Castor oil sourced aqueous epoxy curing agent, and preparation method thereof

A water-based epoxy and castor oil technology, applied in the field of epoxy curing agents, can solve problems such as instability and film performance degradation, and achieve the effect of promoting the utilization of high added value, improving toughness and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

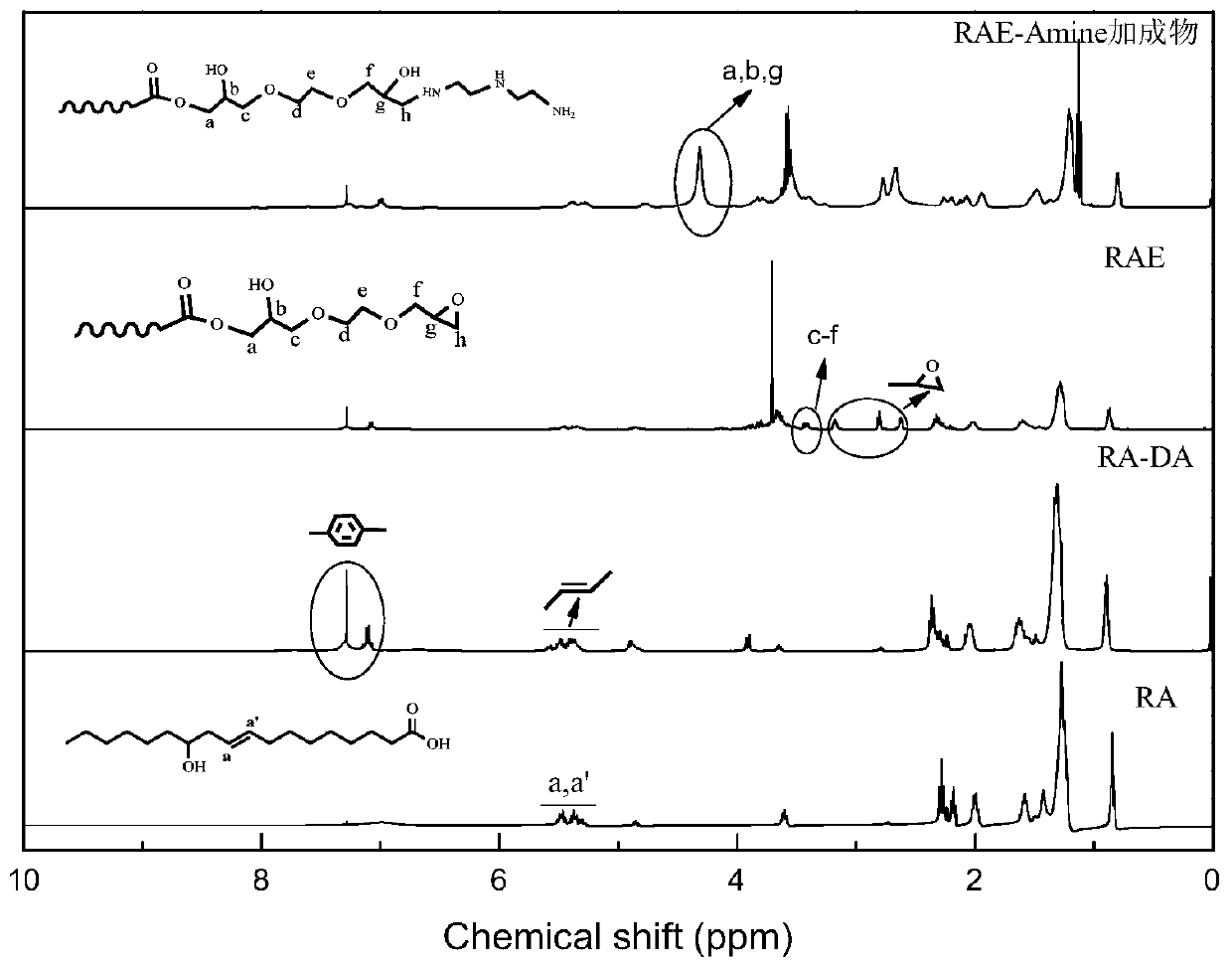

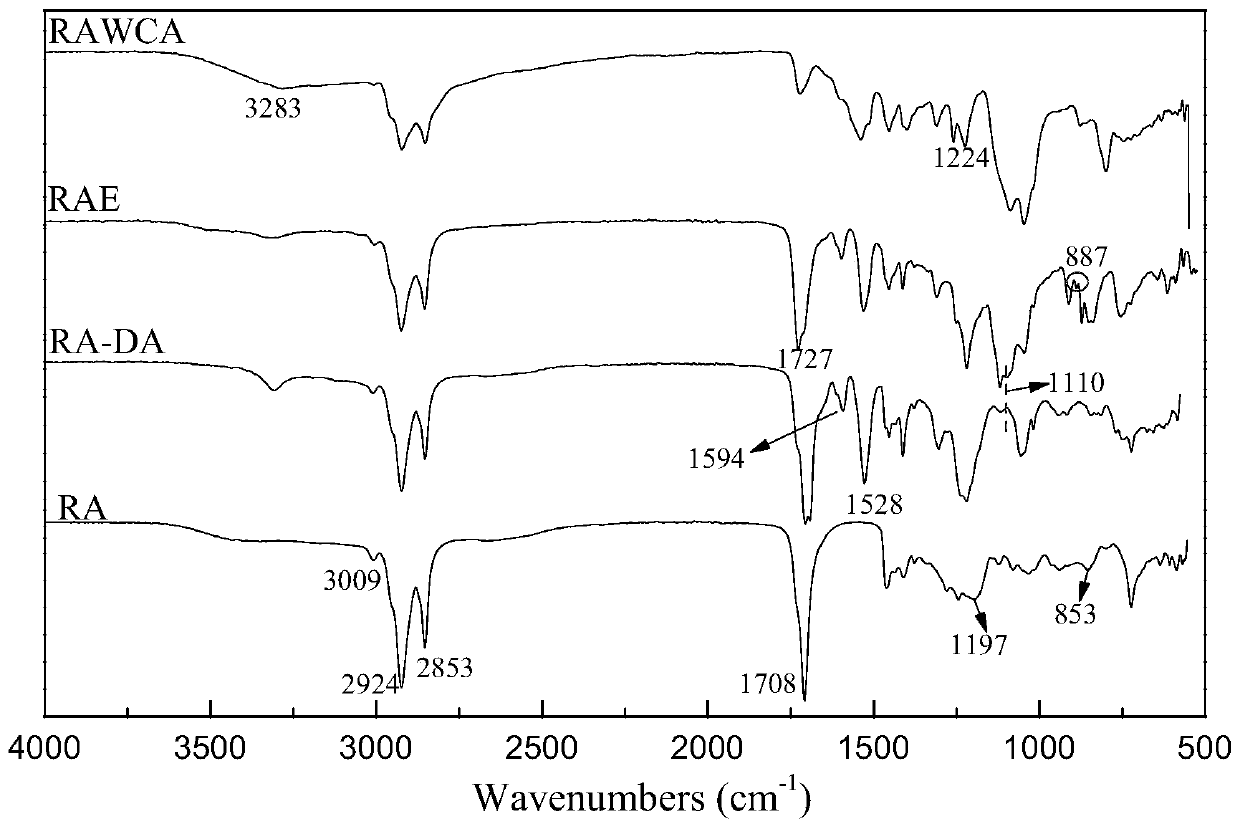

Embodiment 1

[0018] Step 1: Add liquefied MDI, ricinoleic acid, and 5‰ dilaurel in the four-necked flask in sequence according to the ratio of liquefied MDI: ricinoleic acid to 1:3 (mol:mol). dibutyltin acid, and react at a temperature of 85±2°C for 2 hours to obtain castor oil-derived dibasic acid (RA-DA).

[0019] The second step: dissolving RA-DA into an equal mass of 1,4-dioxane solvent to prepare a 1,4-dioxane solution with 50 wt.% of RA-DA. According to the acid value value of RA-DA, according to the ratio of carboxyl group: epoxy group of 1:2 (mol:mol), at 115 ° C, add ethylene glycol diglycidyl ether and the amount of ethylene glycol diglycidyl ether Add the 1,4-dioxane solution of RA-DA dropwise into a four-necked flask of cetyltrimethylammonium chloride with 0.3% glyceryl ether mass, and after the dropwise addition, keep it warm at 115°C for 3 hours. All solvents were distilled off under reduced pressure to obtain castor oil-derived epoxy active intermediate RAE.

[0020] The t...

Embodiment 2

[0023] Step 1: Add liquefied MDI, ricinoleic acid, and 5‰ dilaurel to the four-necked flask in sequence according to the ratio of liquefied MDI: ricinoleic acid to 1:4 (mol:mol). dibutyltin acid, and react at a temperature of 85±2°C for 2 hours to obtain castor oil-derived dibasic acid (RA-DA).

