Manufacturing process for bi-metal composite roll collars

A manufacturing process and technology of composite rolls, which are applied in the field of steel rolling industry, can solve the problems of increased enterprise cost and high roll ring cost, and achieve the effects of low cost and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

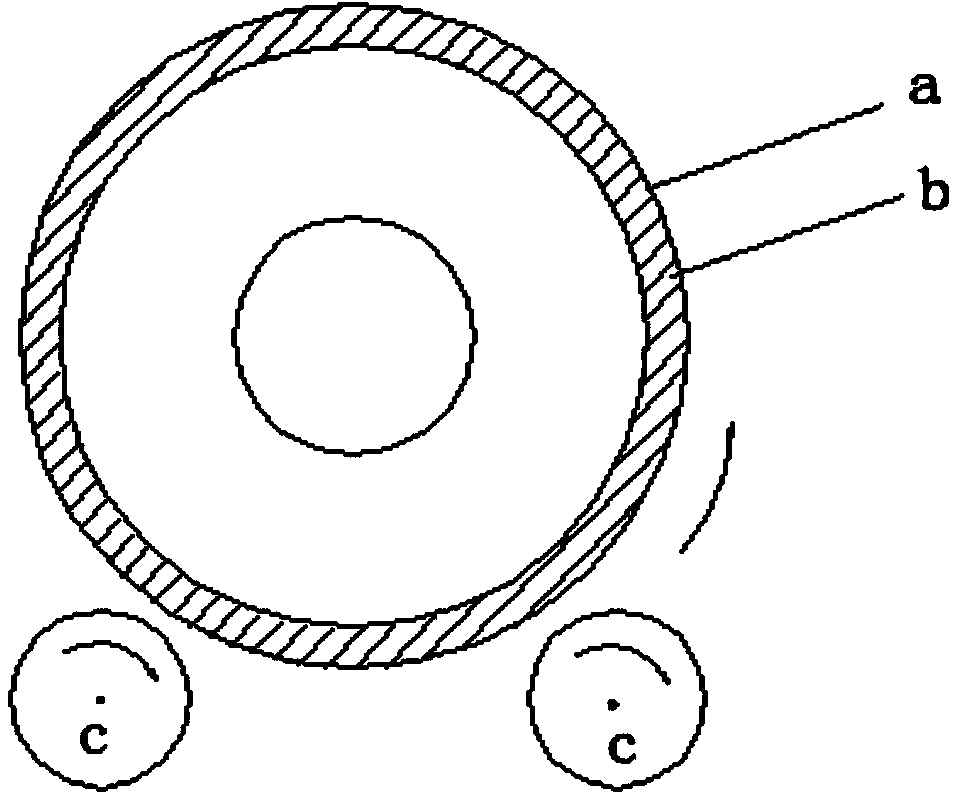

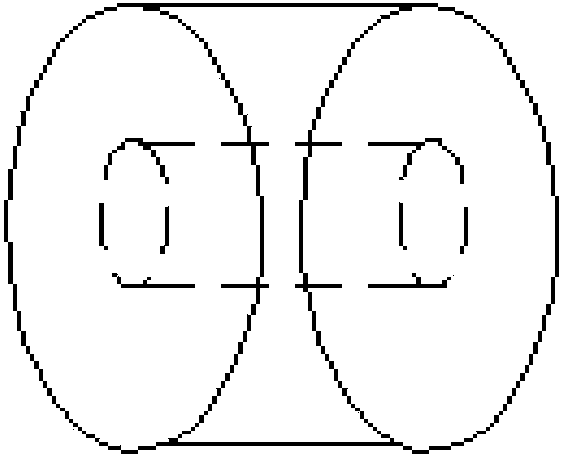

[0017] Such as Figure 1-2 As shown, this specific embodiment adopts the following technical solutions: Its production process is: 1. First, manufacture a centrifugal mold a, and then install end caps b on both ends of the centrifugal mold a; 2. Coat the centrifugal mold a After brushing the paint and laminating, it is baked at a high temperature to 150-350℃, placed on a centrifuge and rotated for pouring preparation; 3. Smelting of semi-steel and spheroidization of core ductile iron material: working layer of roll ring The material is semi-steel material, and the inner layer material is ductile iron material. Firstly, the semi-steel material is smelted in an intermediate frequency furnace and electric furnace. After the alloy composition is reached, it can be fully deoxidized; the ductile iron material is successfully smelted and added with a nodulizer for spheroidizing The chemical dosage is 1.7-2.1% of the molten iron volume, the inoculant dosage is increased by 0.5-1.0% Si,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com