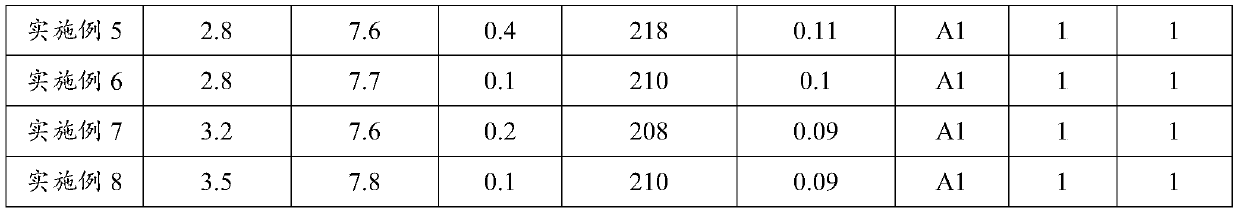

Patents

Literature

444results about How to "High value-added utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

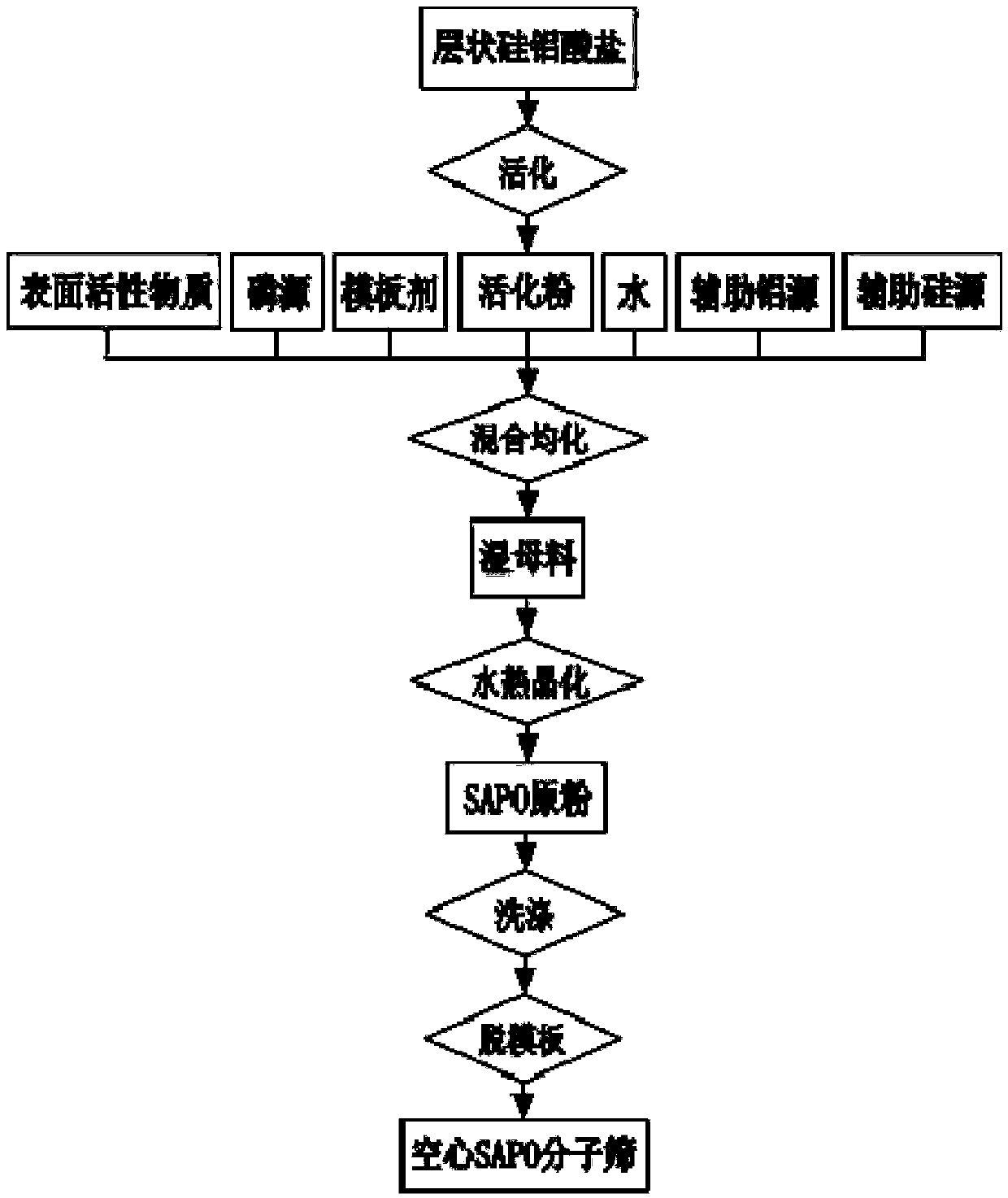

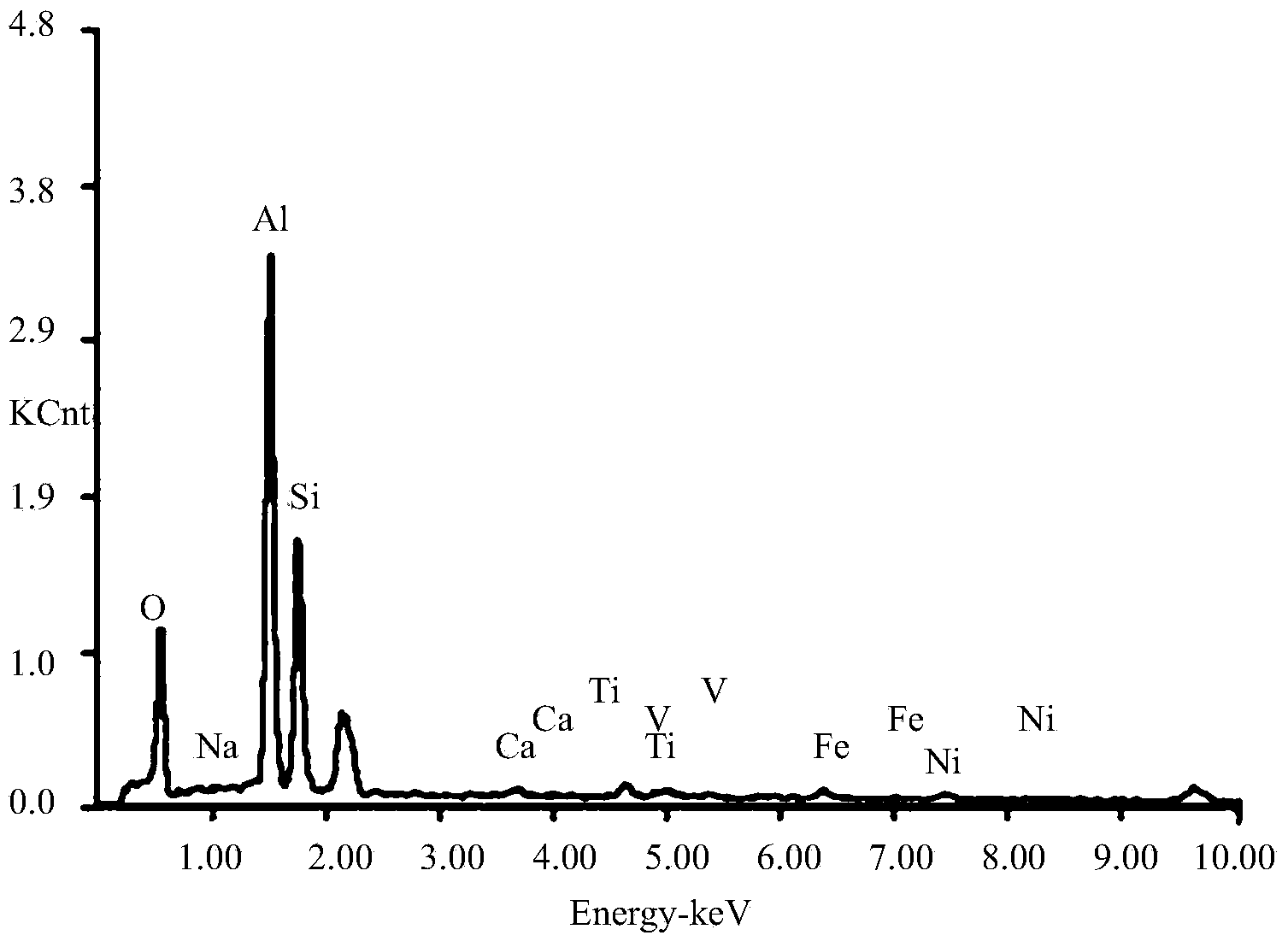

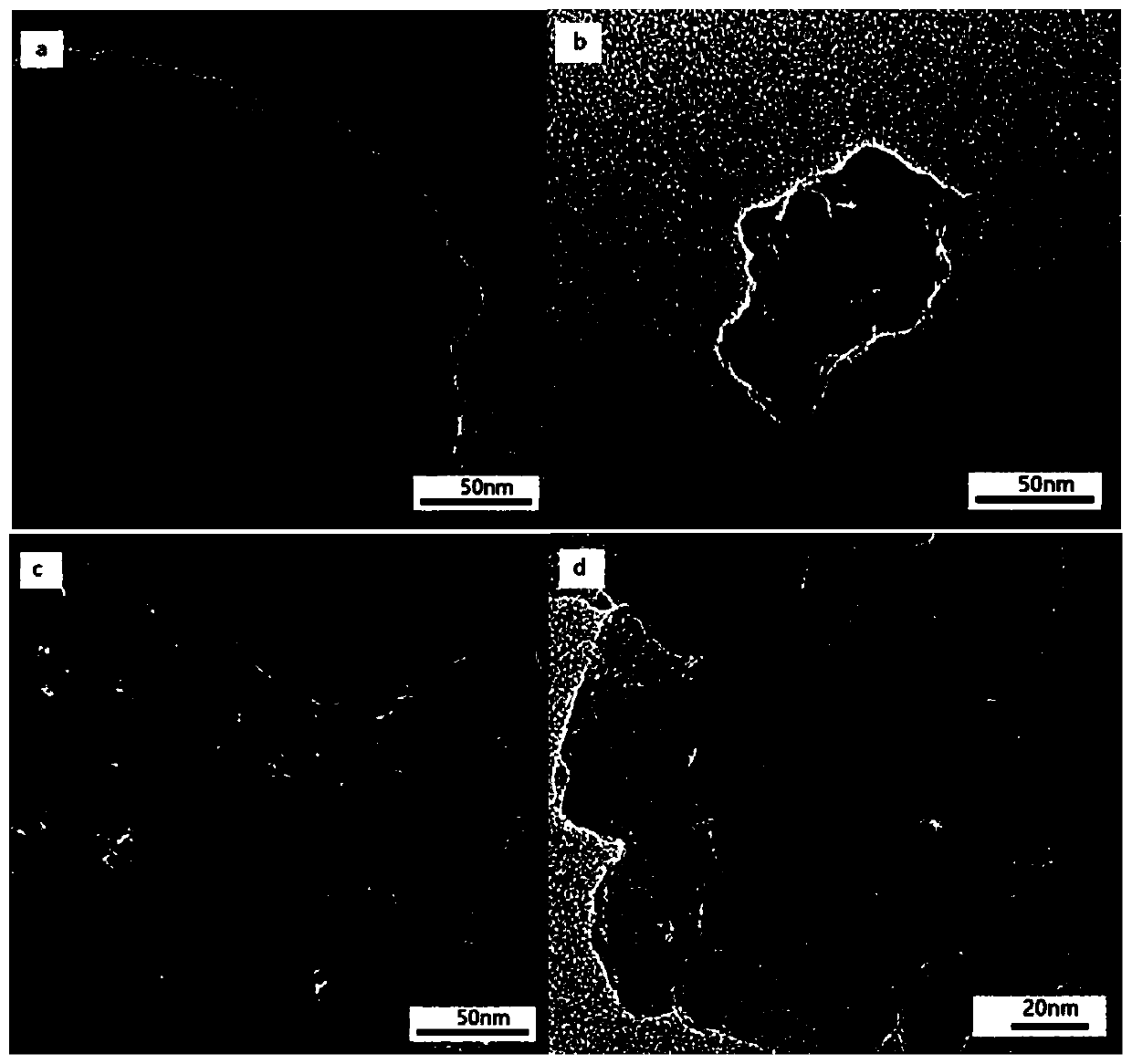

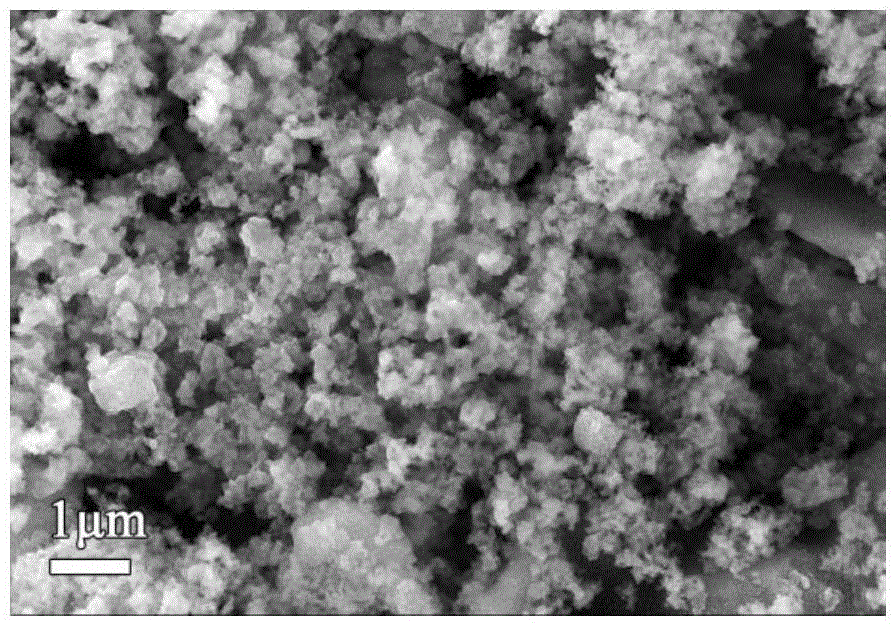

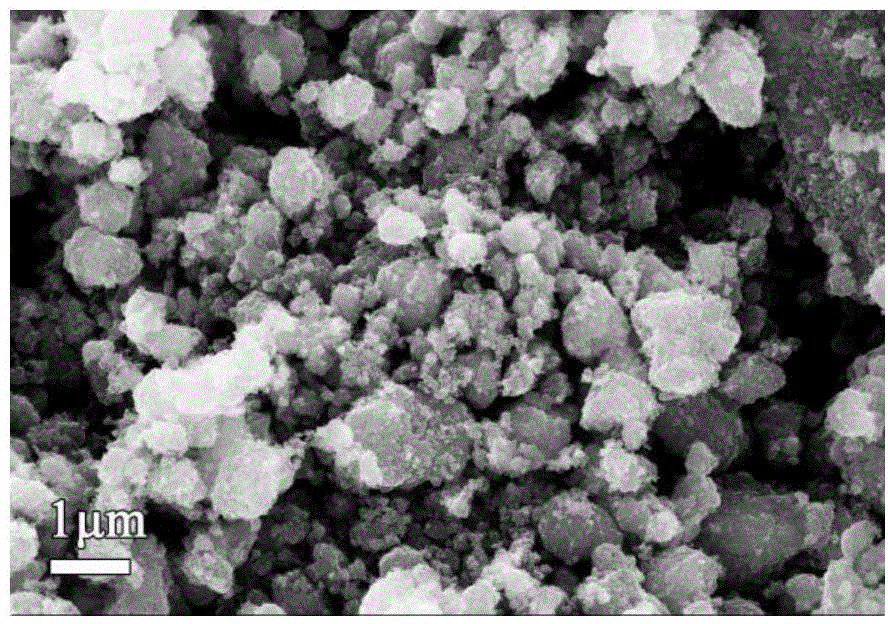

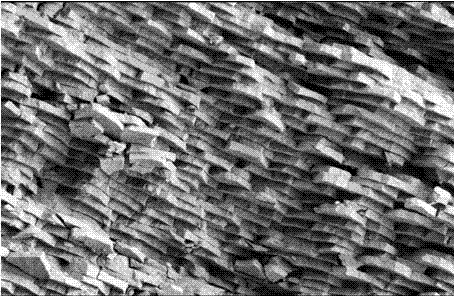

SAPO molecular sieve, and preparation method and purpose thereof

ActiveCN103964457AShorten the diffusion distanceImprove diffusion efficiencyMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveChemistry

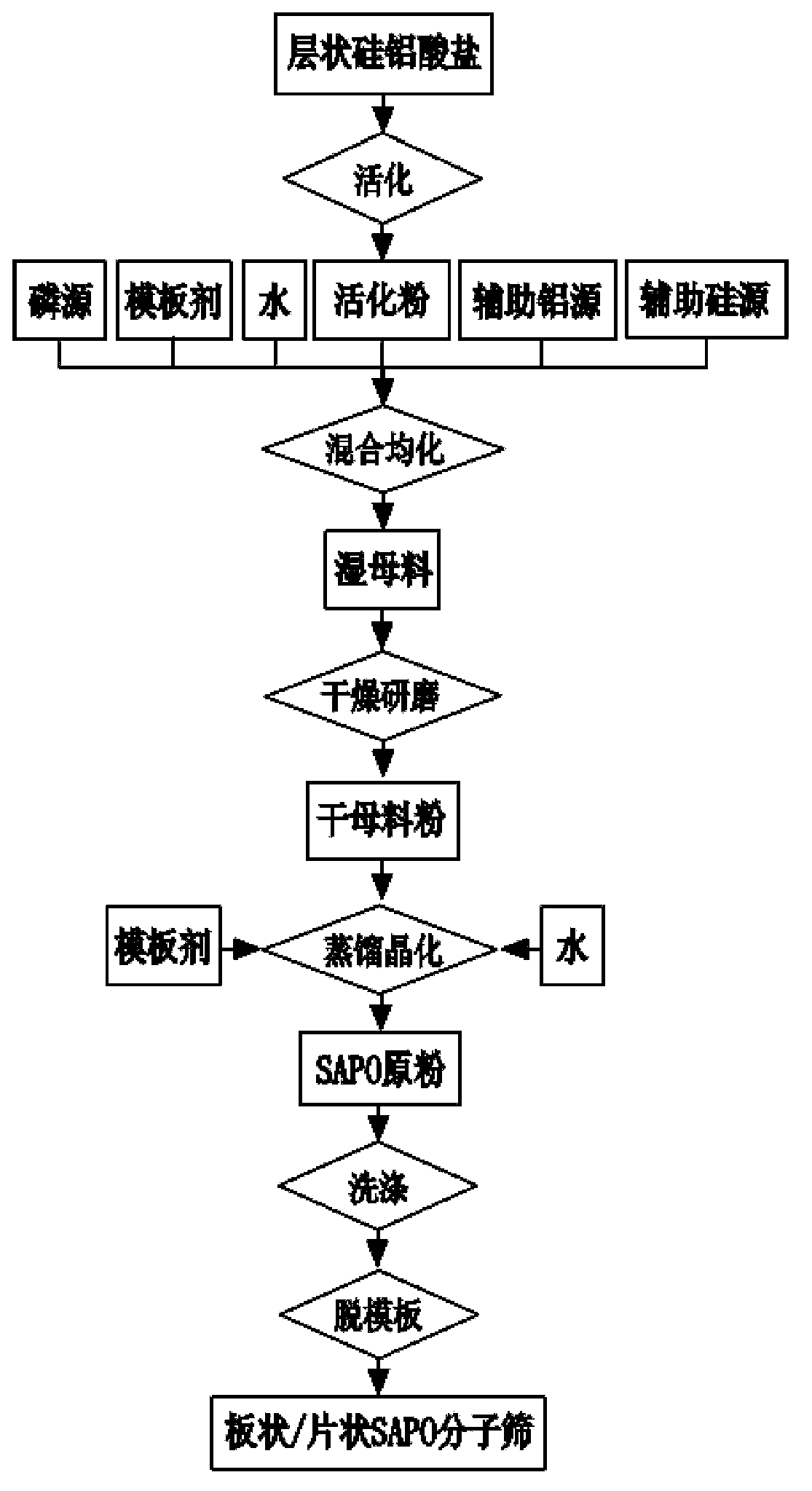

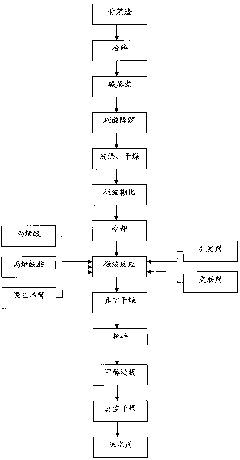

The invention discloses an SAPO molecular sieve, which has single crystals in sheet structure. The SAPO molecular sieve has moderate pore size, and can be used as a catalyst with long service life for olefin preparation from methanol. The invention also discloses a preparation method of the SAPO molecular sieve. The method us as below: activating a raw material of layered aluminosilicate, mixing the raw material with an phosphorus source and water, and homogenizing to obtain a wet masterbatch; drying and grinding the wet masterbatch to obtain a dry powder; and finally distilling the dry powder for crystallization, so as to obtain a raw powder for sheet SAPO molecular sieve. The method requires addition of a template agent, realizes low cost synthesis of SAPO molecular sieve and high additional value utilization of natural layered aluminosilicate, accelerates the rate of diffusion of various substances in the channels of the molecular sieve, increases the diffusion efficiency, and the advanategs of low equipment investment, simple operation and environment-friendliness.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

