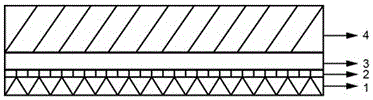

Cement thermal insulation wallboard

A technology for thermal insulation wall panels and thermal insulation panels, which can be applied to household walls, layered products of hydraulically coagulating substances, and solid waste management. Social benefit, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) 20% cement, 50% sand, 1% PVA fiber, 1% wood fiber, 2.5% redispersible latex powder, 3% naphthalene sulfonate formaldehyde condensate, 2% calcium chloride, 1% wood calcium , 19.5% water is mixed according to the proportion of weight percentage, and after stirring evenly, it is made into a decorative layer mortar, which is sprayed into a decorative layer;

[0029] (2) Mix 20% cement, 40% waste fiber-reinforced cement particles, 10% hollow glass microspheres, 10% anti-mud and slump-containing polycarboxylate superplasticizer, 10% cellulose ether, 10% water Mix according to the proportion of weight percentage, stir evenly, prepare the closed layer mortar, and spray it on the decorative layer;

[0030] (3) Place the polystyrene insulation board on the sealing layer to make the insulation layer;

[0031] (4) Mix 20% cement, 47% waste fiber-reinforced cement particles, 3% mud-resistant slump-preserving polycarboxylate-containing superplasticizer, 10% fly ash, and 20% wate...

Embodiment 2

[0034] (1) Mix 55% cement, 34.8% sand, 0.1% polypropylene emulsion, 0.1% potassium carbonate, and 10% water according to the proportion by weight, stir evenly to make a decorative layer mortar, and brush to form a decorative layer;

[0035] (2) Mix 50% cement, 20% waste fiber reinforced cement particles, 5% mineral powder, 3% hollow glass microspheres, 1% adsorption group type polycarboxylate water reducer, 10% cellulose ether, 11% Water is mixed according to the proportion of weight percentage, and after stirring evenly, it is prepared into a closed layer mortar, which is brushed on the decorative layer;

[0036] (3) Put the polyurethane foam insulation board on the sealing layer to make the insulation layer;

[0037] (4) Mix 55% cement, 24% waste fiber-reinforced cement particles, 3% high-branched retarding polycarboxylate superplasticizer, 8% silica fume, and 10% water according to the proportion by weight, and stir evenly to prepare Structural layer mortar, brushed on top...

Embodiment 3

[0040] (1) 48% cement, 15% sand, 0.5% PU fiber, 0.5% pulp fiber, 1% styrene-acrylic emulsion, 2% sulfonated melamine formaldehyde condensate, 1% hydroxyethyl cellulose, 1% sulfate, 1% citric acid and 30% water are mixed according to the proportion by weight, and the decorative layer mortar is made after stirring evenly, and the decorative layer is laid;

[0041] (2) Distribute 30% cement, 50% waste fiber-reinforced cement particles, 1% hollow glass microspheres, 1% high-branched retarding polycarboxylate superplasticizer, 3% cellulose ether, and 15% water by weight Prepare the closed layer mortar after mixing evenly, and lay it on the decorative layer;

[0042] (3) Place the foamed concrete insulation board on the closed layer to make the insulation layer;

[0043] (4) Mix 54% cement, 15% waste fiber-reinforced cement particles, 2% high-branched retarding polycarboxylate superplasticizer, 9% metakaolin, and 20% water according to the proportion by weight, and stir evenly to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com