Patents

Literature

120 results about "Sodium potassium tartrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special high-performance compound fertilizer for woody flowers and plants

InactiveCN104355945AIncrease profitPromote growthAlkali orthophosphate fertiliserExcrement fertilisersSucroseMyriophyllum

The invention discloses a special high-performance compound fertilizer for woody flowers and plants. The high-performance compound fertilizer is prepared from the following raw materials: poultry manure, roots and stems of leguminous plants, bentonite, steel slag, coal ash, ammonium polyphosphate, ammonium hydrogen phosphate, urea, potassium chloride, calcium nitrate, rare earth salts, zinc sulfate, ferrous sulfate, borax, humic acid, lignin, sodium potassium tartrate, amino acid, sucrose, glucose, ethylene diamine tetra-acetic acid, acrylic resin and a microbial agent. The special high-performance compound fertilizer for woody flowers and plants disclosed by the invention has the advantages of high utilization rate, small amount and balanced nutrients; after the compound fertilizer is applied to the woody flowers and plants, the flowers and plants are healthy and strong and has green leaves, bright-colored flowers and long flowering period and the properties of soil can be improved so that the soil has healthy development.

Owner:WUWEI XINYUEHU LIVESTOCK BREEDING CO LTD

Citrate-tartrate dual-complexing non-cyanide alkaline copper-plating electrolyte on steel substrate