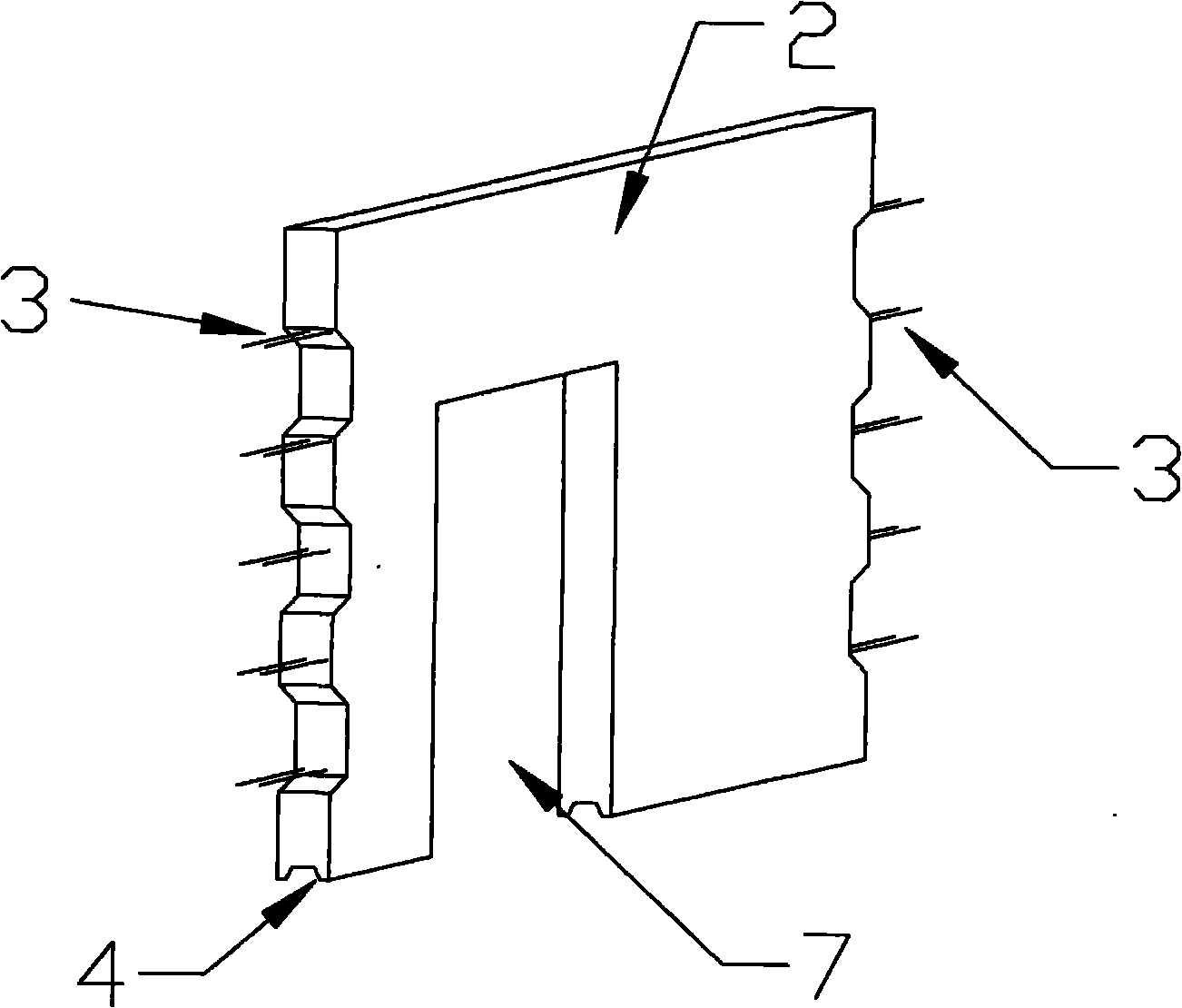

Board-mixing structure assembly type house and building method thereof

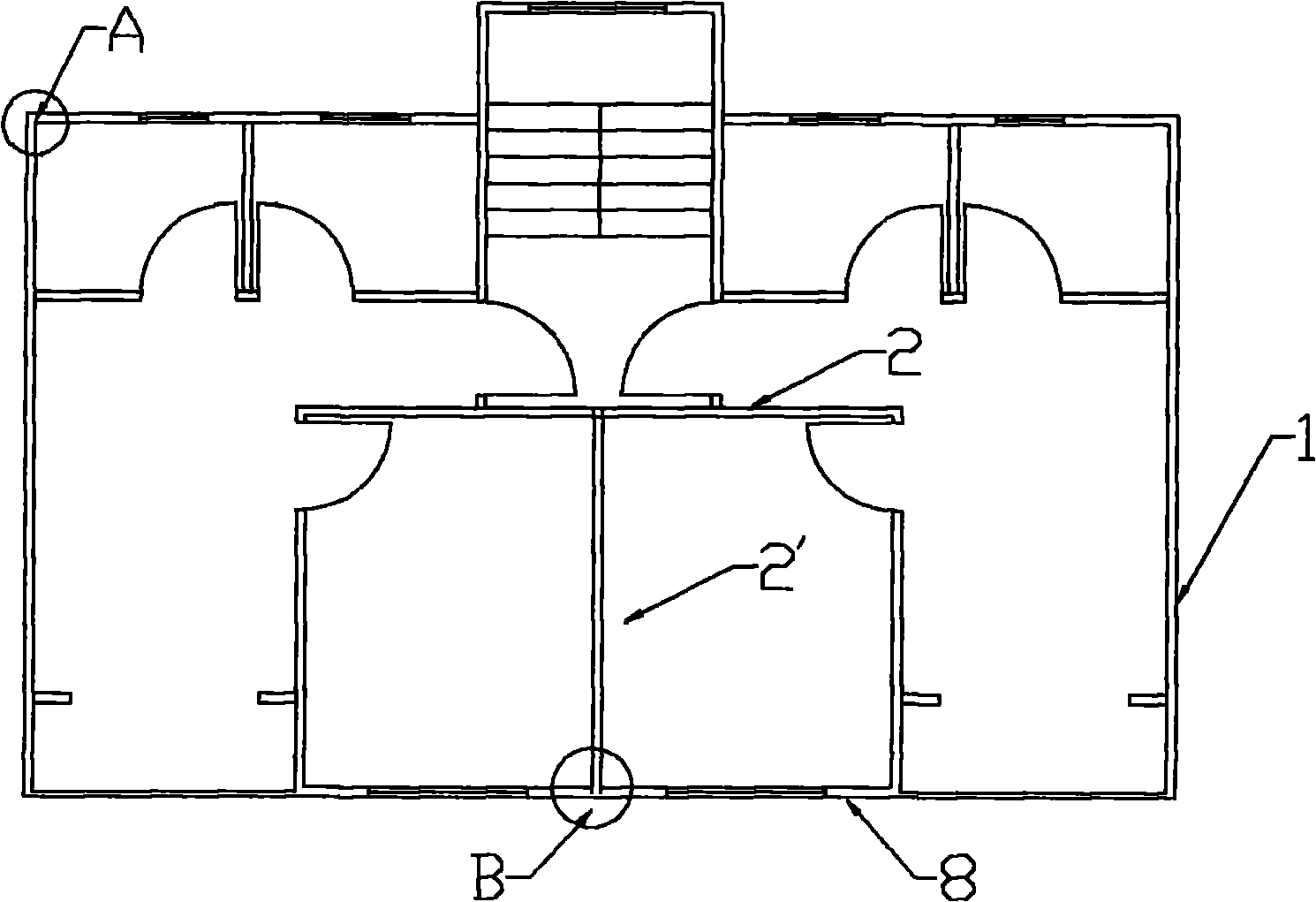

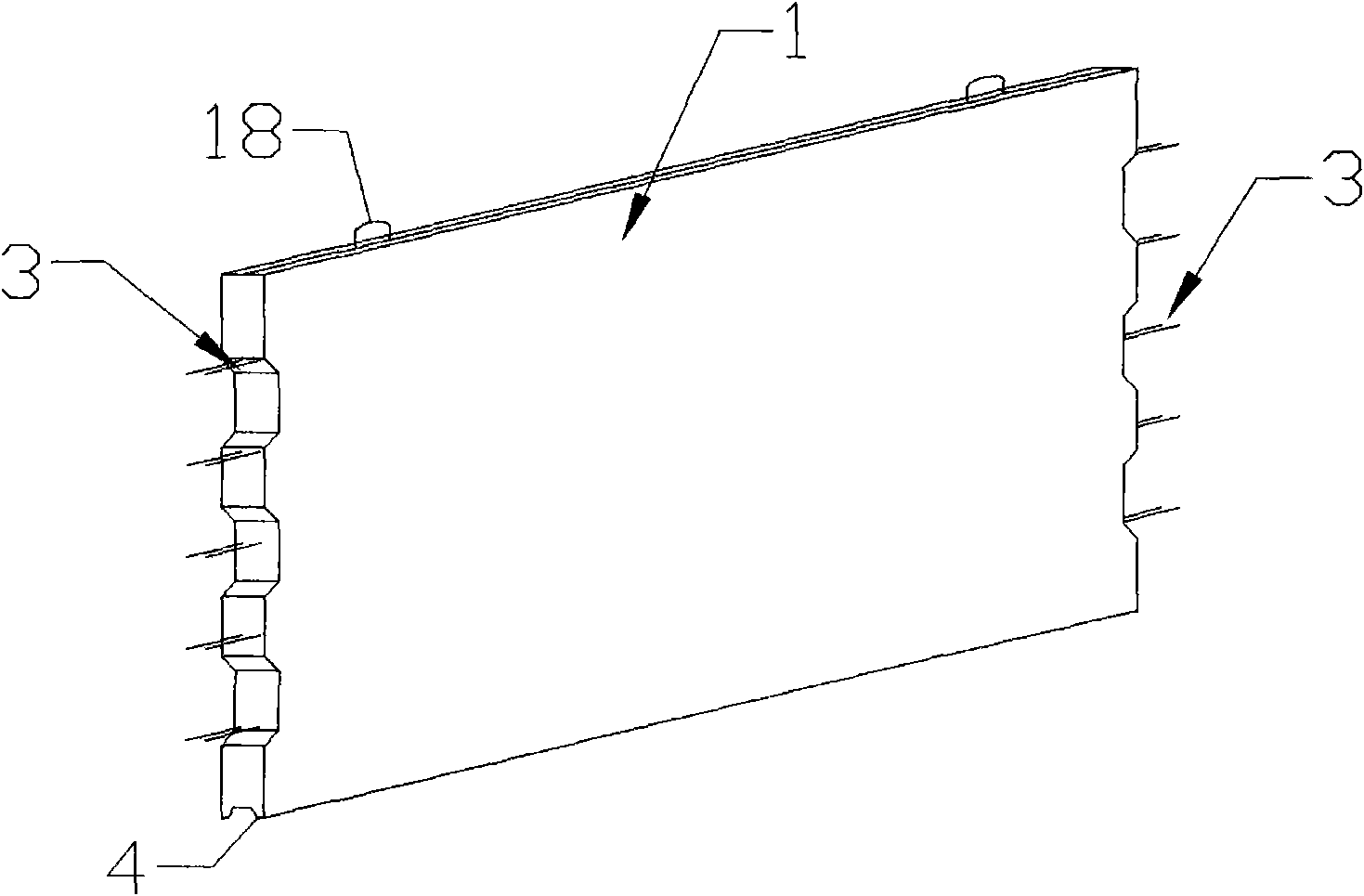

InactiveCN101967851APromote the development of circular economyImprove the level of industrializationBuilding constructionsThermal insulationWall plate

The invention discloses a board-mixing structure assembly type house and a building method thereof. The house is characterized in that an inner wall board, an outer wall board and superimposed floor boards which are prefabricated are connected with constructional columns and floors which are cast in site so as to form a whole; and the inner wall board, the outer wall board, the superimposed floor boards and the constructional columns are prefabricated or cast by adopting green concrete. The house can improve the industrial level of house construction and the whole level of house buildings greatly and reduce the construction difficulty and cost, is beneficial to solving the node waterproofing problem, improving the thermal insulation level and durability of thermal insulating materials and reducing the laying of reinforcing steel bars on the floors and laying of templates, and is beneficial to realizing standardized production and greatly shortening the construction period.

Owner:董杨

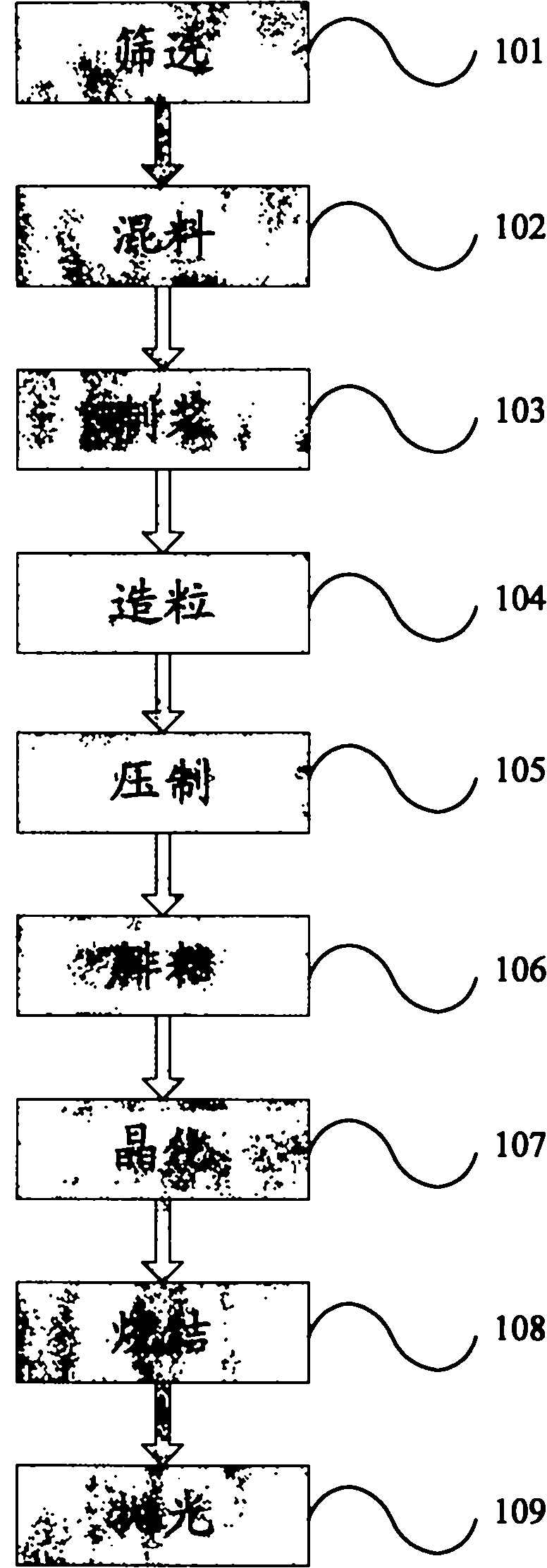

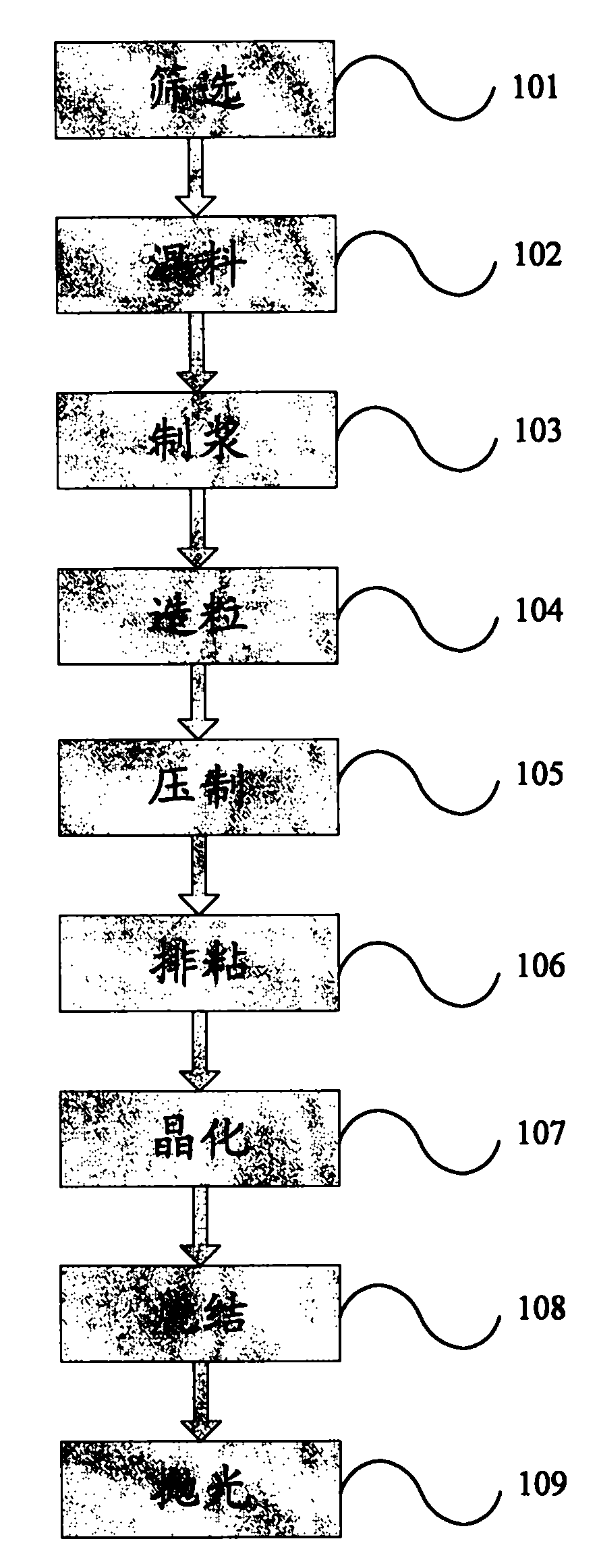

Technology for preparing microcrystal glass by utilizing blast furnace water granulated slag and coal ash

The invention discloses a technology for preparing microcrystal glass by utilizing blast furnace water granulated slag and coal ash, used for solving the problems that technology is complex, production cost is high, waste residue utilization factor is low and large scale commercial production is not benefited in the existing microcrystal glass preparation technology. The technology includes the following processes: screening, blast furnace water granulated slag is smashed and screened, thus obtaining water granulated slag powder less than 200 meshes; material mixing, coal ash with weight percent less than or equal to 20% and auxiliary solvent with weight percent less than or equal to 10% are added into the water granulated slag powder, the balance is water granulated slag powder, thus obtaining mixed powder material; pulping, the mixed material is pulped and then dried, thus obtaining wet material with moisture content less than or equal to 5%; pelleting, binder less than or equal to 5% weight of the wet material is added into the wet material, thus obtaining granules; tabletting, crystallizing and sintering, the granules are subject to tabletting, crystallizing and sintering, thus obtaining waste residue microcrystal glass. The invention has the characteristics of simple technology, low production cost and high waste residue utilization factor.

Owner:ZHENGZHOU UNIV

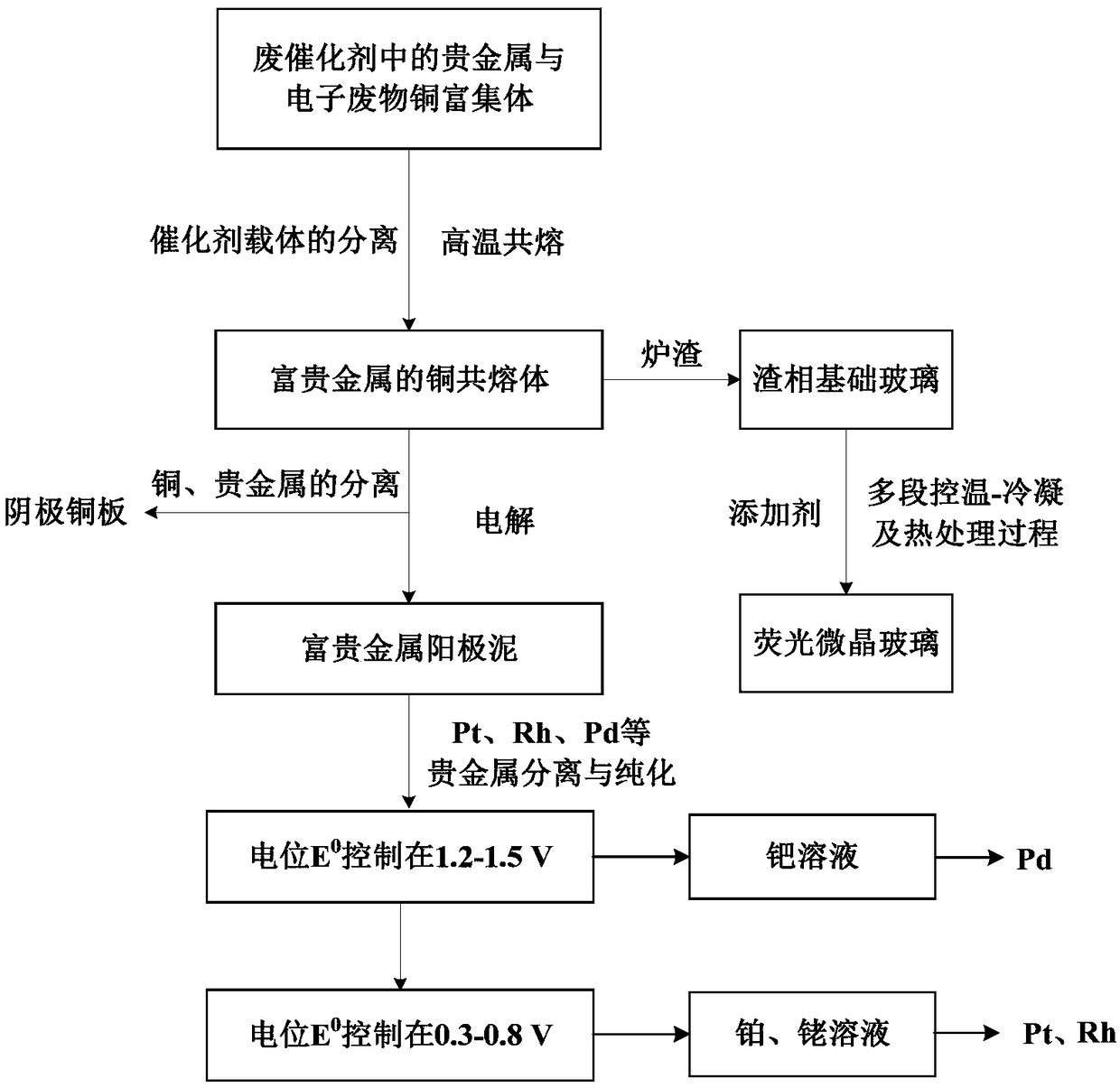

Method for collaborative resource between waste circuit board and automobile tail gas waste catalyst

ActiveCN109136532AEasy to separateEnable co-processingProcess efficiency improvementElectrostatic separationEngineering

The invention discloses a method for collaborative resource between a waste circuit board and an automobile tail gas waste catalyst. The method comprises the following steps: firstly, obtaining a copper-rich collective through performing crushing, magnetic separation and high voltage electrostatic separation on the waste circuit board; crushing the automobile tail gas waste catalyst to obtain waste catalyst powder; mixing the copper-rich collective and the waste catalyst powder to obtain mixed powder; adding a reagent in a certain amount of mixed powder in proportion, placing in a high-temperature muffle furnace for reaction and cooling to a room temperature after the completion of the reaction to obtain a product of which an upper layer is a glass layer, and a lower layer is a copper layer; separating the copper layer from the glass layer, taking out, crushing, then placing the glass layer in the muffle furnace for heat treatment; after the completion of the treatment, pouring microcrystalline glass liquid into a mold while the microcrystalline glass liquid is still hot, reducing the temperature and forming; after a room temperature is lowered, preparing out fluorescent microcrystalline glass. In the process, the recovery rate of precious metals exceeds 98 percent, the precious metals are enriched for 20 times or more, and the obtained fluorescent microcrystalline glass can betaken as an LED fluorescent lamp and other materials. To sum up, the method has the characteristics of being efficient, environmentally friendly and high in resource degree and is suitable for large-scale industrial application.

