Method for preparing water retention agent from bagasse

A technology of bagasse and water-retaining agent, applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of difficult degradation, easy mildew of products, high manufacturing cost of starch-based water-retaining agent, and reduce production The effect of cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

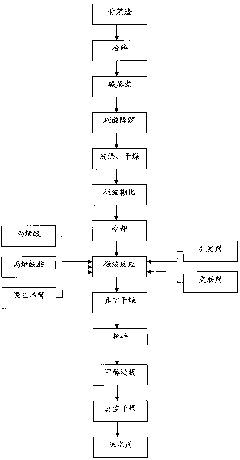

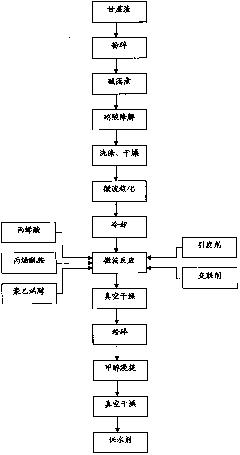

Image

Examples

Embodiment Construction

[0012] The embodiment of the present invention is made by mixing bagasse, acrylic acid, initiator, crosslinking agent, acrylamide, and polyvinyl alcohol, and then chemically synthesizing it under microwave reaction conditions; its percentage by weight is: bagasse 30 %, initiator 8%, acrylic acid 50%, acrylamide 3%, crosslinking agent 0.1%, polyvinyl alcohol 8.9%; among them, the initiator is potassium persulfate, and the crosslinking agent is N, N'-methylenebis Acrylamide. The specific implementation includes the following steps:

[0013] Step 1: Crushing the bagasse to 80-120 meshes, and carrying out alkali cooking at a temperature of 140° C., a pressure of 0.1 MPa, a cooking time of 3 hours, and a mass concentration of alkali of 10%; and then degrading by nitric acid at a temperature of 25 ℃, the pressure is 0.1MPa, the degradation time is 1h, the concentration of nitric acid is 5mol / L, and then washed until neutral, dried and ready for use;

[0014] Step 2, adding the bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com