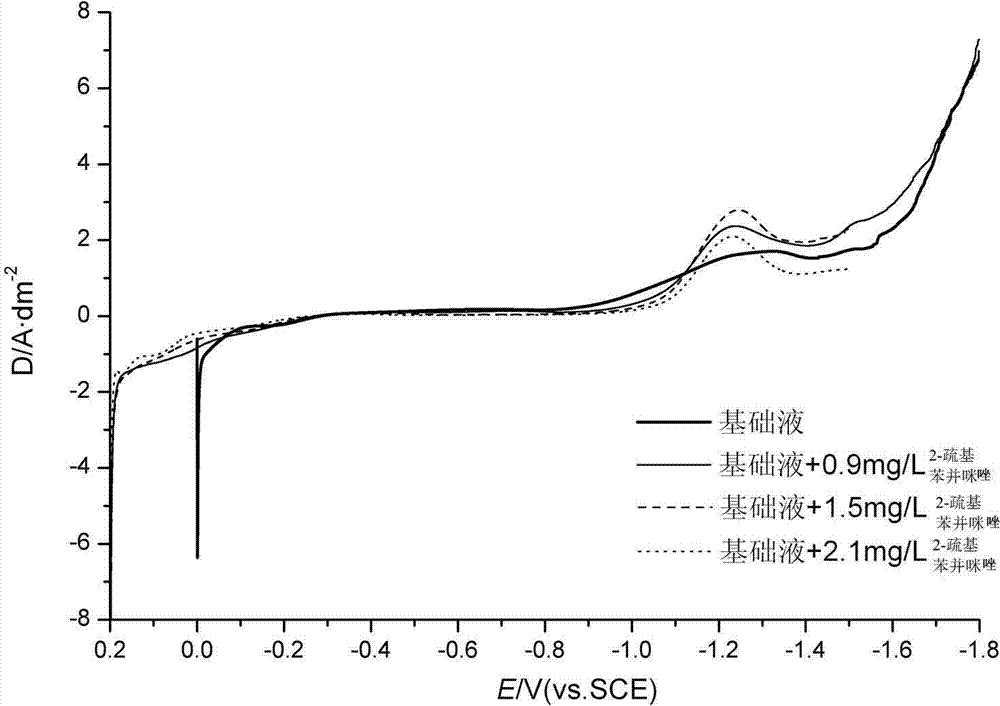

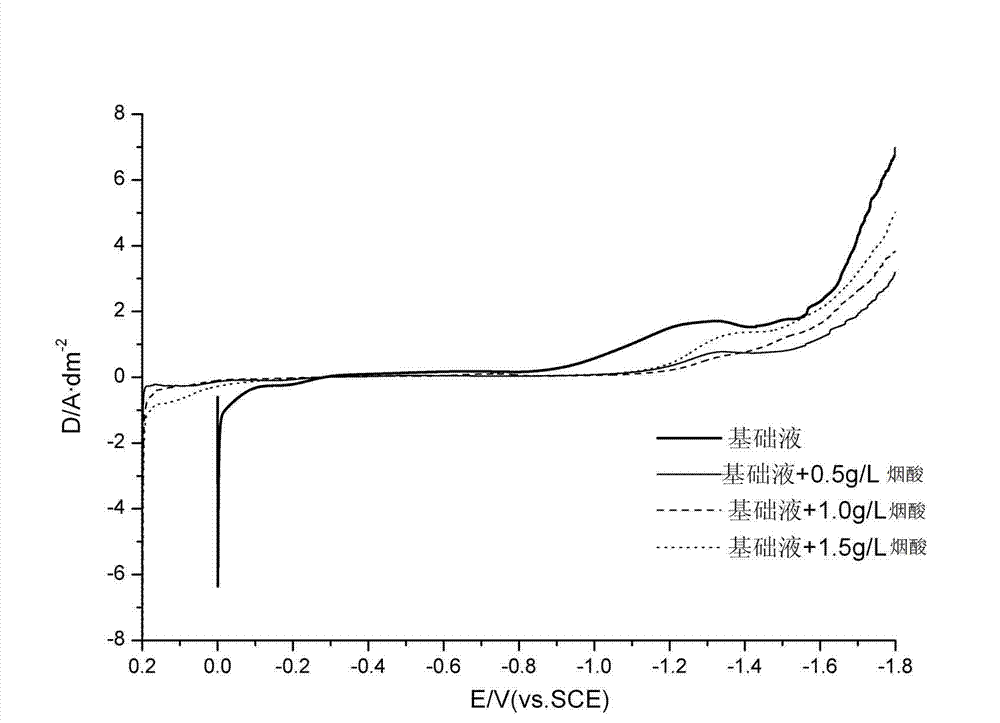

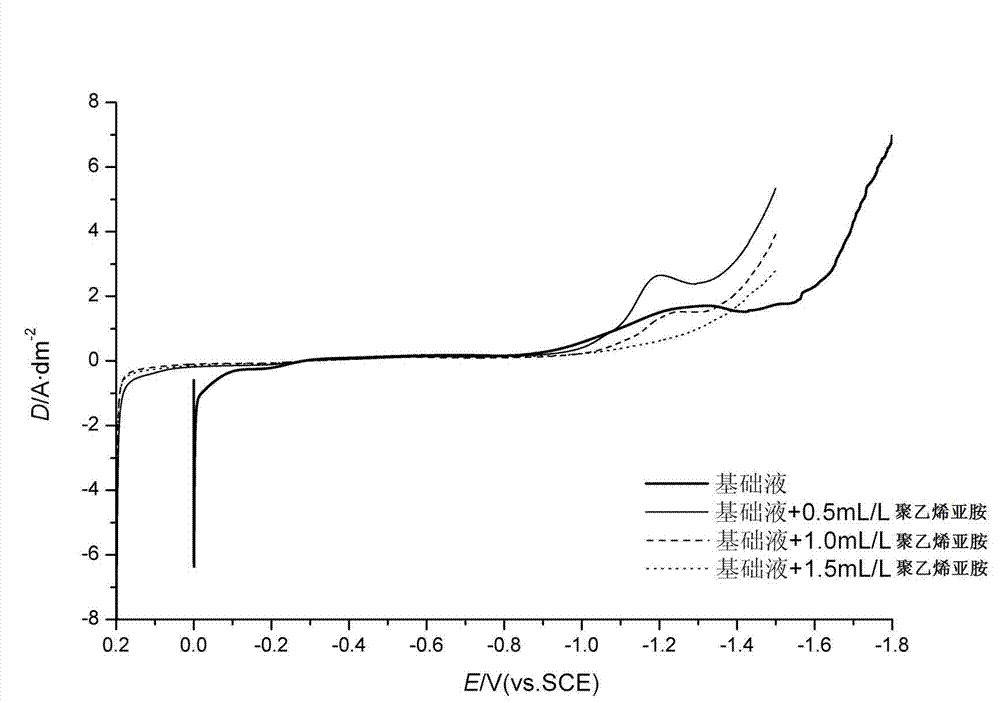

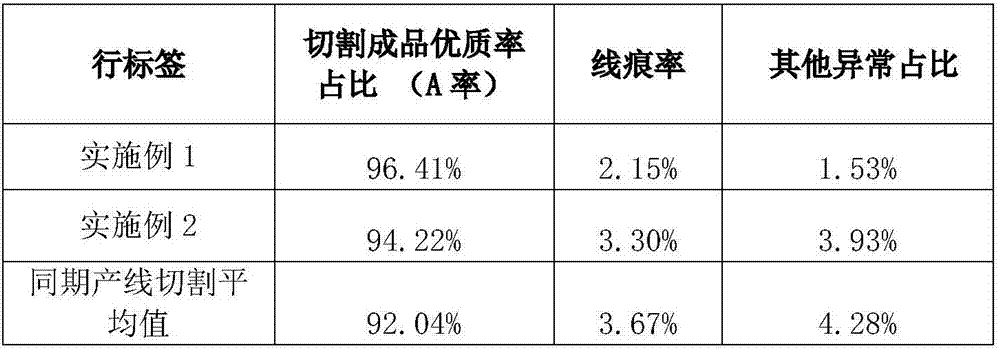

The invention discloses a citrate-tartrate dual-complexing non-cyanide alkaline copper-plating electrolyte on a steel substrate. The electrolyte per liter is prepared from the following raw materials by weight: 29-32g of copper sulfate, 110-147g of sodium citrate, 40-50g of sodium potassium tartrate, 6-8g of potassium nitrate, 8-12g of sodium bicarbonate, 0.5-1.5g of nicotinic acid, 0.1-0.2g of polyethylene glycol, 1-1.5ml of polyethyleneimine, 0.84-1.32mg of 2-mercapto benzimidazole and the balance of water. The electrolyte disclosed by the invention is good in dispersion capability, strong in coverage capability, high in stability, clean and environmentally-friendly in formula and suitable for wide working current density range; a plating coat of a plated part electroplated by the electrolyte is excellent in binding force, uniform in distribution and suitable for preparing a basic layer or a copper-plating layer in a medium thickness on a complex steel part.

Owner:HUBEI HENGXIN ELECTRO PLATING

Hydroponic fertilizer special for fruits and vegetables

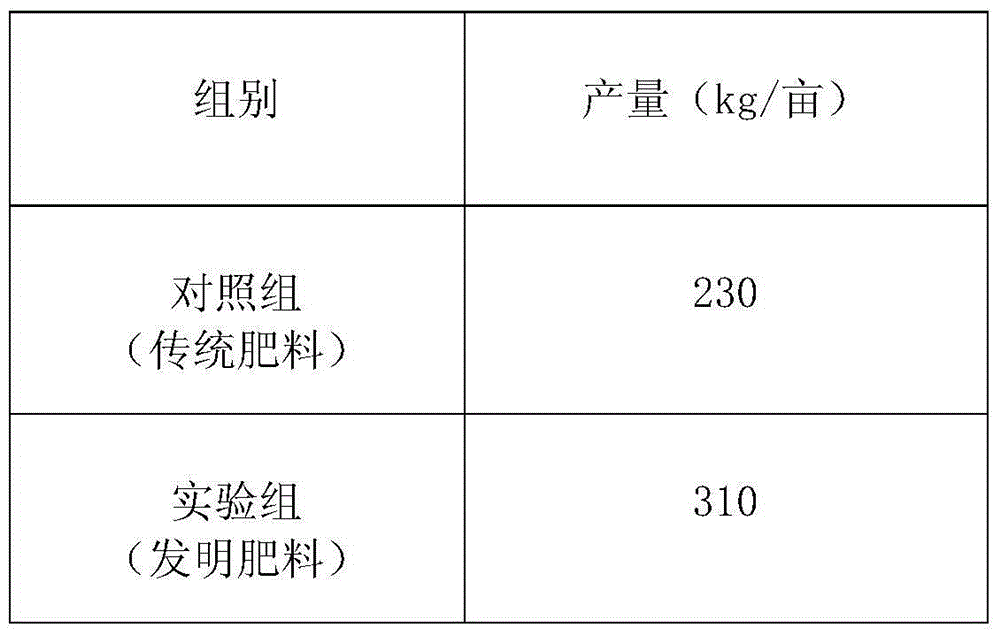

InactiveCN104591880AImprove result rateIncrease productionMagnesium fertilisersAlkali orthophosphate fertiliserPlant hormonePhosphate

The invention discloses a hydroponic fertilizer special for fruits, vegetables and flowers. The hydroponic fertilizer is prepared from the following components in parts by weight: 2-5 parts of nitrogenous fertilizer, 12-15 parts of phosphorus pentoxide, 10-20 parts of growth additive, 10-15 parts of boric acid, 20-25 parts of ferrous sulphate, 2-8 parts of magnesium oxide, 5-8 parts of potassium humate, 12-15 parts of amino acid, 3-8 parts of vitamin, 6-10 parts of fructose, 3-5 parts of glucose, 8-15 parts of sodium potassium tartrate, 10-20 parts of glycol, 0.1-0.5 part of plant hormone indole butyric acid, 0.1-0.5 part of naphthylacetic acid, 5-10 parts of pH value adjusted inorganic acid phosphate or citric acid, and 8-10 parts of monosaccharide. After forming nutrient solution or a leaf fertilizer by adding water, the hydroponic fertilizer disclosed by the invention can be applied to a fruit and vegetable garden; the fruiting rate is increased by above 70%; the yield is increased by 50-60%; fruits are mature 8-10 days ahead; the fruits are large and regular in shape; the colours of the fruits are changed from orange to orange red; the fruits are smooth in peel, sweet in taste, crisp, high in sweetness, easy to melt and good in colour, aroma and taste; the commodity rate is above 90%; and in addition, the components in the invention are proper in mixture rate, so that the components cannot generate adverse effects with each other.

