Board-mixing structure assembly type house and building method thereof

A prefabricated and residential technology, which is applied in the direction of building structure and construction, can solve the problems that do not conform to the development direction of building energy-saving modern houses, the thermal insulation performance can not reach 65% energy saving, and the masonry has poor shear resistance. Achieve the effects of promoting the development of circular economy, reducing construction difficulty and cost, and high earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

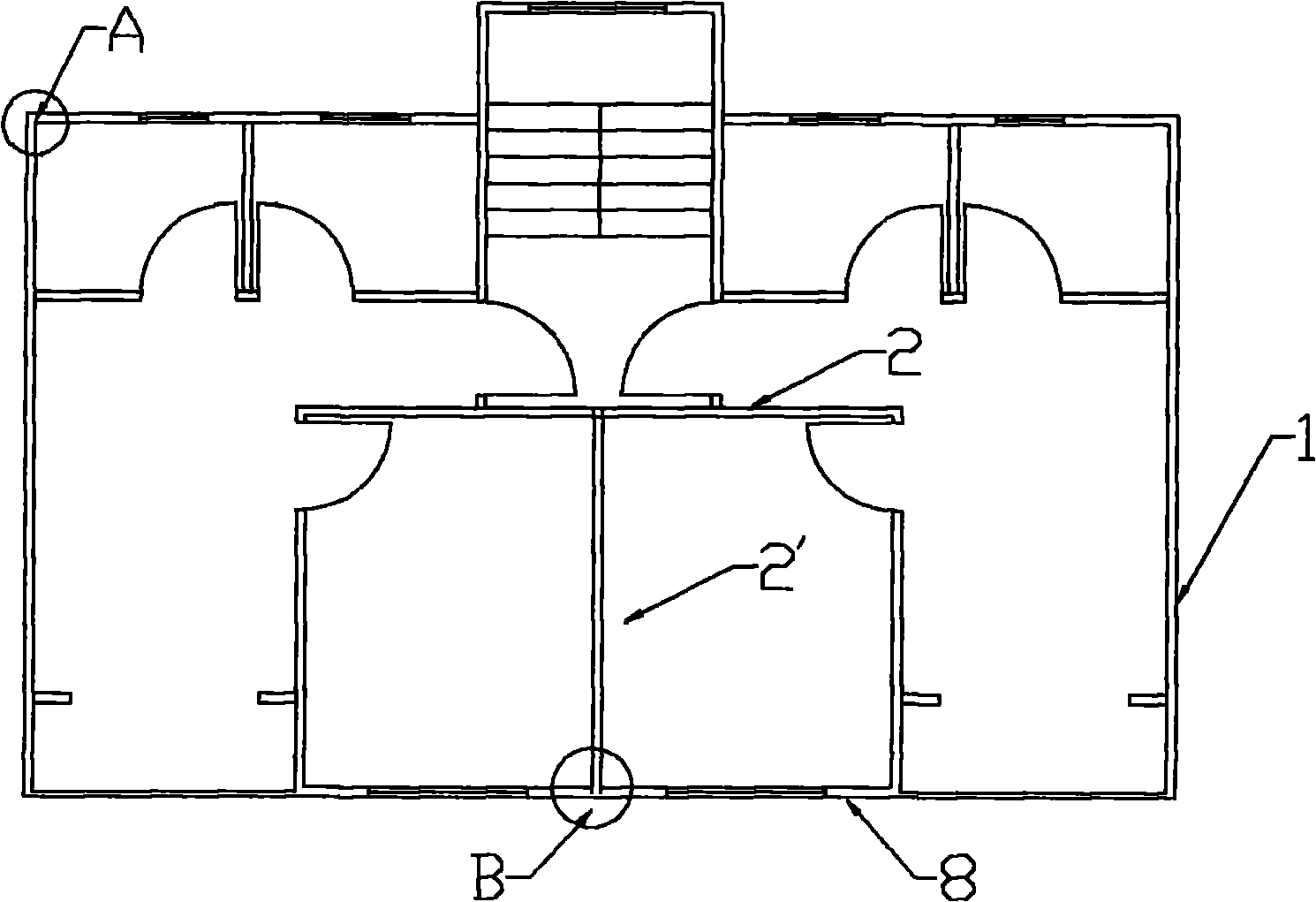

[0059] Embodiment 1, The structure of prefabricated houses with board-concrete structure

