions. The wild eastern Asian king scorpions serving as male parents or female parents before hybridization can be selected, and individuals which are strong and yellow in gourd, yellowish and bright in tails, bulging and round in forelimb pincers, quick in action and sexually mature are selected. The method for breeding scorpions has the advantages of little investment, rapid effect taking, small labor intensity and no pollution. Both wild resources are protected, and requirements of domestic and foreign markets can be met.

Owner:邱民民

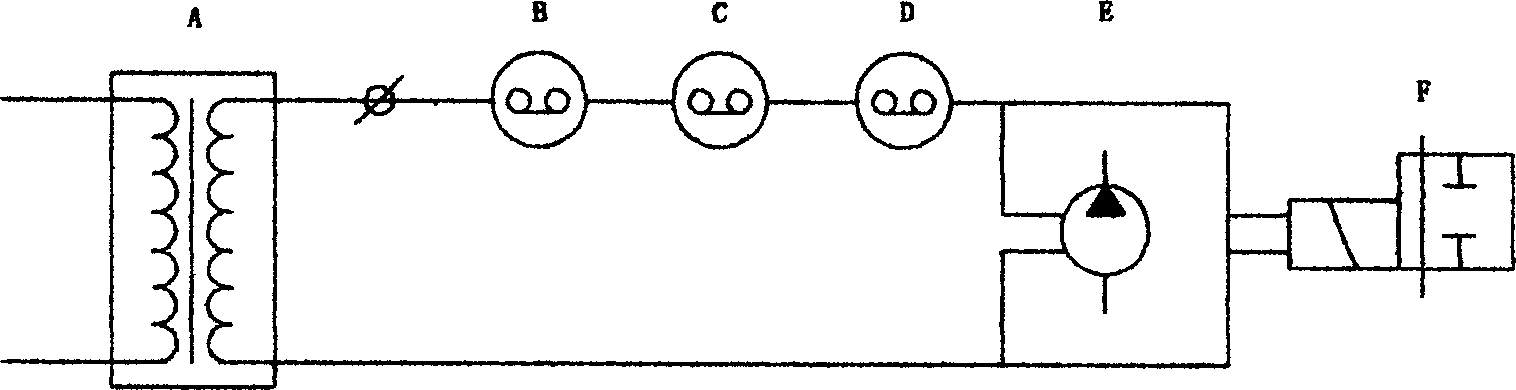

Direct drinking machine for purified water (water-saving civil pipeline type quality-classifying water supplying machine )

InactiveCN1800040AImprove performanceExtended service lifeWater/sewage treatment bu osmosis/dialysisMembrane theoryWater saving

The invention provides a drinking machine for water-saving and water purification which not only uses membrane separation technique, but also saves water. Multi-filter the water by means of micro filter membrane(MF), ultra filter membrane(UF), reverse osmosis membrane(RO or nano filter membrane NF) to get water with stringent specification and high purification for drinking and using. RO water-purifying machine in domestic and foreign market is combined by two membranes: micro filter membrane(MF), hyper filter membrane(UF), whose extraction rate for water purification is about 15~20%. That means: every time we produce 1 ton pure water, at the same time, we have to dump 4~5 ton water. We develop the water-purifying machine (domestic pipeline split water-provider of water-saving type) on the base of the membrane theories and concentrate the concept on water-saving. And add ultra filter membrane(UF) to conduct preprocessing of reverse osmosis membrane. Change the working principle to: add circulating tank of special design to extract circulatively without wasting a drop water.