Owner:东莞市高明企业服务有限公司

Low-foam water-based diamond wire cutting liquid

InactiveCN107011981AReduce stabilityReduce controllabilityLubricant compositionWater basedWire cutting

The invention provides low-foam water-based diamond wire cutting liquid which comprises the following components in percentage by weight: 3-15 percent of low-foam polyether with a molecular weight of 1500-2000, 2-10 percent of polyether modified polysiloxane with a silicone oil molecular weight of 220-20000 and a polyether molecular weight of 500-2000, 0.5-7 percent of an emulsifying agent, 0.5-5 percent of a PH regulating agent, 0.5-5 percent of a complexing agent, 0.2-1.5 percent of an extrusion agent and 70-95 percent of water, wherein the emulsifying agent uses one or more of isodecanol polyoxyethylene ether, iso-tridecanol polyoxyethylene ether, isooctyl alcohol polyoxyethylene ether, glyceryl monostearate, sorbitan polyethylene laurate and sorbitan stearate; the PH regulating agent is organic amine; the complexing agent is one of or a mixture of more of sodium gluconate, potassium gluconate, sodium nitrilotriacetate, sodium citrate, potassium citrate and sodium potassium tartrate; the extrusion agent preferably selects one or several of sodium carbonate, sodium silicate and sodium sulfate. The low-foam water-based diamond wire cutting liquid provided by the invention can realize a lubricating effect, the abrasion resistance, the cooling performance and the like required to be met in the cutting process.

Owner:ZHENJIANG RENDE NEW ENERGY TECH

Heat-resistant insect-proofing polyurethane foam gap filling material

The invention discloses a heat-resistant insect-proofing polyurethane foam gap filling material comprising the raw materials: polyurethane, a styrene-acrylic emulsion, acrylic ester, diphenol propane, xylene, microlite, light calcium carbonate, diatomite, lindane, a talcum powder, zeolite, titanium dioxide, a talcum powder, a cellulose powder, magnesium oxide, nano calcium carbonate, a lamellar-structural mica powder, glass fiber, carbon fiber, quick lime, quartz sand, activated carbon, dichlorinated sodium isocyanurate, sodium potassium tartrate, fumaric acid, glutamine, inulin, borneol, acetyl trioctyl citrate, petroleum sodium sulfonate, sodium lauroyl glutamate, silicone oil, styrene, methyl triethoxysilane, a thickening agent, a silane coupling agent and a foaming agent. The heat-resistant insect-proofing polyurethane foam gap filling material has excellent heat resistant performance and insect-proofing performance.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

