Polarity binding agent applied to lithium-sulfur battery and preparation method of polarity binding agent

A lithium-sulfur battery and adhesive technology, which is applied in the manufacture of electrodes, battery electrodes, electrolyte storage batteries, etc., can solve the problems of poor adsorption capacity of polysulfides, failure to meet the needs of practical applications, and limited adsorption performance. Low cost, improved cycle performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

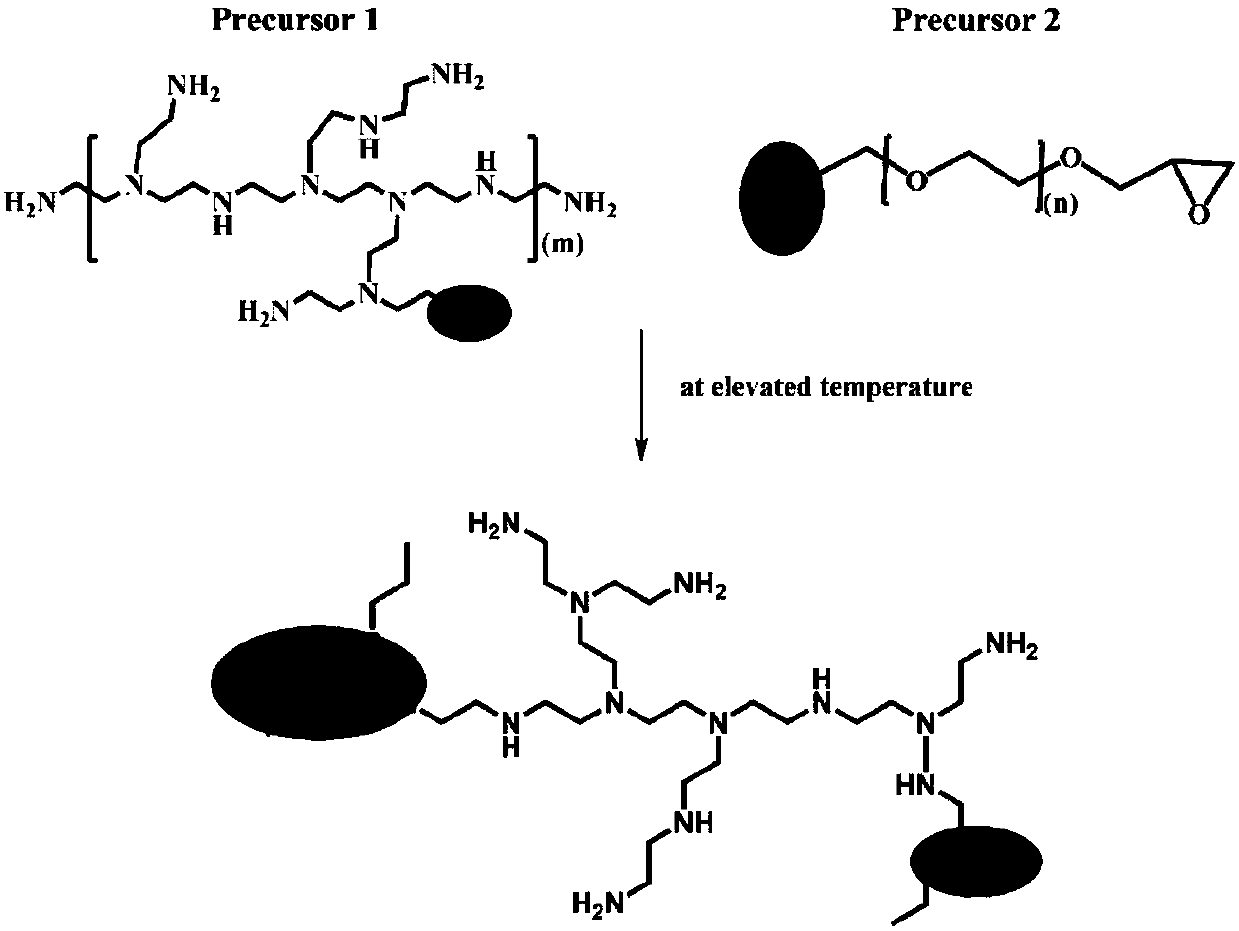

[0030] A preparation method for a polar adhesive applied to a lithium-sulfur battery, specifically comprising the following steps:

[0031] Step 1. After ultrasonically cleaning 30g of dehydration molecular sieves with alcohol for 5 times, bake them in an oven at 100°C for 24 hours to completely remove the moisture in the molecular sieves;

[0032] Step 2. Put the molecular sieve after dehydration in step 1 into 800mL dimethylformamide (DMF), remove the moisture in the DMF, and obtain the DMF after dehydration. When taking the dehydration DMF, use a pipette to absorb upper liquid;

[0033] Step 3, be the polyethyleneimine (PEI) that molecular weight is 800g / mol as solute, the DMF solution (dimethylformamide) that removes water is solvent, the concentration of preparation polyethyleneimine (PEI) is 0.25mol / L The mixture A;

[0034] Step 4, be the polyethylene glycol diglycidyl ether (PEGDGE) that molecular weight is 600g / mol as solute,, the DMF solution (dimethylformamide) th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com