Owner:SHANGHAI JIAO TONG UNIV

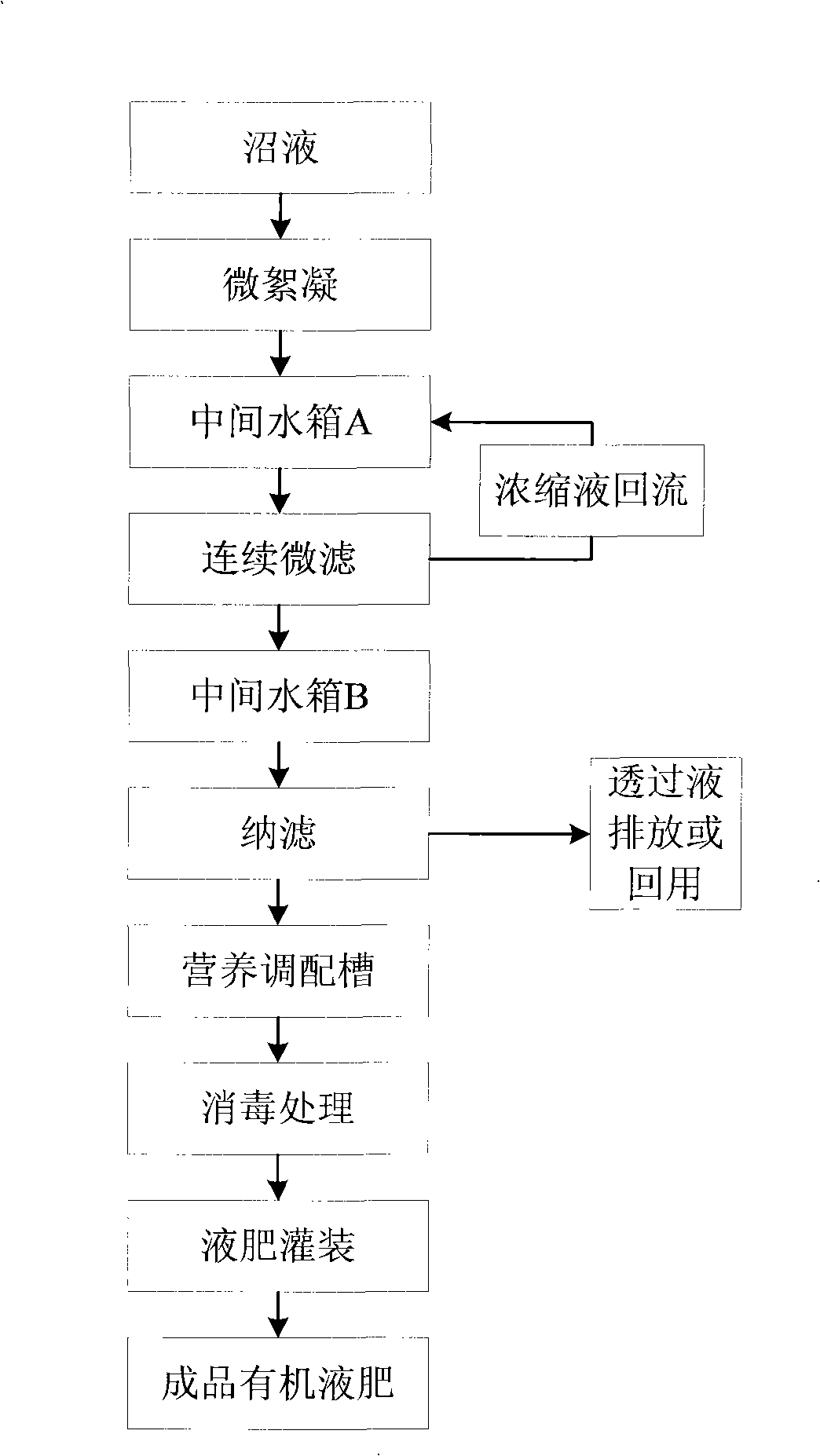

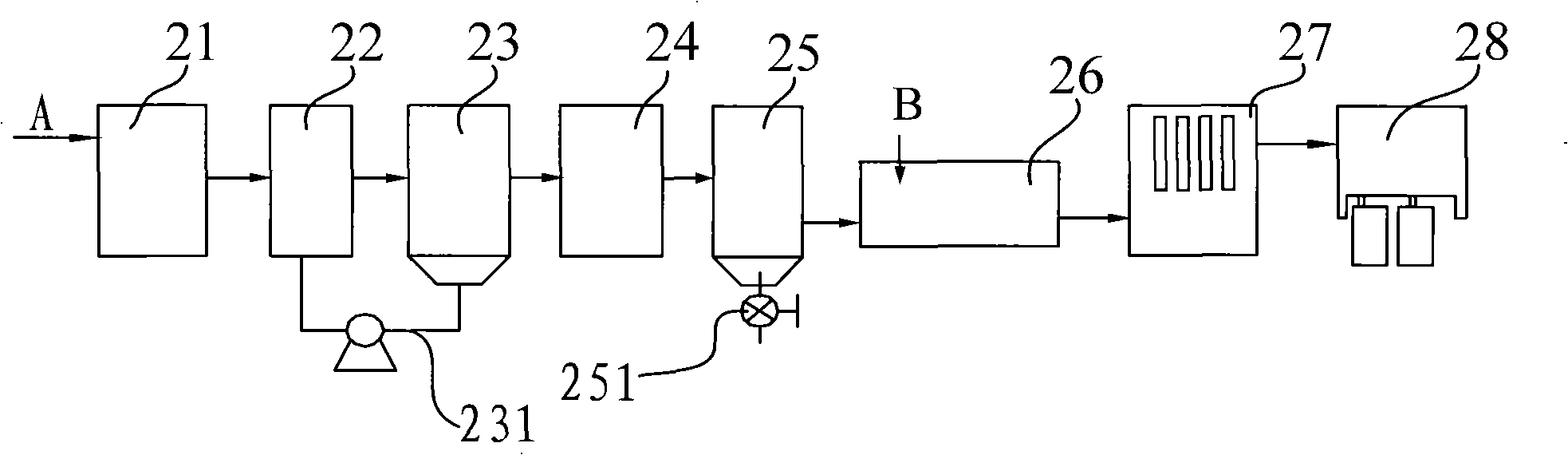

Method and equipment for producing organic liquid fertilizer with biogas slurry

InactiveCN101402530AHigh value-added utilizationWon't breakBio-organic fraction processingClimate change adaptationBiogasFertilizer

The invention discloses a method and a device for preparing organic liquid fertilizer from biogas fermentation slurry. The method comprises six operation steps: micro-flocculation treatment, continuous micro-filtration treatment, nano-filtration treatment, nutrition deployment treatment, disinfection treatment, and package treatment. The method has simple process, can concentrate active ingredients in common biogas fermentation slurry by 3 to 4 times, supplement certain useful ingredients according to different use objects simultaneously to prepare the common biogas fermentation slurry into highly-efficient organic liquid fertilizer products, thus the method and the device can achieve the high utilization of the added value of the biogas fermentation slurry and create significant economic benefits.

Owner:SOUNDGRP CO LTD

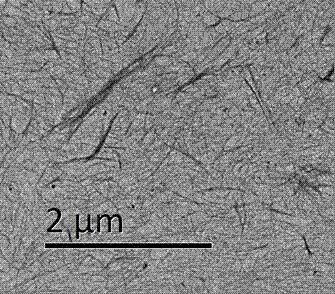

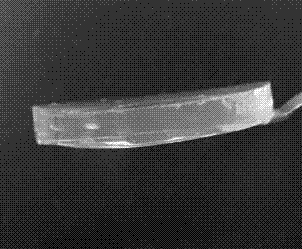

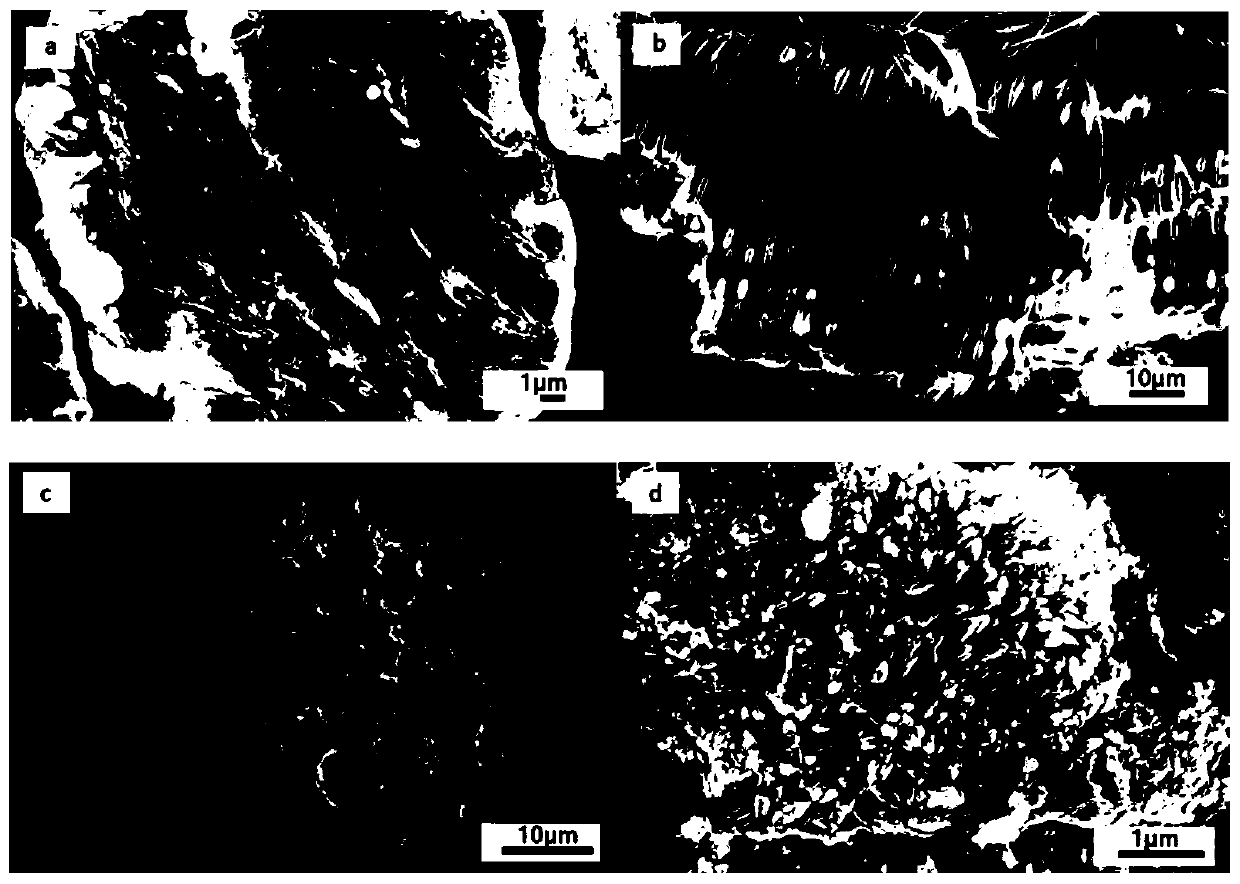

Preparation method of cellulose nanofiber biomass gel and aerogel

The invention relates to a preparation method of cellulose nanofiber biomass gel and airgel, comprising the following steps: (1) treating cellulose with a TEMPO / NaBr / NaClO oxidation system to prepare oxidized cellulose; (2) Mechanically treat oxidized cellulose in an aqueous solution or weakly alkaline aqueous solution to obtain a cellulose nanofiber dispersion; (3) process the cellulose nanofiber dispersion through an acidic coagulation bath or an acidic steam bath to obtain a raw cellulose nanofiber. (4) drying and dehydrating the cellulose nanofiber biomass gel to prepare the cellulose nanofiber biomass aerogel. The preparation method of a cellulose nanofiber biomass gel of the present invention is simple and easy to control, low in cost, and environmentally friendly, and can prepare biomass gels and aerogels with good shape, high strength, and low fiber content. Biocompatible, non-toxic and harmless; the prepared biomass gel and aerogel with negative electrical properties have better reactivity and biological activity.

Owner:HEYE HEALTH TECH CO LTD +1

Cement thermal insulation wallboard

InactiveCN106746992AHigh value-added utilizationLow costSolid waste managementSynthetic resin layered productsGlass fiberThermal insulation

The invention relates to a cement thermal insulation wallboard and a preparation method thereof. particularly, an inorganic closing layer is prepared by combining recovered fiber-reinforced cement material with cement, mineral powder, hollow glass microspheres, a high-performance superplasticizer and cellulose ether, so that the water absorption rate of a thermal insulation layer and the heat conductivity coefficient of the whole thermal insulation wallboard are effectively reduced and the durability of the thermal insulation wallboard is improved. The recovered fiber-reinforced cement material combined with a mineral admixture is added to a glass fiber-enhanced cement (GRC) structure layer, so that the strength of the thermal insulation wallboard is improved. Aggregates and fiber are replaced with waste fiber cement separately, so that the wastes can be efficiently utilized; meanwhile, the defect of poor durability of the thermal insulation wallboard is overcome; the thermal insulation property of the thermal insulation wallboard is improved. The cement thermal insulation wallboard is simple in process, has relatively economical benefits and environmental benefits and belongs to high value-added resource utilization.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

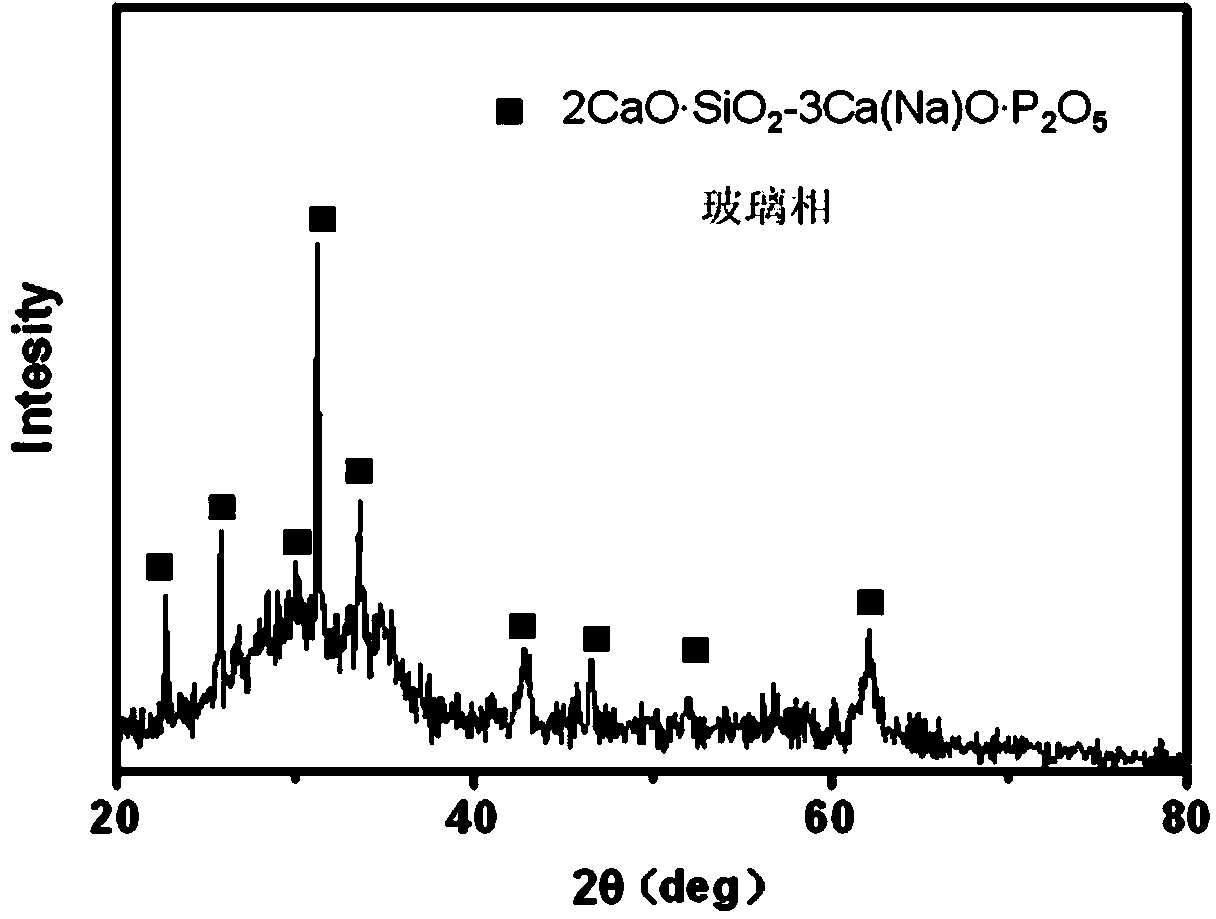

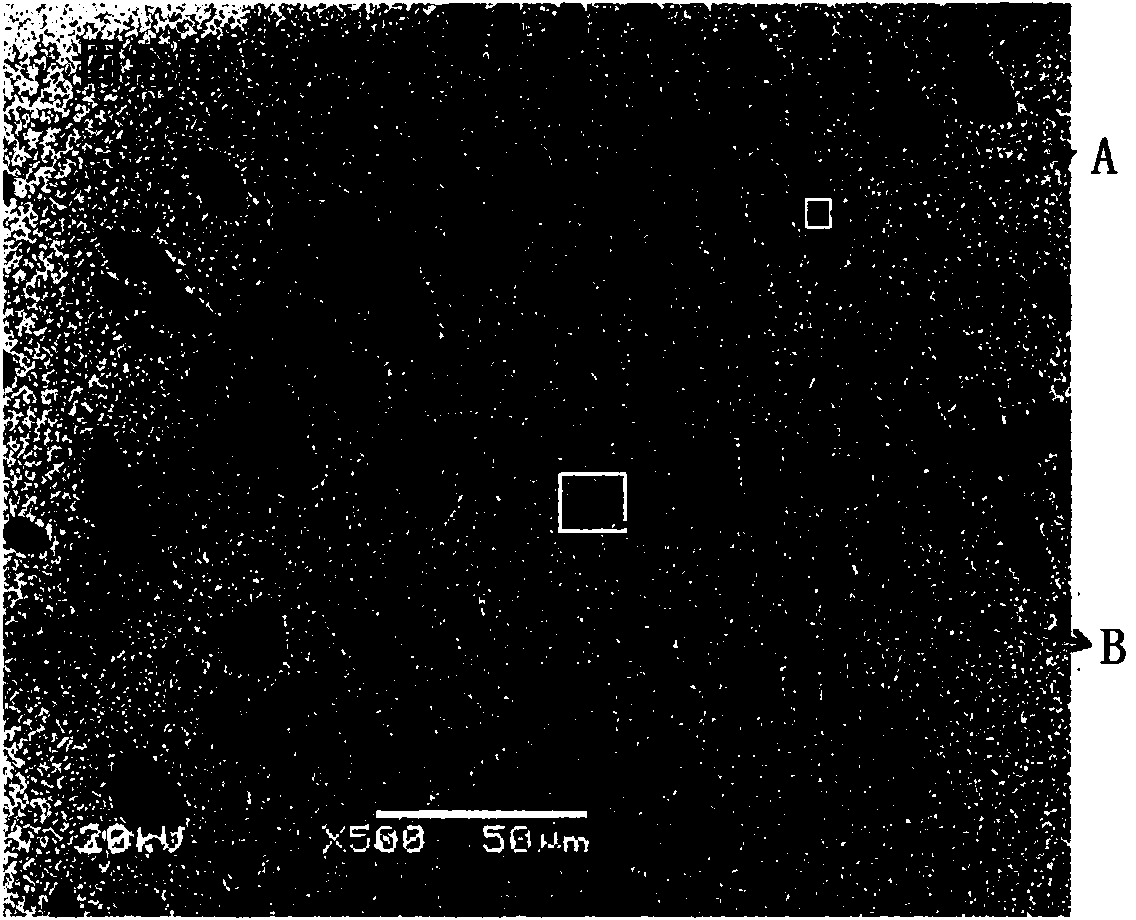

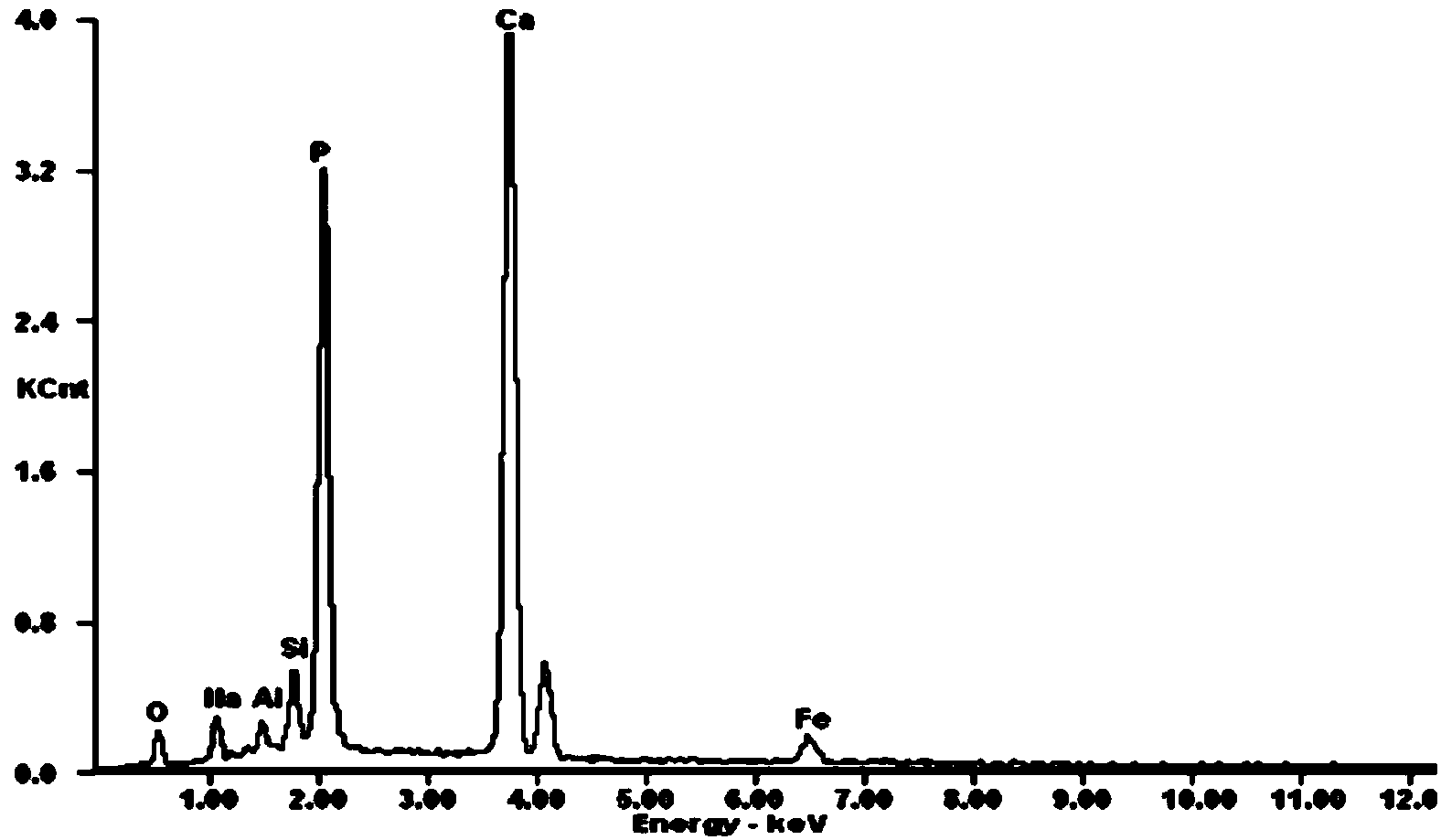

Dephosphorizing agent and application thereof

The invention relates to a dephosphorizing agent and application thereof, belonging to the technical field of ferrous metallurgy. The dephosphorizing agent solves the problems of low dephosphorizing efficiency, high residue consumption, environment pollution and difficulty in resource comprehensive utilization in the existing calcium-oxide-based molten iron pretreatment dephosphorizing agent. The dephosphorizing agent comprises the following components in percentage by mass: 25-50% of FeOt, 20-45% of CaO, 15-30% of SiO2, 2-10% of Na2O and 3-12% of Al2O3. After being molten, the molten iron dephosphorizing can form a solid-phase / liquid-phase coexistent multiphase residue system at 1300-1400 DEG C, wherein the solid phase is a 2CaO.SiO2 phase capable of providing a place for enriching oxidized phosphorus in molten iron, so that the dephosphorizing agent has the characteristics of favorable dephosphorizing effect, low slag consumption, no fluorine and small environmental pollution and is beneficial to comprehensive utilization of dephosphorizing slag.