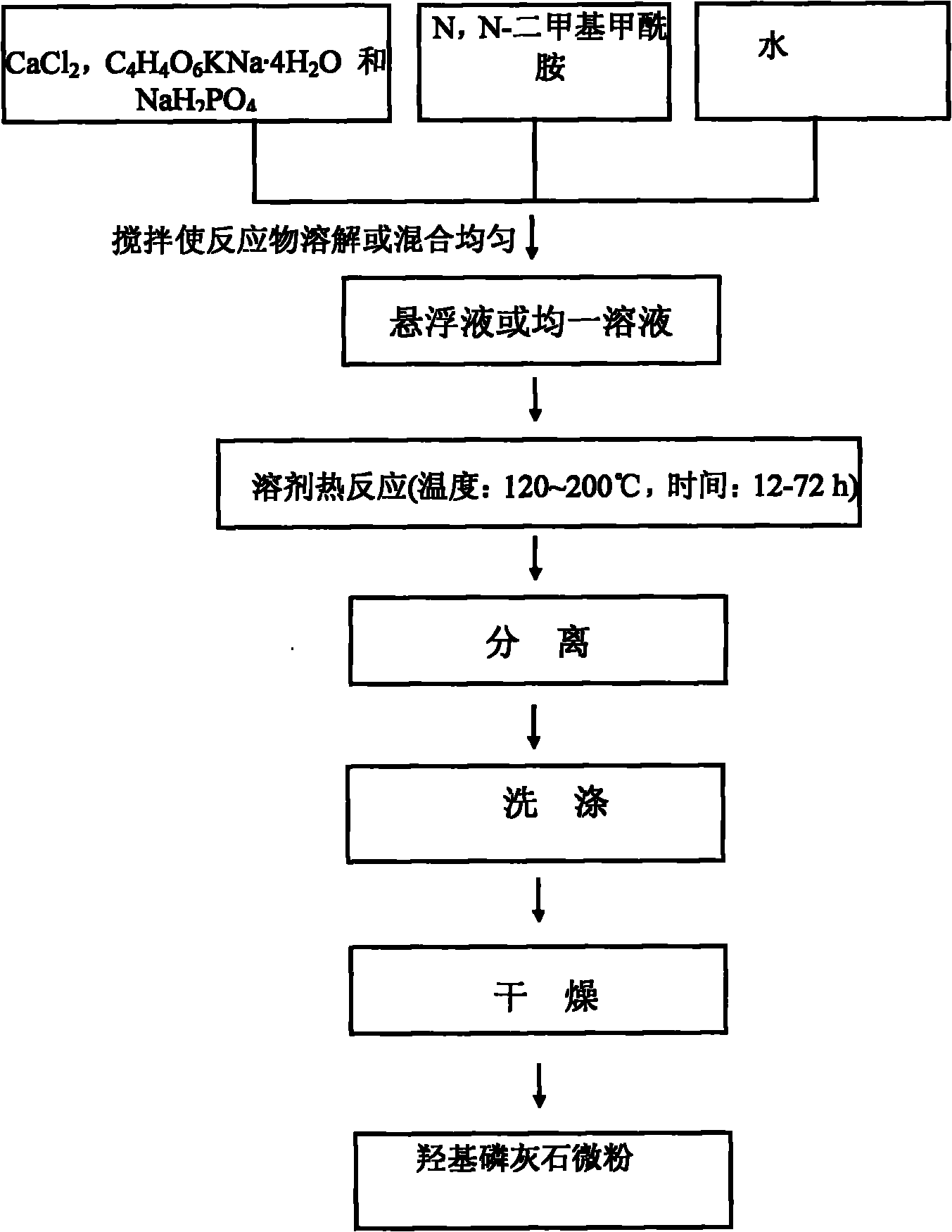

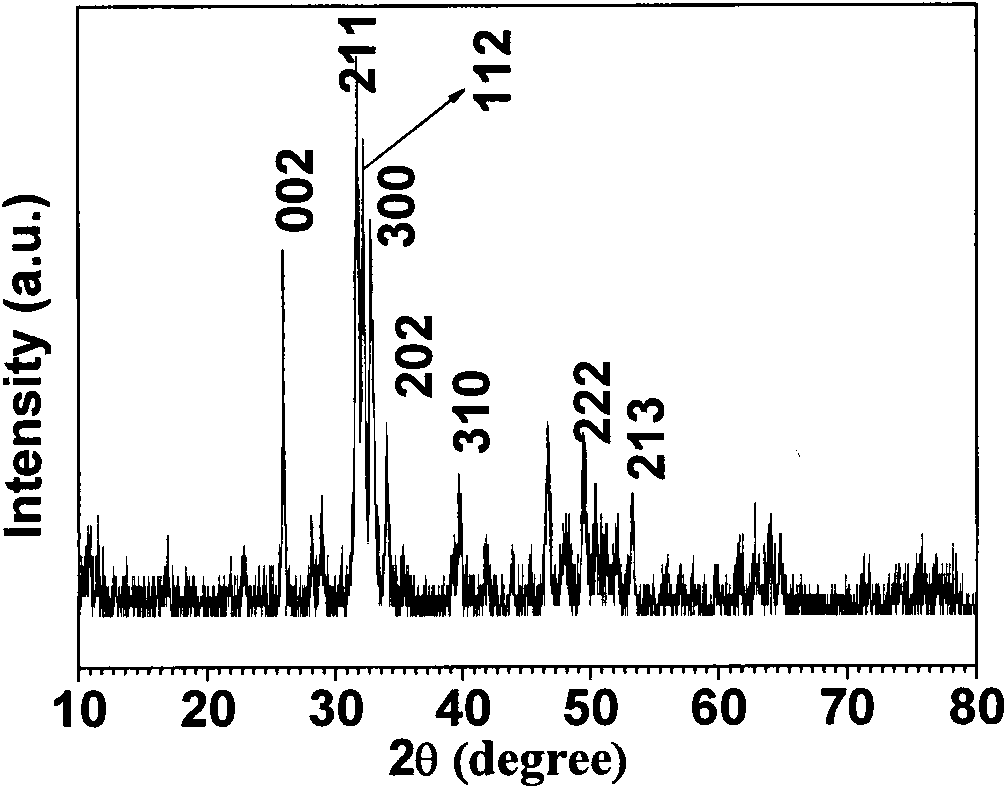

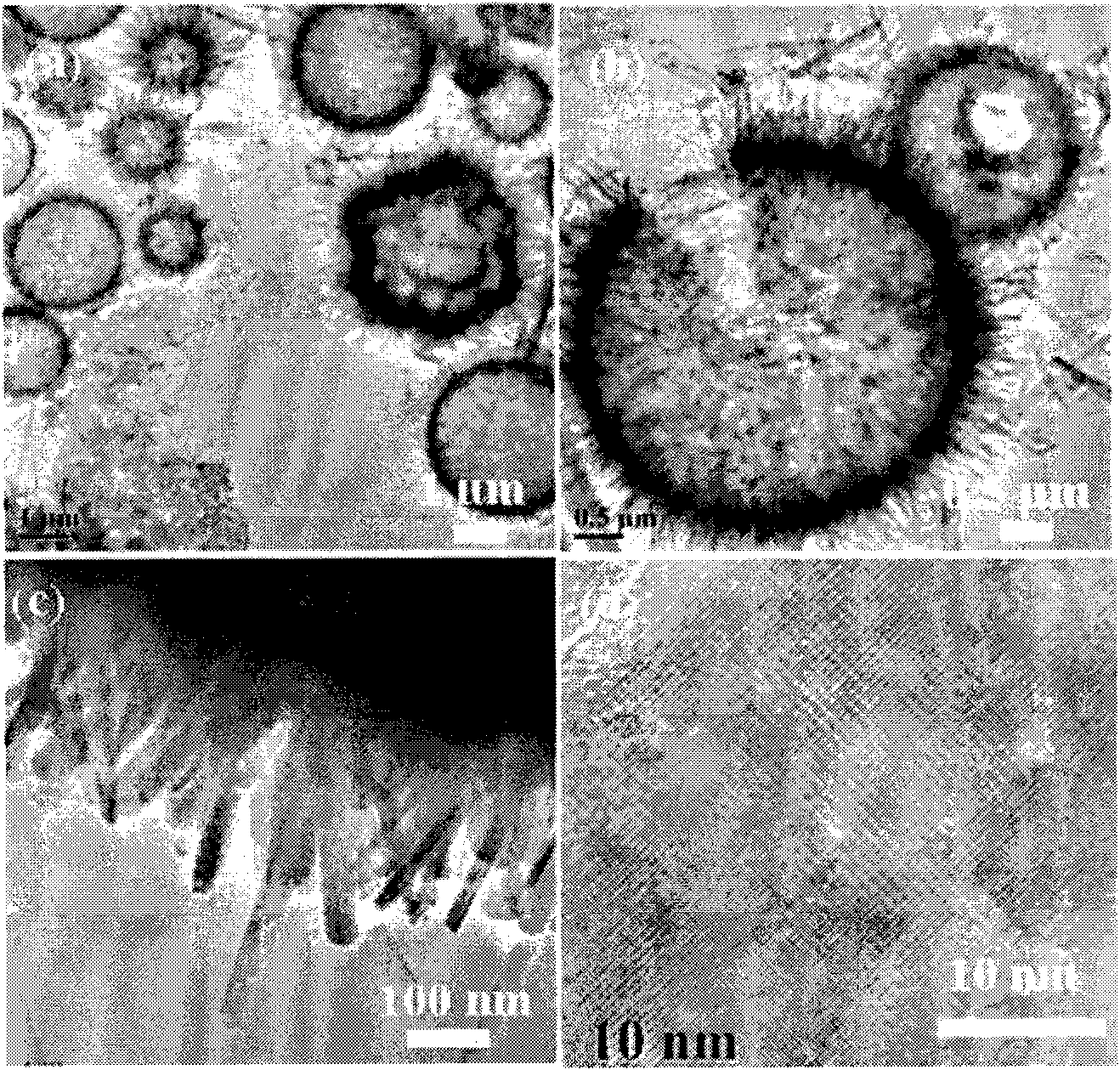

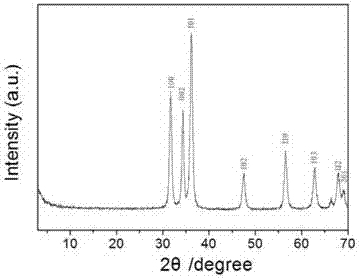

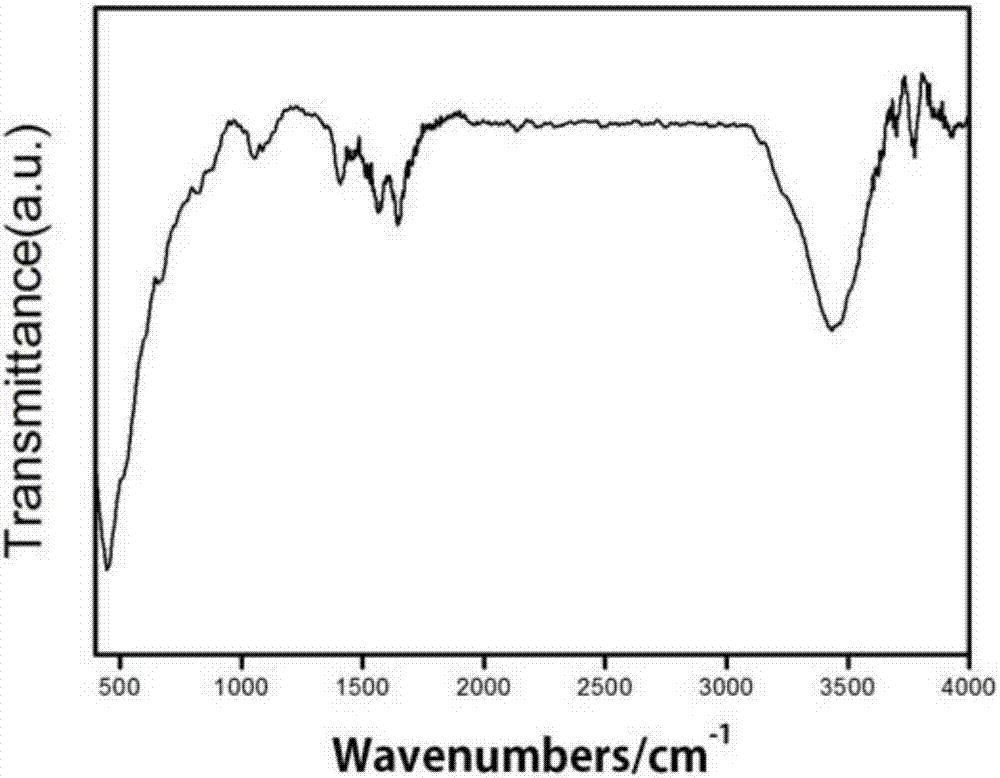

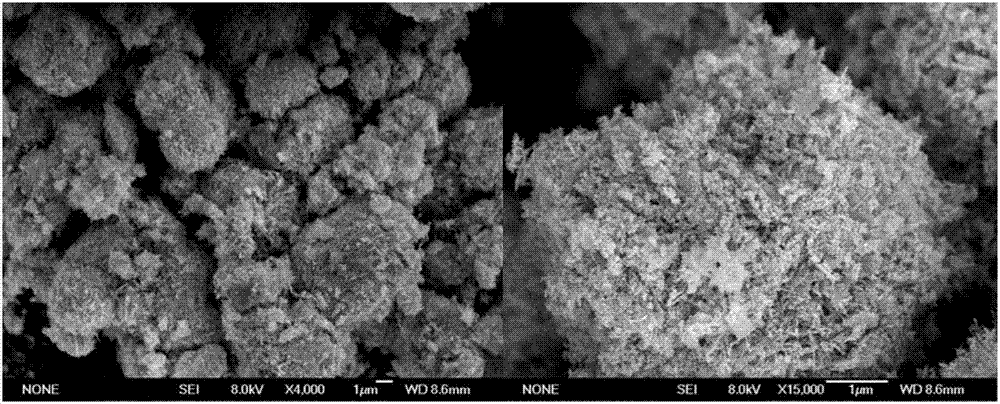

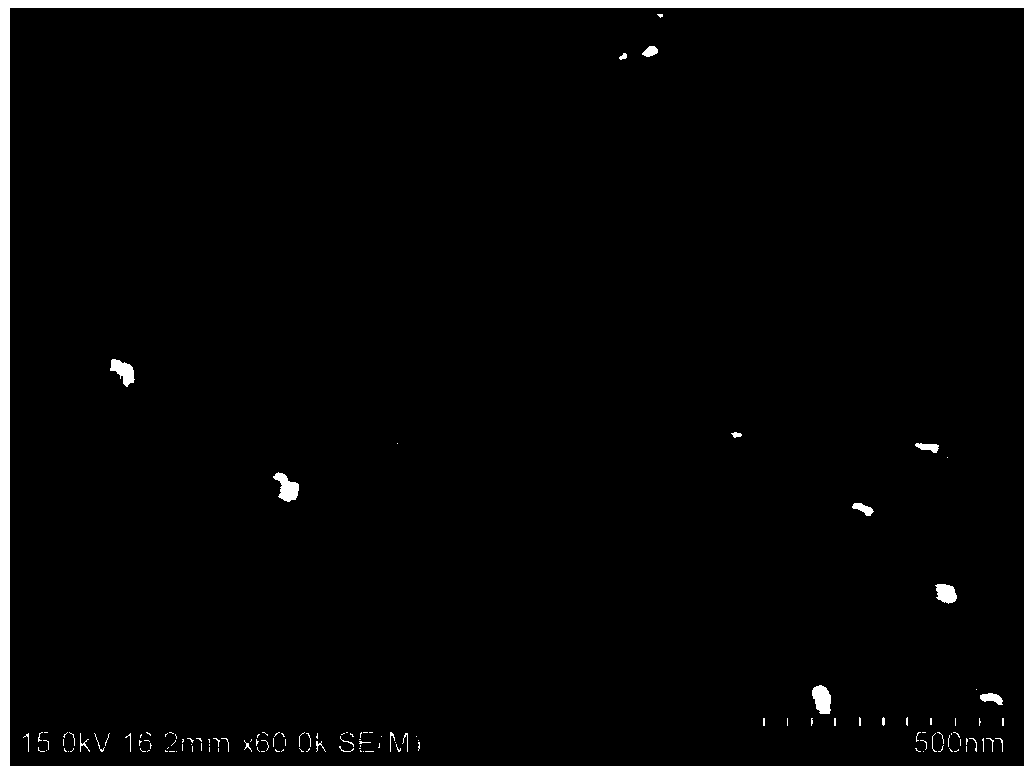

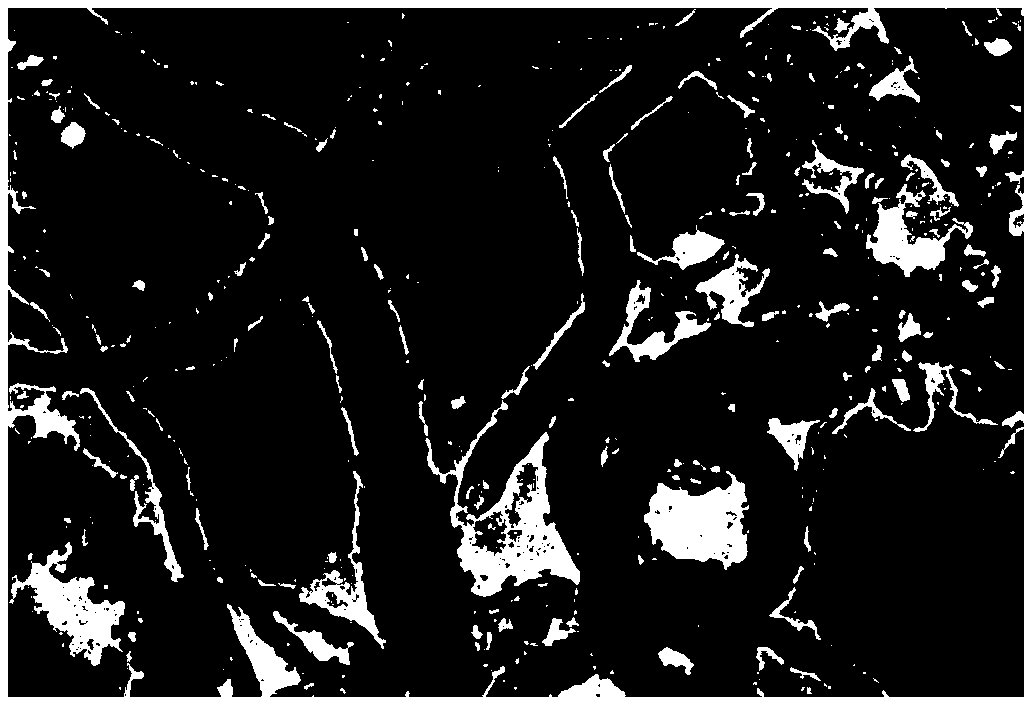

Hydroxyapatite with hollow sphere structure and preparation method thereof

InactiveCN101891174ALarge specific surface areaPromote crystallizationPhosphorus compoundsApatitePhosphate

