Method and equipment for producing organic liquid fertilizer with biogas slurry

A technology for organic liquid fertilizer and biogas slurry, which is applied in the treatment and application of organic fertilizers and bio-organic parts, can solve the problems of low content of active components in biogas slurry, ineffective utilization of biogas slurry, and high cost of long-distance transportation. The effect of distance transportation and sales, realizing high value-added utilization, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

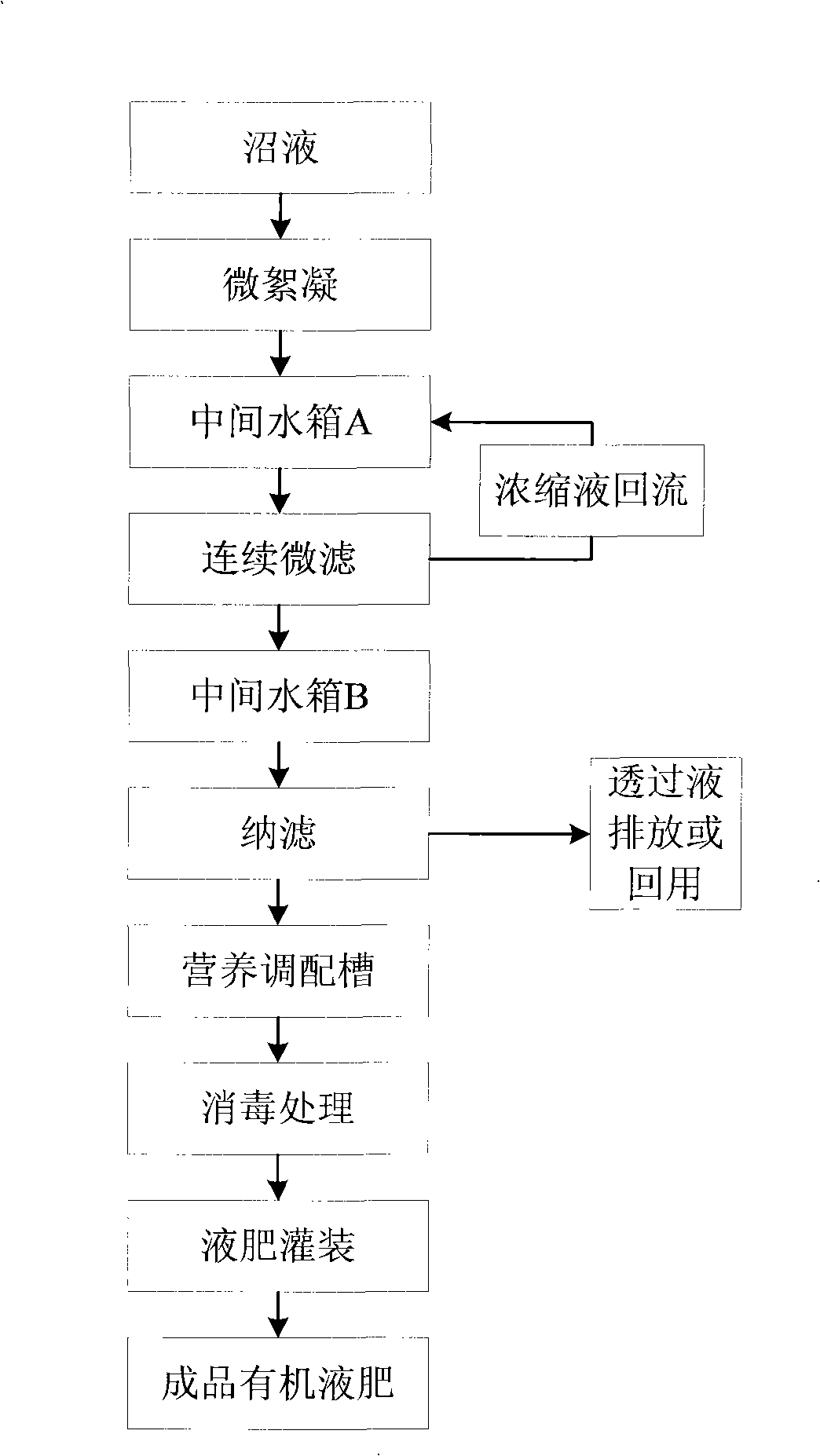

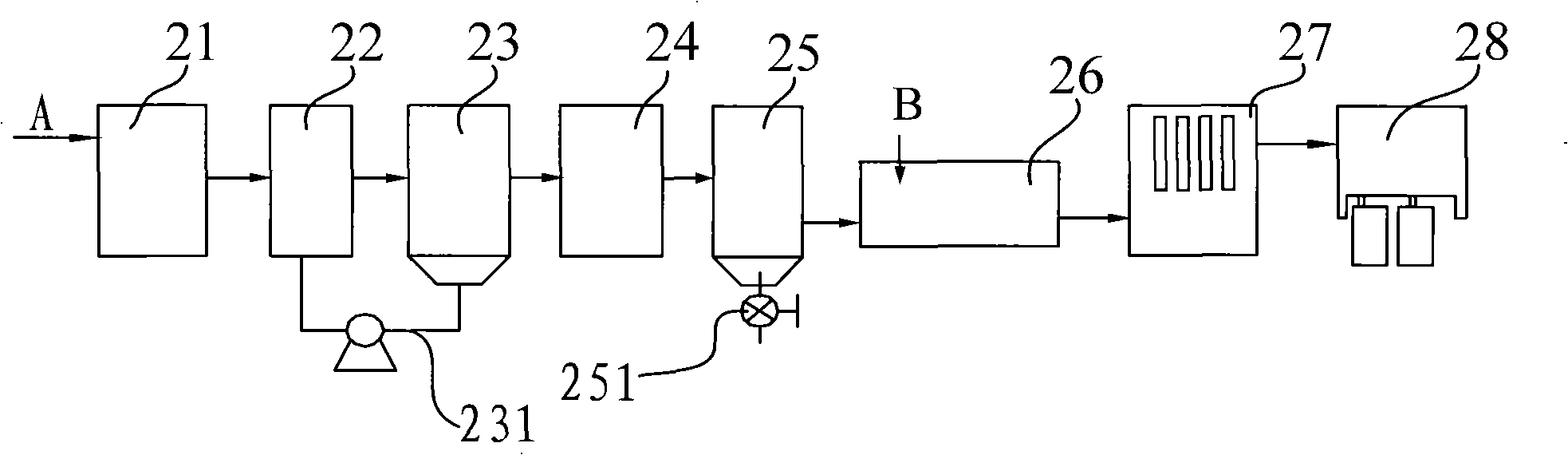

[0030] This example provides a method for preparing organic liquid fertilizer from biogas slurry, which mainly uses membrane separation technology to filter and concentrate biogas slurry to prepare high-efficiency organic liquid fertilizer. The process of this method is as follows figure 1 shown, including:

[0031] a. Micro-flocculation treatment: adding a coagulant to the biogas slurry for micro-flocculation treatment, so that the particles, colloidal substances and partially dissolved organic matter in the biogas slurry can form tiny flocs, wherein the coagulant is iron salt or Aluminum salt, online dosing, the dosage is 20-60mg / L;

[0032] b. Microfiltration treatment: carry out continuous microfiltration treatment on the biogas slurry after the microflocculation treatment, the permeate of the microfiltration treatment enters the subsequent treatment, and the microfiltration treatment is carried out again after the concentrated solution is refluxed; the microfiltration tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com