Owner:CENT SOUTH UNIV

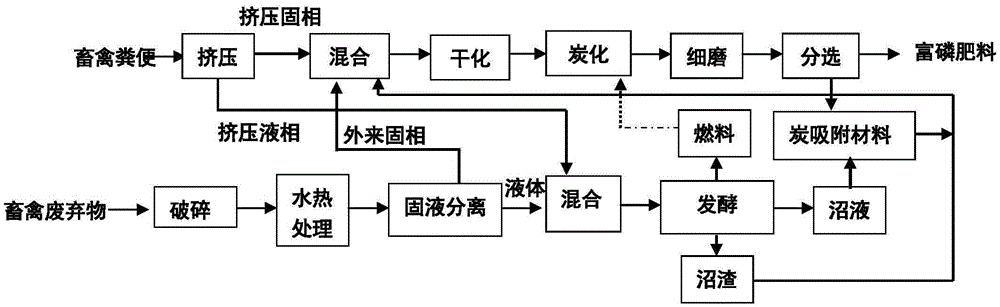

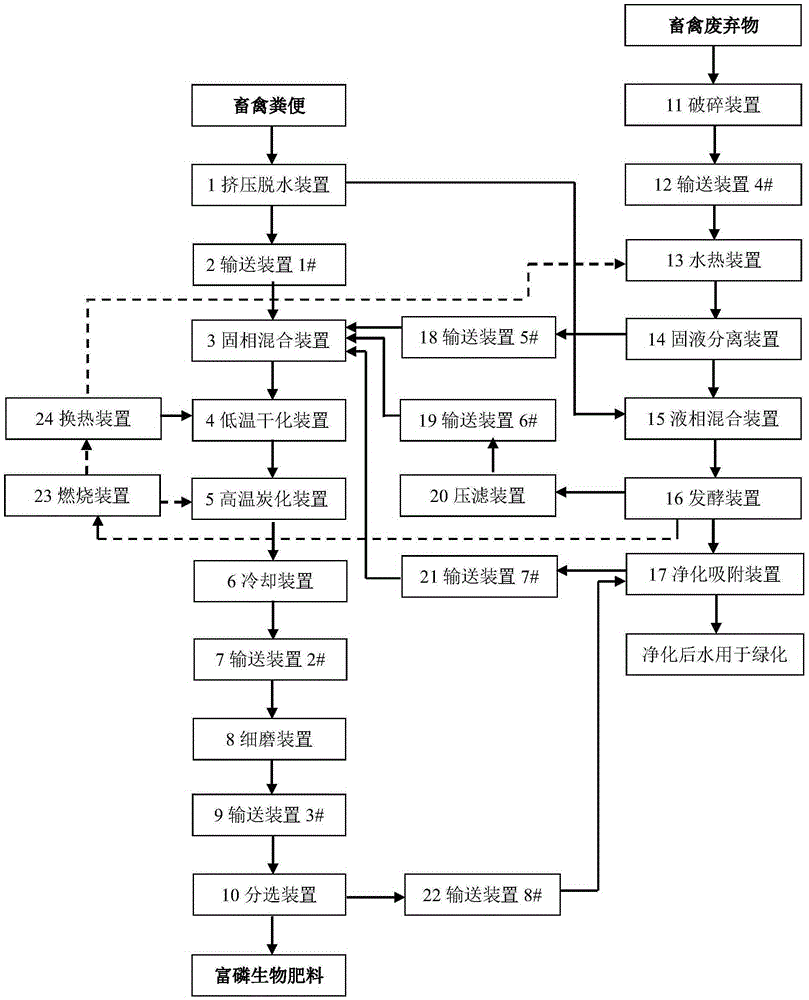

Method and device for preparing phosphorus-rich biofertilizer

The invention relates to a method and device for preparing phosphorus-rich biofertilizer. Phesphorus-rich fertilizer and a carbon adsorption material are obtained through livestock faeces in the steps of squeezing, mixing, drying, carbonization, fine grinding and sorting. Subsequent products obtained after smashing, hydro-thermal treatment and solid-liquid separation of livestock waste can be combined in the preceding steps to be further used, and purified water finally generated can be used for greening. According to the method and device, the livestock faeces and the livestock waste can be effectively used, waste is turned into wealth, the concept of circulating economy and clean production is fully reflected, the adverse influence and risk to the environment are reduced, operation is easy, the technological process saves energy and is remarkable in benefit, operation cost is low, and high-additional-value utilization of products is achieved while harmless treatment of sick and dead livestock is achieved. The method and device have good social benefits, economic benefits and environmental benefits.

Owner:中科环境科技研究院(嘉兴)有限公司

Copper tailing composite mineral mixed material and preparation method thereof

ActiveCN108117292AHigh activityImprove hydration crystal structureSodium metasilicateMixed materials

The invention provides a copper tailing composite mineral mixed material which is prepared from the following raw materials in parts by mass: 25-50 parts of grinded copper tailings, 40-60 parts of coal ash, 0.4-1 part of an active activator and 0-35 parts of an active mineral mixed material, wherein the active activator is a mixture consisting of more than any three of calcium oxide, sodium metasilicate, sodium sulfate, sodium thiosulfate or sodium tripolyphosphate. By adopting the copper tailing composite mineral mixed material provided by the invention, high-cost raw materials such as coal ash are massively replaced by the copper tailings, high-value recycling of the copper tailings is achieved, environment protection can be facilitated, the cost of the mixed material is reduced, the mixed material has ideal activity as a whole, early-stage hydration crystallization structures and products of cement concrete are improved, and good late-stage strength is achieved. The invention further provides a method for preparing a premixed concrete mineral mixed material from copper tailings.

Owner:江西万铜环保材料有限公司

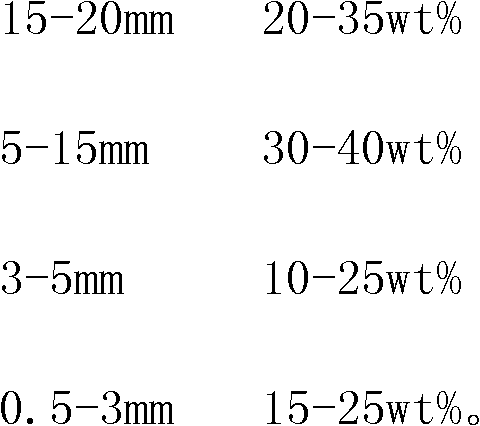

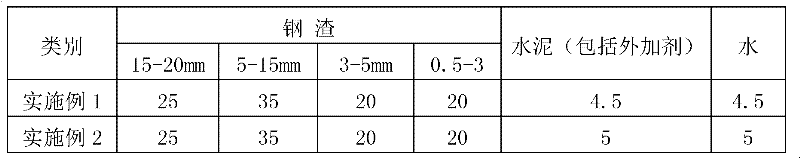

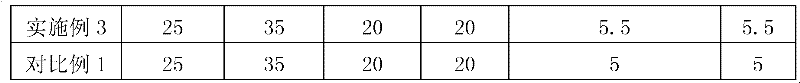

Steel slag and cement stabilized base material

The invention provides a steel slag and cement stabilized base material comprising components of steel, cement, water, and an additive. The weight ratio of steel to cement to water is 100:4-6:4-6; and the weight of the additive is 0.6-6% of the weight of cement. According to the invention, graded steel slag serves as an aggregate, and is used for replacing crushed stones. The voids of the aggregate are filled by using a certain amount of a cementing material and the volume of enough mortar. The materials are paved and compacted according to an interlocking principle. The strength of the base is high. With increasing age periods, the base rapidly turns into a board body. Therefore, the material has high strength, high water permeability and high freezing resistance. The material can be used in road base constructions.

Owner:MCC BAOSTEEL TECH SERVICE

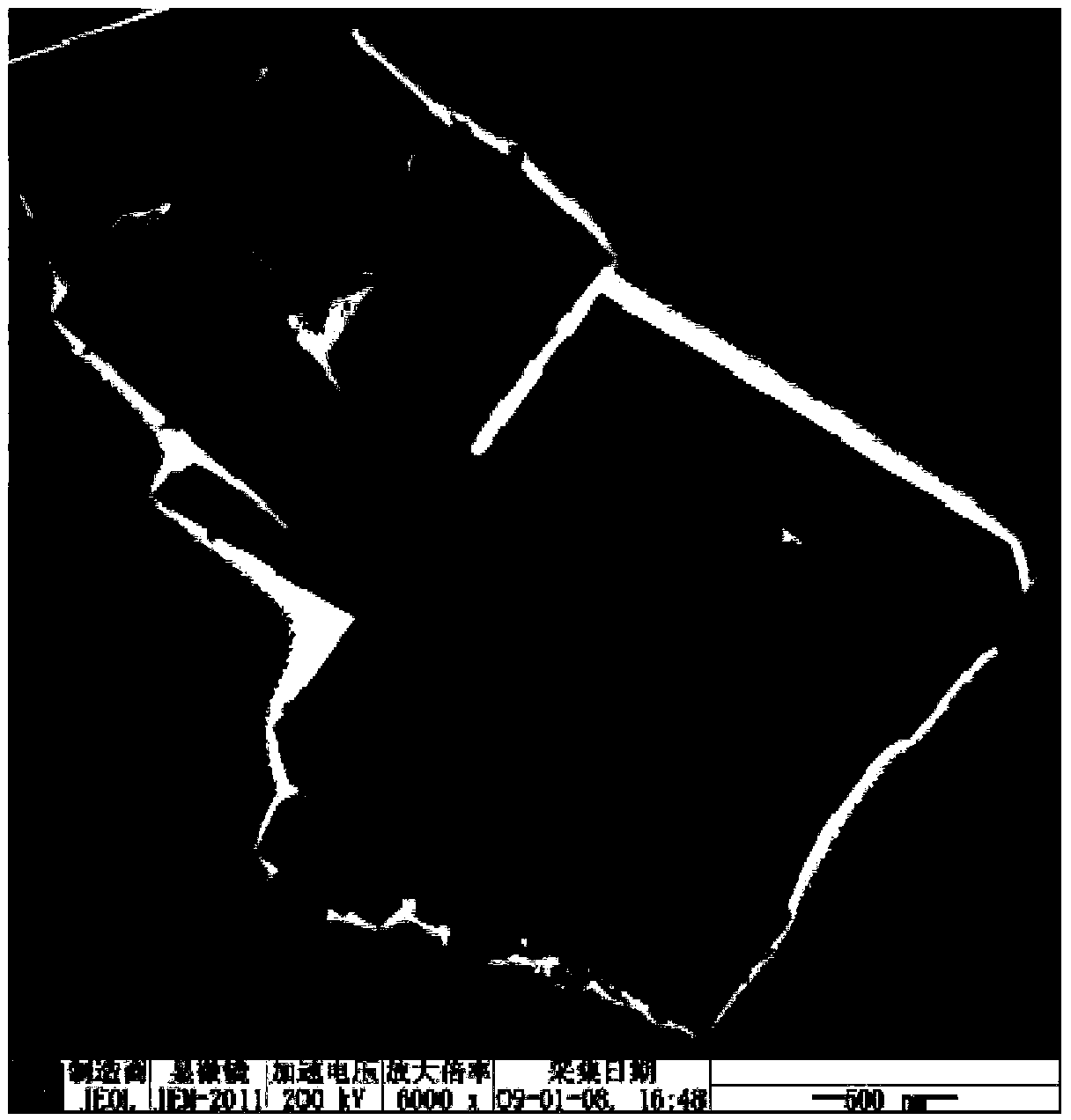

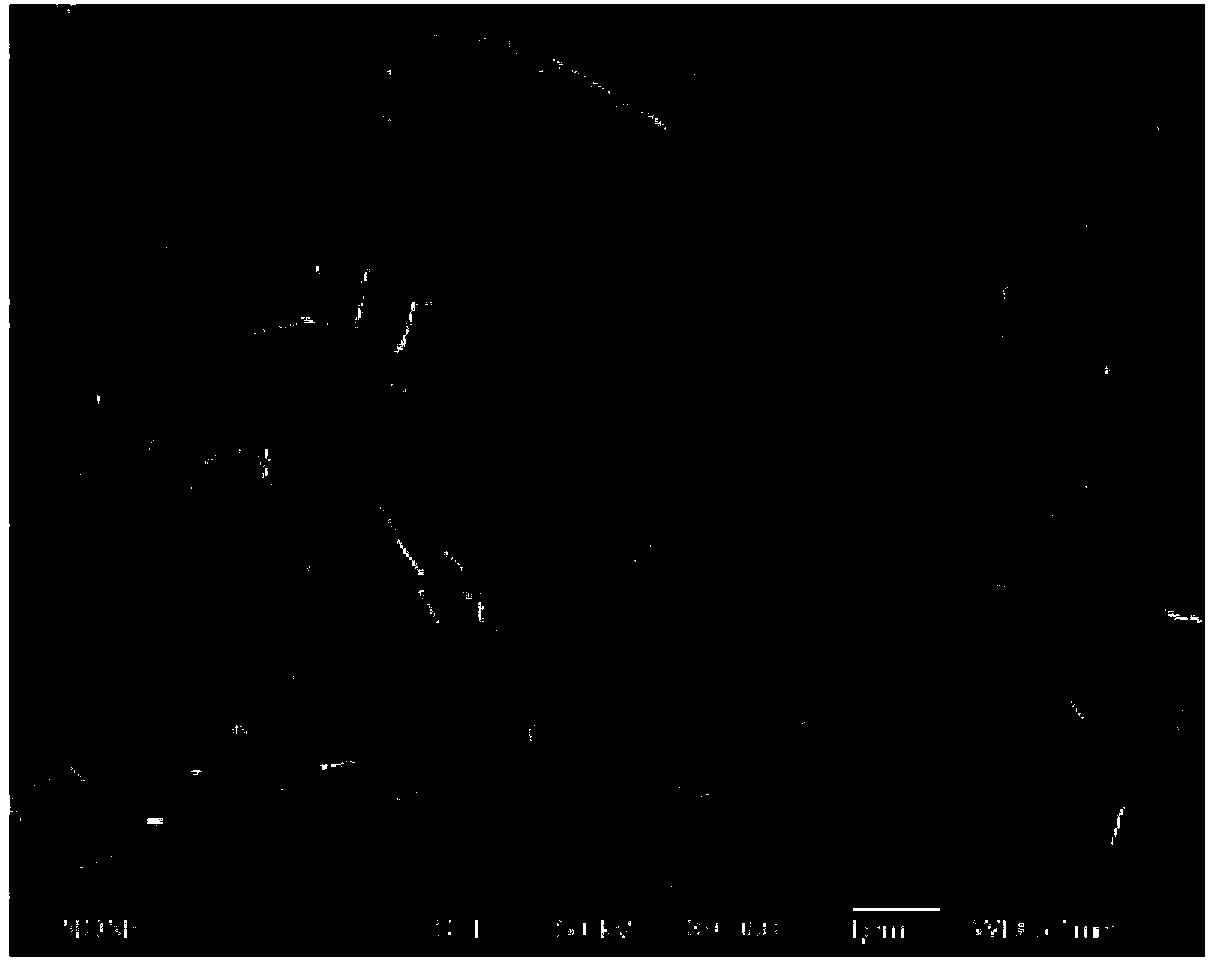

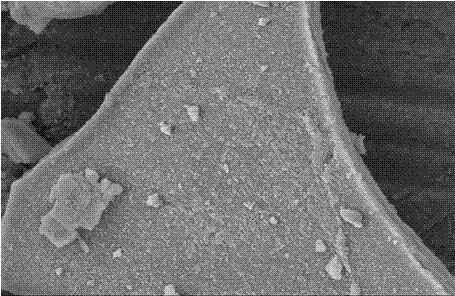

SAPO molecular sieve, and preparation method and purpose thereof

ActiveCN103964456ASuitable for acidityExtend your lifeMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveSingle crystal

The invention discloses an SAPO molecular sieve, which has hollow single crystals. The SAPO molecular sieve has optional pore structure, adjustable silicon content and distribution, controllable strength and density of acid site, and long service life of catalyst. The invention also discloses a preparation method of the SAPO molecular sieve. The method uses layered silicate as a raw material, which is subjected to activation, and mixed and homogenized with a phosphorus source, an auxiliary aluminum source and water to obtain a wet masterbatch; and the wet masterbatch is subjected to hydrothermal crystallization to obtain a raw powder of the hollow SAPO molecular sieve, wherein the molar ratio of Al and Si in the wet masterbatch is higher than 1. The method use easily available raw materials, has low cost and can be prepare the SAPO molecular sieve with hollow structure.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

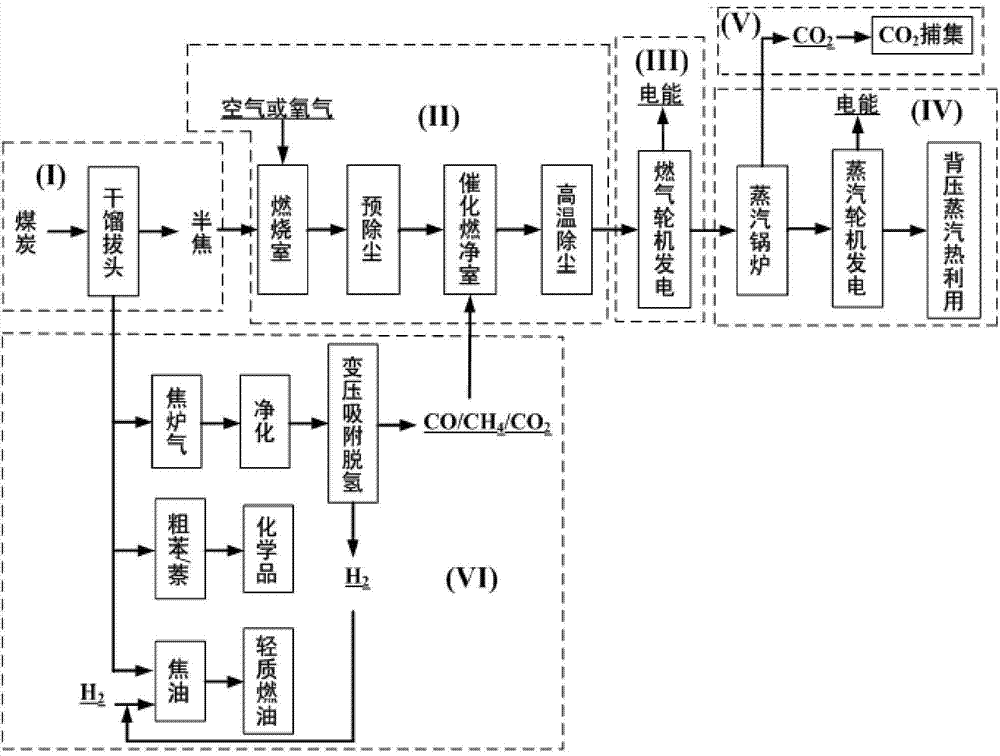

Efficient and clean utilization technology for highly volatile young coal

ActiveCN102965131AEfficient use ofHigh value-added utilizationHydrogen separationEnergy inputTrappingFuel oil

The invention relates to an efficient and clean utilization technology for highly volatile young coal. By means of integrated innovation of the following six technological modules: ''a young coal dry distillation topping process, a system for preparation of a high temperature gas turbine working medium by semi-coke oxygen-enriched direct combustion, gas-fired power generation, supercritical / ultra supercritical power generation, CO2 trapping, and a dry distillation topping gaseous product high-value utilization technique'', especially the method for preparation of high-temperature and high-pressure fuel gas meeting the gas turbine working medium purity requirement directly by semi-coke oxygen-enriched direct combustion without lowering temperature to remove dust and impurities, thermodynamic-chemical full-value clean utilization of coal can be realized. The power generation efficiency can reach over 60%. Compared with the IGCC (integrated gasification combined cycle) technology, the invention substitutes semi-coke oxygen-enriched direct combustion for a coal gasification process needing large investment, develops a high temperature dust removal technology, and makes full use of the useful work of high temperature fuel gas. The invention has the characteristics of less investment, simple process, and high power generation efficiency, etc., and also generates benzene, naphthalene, fuel oil and other high value-added chemicals as byproducts.

