Preparation method of adsorbing material based on natural polysaccharides

An adsorption material, a technology of natural polysaccharides, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as poor mechanical strength, salt intolerance, etc., to improve mechanical strength, low cost, source of wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

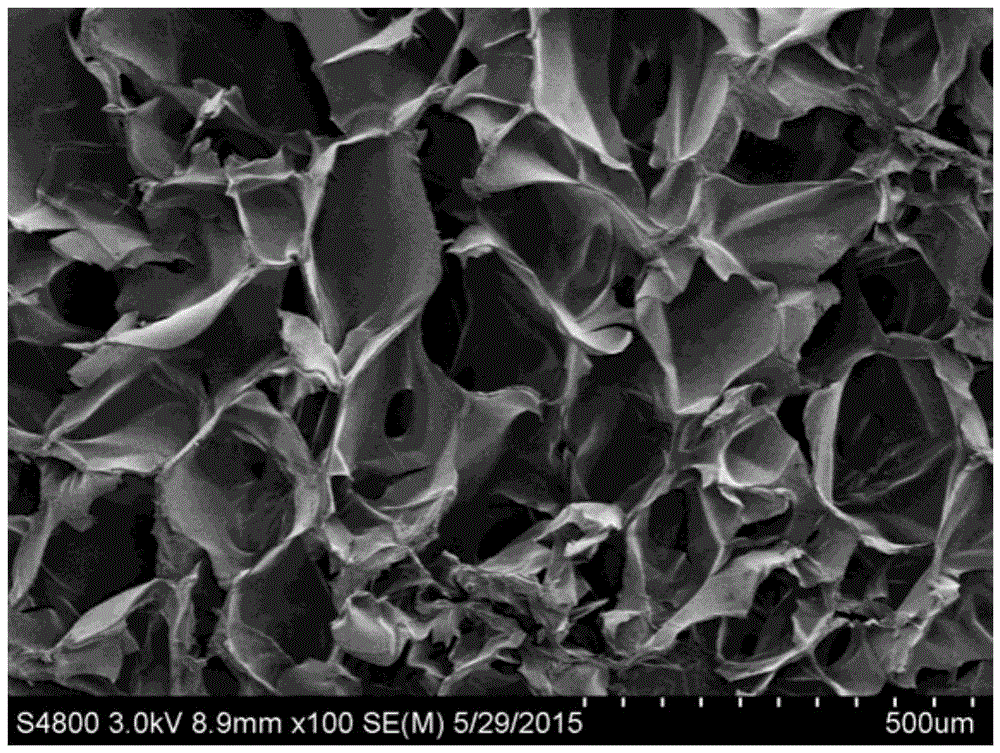

[0025] Dissolve 0.10g of hemicellulose in a glass bottle filled with 1mL, 1mol / L NaOH solution in advance, slowly add 0.01g of nano-clay particles, stir for 1h to disperse the nano-clay particles evenly, add 0.15g of PEGDE, and stir again for 15-20min, Then place the glass bottle in a water bath at 50°C, heat for 4 hours, then take out the product and place it in a beaker filled with distilled water for 48 hours, during which the distilled water is replaced regularly to remove unreacted substances, and the hydrogel is freeze-dried to obtain adsorption material, and its SEM photograph as figure 1 As shown in the figure, it can be seen that the prepared adsorbent has a porous structure with a pore size of 100-200 μm, and the surface is covered with negatively charged nano-clay particles, which is conducive to the penetration and adsorption of methylene blue cations. Take 0.10 g of the dried adsorbent material and place it in a methylene blue solution with a pH of 5 and an initia...

Embodiment 2

[0027]Dissolve 0.10g of hemicellulose in a glass bottle filled with 1mL, 1mol / L NaOH solution in advance, slowly add 0.03g of nano-clay particles, stir for 1h to disperse the nano-clay particles evenly, add 0.15g of PEGDE, stir for 15-20min, and then Place the glass bottle in a 60°C water bath, heat for 2 hours, then take out the product and place it in a beaker filled with distilled water for 48 hours, during which the distilled water is replaced regularly to remove unreacted substances, then freeze-dry the hydrogel to obtain adsorption Material. Take 0.10 g of the dried adsorption material and place it in a methylene blue solution with a pH of 5 and a concentration of 50 mg / L for oscillating adsorption at room temperature for 2 h, and the adsorption capacity is 47 mg / g.

Embodiment 3

[0029] Dissolve 0.10g hemicellulose in a glass bottle filled with 1mL, 1mol / L NaOH solution in advance, add 0.15g PEGDE, stir for 15-20min, then place the glass bottle in a water bath at 60°C, heat for 3h, then take out the product and store Place in a beaker filled with distilled water for 48 hours, during which the distilled water is replaced regularly, after removing unreacted substances, the hydrogel is freeze-dried to obtain the adsorption material. Take 0.10 g of the dried adsorbent material and place it in a methylene blue solution with a pH of 5 and a concentration of 50 mg / L for oscillating adsorption at room temperature for 1 h, and the adsorption capacity is 32 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com