Owner:王建华

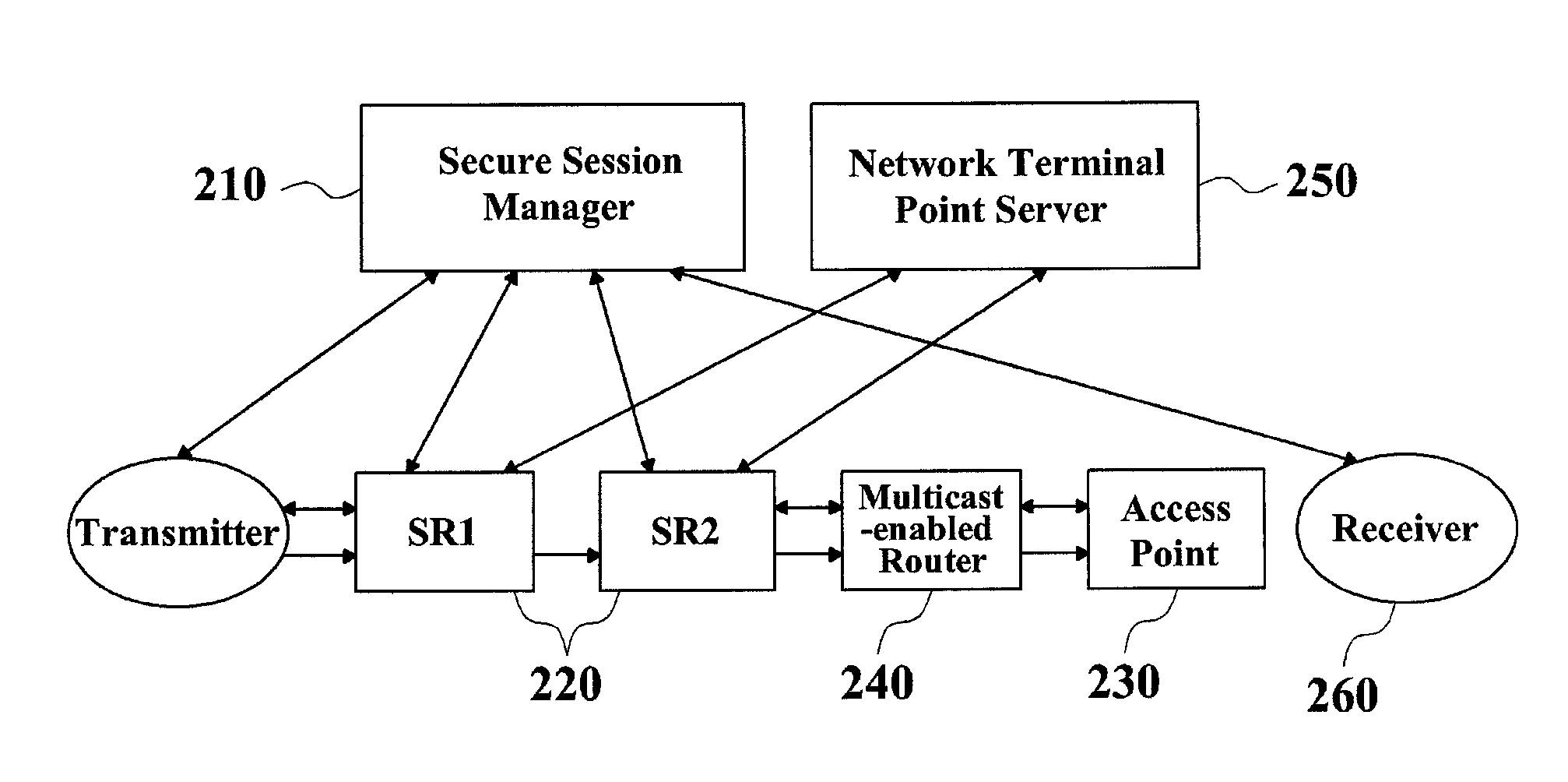

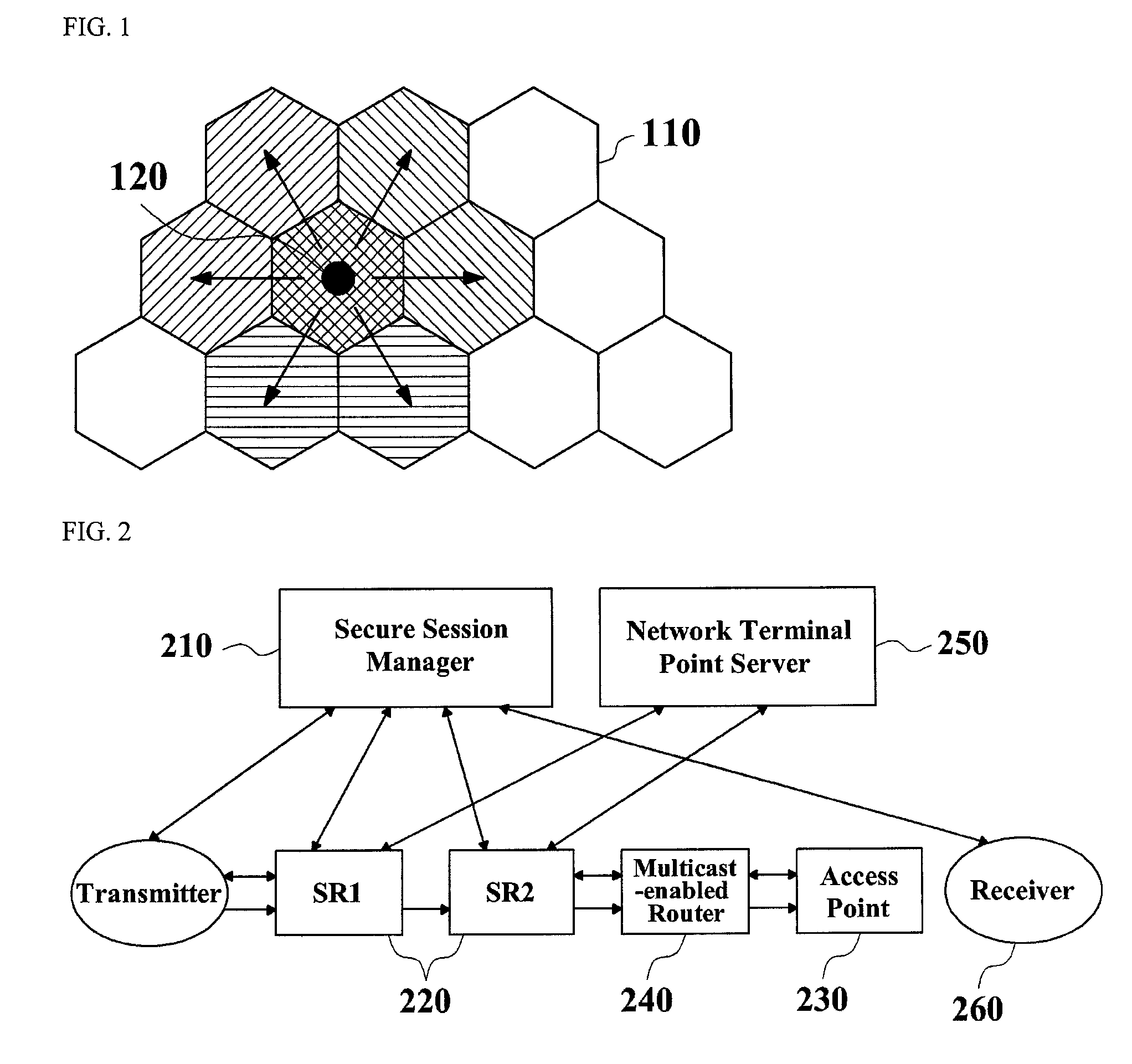

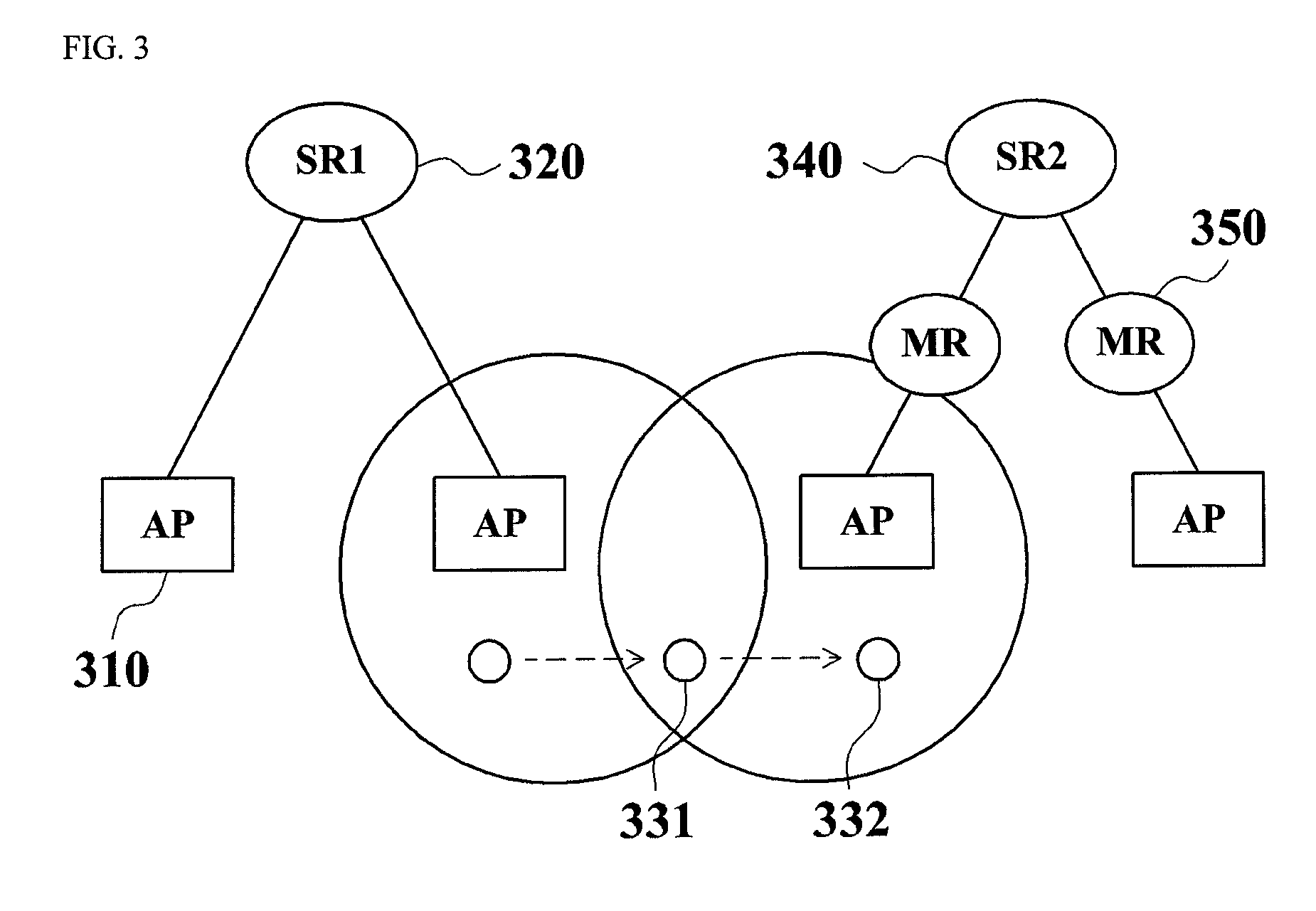

Method of managing a mobile multicast key using a foreign group key

InactiveUS7864961B2Address security threatsSecurity arrangementSecuring communicationSecure communicationMicrowave

The present invention relates to a method of managing a mobile multicast key using a foreign key. More specifically, the present invention relates to a method of managing a mobile multicast key using a foreign key for secure communication between a mobile terminal and a secure relay server in the region where microwaves from plural access points overlap. A method of managing a mobile multicast key using a foreign key according to the present invention has an advantage that multicast secure relay servers perform delegated authentication in advance in a