Owner:金涌

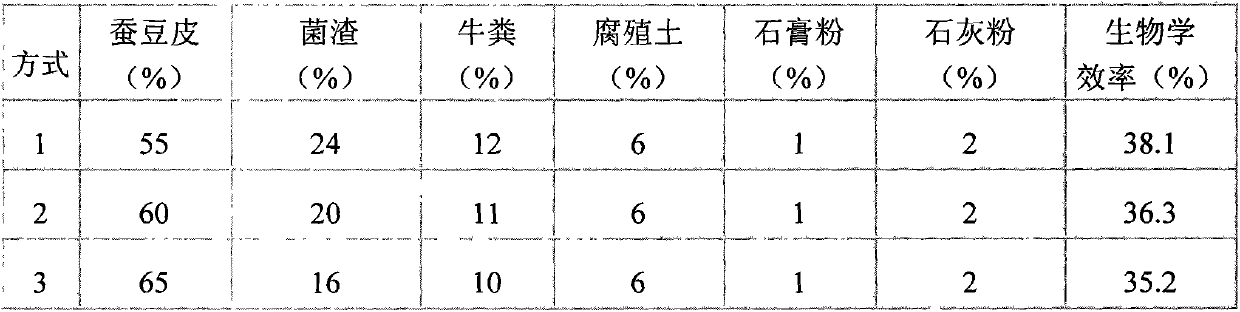

Medicine compatibility and manufacturing method of straw mushroom cultivation material

InactiveCN103420734AQuick ratioReasonable ratioBio-organic fraction processingOrganic fertiliser preparationBiotechnologyMicroorganism

The invention provides a straw mushroom cultivation material which is characterized in that broad bean skin is used as the main raw material, mushroom dregs, cow dung, humus, land plaster, lime powder and the like are used as auxiliary materials, and the water content of the cultivation material is 63-65%. The invention further provides a manufacturing method of the cultivation material. The cultivation material has the advantages that broad bean skin is processed through microbial fermentation, macromolecule matter is made to be degraded, straw mushroom hypha can conveniently absorb the macromolecule matter, and the hypha absorbs the cultivation material quickly and can grow vigorously; the cultivation material is reasonable in ratio, balanced in nutrition, good in hypha ventilation, strong in water retention and high in straw mushroom yield, and the biology efficiency reaches 35.2-38.1%; high value-added utilization of waste resources is achieved.

Owner:邬金飞

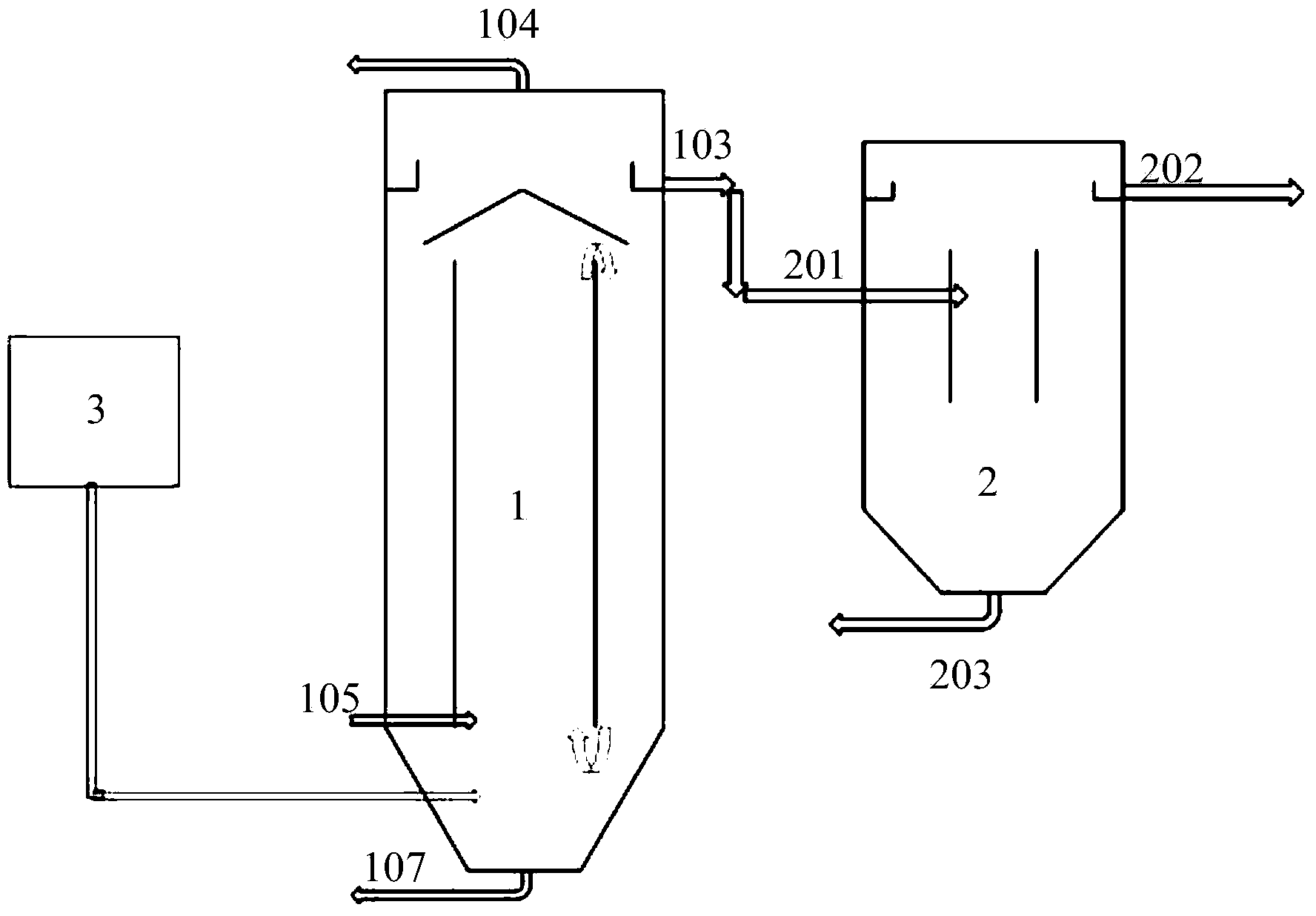

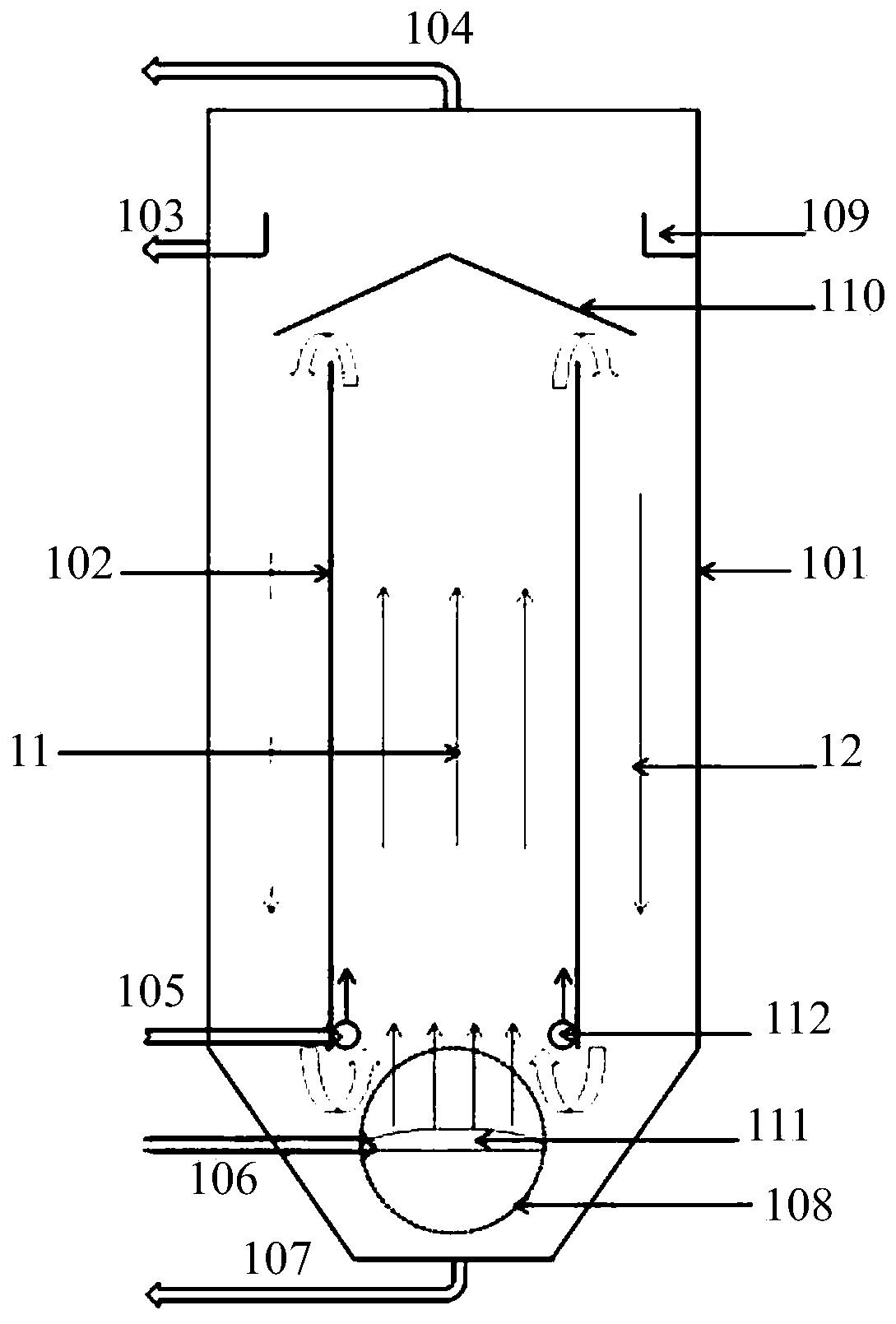

Method and device for treating oil refining salt-containing sewage by using oil refining waste catalyst and ozone

ActiveCN104370358AHigh value-added utilizationIncrease production capacityWater treatment compoundsWater/sewage treatment apparatusChemical oxygen demandPrimary standard

The invention provides a method and device for treating oil refining salt-containing sewage by using an oil refining waste catalyst and ozone. According to the method, the oil refining salt-containing sewage is subjected to catalytic oxidation treatment of internal circulation in a fluidized bed reactor by using ozone-containing gas and an activated oil refining waste catalyst, and the treated sewage flows through a vertical sedimentation basin and then is discharged outwards, wherein the CODcr (chemical oxygen demand) value of the effluent satisfies the primary standard A of Chinese Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB 18918-2002). The device is used for implementing the method, and at least comprises a fluidized bed reactor and a vertical sedimentation basin. According to the method and the device disclosed by the invention, the oil refining waste catalyst is used as a sewage ozone treatment cooperating catalyst, so that a utilization direction of 'waste control by waste' is provided for solid wastes of oil refining plants, and the problem of relatively high cost of a catalyst is solved; and the mass transfer effect among ozone, a catalyst and organic pollutants is strengthened by using a fluidization technology, and the problems that the utilization rate of ozone is relatively low and the catalyst is easy to scale are solved.

Owner:北京中实奥杰石油科技有限公司

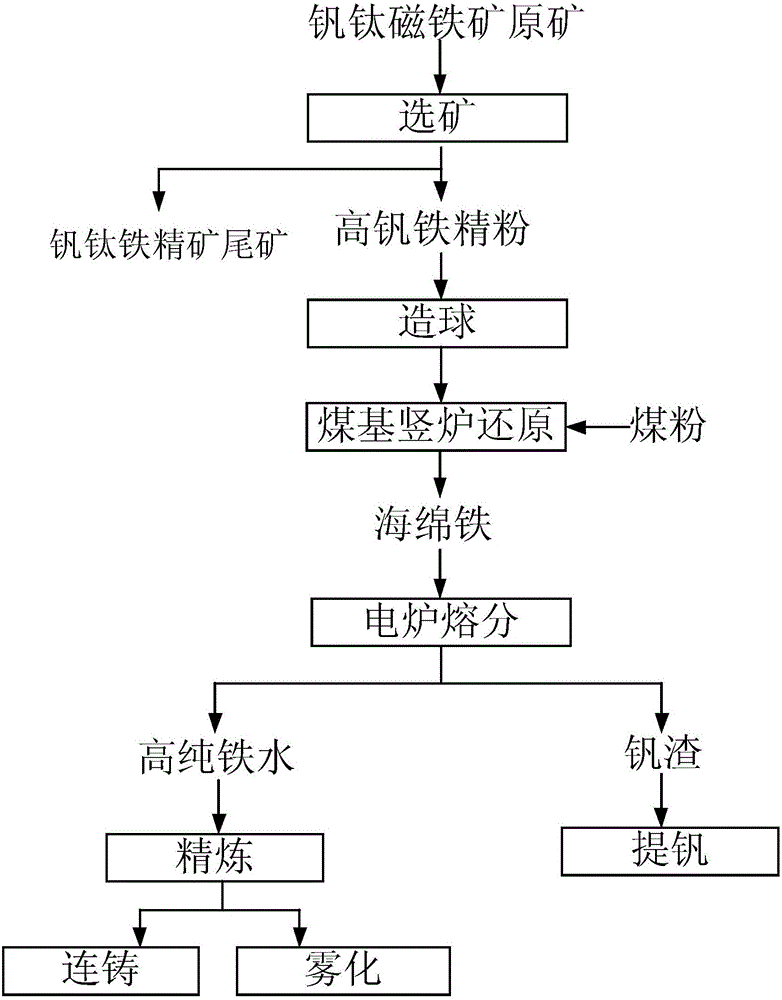

Process for comprehensively utilizing vanadium-titanium magnetite

The invention relates to a process for treating and comprehensively utilizing a vanadium-titanium magnetite. The process is characterized by comprising the following steps: (1) treating a raw vanadium-titanium magnetite by crushing, tailings discarding, fine grinding, low-intensity magnetic separating, high-intensity magnetic separating, and separating by a shaking table, so as to obtain a titanium concentrate and a high-vanadium-ferrum concentrate; (2) adding an adhesive to the high-vanadium-ferrum concentrate; uniformly mixing and pelletizing; drying; uniformly mixing with pulverized coal or coke powder; distributing; performing controlled reduction that V is not reduced through a coal based shaft furnace so as to obtain sponge iron, wherein the amount of used reducing agents such as the pulverized coal is 30 to 70% of the weight of high-vanadium-ferrum concentrate powder, and the reduction is performed for 10 to 18 hours at the temperature of 850 to 1060 DEG C; (3) heating the obtained sponge iron for 0.5 to 1.0 hour at the temperature less than 1050 DEG C through an intermediate frequency / main frequency furnace under a weak reduction atmosphere; then heating until the temperature is more than 1500 DEG C; performing melt separation to enable vanadium to enter slag, thus obtaining high-grade vanadium slag and high-purity molten iron. With the adoption of the process, a plurality of valuable elements in the vanadium-titanium magnetite can be effectively separated and utilized with high additional value.

