Rapid tapioca flour detoxification method

A kind of cassava flour, fast technology, applied in food science, animal feed, animal feed and other directions, can solve the problem of time-consuming, laborious and inconvenient cassava eating method, and achieve the goal of promoting whole meal nutrition, improving food taste, and adjusting food nutrition structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

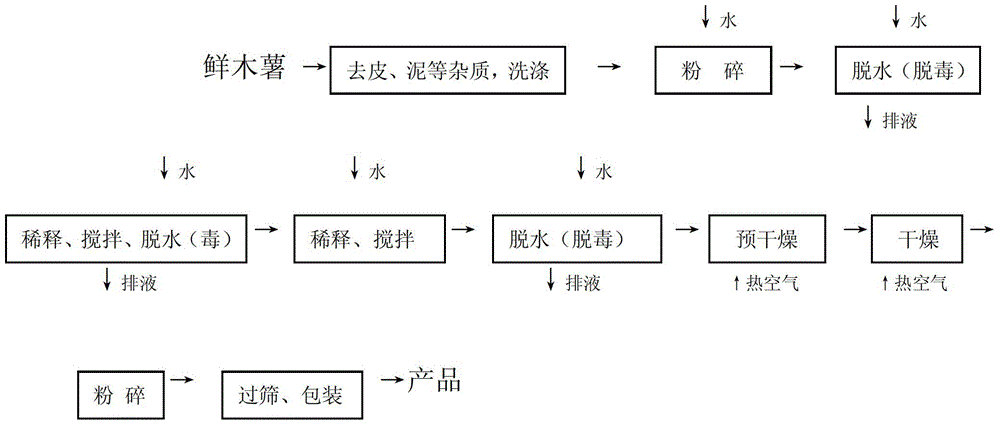

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1, the production process parameter optimization of cassava flour rapid disinfection method

[0074] 1. Raw material preparation:

[0075] Cassava is a root crop with a rough surface and a large number of lenticels. The lenticels cannot open and close freely, which accelerates the exchange of water. The water content of edible fresh cassava decreases continuously during storage. The dry powder content of fresh cassava decreased mainly due to respiration and water loss. The shelf life of cassava is very short, and it is generally believed that postharvest physiological deterioration will occur after 24 to 48 hours after harvest. Fresh cassava after harvest is susceptible to physiological diseases such as root soft rot, root dry rot and postharvest root rot, which seriously affect product quality.

[0076] Table 5 Comparison Table of Moisture, Starch Content and Rotation Rate of Fresh Cassava

[0077] Storage time (hours)

Moisture %

Starch c...

Embodiment 2

[0159] Embodiment 2, quick detoxification and product performance of cassava flour

[0160] (1) Rapid detoxification of cassava flour

[0161] (1) Test location: a starch processing factory in Wuming, Guangxi. Random processing of cassava raw materials (17 hours) purchased from the processing plant, the starch content of fresh cassava is 26.3%, and the hydrocyanic acid content measured by sampling at the discharge port of the pulverizer is: 397.21mg / kg.

[0162] (2) The fresh cassava obtained in step (1) is dehulled by water pressure at 0.0389Mpa, and washed until the dehulling rate is above 99.99%.

[0163] (3) The cleaned raw materials obtained in step (2) use water as the medium, the water ratio between fresh cassava raw materials and water is 1:0.8, and the fineness of the pulverized material passes through an 80-mesh aperture with a pass rate of 100% to enter the next process.

[0164] (4) The material obtained in step (3) is dehydrated by a plate and frame filter press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com