Supporting leg assembly of child safety seat

A child safety seat and support leg technology, applied in child seats, child chairs, children's furniture, etc., can solve the problems that can only be designed to about 200mm, or even lower, inconvenient to operate, and cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

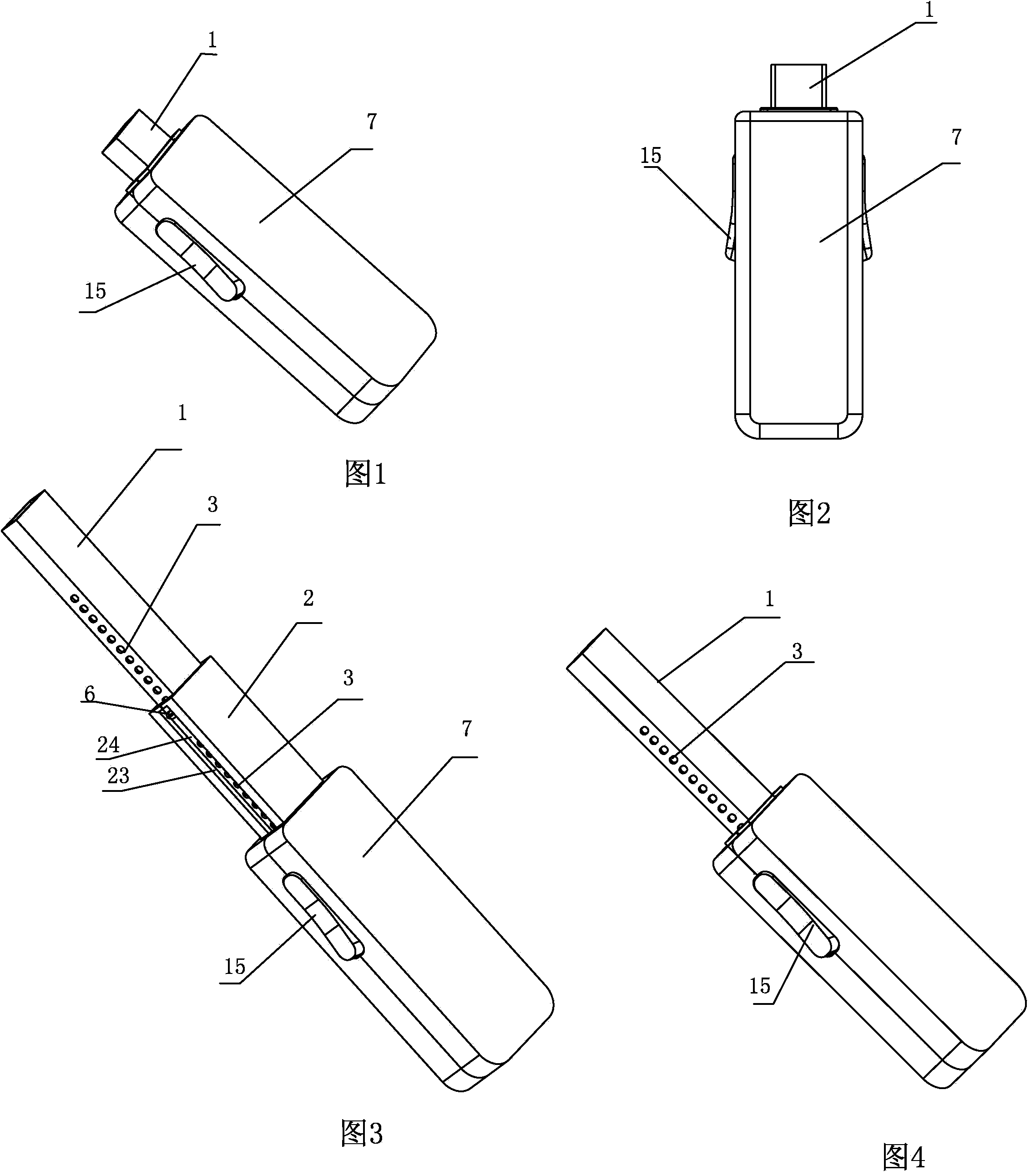

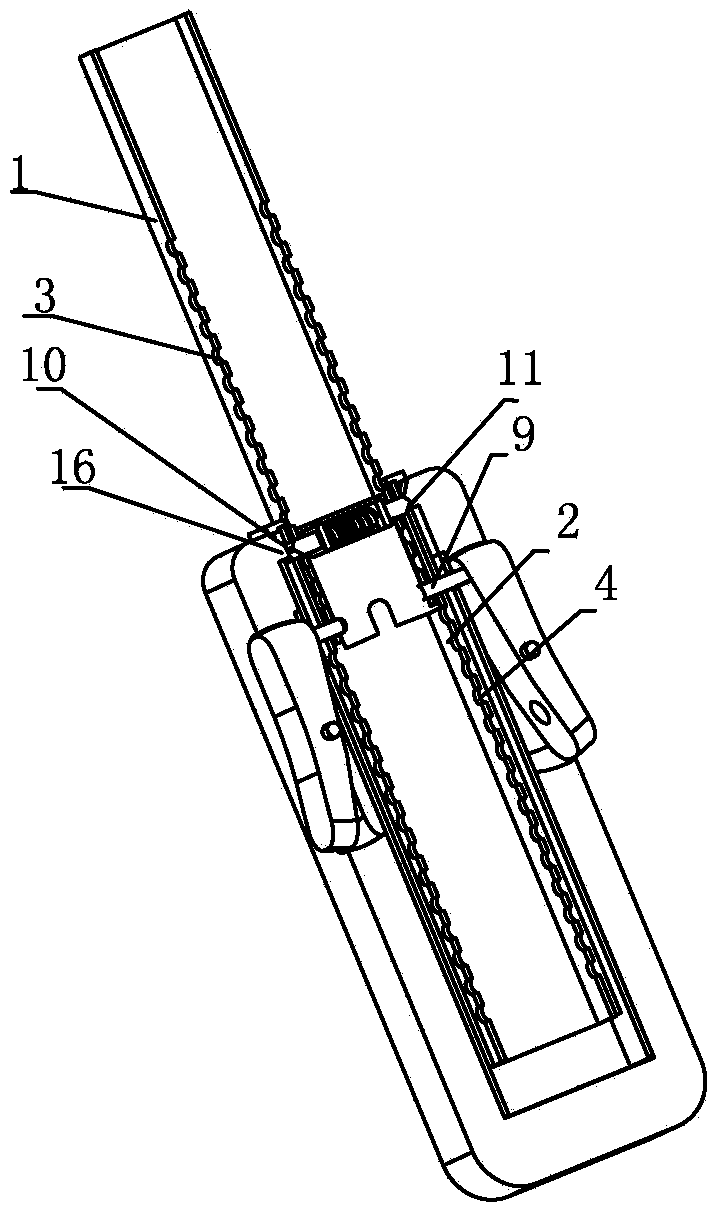

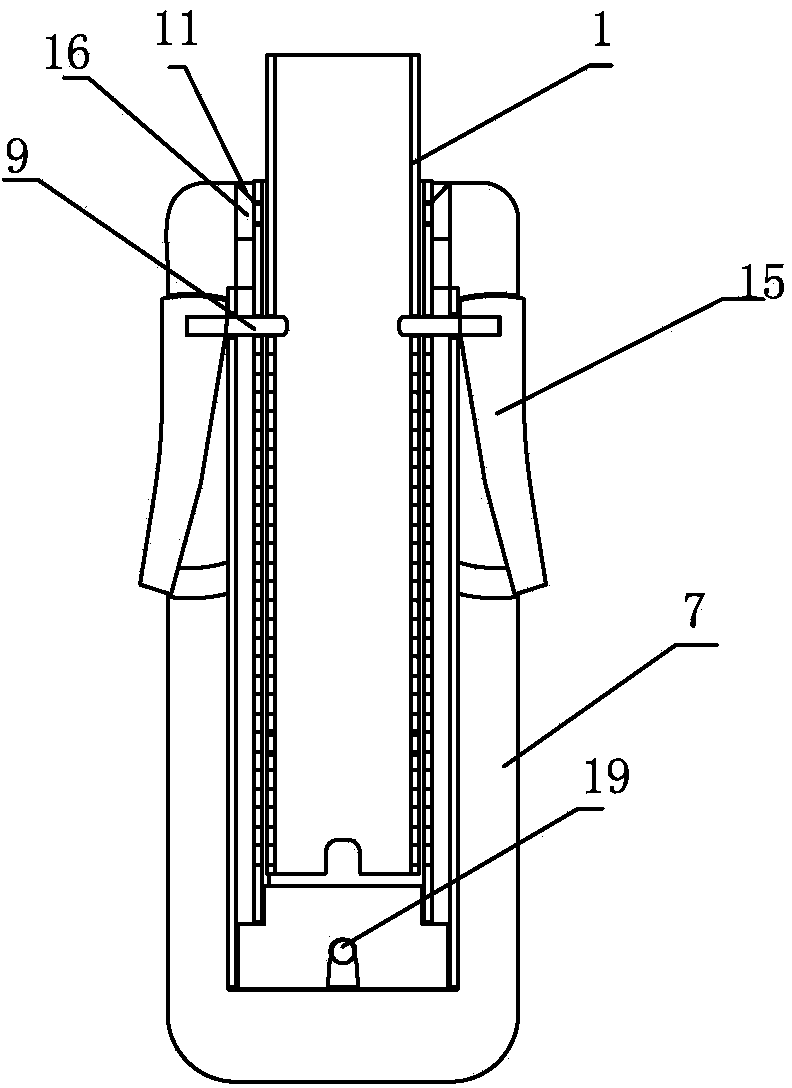

[0029] A supporting leg assembly of a child safety seat, comprising a fixed upper tube 1 and a middle square tube 2, the middle square tube 2 is set outside the upper tube 1, and a row of first locking holes 3 are distributed longitudinally on the upper tube 1, A row of second locking holes 4 is longitudinally distributed on the middle square tube 2, and an elastic locking assembly 5 is arranged between the lower end of the upper pipe 1 and the upper end of the middle square pipe 2, and the elastic locking assembly 5 includes a movable locking block 6 , the locking block 6 passes through the upper pipe 1 and the middle square pipe 2 respectively, and the middle square pipe 2 is provided with a supporting seat 7 supported on the automobile floor, and an elastic locking mechanism 8 is arranged on the supporting seat 7, and the elastic locking mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com