Owner:WUHAN COSRED SCI & TECH LTD

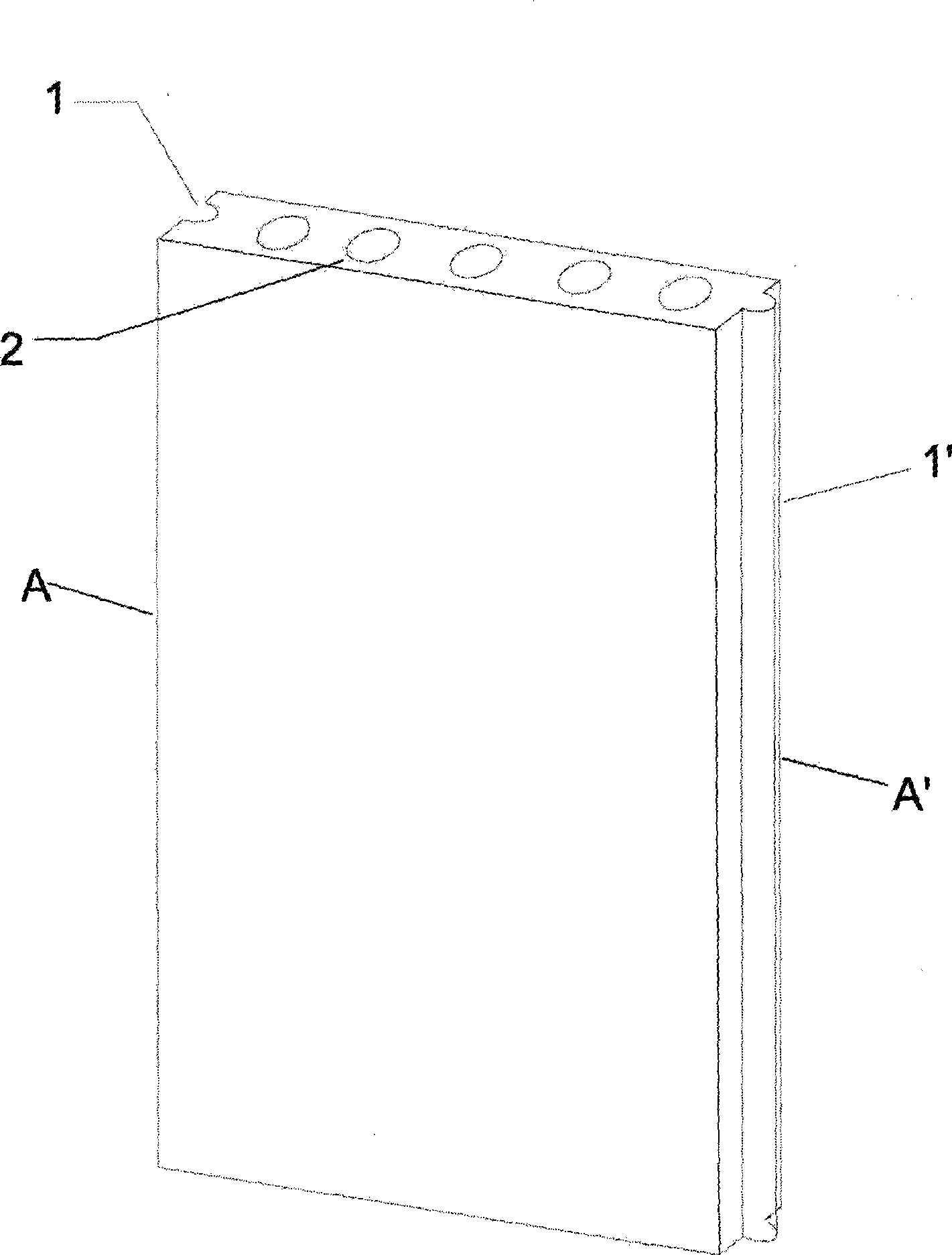

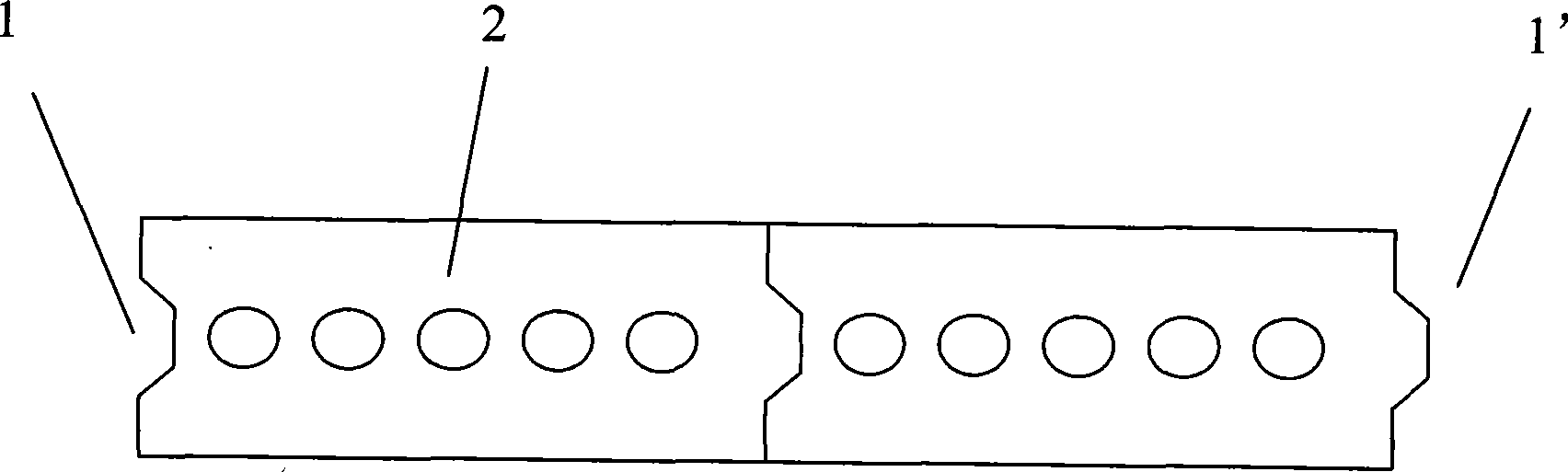

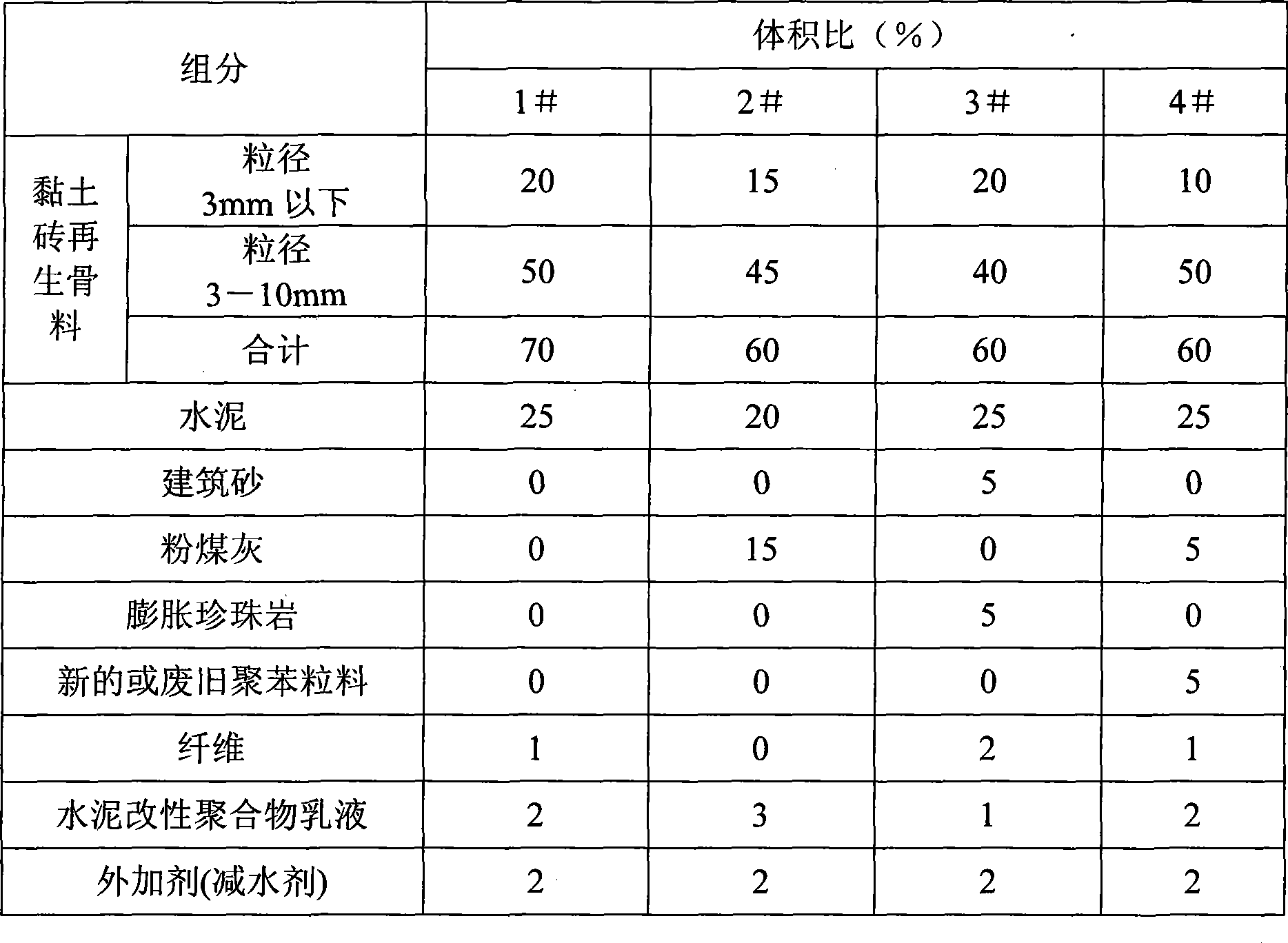

Clay brick recycled aggregate concrete partition slat

InactiveCN101456702AModerate densityHigh strengthSolid waste managementCrazingStructural engineering

The invention discloses a clay brick regenerative aggregate concrete partition lath. The partition lath is manufactured by the following components by volume percentage: 60 to 70 percent of clay brick regenerative aggregate, 20 to 25 percent of cement, 0 to 5 percent of building sand, 0 to 15 percent of coal ash, 0 to 5 percent of expanded perlite, 0 to 5 percent of new or waste polyphenyl granules, 0 to 2 percent of fibers, 1 to 3 percent of cement modified polymer emulsion, and 2 percent of additive. The invention also discloses a method for manufacturing the clay brick regenerative aggregate concrete partition lath. The clay brick regenerative aggregate concrete partition lath has proper density, excellent performances on strength, shrinkage value, sound insulation and the like, is favorable for controlling crack on wall surfaces, has manpower tolerable range on installation construction of the lath, and realizes high added value utilization of building waste.

Owner:上海德滨环保科技有限公司

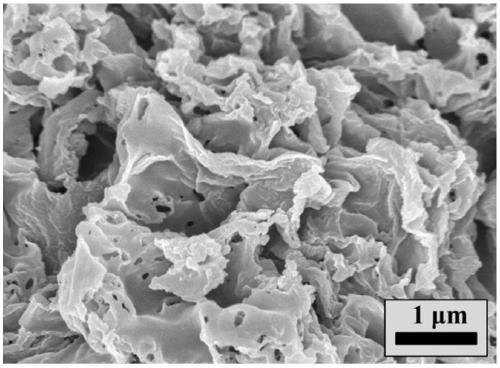

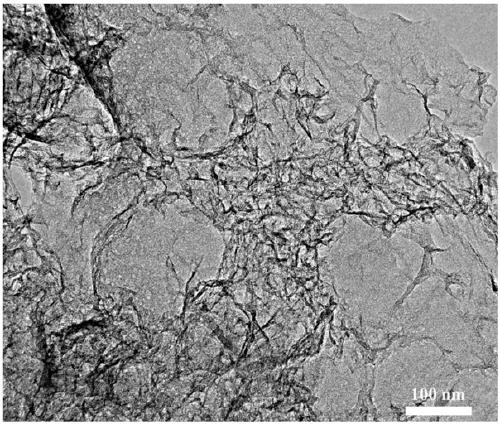

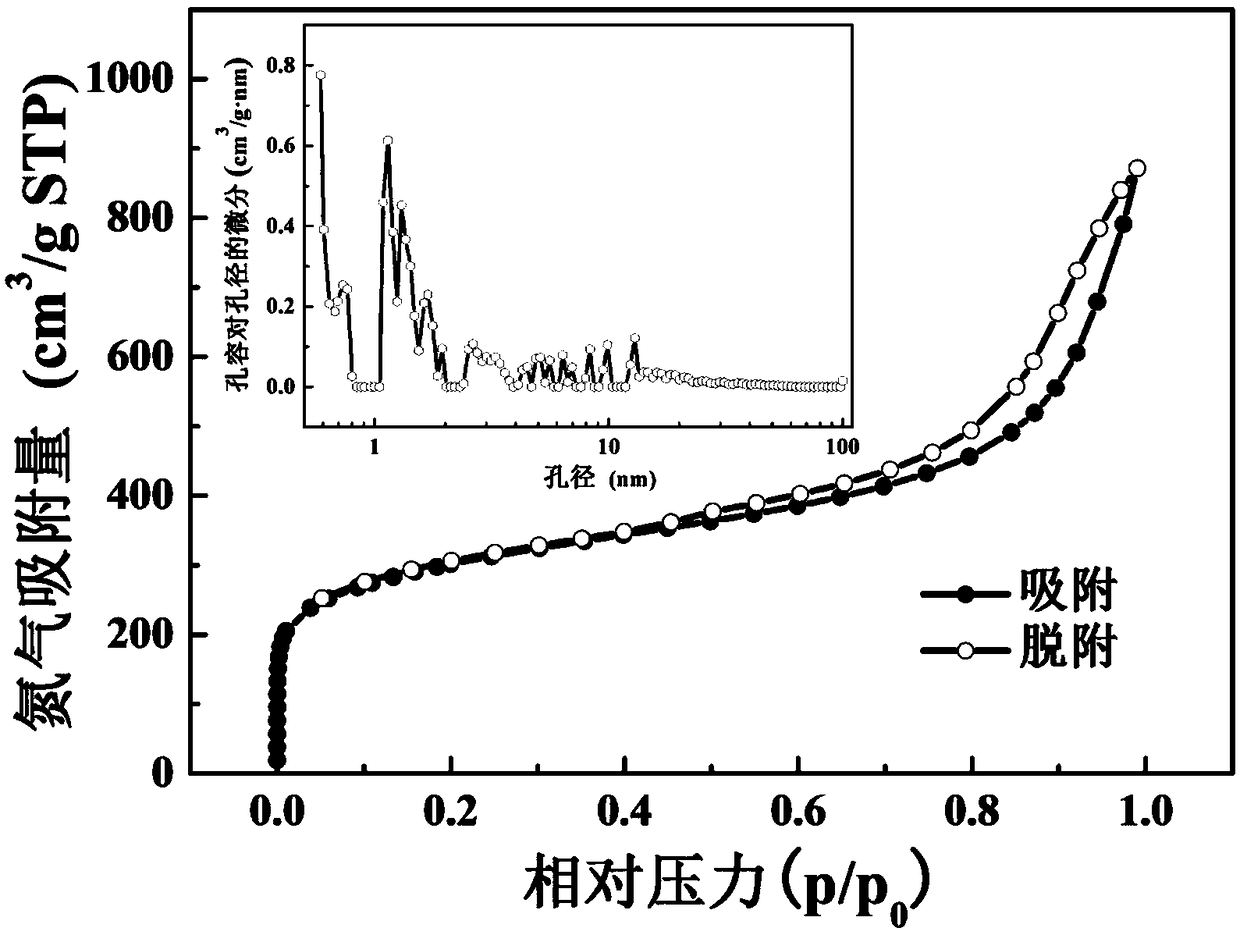

Lignin porous carbon nanosheet as well as preparation method thereof and application in supercapacitor electrode material

ActiveCN109485029ADiffusion fastFast transferHybrid capacitor electrodesNano-carbonPorous carbonSolvent

Owner:SOUTH CHINA UNIV OF TECH

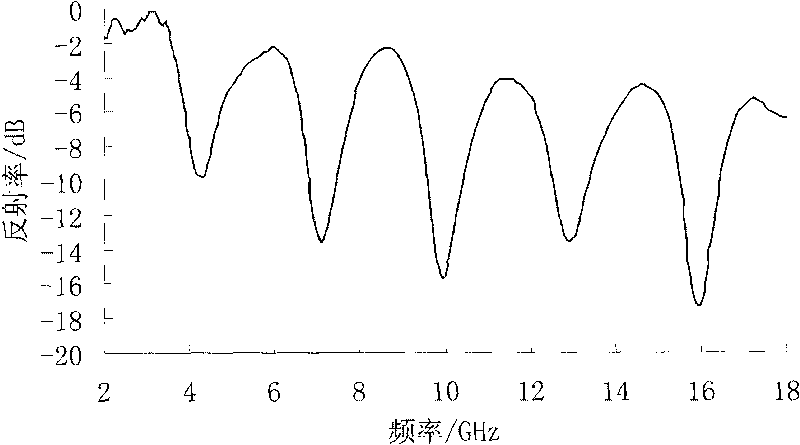

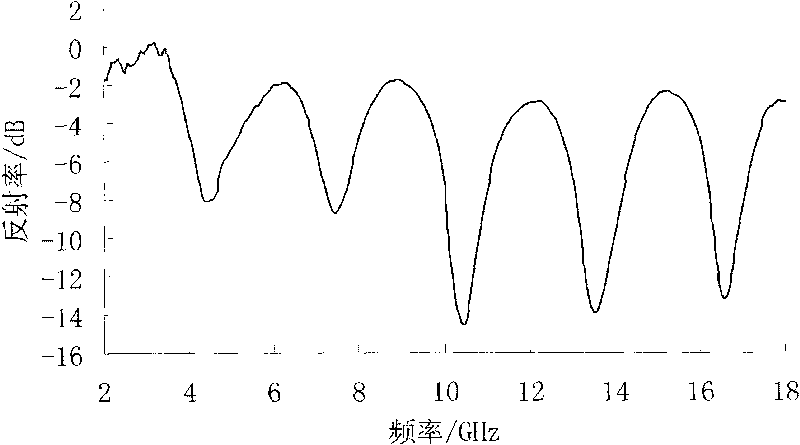

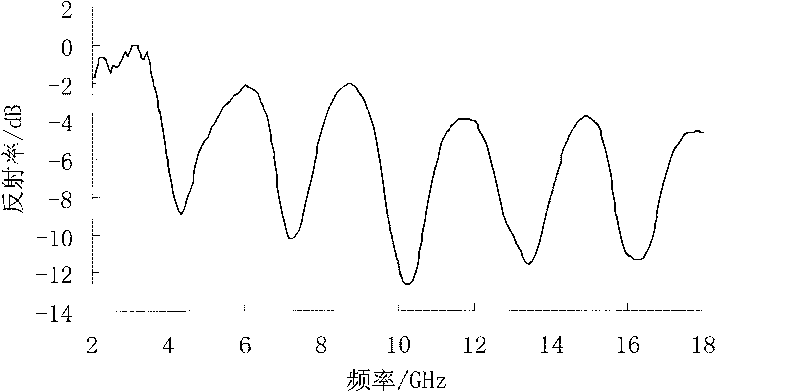

Kieselguhr application in absorbing material preparation, kieselguhr cement-based composite absorbing material and preparation method thereof

InactiveCN101747861AHigh value-added utilizationWide variety of sourcesOther chemical processesCeramic shaping apparatusMaterials preparationMaterials science

The invention discloses a kieselguhr application in electromagnetic wave absorbing material preparation, a low-cost kieselguhr cement-based composite absorbing material and a preparation method thereof. The raw materials of the kieselguhr cement-based composite absorbing material are dry material and water, wherein the dry material is composed of 80-90% cement and 10-20% kieselguhr by weight percent, and the ratio of water to the dry material is 0.30-0.40. The kieselguhr used as absorbing agent has wide material sources and low cost and can realize high value-added utilization of kieselguhr. The kieselguhr can be used as mineral additive of cement concrete material, so that kieselguhr application has no unfavorable influence on the physical mechanics performance of the cement-based material. The preparation method of the kieselguhr cement-based composite absorbing material has the advantages of simple technology, convenient construction, no difference with common cement concrete material, no need of special devices and easy promotion.

Owner:CHONGQING UNIV

Nano channel type natural controlled-release carrier material and preparation method thereof

ActiveCN109966505AAvoid Breakdown and LossGuaranteed long-term effectBiocideOrganic active ingredientsChannel typesFertilizer

The invention relates to a nano channel type natural controlled-release carrier material and a preparation and application methods thereof. Shrimp and crab shells and other products with natural nanochannels are used as the carriers, and the series of functional chemical substance controlled-release carriers with natural nano channels are produced directly or through a coproduction process. Researches discover that the micro-channels with the average pore diameter being about 10 nanometers can effectively store and release various functional substances in a controlled manner, and rich novel carrier product series and flexible combination are provided to satisfy the performance requirements of various controlled-release products. The preparation method is wide in biomass raw material source and cheap, and the produced carriers can satisfy the cost performance requirements of simpleness, high efficiency, greenness and safety. The preparation method can promote the application of controlled-release medicine, pesticides and plant growth regulators and controlled availability fertilizer, the pesticides and fertilizer can be prevented from being decomposed by enzymes or microorganism and from losing by the protection of the nano channels which the microorganisms cannot enter, and a novel efficient, long-acting, safe and cheap animal and plant pesticide and fertilizer system is developed.

Owner:XIAMEN UNIV +2

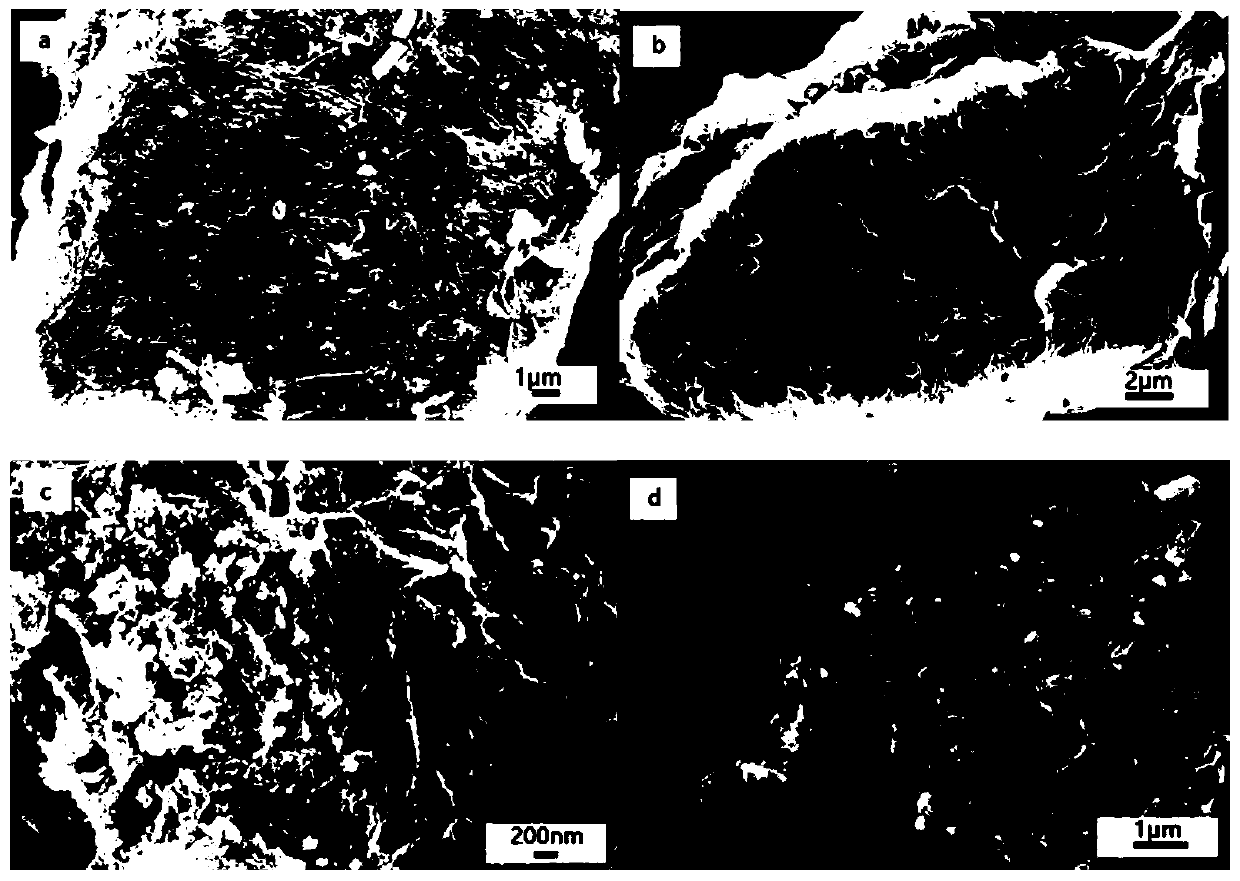

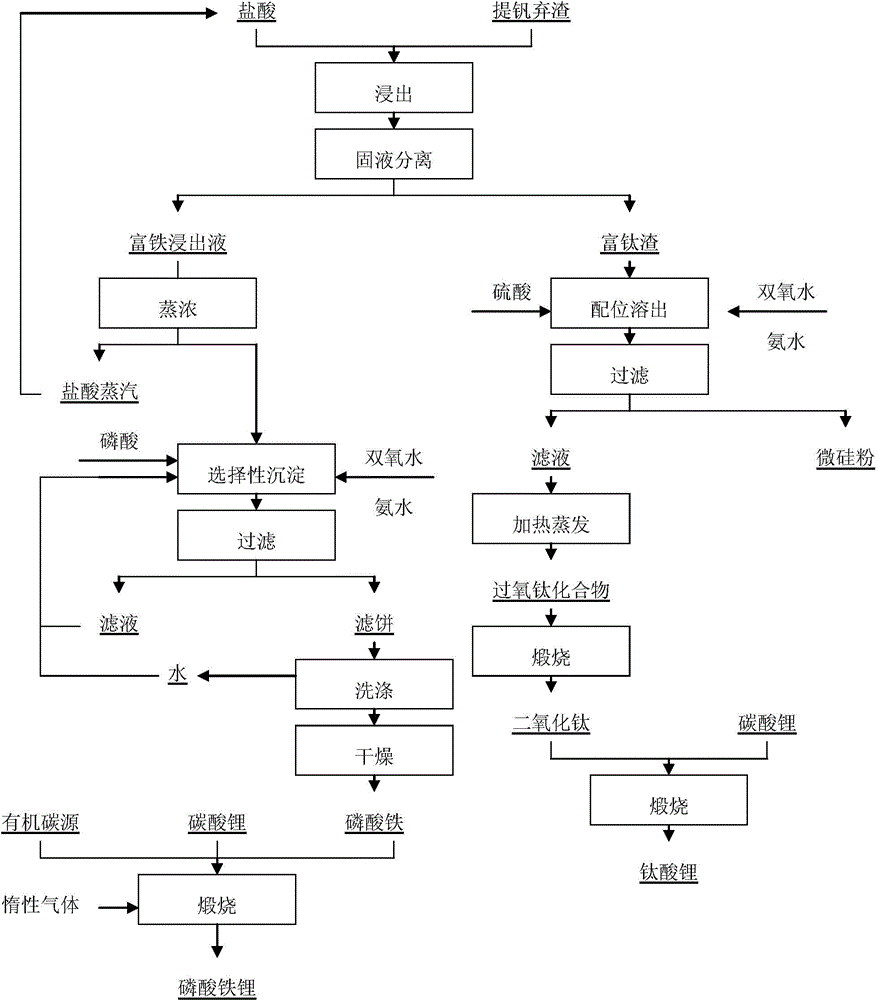

Method for preparing lithium battery electrode materials LiFePO4 and Li4Ti5O12 from vanadium extraction slag

ActiveCN104805299AImprove electrochemical performanceAvoid pollutionTitanium compoundsProcess efficiency improvementSlagPhosphoric acid

The invention discloses a method for preparing lithium battery electrode materials LiFePO4 and Li4Ti5O12 from vanadium extraction slag. The method comprises the following steps: (1), iron and titanium separation: the vanadium extraction slag is leached with hydrochloric acid and filtered to obtain iron-rich leached filtrate and titanium-rich leached residues; (2), preparation of a LiFePO4 precursor: phosphoric acid is added to the iron-rich leached filtrate, H2O2 and ammonia water are added, and the mixture is precipitated, filtered and dried to obtain FePO4 powder; (3) preparation of a LiFePO4 lithium secondary battery cathode material: the FePO4 precursor, Li2CO3 and an organic carbon source are mixed and calcined to obtain LiFePO4 / C; (4) preparation of a Li4Ti5O12 precursor: NH3*H2O is added to the titanium-rich leached residues, the mixture is heated, then H2O2, ammonia water and concentrated H2SO4 are added, and filtrate is subjected to heating reaction and evaporated to dryness to obtain a titanium peroxide compound; (5), preparation of Li4Ti5O12 lithium secondary battery anode material: the titanium peroxide compound is calcined to obtain TiO2, and TiO2 and Li2CO3 are mixed and calcined to obtain Li4Ti5O12. Valuable elements of the vanadium extraction slag are wholly used to acquire a high added-value product, and efficient vanadium extraction slag utilization and environmental protection are realized.

