Polymer gel electrolyte membrane, preparation method and sodium ion battery

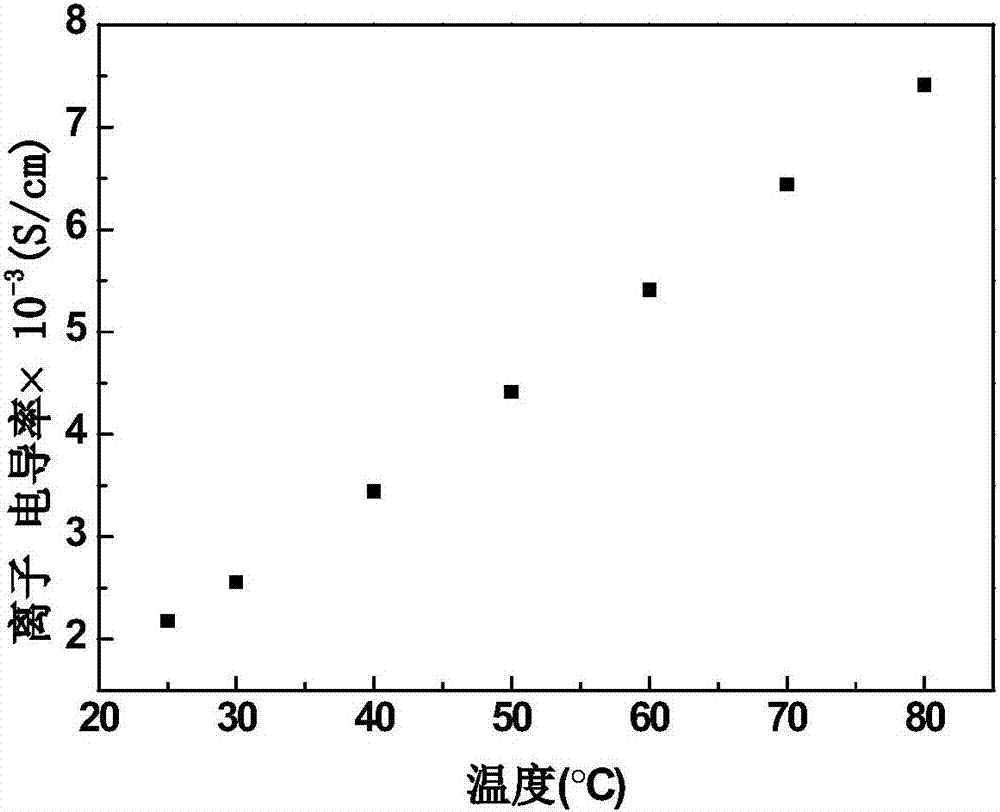

A technology of gel electrolyte and polymer membrane, applied in electrolyte immobilization/gelation, secondary batteries, circuits, etc., can solve the problems of low porosity, low ionic conductivity, and poor high-temperature dimensional stability of polyolefin separators , to achieve good interfacial compatibility, high ionic conductivity and good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

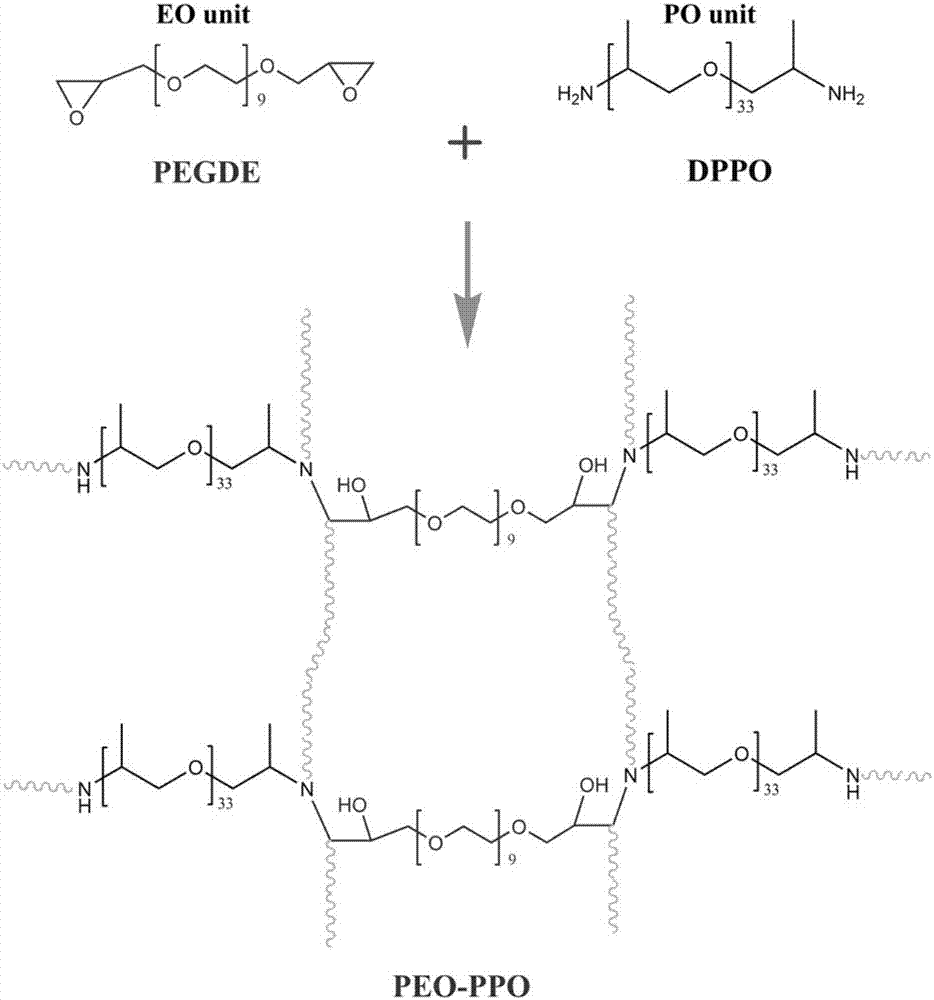

[0037] see figure 1 , in one embodiment, a kind of preparation method of polymer gel electrolyte membrane, the polymer gel electrolyte membrane supported by this porous film is mainly used in sodium-ion battery, and it comprises the steps:

[0038] In step S1, a certain amount of polyethylene glycol diglycidyl ether, polyether amine and a solvent are mixed to obtain a precursor solution.

