'Copper/straw' electromagnetic wave shield composite material and preparation method thereof

A composite material, electromagnetic wave technology, applied in the fields of magnetic/electric field shielding, electrical components, layered products, etc., can solve problems such as action errors, and achieve high conductivity, high electromagnetic wave shielding efficiency, large market prospects and application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

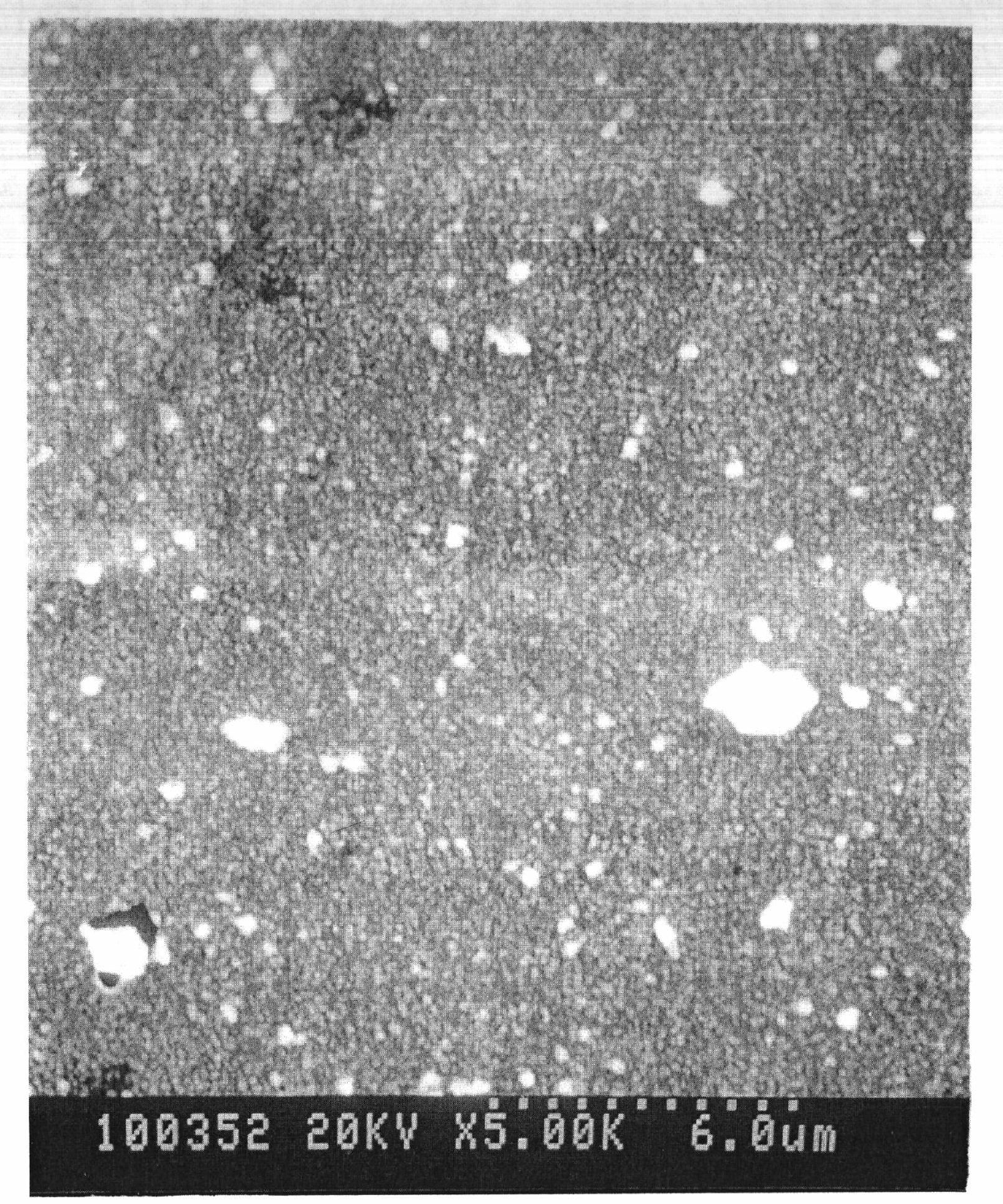

Image

Examples

Embodiment 1

[0024] Wash 3 g of wheat straw with deionized water, dry it, place it in a 0.01% ethanol solution of 3-aminopropyltrimethoxysilane, soak it for 5 minutes, take it out, rinse it with ethanol, and dry it. dry to obtain surface-modified wheat straw.

[0025] putting the modified straw into the silver nanoparticle sol solution, standing for 1 hour, taking it out and washing it, and obtaining the surface-activated wheat straw.

[0026] Dissolve copper sulfate (10g), nickel sulfate (1.5g), sodium potassium tartrate (50g), sodium carbonate (7.5g), sodium hydroxide (10g), glucose (18g) in 500mL of deionized water, after the dissolution is complete, add deionized water until the volume of the solution is 1 L to obtain a copper electroless plating solution.

[0027] Place the surface-activated wheat straw in the above-mentioned plating solution, perform electroless plating at room temperature for 10 minutes, take it out, wash it with water, and dry it to obtain a "copper / straw" composi...

Embodiment 2

[0029] Wash 3 g of rice straw with deionized water, dry it, place it in a methanol solution of 0.05% 3-aminopropyltriethoxysilane, soak it for 3 minutes, take it out, rinse it with methanol, drying to obtain surface-modified rice straw.

[0030] Putting the modified straw into the silver nanoparticle sol solution, standing for 1 hour, taking it out and washing it, to obtain surface-activated rice straw.

[0031] Dissolve copper sulfate (15g), nickel sulfate (2g), sodium potassium tartrate (70g), sodium carbonate (10g), sodium hydroxide (12g), glucose (20g) in 500mL deionized water, after the dissolution is complete, add deionized water until the volume of the solution is 1L to obtain a copper electroless plating solution.

[0032] Place the surface-activated rice straw in the above-mentioned plating solution, electroless plate at room temperature for 30 minutes, take it out, wash it with water, and dry it to obtain a "copper / straw" composite material, the weight ratio of copp...

Embodiment 3

[0034] Wash 10 g of corn stalks with deionized water, dry them, place them in a 5% acetone solution of 3-mercaptopropyltrimethoxysilane, soak them for 5 minutes, take them out, rinse them with acetone, and dry them. dried to obtain surface-modified corn stover.

[0035] putting the modified straw into the silver nanoparticle sol solution, standing for 1 hour, taking it out and washing it, and obtaining the surface-activated corn straw.

[0036] Dissolve copper sulfate (10g), nickel sulfate (1.5g), sodium potassium tartrate (50g), sodium carbonate (10g), sodium hydroxide (12g) and glucose (20g) in 500mL of deionized water. deionized water until the volume of the solution is 1L to obtain a copper electroless plating solution.

[0037] Place the surface-activated corn stalks in the above-mentioned plating solution, electroless plate at room temperature for 5 minutes, take them out, wash them with water, and dry them to obtain a "copper / stalk" composite material, the weight ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com