Preparation method of shell nacreous layer laminated materials applied to marine heavy-duty coating instead of glass flakes

A glass flake and lamellar material technology, applied in antifouling/underwater coatings, biocide-containing paints, etc. High value-added utilization, excellent natural lipophilicity and hydrophobicity, low equipment investment and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The steps of the preparation method of the shell nacre layer material used for marine heavy-duty anti-corrosion coatings instead of glass flakes are as follows:

[0028] 1) After washing the shells with water to remove the residue, soak them in 0.05-0.75 mol / L sodium hydroxide solution, potassium hydroxide solution or dilute sodium hypochlorite solution for 5-120 minutes at 25-100 °C, and then wash to remove the cuticle;

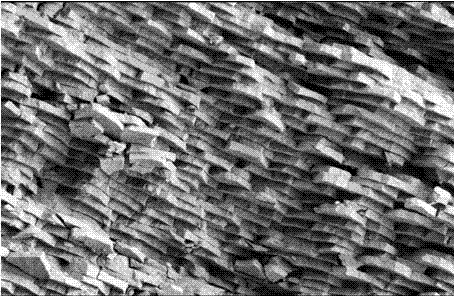

[0029] 2) Soak the cuticle-removed sample in 0.3-5 mol / L sodium hydroxide solution or potassium hydroxide solution for 30-180 minutes at 50-200 °C, wash with water to remove the prism layer, and obtain the shell nacre, and Shell nacre is crushed to 100~400 mesh;

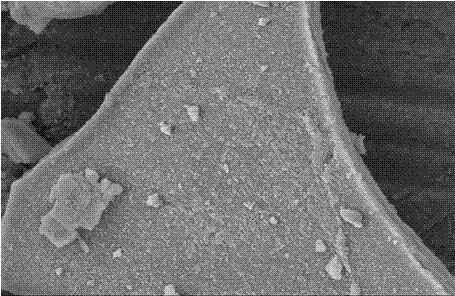

[0030] 3) Mix the pulverized shell nacre with water and a grinding aid, and stir at a high speed to prepare a slurry. The quality of the shell nacre is 10% to 50% of the water mass, and the mass of the grinding aid is 0.25% to 5% of the mass of shell nacre;

[0031] 4) Using zirc...

Embodiment 1

[0040] 1) After washing the mussel shells with water to remove the residue, soak them in 0.75 mol / L sodium hydroxide solution for 120 minutes at 25 °C, and wash with water to remove the cuticle;

[0041] 2) Soak the cuticle-removed sample in 5 mol / L sodium hydroxide solution at 50 °C for 180 minutes, wash with water to remove the prism layer, and obtain the shell nacre, and crush the shell nacre to 100 mesh by conventional crushing methods ;

[0042] 3) Mix the pulverized shell nacre with water and grinding aid, and stir at a high speed to obtain a slurry. The quality of the shell nacre is 10% of the water quality, and the quality of the grinding aid polyacrylic acid is 0.25% of the shell nacre quality. %;

[0043] 4) Using zirconia balls as the grinding and peeling medium, put the grinding and peeling media with particle sizes of 0.5 mm, 1.5 mm, and 2.5 mm into the grinding and peeling barrel according to the mass ratio of 3:2:1. The mass ratio of nacre is 0.5:1, ad...

Embodiment 2

[0047] 1) After washing the abalone shells with water to remove the residues, soak them in 0.05 mol / L sodium hydroxide solution at 100°C for 100 minutes, and wash with water to remove the cuticle;

[0048] 2) Soak the cuticle-removed sample in 0.3 mol / L sodium hydroxide solution at 200 °C for 30 minutes, wash with water to remove the prism layer, and obtain the shell nacre, and crush the shell nacre to 400 mesh by conventional crushing methods ;

[0049] 3) Mix the pulverized shell nacre with water and a grinding aid, and stir at a high speed to obtain a slurry. The quality of the shell nacre is 50% of the water quality, and the quality of the grinding aid sodium silicate is 50% of the quality of the shell nacre. 5%;

[0050] 4) Using alumina balls as the grinding and peeling medium, put the grinding and peeling media with particle sizes of 1 mm, 2 mm, and 3 mm into the grinding and peeling barrel according to the mass ratio of 3:2:1. The mass ratio of nacre is 5:1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com