Preparation method of biosensing film, biosensing film and monitoring device

A sensing membrane, biological technology, applied in biochemical equipment and methods, measuring devices, enzymes, etc., can solve problems such as low electron transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

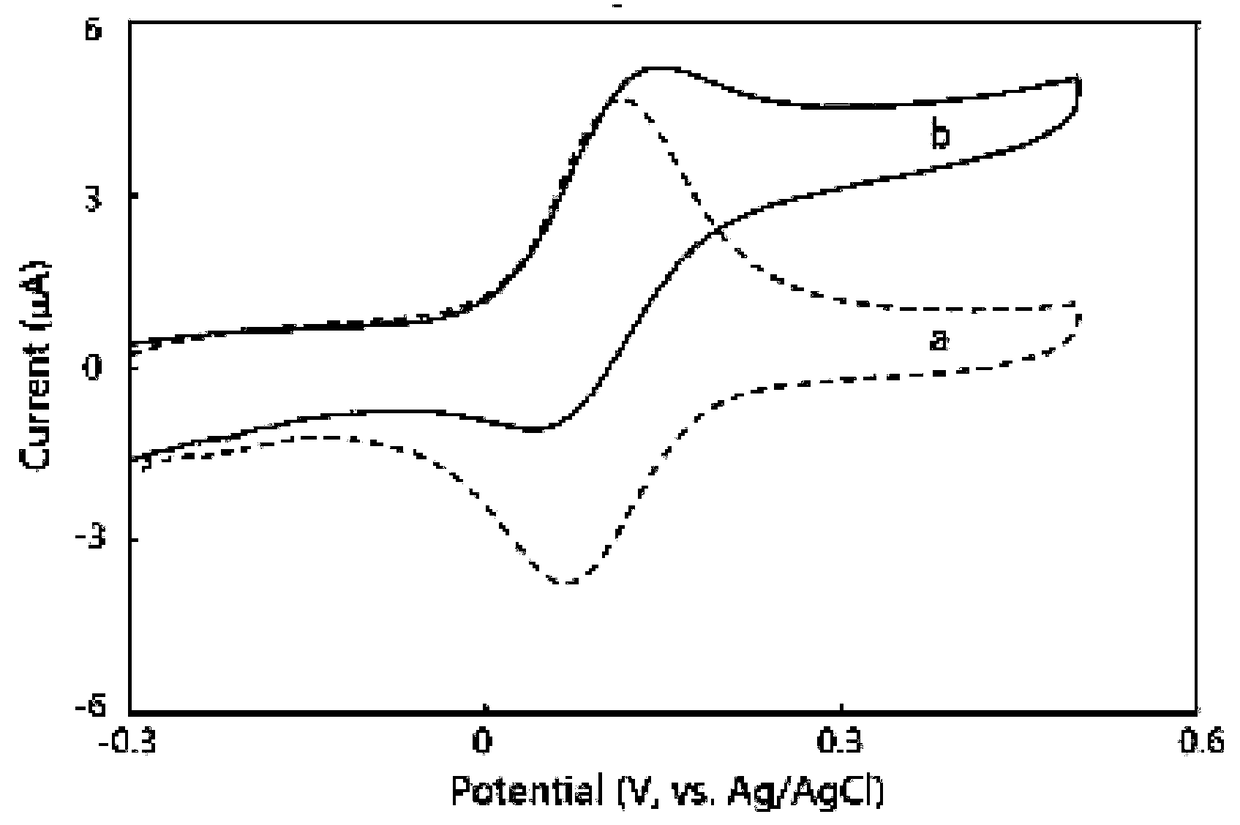

[0031] The invention provides a method for preparing a biosensing membrane. After electrochemically activating and modifying an oxidoreductase, it is crosslinked with a chemical crosslinking agent and coated on the surface of an electrode to form a biosensing membrane. The chemical cross-linking agent is glutaraldehyde or polyethylene glycol diglycidyl ether. In the preparation method provided by the present invention, by using glutaraldehyde or polyethylene glycol diglycidyl ether as a chemical cross-linking agent, the modified oxidoreductase is treated, and then coated on the surface of the electrode to form a biosensing membrane. The biosensing film formed by glutaraldehyde or polyethylene glycol diglycidyl ether cross-linking treatment is stable and durable, and can be detected many times, and is especially suitable for the biosensing film as a living body monitoring device.