region where microwaves overlap, thus reducing a delay time for authentication in a mobile terminal and it has an advantage that it can minimize an effect from changes in group keys that user's movement make, by using a primary group key and a foreign key. This results in a reduction of an overhead from update of a group key while moving, and accordingly a reduction of a delay time. In addition, it has an advantage that it centralizes functions of key management to a secure relay server, thus overcoming the limitations on processing ability or network bandwidth of a mobile terminal.

Owner:KOREA INTERNET & SECURITY AGENCY

Selenium-rich black fungus planting method

InactiveCN107278618AAchieve plantingSimple technical routeCalcareous fertilisersBioloigcal waste fertilisersEconomic benefitsEnvironment of Albania

The invention provides a selenium-rich black fungus planting method which includes the steps: inoculation; fungus bag cultivation; cutting and discharging funguses; discharged fungus management; harvesting. The planting method is simple and practical in technical route, easy to operate and wide in application range. Selenium-rich black funguses acquired by the planting method are detected by an agricultural product safety and environment quality detection center of Shenyang Institute of Applied Ecology, Chinese Academy of Sciences, calcium content is 0.80g / 100g, and selenium content is 0.883mg / kg. According to the planting method, selenium-rich black funguses are planted, health food is provided for consumers, a new path is developed for farmer richness, and the selenium-rich black funguses have good economic benefits and wide domestic and foreign markets.

Owner:张艳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com