Water-based indoor intumescent fire-retardant coating for steel structure and preparation method thereof

A fire-resistant coating and internal expansion technology, which is applied in fire-resistant coatings, coatings, etc., can solve the problems of water resistance that cannot meet the requirements, environmental protection, and performance that cannot be met.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

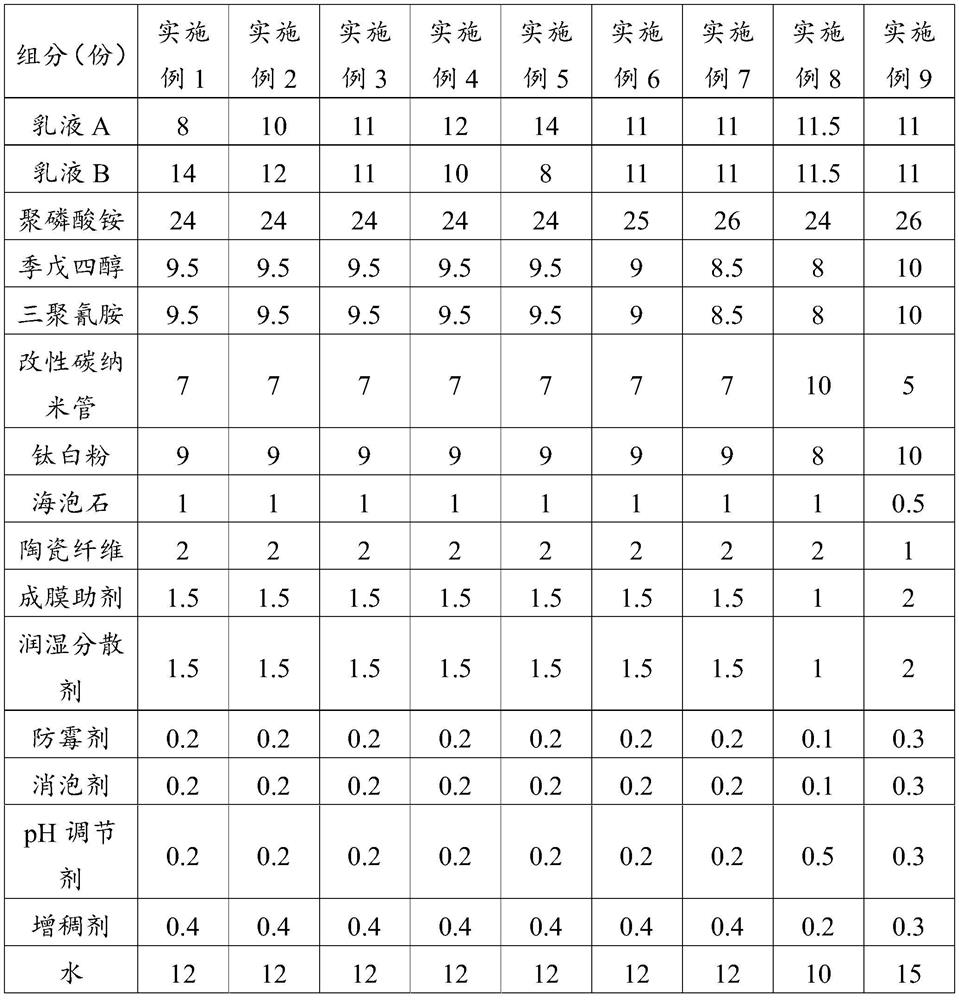

[0067] Embodiment 3, the coating of embodiment 6~7, the fire resistance of the coating of embodiment 3 is the best, illustrates that the component distribution ratio of flame retardant system (ammonium polyphosphate, pentaerythritol and melamine) can significantly affect the fire resistance of coating, Effect is better when adopting the proportioning among the embodiment 3.

[0068] Comparing Example 3 and Comparative Examples 1 to 2, it can be seen that the water resistance and fire resistance of the coating of Example 3 are significantly better than those of Comparative Example 1 and Comparative Example 2, indicating that the compounding of emulsion A and emulsion B has synergistic enhancement. The effect can significantly improve the water resistance and fire resistance of the coating.

[0069] Comparing Example 3 and Comparative Examples 3-4, it can be seen that the use of polyvinyl acetate modified carbon nanotubes of the present invention can effectively improve the fire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com