[0032] Preferably, the oxidoreductase is any one or more of glucose oxidase, glucose dehydrogena...

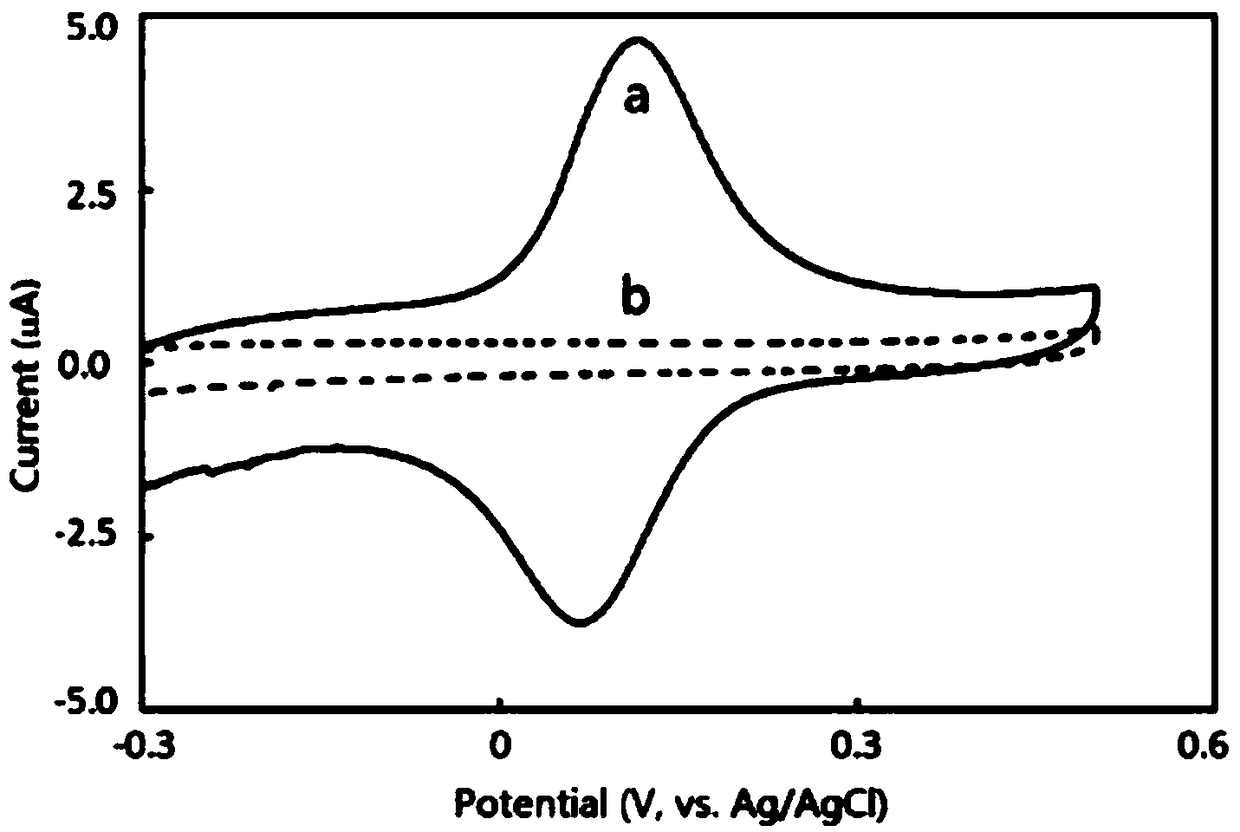

Embodiment 1

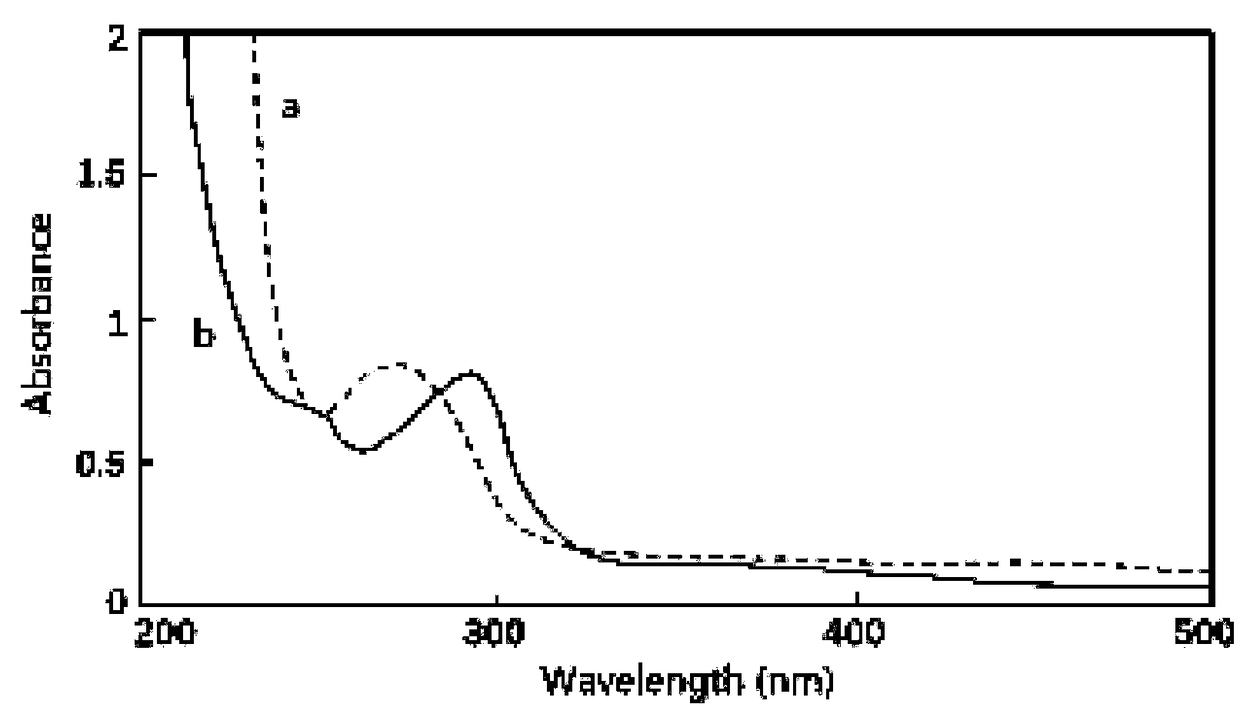

[0053] Add 1-20mg / ml of Os(bpy) 2 (3-Aminopropylimidazole) Cl, and glucose oxidase in PBS buffer solution are fully mixed, then sequentially add 0.1-25mmol / L carbodiimide and 0.01-5mmol / L N-hydroxysuccinimide, fully After mixing, react at 4°C for 24h. Then, the oxidoreductase after the first modification is separated and purified by ultrafiltration bag dialysis to cut off the molecular weight of 5000-50000. Then add 1-20mg / ml of Os(bpy) to the purified oxidoreductase solution 2 (4-imidazole butyric acid) Cl, then add 0.1-25mmol / L carbodiimide and 0.01-5mmol / L N-hydroxysuccinimide in turn, mix well and react at 4°C for 24h, after the reaction, use ultrafiltration again Bag dialysis, cutting molecular weight 500-50000, to separate and purify the oxidoreductase after the second modification. After glucose oxidase is modified, its catalytic active center can directly exchange very fast electrons with the electrode (see attached figure 1 shown). Using spectrophotometric analys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com