Janus-structured polyether/Ag particle and preparation method and application thereof

A technology of polyether and particles, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., which can solve complex processes, low preparation efficiency, unfavorable environmental protection and mass production, etc. problem, to achieve the effect of narrow size distribution, fast operation process and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of Janus structure polyether / Ag particle, concrete preparation steps are as follows:

[0025] a) Preparation of mercaptopolyetheramine

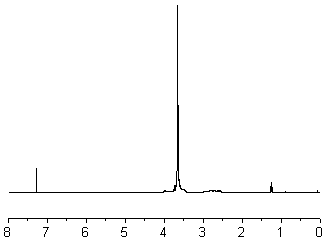

[0026] Dissolve 2 g of polyethylene glycol diglycidyl ether (number average molecular weight Mn=500 g / mol) and 0.308 g of mercaptoethylamine in 10 mL of absolute ethanol, react at 80°C for 10 hours, and precipitate the reaction mixture into n-hexane, separated and dried to obtain mercaptopolyetheramine. The nuclear magnetic spectrum of gained mercapto polyether amine is shown in figure 1 (The peaks with chemical shifts of 1.3, 2.4~2.8, and 3.6 belong to the thiol group on the molecular chain of mercaptopolyetheramine, the methylene group adjacent to the nitrogen atom, and the hydrogen atom on polyethylene glycol, respectively);

[0027] b) Preparation of Janus structured polyether / Ag particles

[0028] The above 20 mg mercaptopolyetheramine, 4 mg AgNO 3 Dissolved in 20 mL of water and irradiated with 36...

Embodiment 2

[0030] A kind of preparation method of Janus structure polyether / Ag particle, concrete preparation steps are as follows:

[0031] a) Preparation of mercaptopolyetheramine

[0032] 2 g of polyethylene glycol diglycidyl ether (number-average molecular weight Mn=500 g / mol) and 0.308 g of mercaptopropylamine were dissolved in 10 mL of absolute ethanol, and reacted at 70°C for 15 hours, and the reaction mixture was precipitated to In n-hexane, separate and dry to obtain mercaptopolyetheramine;

[0033] b) Preparation of Janus structured polyether / Ag particles

[0034] The above 20 mg mercaptopolyetheramine, 6 mg AgNO 3 Dissolve in 20 mL of water, and irradiate under 450 nm ultraviolet light for 10 minutes to obtain a Janus structure polyether / Ag particle aqueous solution; it is obtained after separation and drying.

Embodiment 3

[0036] A kind of preparation method of Janus structure polyether / Ag particle, concrete preparation steps are as follows:

[0037] a) Preparation of mercaptopolyetheramine

[0038] 2 g of polyethylene glycol diglycidyl ether (number-average molecular weight Mn=500 g / mol) and 0.308 g of mercaptoethylamine, dissolved in 10 mL of N,N-dimethylformamide, reacted at 90°C for 6 hours , precipitate the reaction mixture into n-hexane, separate and dry to obtain mercaptopolyetheramine;

[0039] b) Preparation of Janus structured polyether / Ag particles

[0040] The above 20 mg mercaptopolyetheramine, 10 mg AgNO 3 Dissolve in 20 mL of water and irradiate under sunlight for 20 minutes to obtain a Janus structure polyether / Ag particle aqueous solution; obtain it after separation and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com