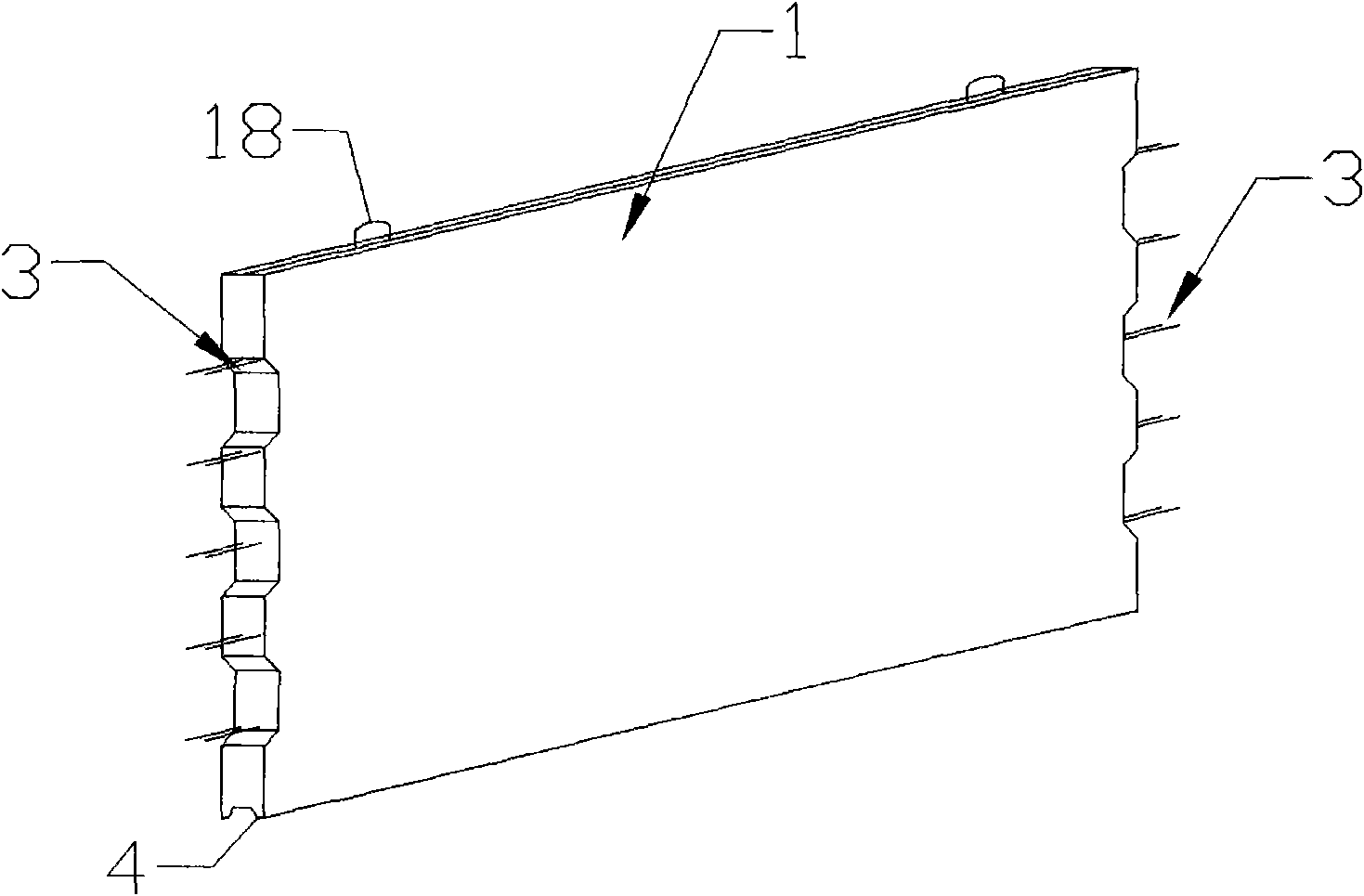

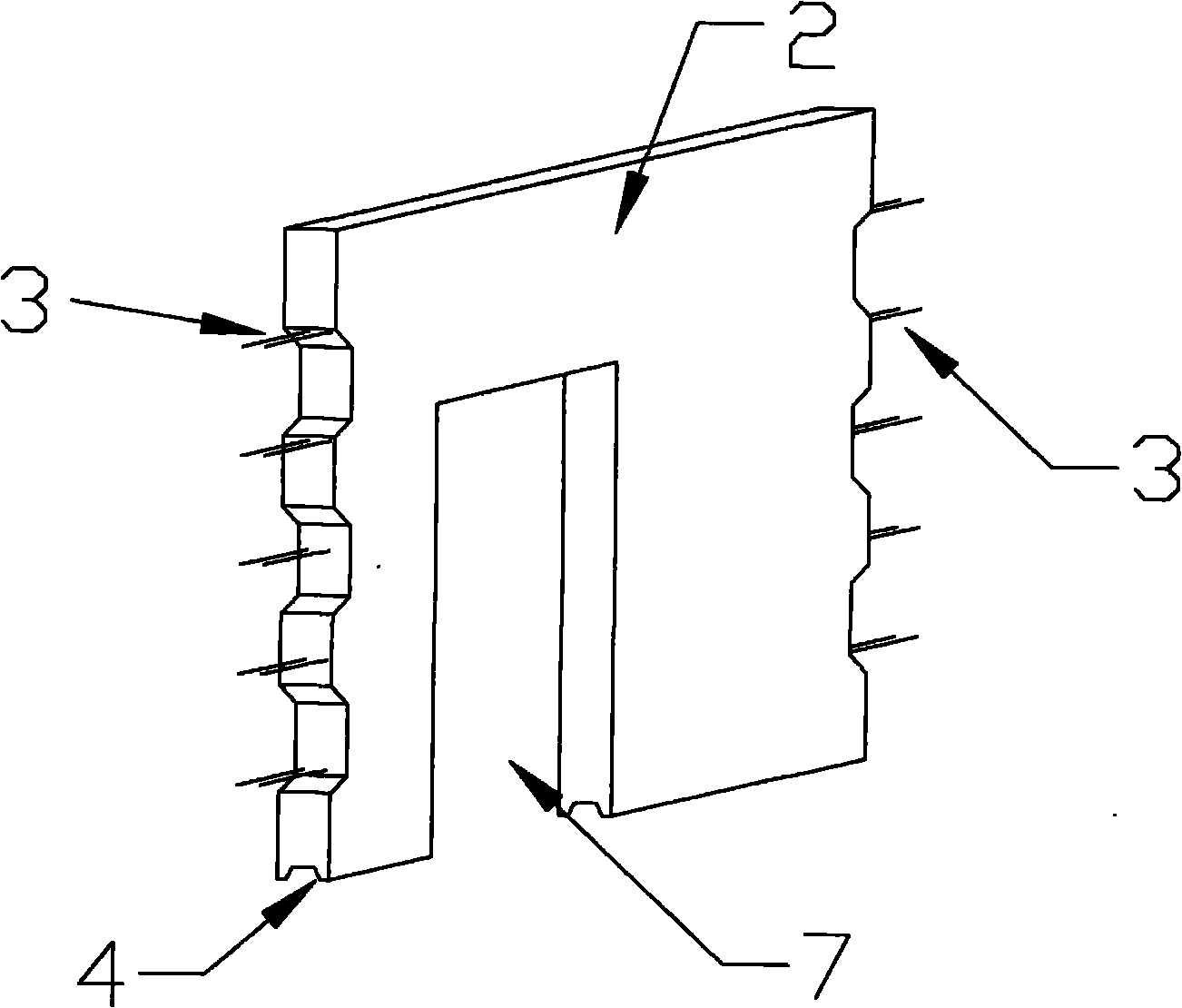

[0060] Such as figure 1 with Image 6 As shown, the prefabricated exterior wall panels 1, 8, interior wall panels 2, 2', and laminated floor panels 24 are integrated with the construction columns and floors cast on site in the prefabricated house of the present invention. , the inner and outer wall panels, laminated floor panels, and structural columns are prefabricated or poured with green concrete.

[0061] The exterior wall panels of the present invention include a load-bearing exterior wall panel 1 and a non-load-bearing exterior wall panel 8. Similarly, the interior wall panels include a load-bearing interior wall panel 2' and a non-load-bearing interior wall panel 2. The load-bearing interior and exterior wall panels, The composite floor slab and the cast-in-place concrete are green concrete prepared from concrete recycled aggregates, and the non-load-bearing inner and outer wa...

Embodiment 2

[0069] Embodiment 2, Construction method of prefabricated house with board-concrete structure

[0070] Taking the low-rent housing with one elevator and two households of no more than 50 square meters per household under construction as an example, the construction steps are as follows:

[0071] A. Making prefabricated inner and outer wall panels and laminated floor panels

[0072] According to the formula shown in Tables 1 and 2, the exterior wall panels with a height of 2550mm, a length of 6200mm, a thickness of 200mm, and a 50mm benzene board in the middle are manufactured by molds in the factory; height 2550mm, length 2500-3300mm, thickness 200mm, and a middle rest of 50mm For the interior wall panels of benzene panels, according to the design requirements, the positions of door frames or window frames are reserved on the panels. Manufacture laminated panels (including 50mm precast concrete panels) with a length of 930mm-2000mm, a width of 3160mm, and a thickness of 150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com