The invention provides hydroxyapatite with a hollow sphere structure and a preparation method thereof. In the method, water-soluble calcium salt, acidic phosphate and sodium potassium tartrate (a structure setting agent) which serve as raw materials are subjected to solvothermal reaction to form the hydroxyapatite. The hydroxyapatite with the hollow sphere structure prepared by the method has the advantages of uniform particle size, single shape, high dispersibility, large specific surface area, and wide application prospect in medicament release property and the field of biomedicine; and the preparation method has the advantages of low-cost raw materials, simple process, convenient operation, easy control of process conditions, capability of reducing the cost and greatly simplifying the production process, no need of complex and expensive equipment, and contribution to industrial popularization. The method for synthesizing hydroxyapatite hollow spheres with a multilevel structure is firstly reported.

Owner:BEIJING FORESTRY UNIVERSITY

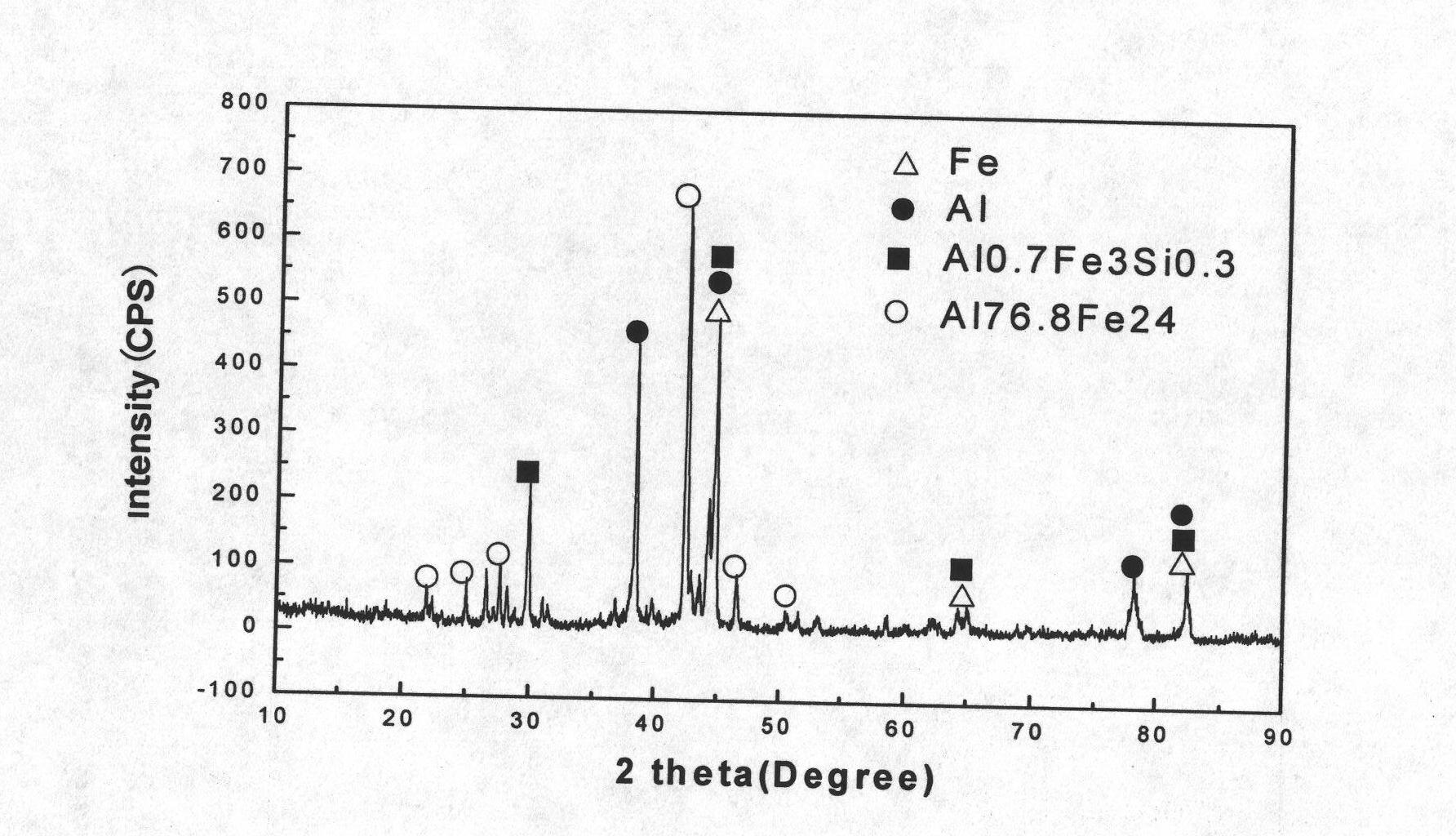

Brazing filler metal for high-frequency induction brazing of aluminum steel and brazing method of brazing filler metal

