Preparation method for petroleum-coke-based mesoporous carbon and application

A technology of coke-based mesoporous and petroleum coke, which is applied in the field of preparation of petroleum coke-based mesoporous carbon, can solve the problems of harsh preparation process conditions and relatively expensive prices, and achieve the effect of high value-added utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Add 5g of 80-100mesh petroleum coke into a 500mL three-neck flask, add 30mL of concentrated nitric acid and 70mL of concentrated sulfuric acid, and oxidize at 80°C for 3h to finally obtain an amphiphilic carbonaceous material.

[0031] 2) Dissolve 2.4g of F127 in 20mL of sodium hydroxide solution with a pH of 12, stir well to obtain a clear solution.

[0032] 3) Add 0.6 g of amphiphilic carbonaceous material to the mixture obtained in step 2), seal and stir in a water bath at 75 °C for 1 h, then slowly add 5 mL of 1 mol / L hydrochloric acid solution dropwise, continue to seal and stir for 2 h, and finally Evaporate to dryness in a water bath and age in an oven at 100°C for 24h.

[0033] 4) Put the solid obtained in step 3) into a tube furnace, heat up to 350°C at 1°C / min under nitrogen atmosphere, and stabilize for 0.5h, then raise the temperature to 800°C at 3°C / min, and stabilize for 2h; after grinding Finally, wash with 1 mol / L dilute hydrochloric acid, then wash ...

Embodiment 2

[0035] 1) Add 5g of 80-100mesh petroleum coke into a 500mL three-neck flask, add 30mL of concentrated nitric acid and 70mL of concentrated sulfuric acid, and oxidize at 80°C for 3h to finally obtain an amphiphilic carbonaceous material.

[0036] 2) Dissolve 1.2g of F127 in 20mL of sodium hydroxide solution with a pH of 12, stir well to obtain a clear solution.

[0037] 3) Add 0.6 g of amphiphilic carbonaceous material to the mixture obtained in step 2), seal and stir in a water bath at 75 °C for 1 h, then slowly add 2 mL of 1 mol / L hydrochloric acid solution dropwise, continue to seal and stir for 2 h, and finally Evaporate to dryness in a water bath and age in an oven at 120°C for 24h.

[0038] 4) Put the solid obtained in step 3) into a tube furnace, heat up to 350°C at 1°C / min under nitrogen atmosphere, and stabilize for 0.5h, then raise the temperature to 750°C at 3°C / min, and stabilize for 2h; after grinding Finally, wash with 1.5 mol / L dilute hydrochloric acid, then was...

Embodiment 3

[0040] 1) Add 5g of 80-100mesh petroleum coke into a 500mL three-neck flask, add 30mL of concentrated nitric acid and 70mL of concentrated sulfuric acid, and oxidize at 80°C for 3h to finally obtain an amphiphilic carbonaceous material.

[0041] 2) Dissolve 2.4g of F127 in 20mL of sodium hydroxide solution with a pH of 12, stir well to obtain a clear solution.

[0042] 3) Add 0.6 g of amphiphilic carbonaceous material to the mixture obtained in step 2), and stir in a water bath at 40°C for 1 h, then slowly add 5 mL of 1 mol / L hydrochloric acid solution dropwise, continue to stir for 2 h, and finally Evaporate to dryness in a water bath and age in an oven at 100°C for 48h.

[0043] 4) Put the solid obtained in step 3) into a tube furnace, heat up to 350°C at 1°C / min under a nitrogen atmosphere, and stabilize for 0.5h, then raise the temperature to 900°C at 3°C / min, and stabilize for 1.5h; After grinding, wash with 1 mol / L dilute hydrochloric acid, then wash with deionized wate...

PUM

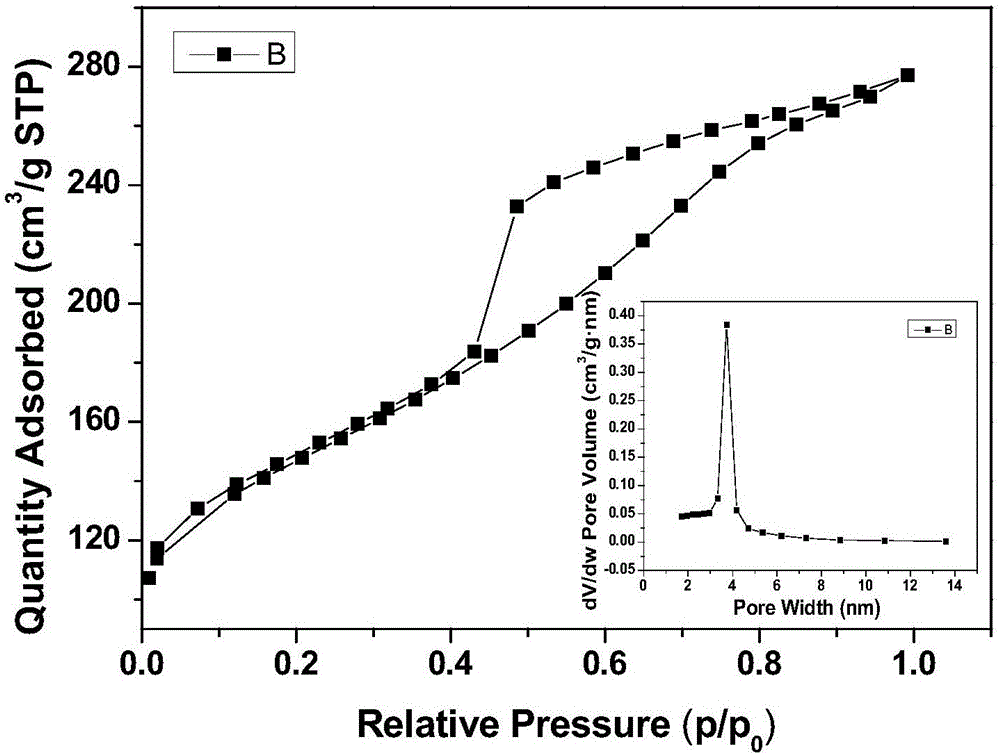

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com