Bogie for A-type broad-gauge metro vehicle

A technology for bogies and subway cars, which is applied in directions such as bogies, railway car body parts, devices for lateral relative movement between the underframe and the bogies, etc. The effect of reducing the slewing resistance, solving the unstable traction performance and improving the fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

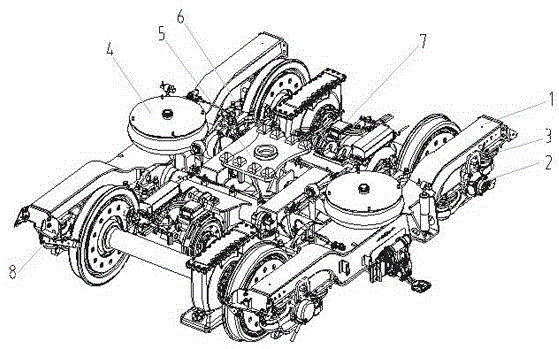

[0023] refer to figure 1 The bogie of the present invention is composed of a frame 1, a wheel-to-axle box positioning device 2, a primary suspension device 3, a secondary suspension device 4, a central traction device 5, a foundation braking device 6, a driving device 7, and a wheel flange lubrication device 8. Assembled.

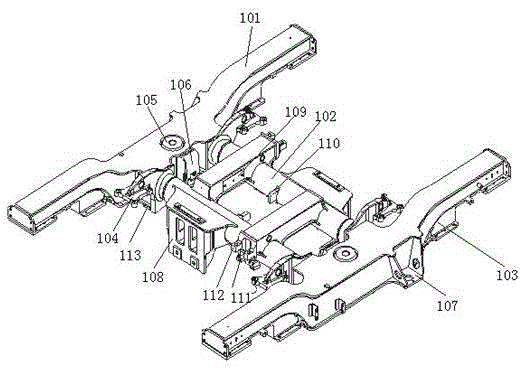

[0024] refer to figure 2 , the frame is welded together by two side beams 101 and a beam structure 102, in which a series of spring mounts 103, brake cylinder mounts and hoisting mounts are integrated into one horizontal beam connection according to functional requirements Block 104. The air spring mounting seat 105 is provided in the middle of the side beam, the transverse shock absorber mounting seat 106 is provided on the inner side, the secondary vertical shock absorber mounting seat 107 is provided on the outer side, and the anti-rolling torsion bar seat 113 is provided at the bottom; There is a motor hanger 108, a transverse stop mount 109, a vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com