InactiveCN102152023AReduce adverse effectsImprove reliabilityWelding/cutting media/materialsSoldering mediaGranularitySodium potassium tartrate

The invention relates to a brazing filler metal for high-frequency induction brazing of aluminum steel and a brazing method of the brazing filler metal. In the brazing filler metal, Al-Si based alloy powder is used as a brazing filler metal component of a welding flux; the granularity of the brazing filler metal alloy is -150 to +300 meshes, and the melting point of the brazing filler metal alloy is 570 to 580 DEG C; three kinds of villiaumite, namely KF, NaF and AlF3, are used as a brazing flux in a ratio of (KF and NaF) to AlF3 of 1 to 10; sodium potassium tartrate is used as a bonding agent; and the content of the brazing filler metal in the welding flux is 60 percent, the content of the brazing flux is 38 to 39 percent, and the bonding agent accounts for 1 to 2 percent. The brazing method comprises the following steps of: preparing the components; making the components pasty by using absolute ethanol; removing oxidized membranes from the surfaces to be brazed of steel and aluminum workpieces, and washing by using acetone; uniformly coating the mixed welding flux on the surfaces to be brazed and pressurizing, placing the welding flux into high-frequency induction heating equipment and protecting by using argon; and under a voltage of 4.5kV, heating for 30 seconds and unloading the voltage, and taking the workpiece out if the temperature of the workpiece is below 50 DEG C.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Surface treatment method for aluminum or aluminum alloy and product prepared thereby

InactiveCN103103508AAccelerated corrosionImprove wear resistanceLiquid/solution decomposition chemical coatingThin material handlingSulfateBiological activation

The invention provides a surface treatment method for aluminum or aluminum alloy, which mainly comprises the following steps of offering an aluminum matrix or an aluminum alloy matrix; forming a metallic nickel layer on the surface of the aluminum matrix or the aluminum alloy matrix treated by activation by adopting a replacement reaction manner, wherein a treatment fluid is adopted in the process of forming the metallic nickel layer, and the treatment fluid mainly comprises nickel sulfate, sodium citrate, sodium potassium tartrate terahyddrate and sodium hydroxide; and carrying out chemical nickel plating treatment on the aluminum matrix or the aluminum alloy matrix so as to form a chemical nickel plating layer on the metallic nickel layer. The invention also provides aluminum products or aluminum alloy products prepared by the method. The aluminum products or the aluminum alloy products have good corrosion resistance and abrasion resistance.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Silt curing agent using furnace slags

ActiveCN105622023ALow costHigh strengthSludge treatment by de-watering/drying/thickeningSolid waste managementFoaming agentPolyvinyl alcohol

The invention provides a silt curing agent using furnace slags. The silt curing agent is characterized by being prepared from the following components in percentage by mass: 30 to 50 percent of furnace slags, 20 to 30 percent of cement, 20 to 40 percent of waste gypsum, 0.1 to 1 percent of ethyl cellulose, 0.1 to 0.8 percent of polyvinyl alcohol, 0.2 to 0.5 percent of sodium potassium tartrate, 0.5 to 0.1 percent of alpha-octadecylamine, 0.1 to 0.5 percent of foaming agent, 0.5 to 1 percent of dispersing agent and 1 to 3 percent of high-efficiency slushing agent. The silt curing agent provided by the invention has the advantages of low cost, high curing strength, good water stability, good insulating performance, good sound insulation effect and suitability for reinforcing silt; reasonable utilization of natural silt and industrial wastes is realized.