[0024] The second step: according to the acid value of RA-DA, according to the ratio of carboxyl: epoxy group of 1:2 (mol:mol), at 115 ° C, add ethylene glycol diglycidyl ether and the amount of ethyl In a four-necked flask of cetyltrimethylammonium chloride with a glycol diglycidyl ether mass of 0.35%, add RA-DA 50wt.% 1,4-dioxane solution dropwise. Heat the reaction at 115°C for another 3 hours, and distill off all the solvent under reduced pressure to obtain the castor oil-derived epoxy active intermediate RAE.

[0025] The third step: according to the epoxy value value of RAE, according to the ratio of epoxy group: diethylenetriamine is 1:2.1 (mol:mol), take RAE and make 50wt.% e...

Embodiment 3

[0027] The first step: according to the ratio of dicyclohexylmethane diisocyanate (HMDI): ricinoleic acid is 1:3 (mol:mol), add HMDI, ricinoleic acid and the total amount of HMDI and ricinoleic acid to the four-necked flask successively The quality is 5‰ dibutyltin dilaurate, and the temperature is controlled to 75±2°C for 3 hours to obtain the castor oil-derived dibasic acid (RA-DA).

[0028] The second step: according to the acid value value of RA-DA, according to the ratio of carboxyl group: epoxy group of 1:2 (mol:mol), at 115 ° C, add polyethylene glycol diglycidyl ether XY215 and the dosage In a four-necked flask containing 0.3% cetyltrimethylammonium chloride by weight of polyethylene glycol diglycidyl ether XY215, a 1,4-dioxane solution of 50 wt.% RA-DA was added dropwise, After the dropwise addition, keep the temperature at 115°C for another 3 hours, and distill off all the solvent under reduced pressure to obtain the castor oil-derived epoxy active intermediate RAE. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com