[0039] Specifically, polyethylene glycol diglycidyl ether and polyether amine are added into the solvent, stirred and mixed uniformly to obtain a colorless and transparent precursor solution.

[0040] The solvent is one of acetone, N,N-dimethylformamide, N,N-dimethylacetamide or N-methylpyrrolidone.

[0041]The mass percentages of the polyethylene glycol diglycidyl ether and the polyether amine in the solution are 1-3% and 2-6% respectively. The number average molecular weight of the polyethylene glycol diglycidyl ether is 500, 1000, 2000 or 6000 Da. The number average molecular weight of...

Embodiment 1

[0051] This embodiment relates to a preparation method of a polymer gel electrolyte membrane supported by a porous film, the method comprising the following steps:

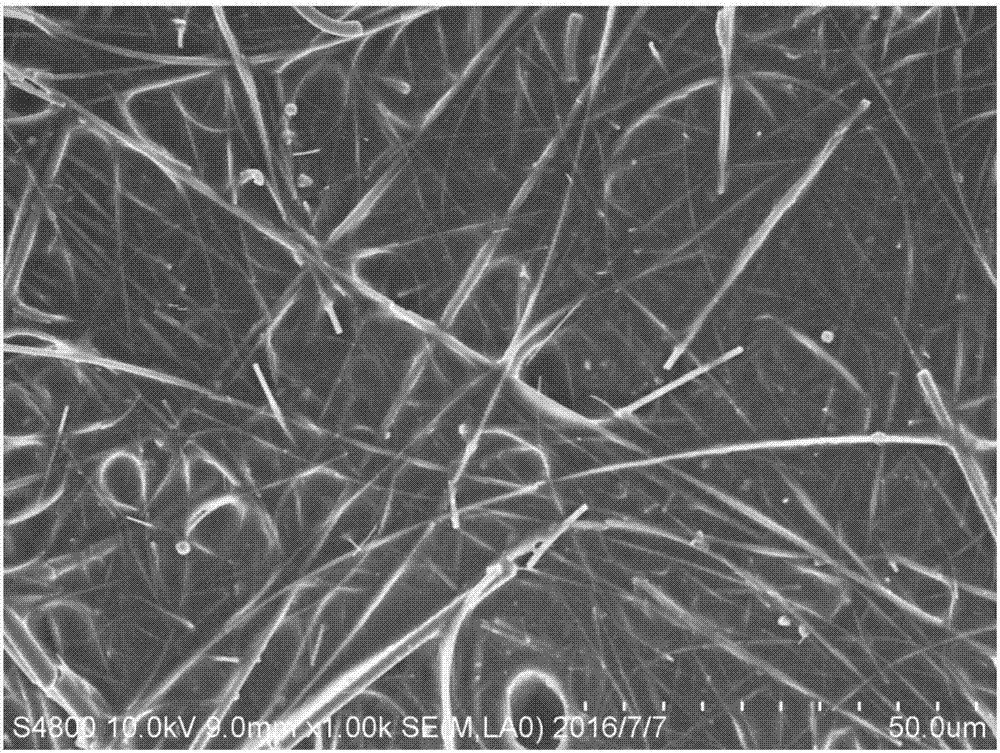

[0052] (1) Add 4.0g of N,N-dimethylformamide into a 25ml beaker, then weigh 0.4g of polyethylene glycol diglycidyl ether (Mn=500) and 0.88g of polyetheramine (Mn=2000 ) into the beaker, stirred for 2h to mix well. Put the porous film into a clean polytetrafluoroethylene mold and pour the above solution, and after standing for a period of time, place it in a constant temperature blast oven for ring-opening polymerization at a constant temperature of 80°C for 24 hours to obtain a polymer supported by a heat-cured porous film membrane;

[0053] (2) The polymer film supported by the prepared porous film was washed three times with absolute ethanol to remove residual monomers and solvents contained in the film, and then the polymer film was placed in a vacuum oven at 60° C. for 12 h, and then moved to In the glove bo...

Embodiment 2

[0066] This embodiment relates to a preparation method of a polymer gel electrolyte membrane supported by a porous film, the method comprising the following steps:

[0067] (1) Add 0.2g polyethylene glycol diglycidyl ether (Mn=500) and 0.4g polyetheramine (Mn=2000) into a 25ml beaker, stir for 2h and mix well. And put the polyimide film in a clean polytetrafluoroethylene mold, pour the above solution, and after standing for a period of time, place it in a constant temperature blast oven and perform ring-opening polymerization at a constant temperature of 80°C for 24 hours to obtain a heat-cured porous film. Thin-film supported polymer membranes;

[0068] (2) The polymer film supported by the prepared porous film was washed three times with absolute ethanol to remove residual monomers and solvents contained in the film, and then the polymer film was placed in a vacuum oven at 60° C. for 12 h, and then moved to In the glove box, in the liquid electrolyte of 1.0M sodium hexafluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com