Owner:NORTHEASTERN UNIV LIAONING

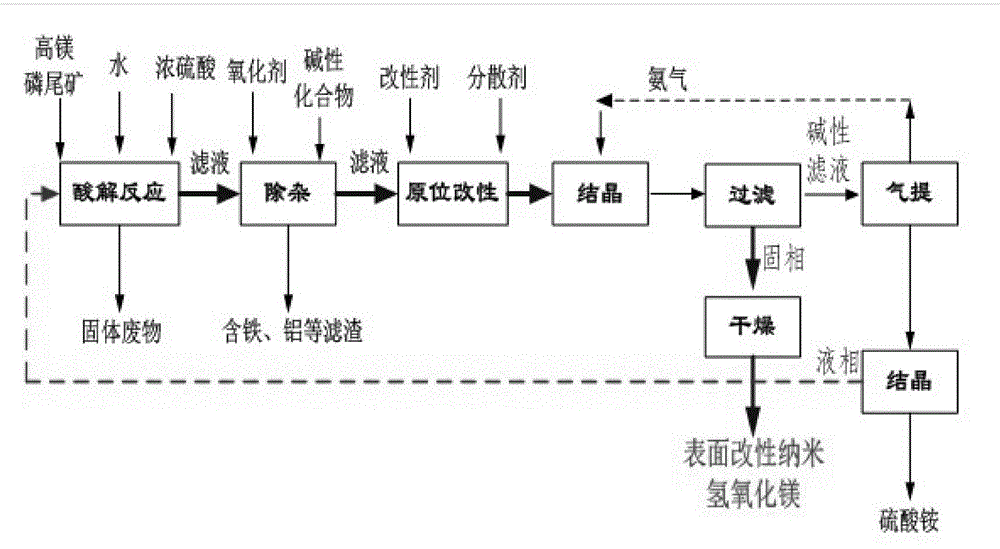

Process for producing in-situ modified nano-magnesium hydroxide by taking phosphate tailings as raw materials

InactiveCN104528778AHigh value-added utilizationKeep shapeMaterial nanotechnologySolid waste disposalFiltrationInterfacial adhesion

The invention discloses a process for producing in-situ modified nano-magnesium hydroxide by taking phosphate tailings as raw materials. The process comprises the following steps: putting the phosphate tailings obtained by flotation into an acidolysis reactor, reacting for a certain period of time, and then filtering; adding filtrate into an impurity removal reactor, firstly adding an oxidant for oxidation, further adding an alkaline compound, controlling the pH value, filtering a precipitate, then adding the filtrate, a silane coupling agent and a dispersant into an in-situ modification reactor, stirring for a period of time, then adding into a crystallization reactor, introducing ammonia gas, and performing crystallization and precipitation reaction to obtain surface-modified nano-magnesium hydroxide; and producing the filtrate which is rich in free ammonia after crystallization and filtration, obtaining the ammonia gas by air stripping, returning the ammonia gas into the crystallization working section, crystallizing a liquid phase to remove a large amount of ammonium sulfate, and then circulating to the acidolysis reaction process step, thereby realizing closed-loop circulation of wastewater of the process. Surface-modified nano-magnesium hydroxide produced by an in-situ modification method has good interfacial adhesion property and dispersivity in a polymer matrix and can be widely applied to the fields of plastics, coatings, environmental friendliness and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

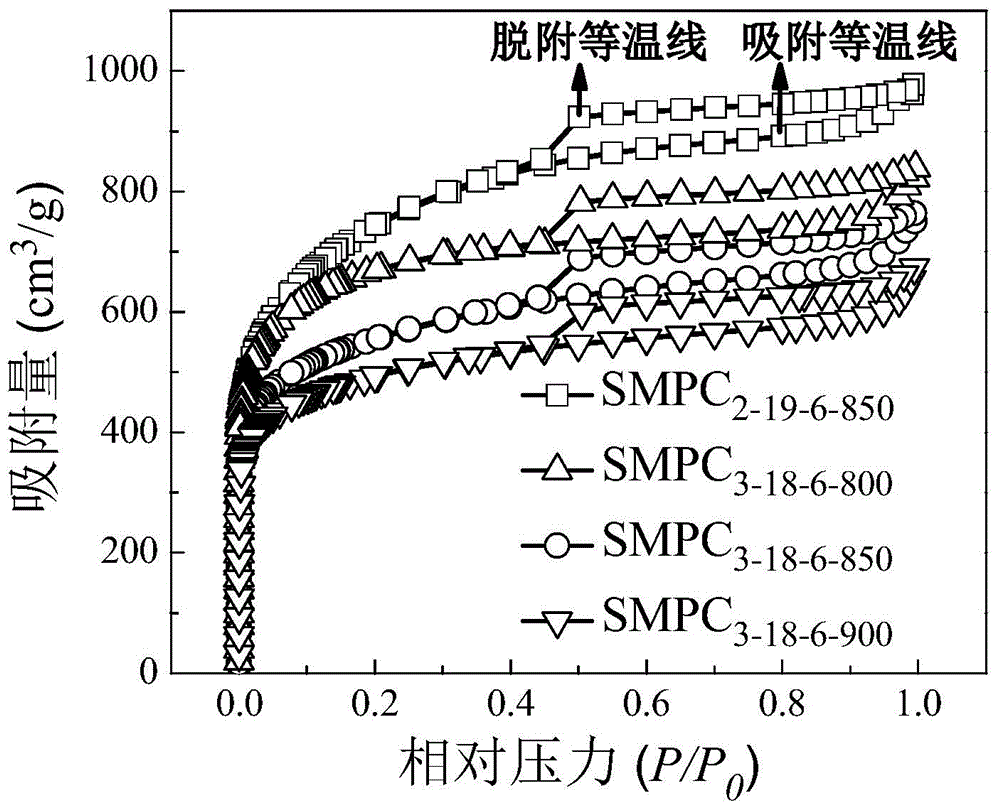

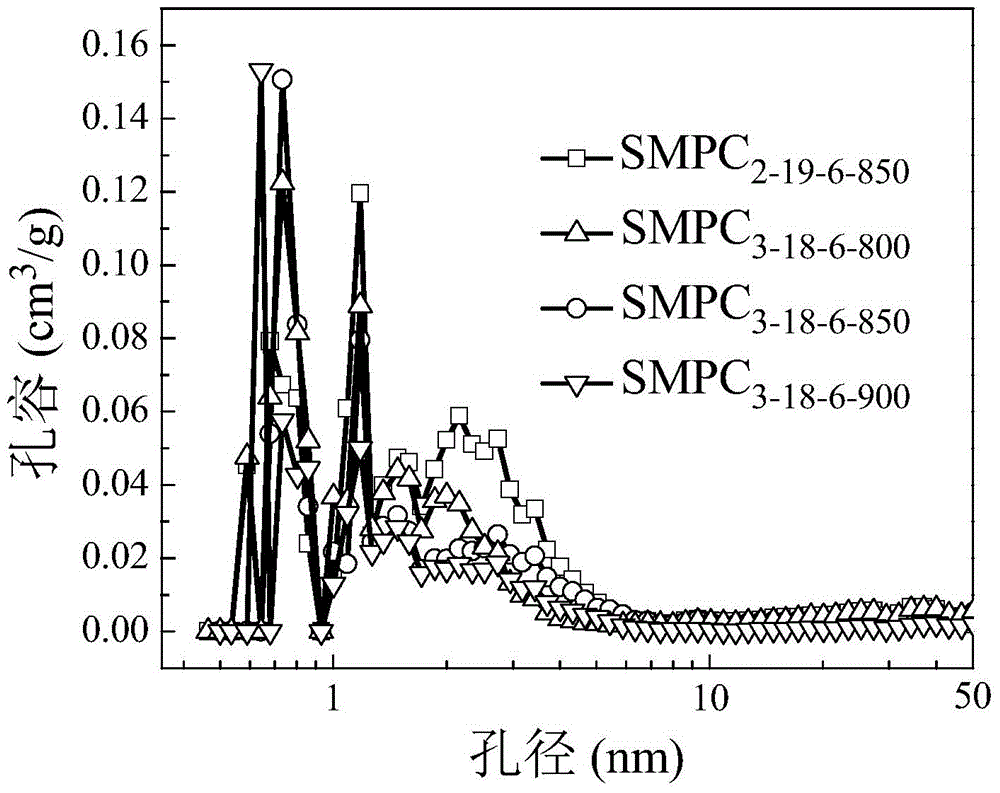

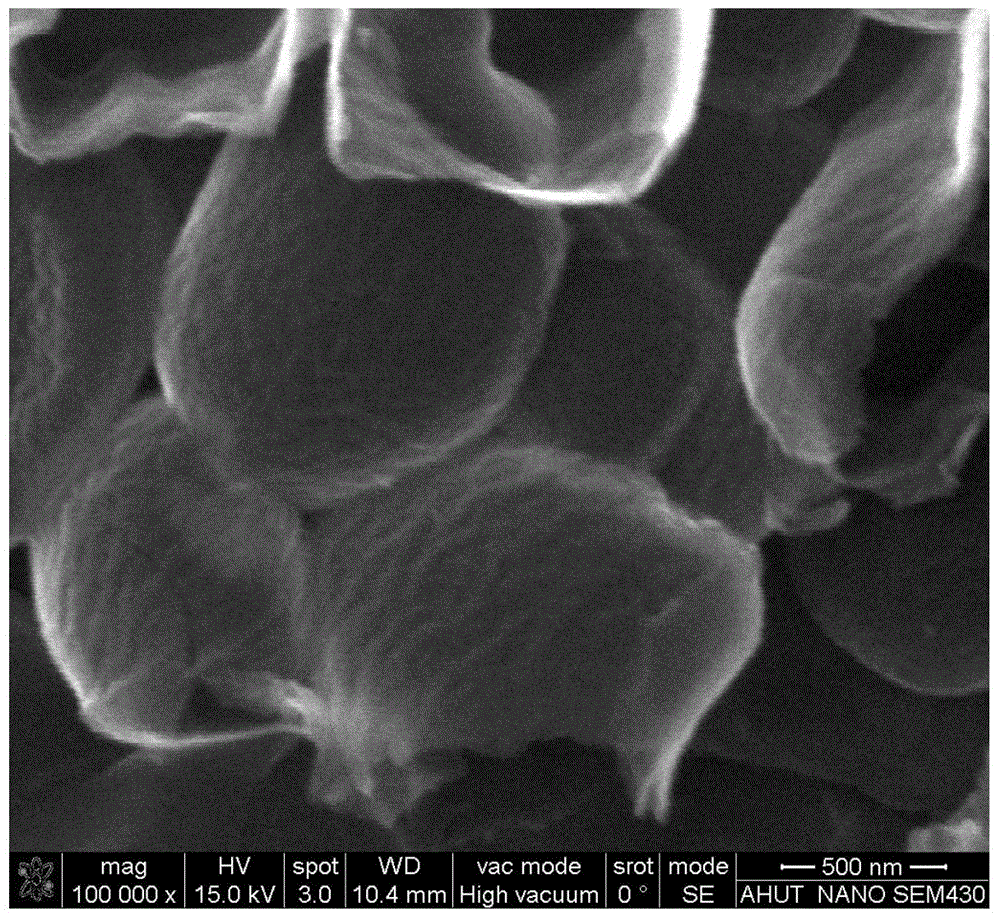

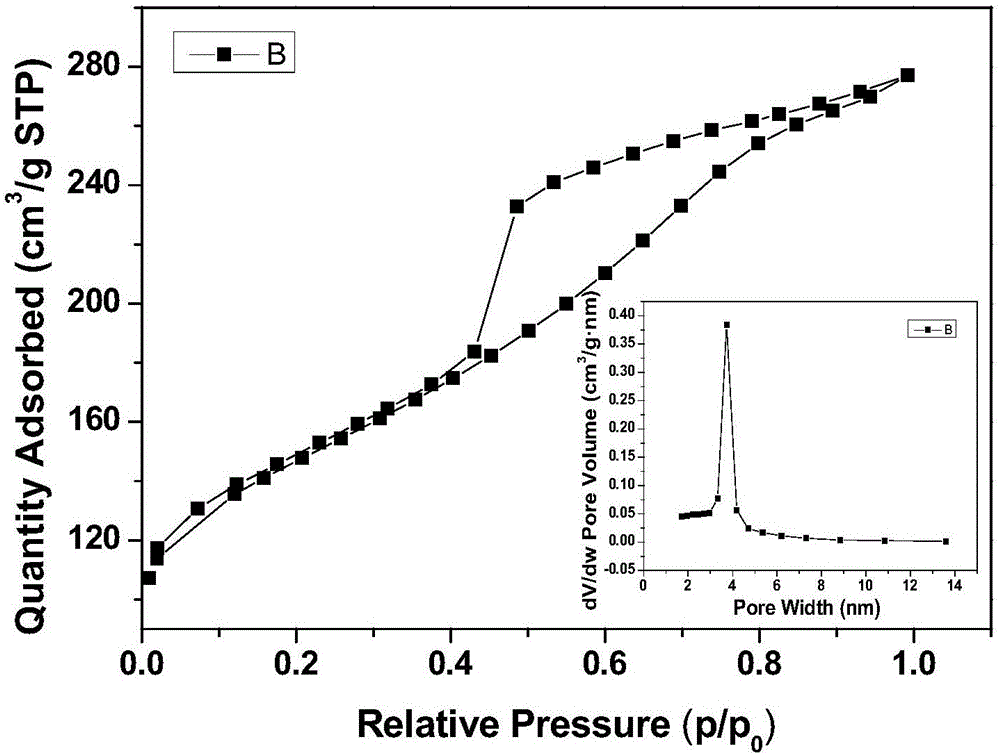

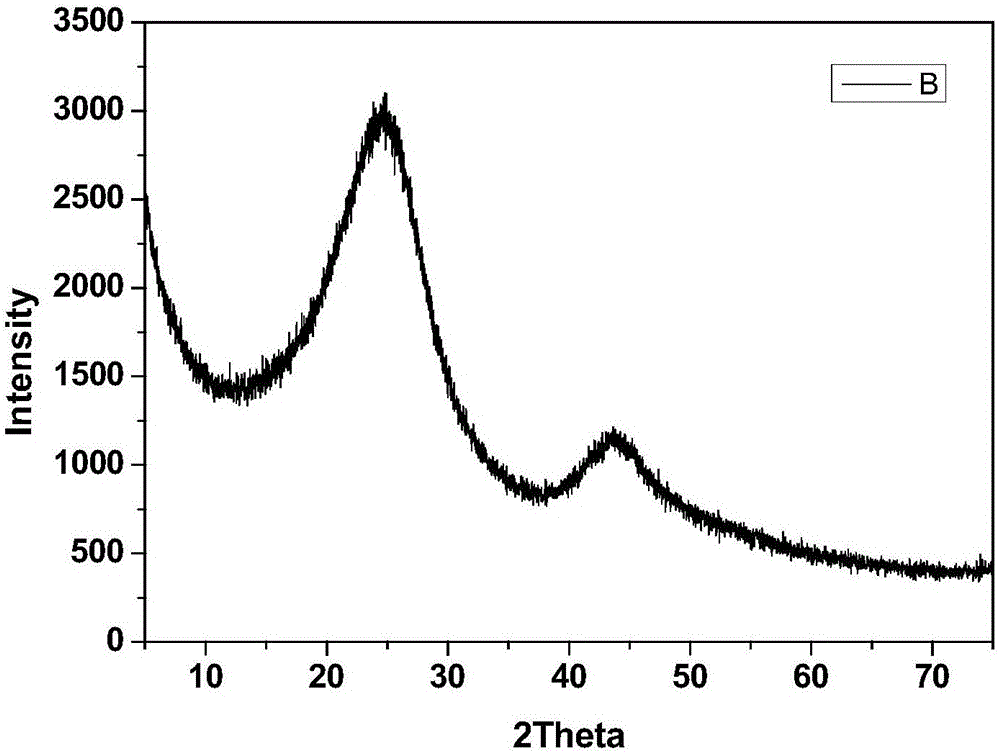

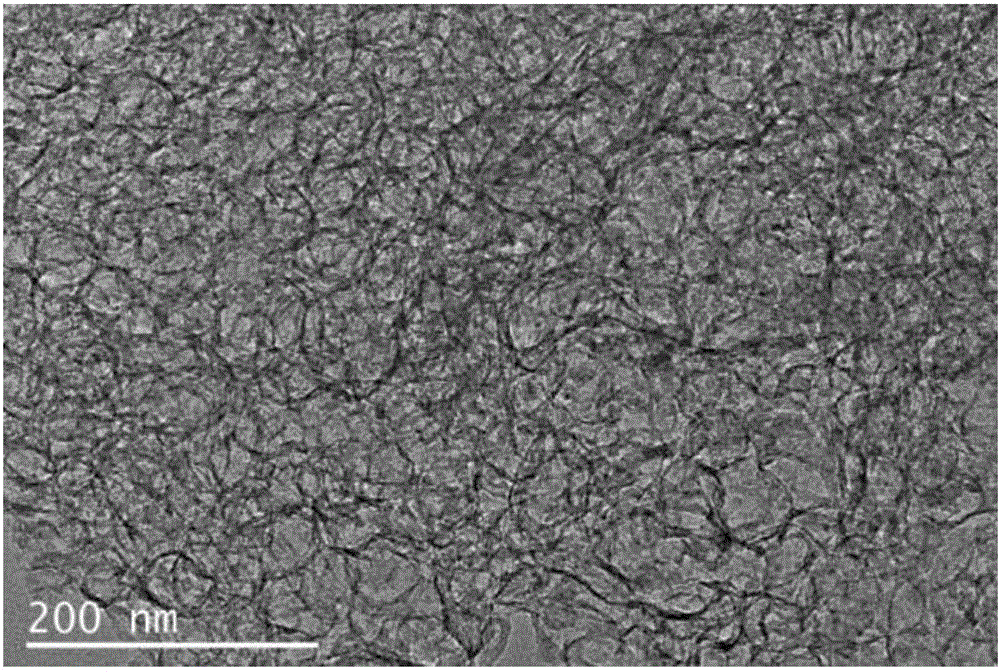

Preparation method of shell-like mesoporous carbon material for super capacitors

InactiveCN104591184AHigh value-added utilizationExcellent rate performanceArgon atmospherePotassium hydroxide

The invention discloses a preparation method of shell-like mesoporous carbon material for super capacitors, belonging to the technical field of carbon material preparation. The method comprises the following steps of: grinding and uniformly mixing petroleum asphalt serving as carbon source, nano zinc oxide serving as a template and potassium hydroxide serving as an activator together and putting the mixture into a porcelain boat, placing the porcelain boat in a tube furnace and heating in an argon atmosphere, thus obtaining the shell-like mesoporous carbon material. The specific area of the shell-like mesoporous carbon material is in a range of 1766-2646m<2> / g, and mean pore size of the shell-like mesoporous carbon material is in a range of 2.05-2.25nm; when used as super capacitor electrode material, in 6mol / L KOH electrolyte, the shell-like mesoporous carbon material has the specific capacity high up to 296F / g under the condition of 0.05A / g current density. In the preparation method provided by the invention, cheap petroleum asphalt is used as carbon source, so that high value-added utilization of petroleum asphalt is realized. The obtained shell-like mesoporous carbon material is used as a super capacitor electrode material, has the advantages of good rate capability, high specific capacity, good cycling stability, and so on.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method for petroleum-coke-based mesoporous carbon and application

ActiveCN106495125AHigh value-added utilizationIncrease the areaCarbon preparation/purificationPetroleumSorbent

The invention relates to the technical field of the nano carbon material, and in particular to a preparation method for petroleum-coke-based mesoporous carbon and an application. The method comprises the following steps: 1) performing concentrated sulfuric acid and concentrated nitric acid oxidation treatments to smashed petroleum coke particles, preparing and obtaining an amphipathicity carbonaceous material; 2) dissolving a templating agent of triblock copolymer in alkaline solution, uniformly stirring, and obtaining settled solution; 3) adding the amphipathicity carbonaceous material obtained in the step 1) into the solution obtained in the step 2), sealing and stirring in the water bath, adding acidic solution, continuously sealing and stirring, finally drying in the water bath, and aging in an oven; and 4) carbonizing solid obtained in the step 3) under the inert atmosphere, grinding, acid-pickling, water-washing, and drying. The method is capable of synthesizing the mesoporous carbon with larger specific surface area and pore volume, and adjustable pore diameter, and realizing the high added-value utilization of the petroleum coke, and can be used as carriers of adsorbents and catalysts of a macromolecular pollutant and electrode materials of a super capacitor.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

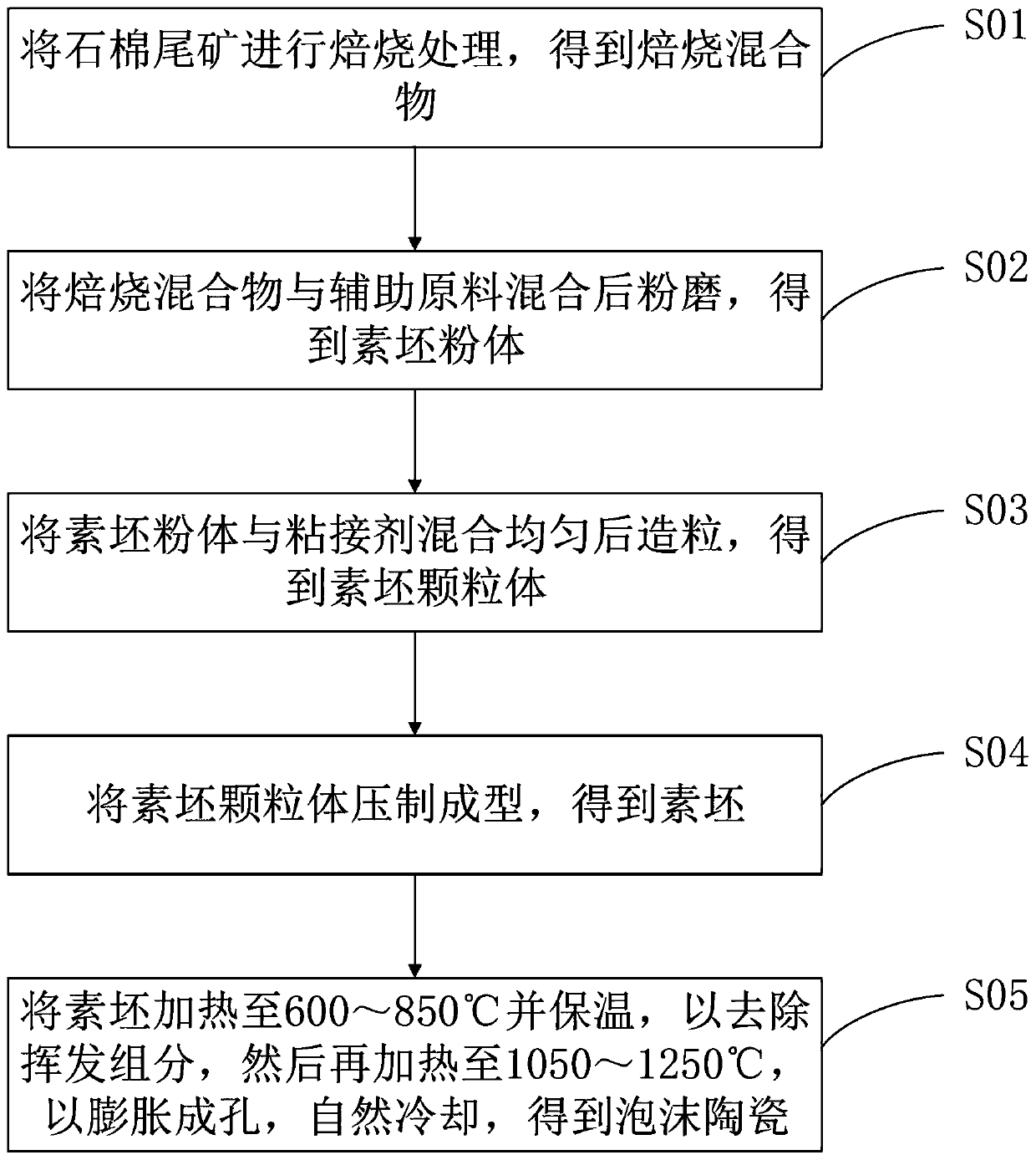

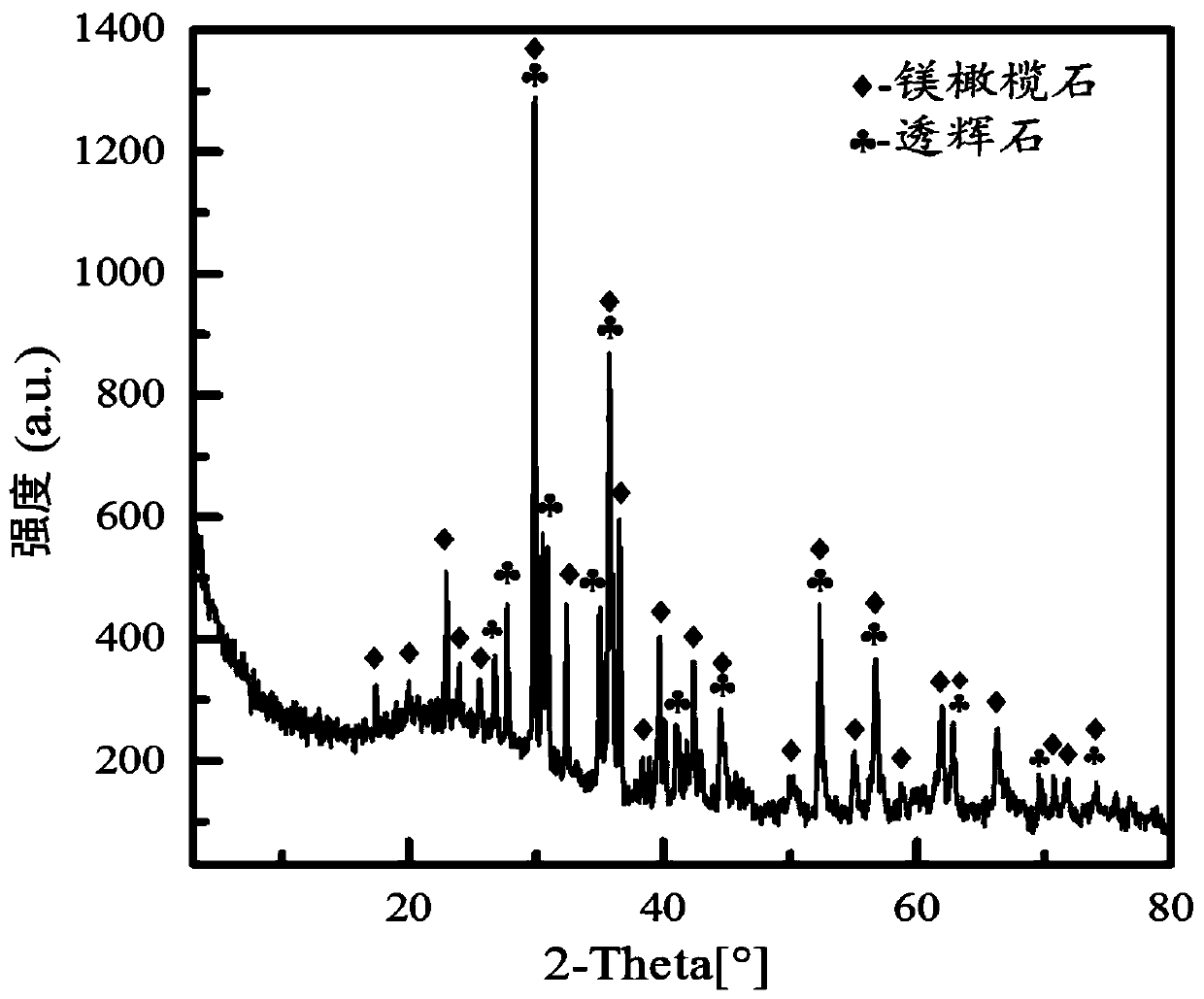

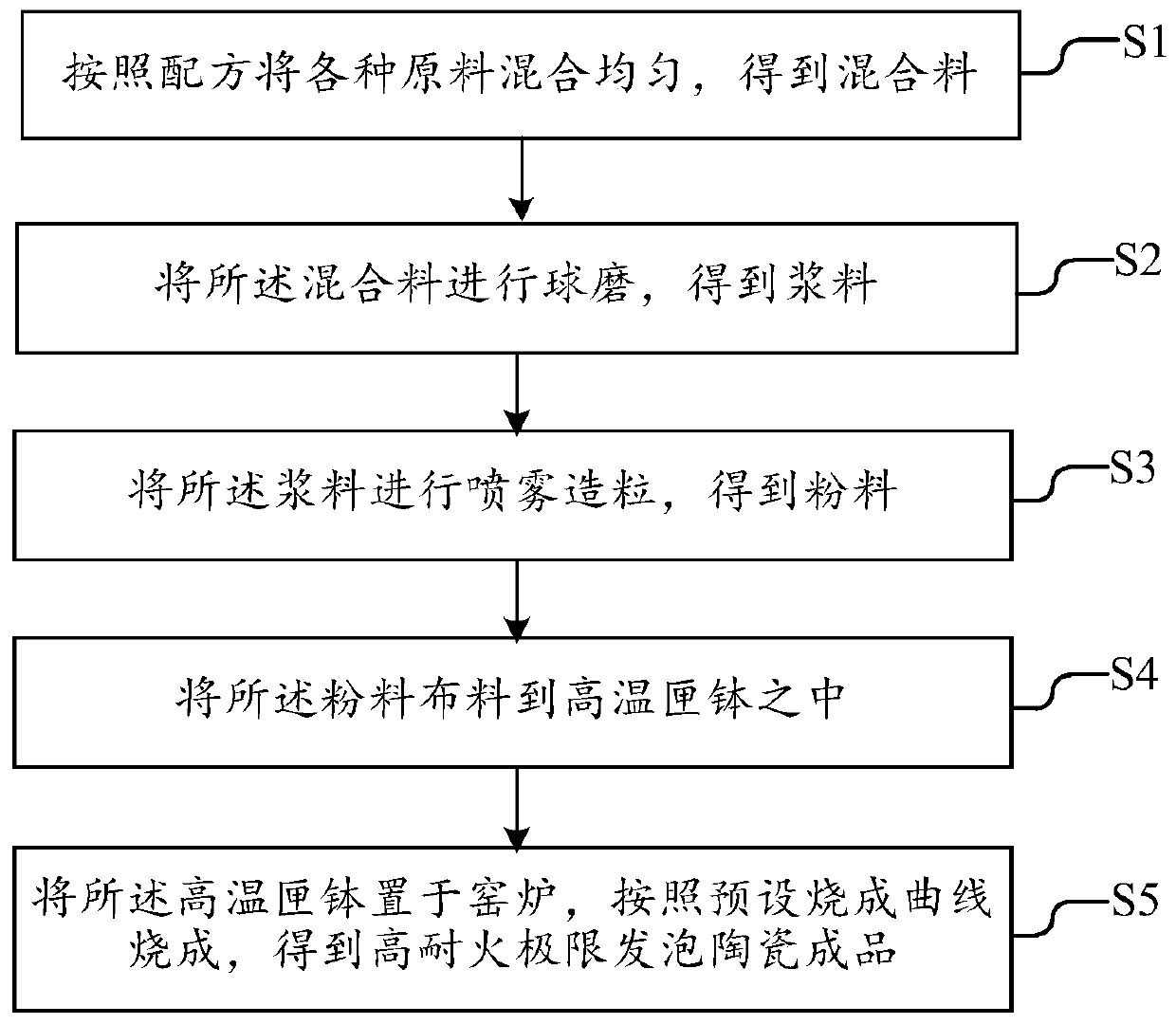

Method for preparing CaO-MgO-SiO2 series foamed ceramic by utilizing asbestos tailings

ActiveCN110713377ALow costImprove performanceCeramic materials productionCeramicwareCarboxymethyl celluloseCellulose

The invention provides a method for preparing CaO-MgO-SiO2 series foamed ceramic by utilizing asbestos tailings. The method comprises the following steps: roasting asbestos tailings at the temperatureof 650-950 DEG C to obtain a roasted mixture; mixing and milling the roasted mixture and auxiliary raw materials to obtain biscuit powder; uniformly mixing the biscuit powder with an adhesive, and granulating the mixture to obtain biscuit granules, the adhesive comprising one or a water suspension or a solution of two of starch, polyvinyl alcohol and carboxymethyl cellulose; pressing and moldingthe biscuit granules to obtain a biscuit; and heating the biscuit to 600-850 DEG C, carrying out heat preservation to remove volatile components in the biscuit, then heating the biscuit to 1050-1250 DEG C to enable the biscuit to expand to form pores, and cooling the treated biscuit to obtain the foamed ceramic. The method has the beneficial effects of low-cost, high-utilization-rate and high-additional-value utilization of the tailings and the waste residues.

Owner:SOUTHWEAT UNIV OF SCI & TECH

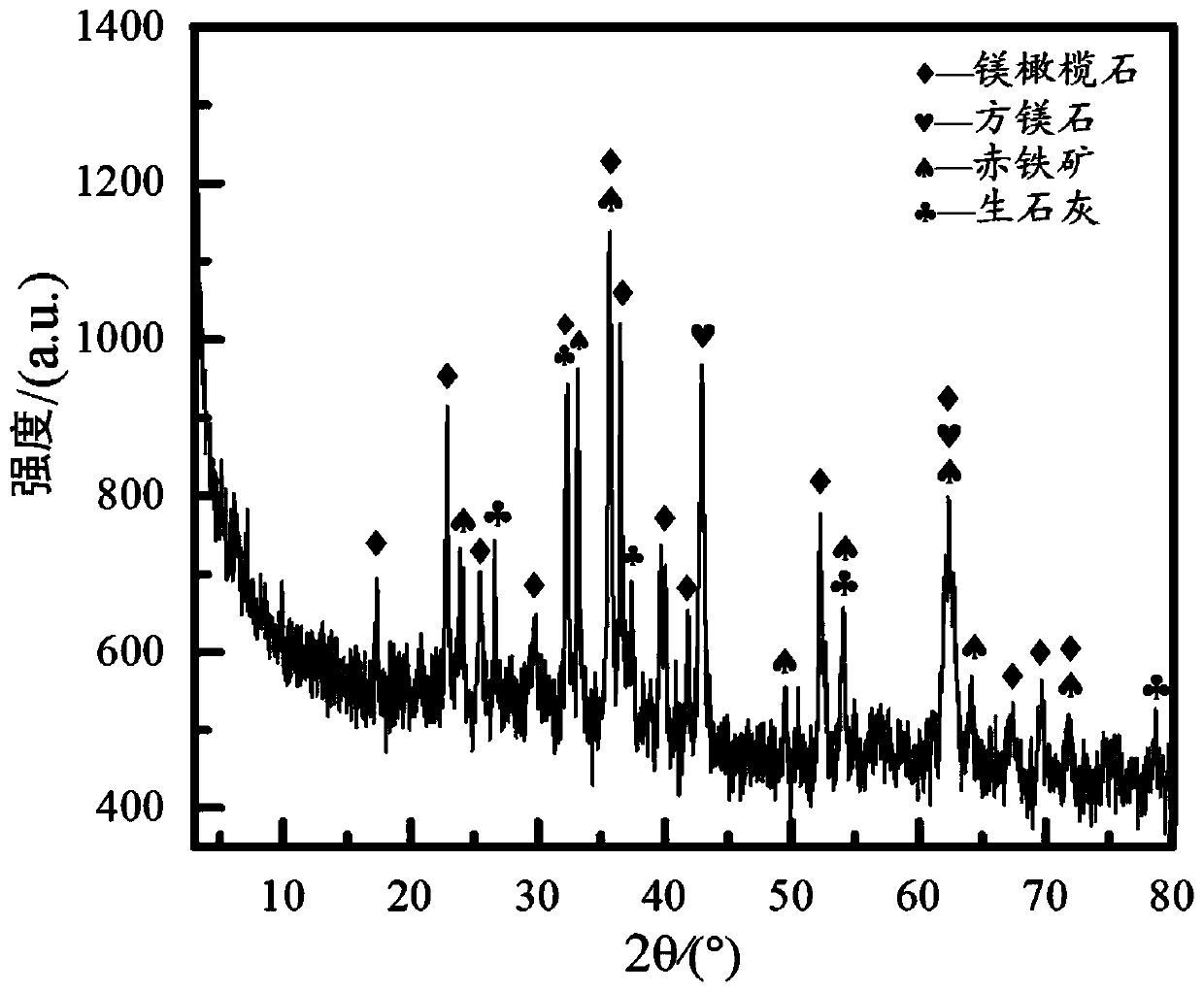

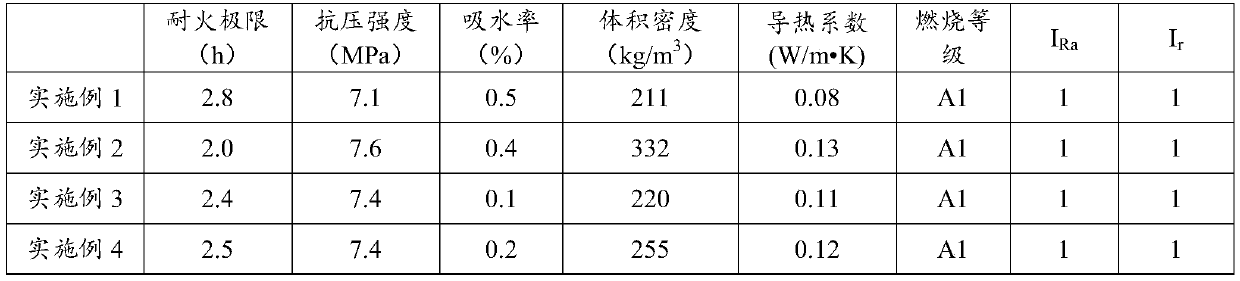

High fire resistance limit foamed ceramic and preparation method thereof

InactiveCN110526681AReduce crystallization tendencySmall coefficient of thermal expansionCeramic materials productionCeramicwareThermal expansionLithium compound

The invention discloses a high fire resistance limit foamed ceramic. The foamed ceramic is mainly prepared by the following raw materials in parts by weight: 90-95 parts of Luoyuan red tailings, 1-5 parts of a lithium compound, 1-3 parts of clay, 0.5-1 part of a foaming agent, and 0.2-1 part of a stabilizer, and the sum of parts by weight of each raw material component is 100 parts, wherein the lithium compound is one or more selected from spodumene, lithium porcelain stone, lithia mica, amblygonite, petalite, lithia mica, and zinnwaldite. The lithium-containing compound is added into the formula, the Li particle has a small radius and large electric field strength, so that the Li particle has the effect of strengthening a network, and thereby a thermal expansion coefficient of the foamedceramic can be reduced, crystallization tendency is reduced, fire resistance of the foamed ceramic can be improved, and application fields of the foamed ceramic is broadened.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Preparation method of shell nacreous layer laminated materials applied to marine heavy-duty coating instead of glass flakes

InactiveCN103571246AMild operating conditionsExtensive sources of raw materialsAntifouling/underwater paintsPaints with biocidesComposite materialPotassium hydroxide

The invention discloses a preparation method of shell nacreous layer laminated materials applied to a marine heavy-duty coating instead of glass flakes. The preparation method comprises the following steps: washing shells to remove residues, soaking the shells in a sodium hydroxide solution, a potassium hydroxide solution or a dilute sodium hypochlorite solution and washing the shells to remove stratum corneum; soaking the samples without the stratum corneum in a sodium hydroxide solution or a potassium hydroxide solution and washing the samples to remove prismatic layers, thus obtaining nacreous layers of the shells; mixing the ground nacreous layers of the shells with water and grinding aids and stirring the mixture at high speed to prepare pulp; grinding the pulp in a grinding and stripping barrel and then performing dehydration, washing and re-dehydration to obtain filter cakes; adding water to the washed filter cakes to prepare pulp and adding surfactants in the stirring process; drying surface modified shell nacreous layer laminated materials and then breaking the dried surface modified shell nacreous layer laminated materials apart, thus obtaining the finished products. The shell nacreous layer laminated materials have natural oleophylic hydrophobicity and excellent mechanical properties, can be uniformly distributed in matrix resin of the heavy-duty coating and have good compatibility with the matrix resins.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

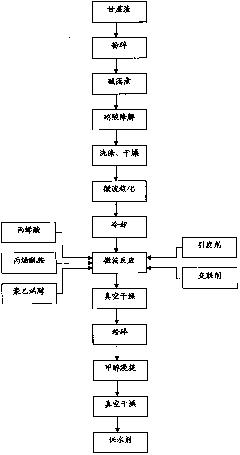

Method for preparing water retention agent from bagasse

InactiveCN102190762AReduce manufacturing costHigh value-added utilizationChemical industryVacuum dryingMicrowave irradiation

The invention relates to a method for preparing a water retention agent from bagasse under microwave conditions. The invention develops a method for synthesizing a water retention agent by using bagasse as the raw material and adopting microwave radiation technology. The method comprises the following steps: pulverizing bagasse, screening, boiling with alkali, degrading with nitric acid, washing, drying, gelatinizing with microwaves, adding acrylic acid, initiator, crosslinking agent, acrylamide and polyvinyl alcohol, and reacting in a microwave oven under certain conditions; and carrying out vacuum drying on the crude product, pulverizing, leaching with leaching, and carrying out vacuum drying to obtain the water retention agent. The invention is simple to operate, has the characteristics of high efficiency and energy saving, can lower the production cost of the water retention agent, and implements utilization of renewable resources at high added value; and the prepared water retention agent is easily degradable, and can not easily become moldy.

Owner:MASTERFUL +1

Method for purifying phosphine by-product and application method of phosphine by-product

ActiveCN101638224AHigh value-added utilizationReduce manufacturing costDispersed particle separationLiquid/solution decomposition chemical coatingAqueous sodium hydroxideGas passing

The invention relates to a method for purifying a phosphine by-product in a process of producing sodium hypophosphite, and a method for synthesizing trialkyl phosphine by using the phosphine by-product. The method for purifying the phosphine by-product comprises the following steps that: 1) phosphine tail gas produced in a sodium hypophosphite reactor is drawn out from a tail gas exhaust port at the upper end of the reactor, and then naturally passes through a water seal tank by means of the pressure produced by a water seal in the water seal tank; 2) the gas passing through the water seal tank enters a water seal purifier filled with sodium hydroxide aqueous solution for purification; and 3) the phosphine gas purified by the purifier enters a gas-water separator to carry out gas-water separation so as to obtain a dried gas. The method provided by the invention realizes high added value utilization of the phosphine by-product, and greatly reduces the production cost of the trialkyl phosphine.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of extracting undenatured natural collagen from tanning waste leather offcut

InactiveCN1948412AReduce pollutionHigh value-added utilizationGlue/gelatin preparationChemistryScrap

This invention relates to an extraction method of un-denatued natural collagen from tanning scrap material. The feature is that 100 weight amount splitting glaubered pigskin scrap material is washed with 2-5 amount water for 3-5 times at 30-35DEG C and is soaked with 5-15 amount for 3-6 hours. After repeating twice, filtering, and then treating it with 10-50 amount organic solvent for 12-24 hours, and then filtering for sediment. Or 100 weight amount splitting limed buffalo-hide scrap material is swelled for 24-48 hours with pH adjusted to 8-12, and bleached with H2O2 with pH=8-12 and concentration 15-60g / L, and then Decalcified, washed, filtered for sediment. Either above-mentioned 100 amounts of sediment is added into protease 0.5-6 amount and adjusted with acid to pH=2-4, and stirred for 1-3 days at 4-6DEG C, and then collagen solution is obtained by centrifugal separation, and then salting out is conducted with 0.5-3MNaC. The sediment is treated with 0.05-2M acid for twice after centrifugal separation, at last, 5-8% un-denatued pigskin or buffalo-hide collagen protein liquid is produced by membrane dialysis.

Owner:柳州市宏升胶原蛋白肠衣有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com