Owner:温岭市众城环保科技发展有限公司

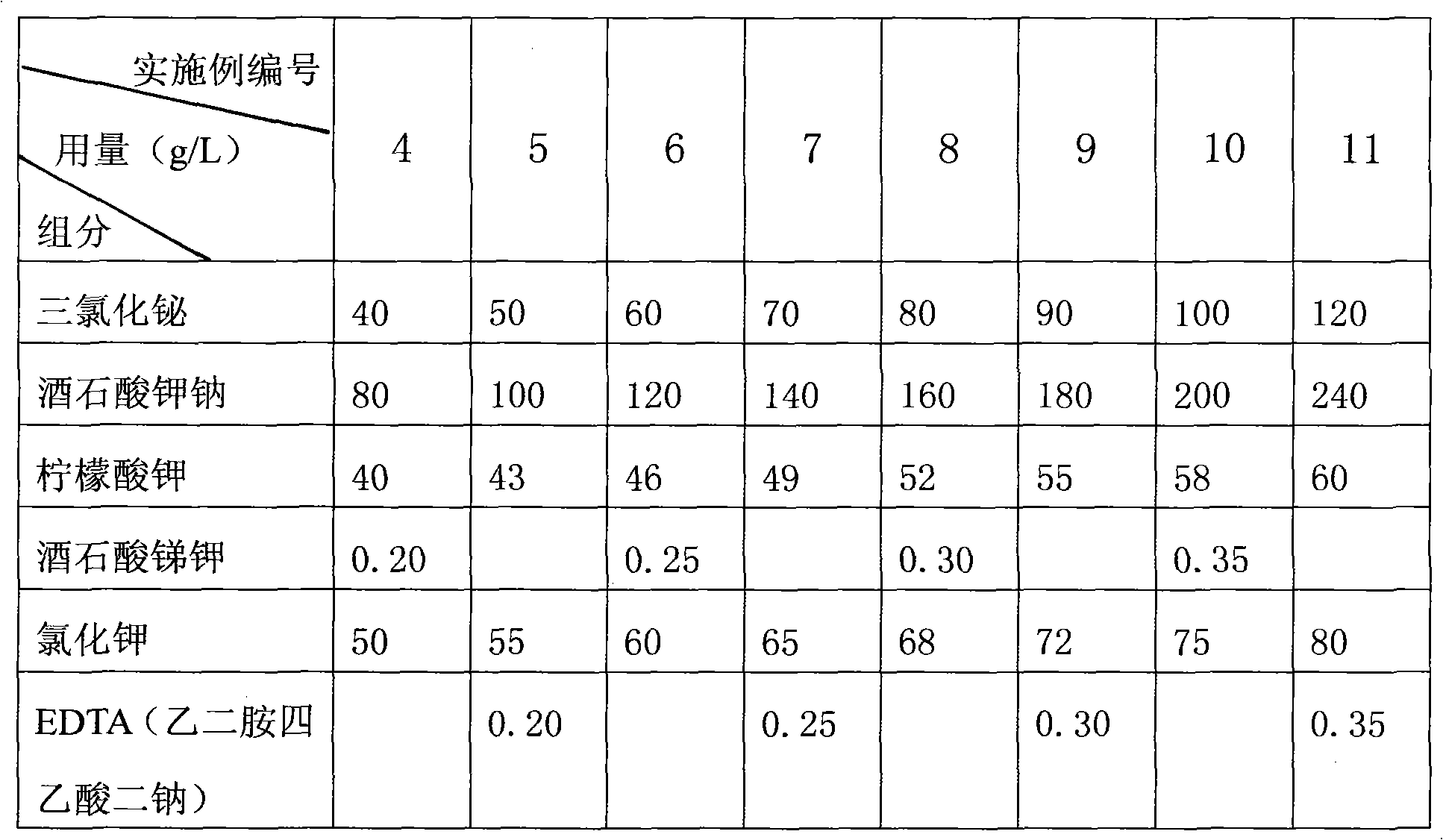

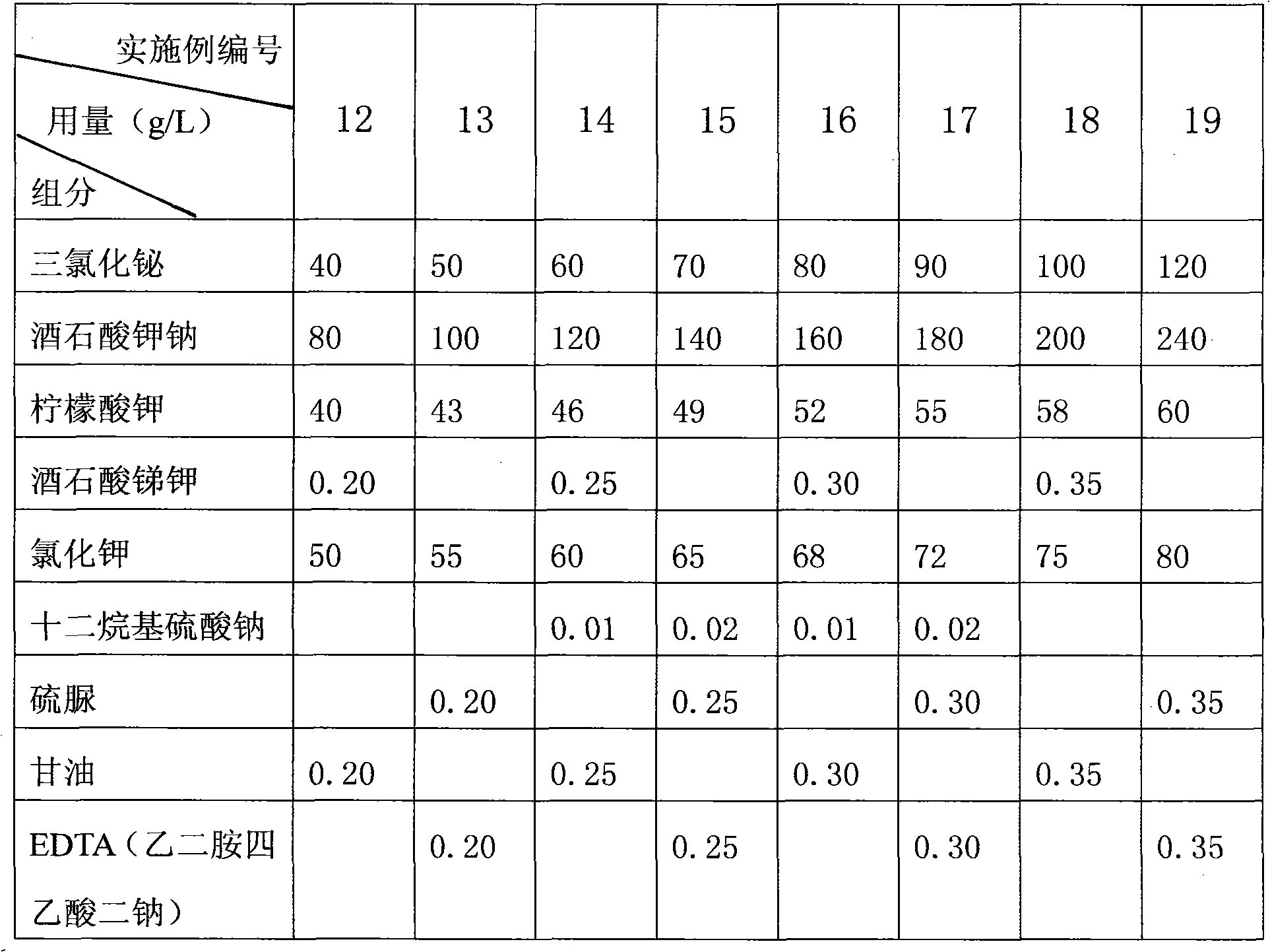

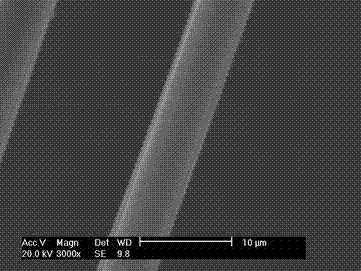

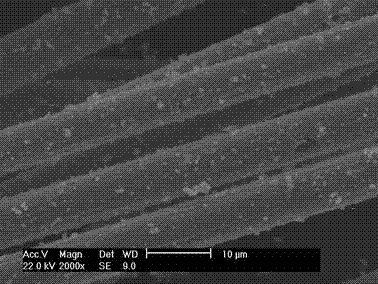

Method for preparing bismuth film by pulse plating process

The invention discloses a method for preparing a bismuth film by a pulse plating process. The method is characterized by comprising the following steps of: preparing one liter of plating solution by using 40 to 120g of bismuth trichloride, 80 to 240g of sodium potassium tartrate, 40 to 60g of potassium citrate, 0.20 to 0.35g of antimony potassium tartrate and 50 to 80g of potassium chloride; and plating by using a copper sheet as a cathode and using a pure gold plate as an anode under the pulse plating process conditions that the current density is 0.55 to 0.85A / dm<2>, the frequency is 500 to 700Hz, the duty ratio is 1:7-1:11, the temperature of the plating solution is 25 to 50 DEG C and the pH value is 7.5 to 11.5, wherein the film deposited on the copper sheet is the prepared bismuth film. The cyanogen-free plating solution is environmentally-friendly and has stable performance; and the prepared bismuth film has smooth and bright surface, low porosity, good bonding force and easily controlled thickness, and has broad application prospect in the fields of electronic materials, component industry and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Reagent and method for quickly testing content of ammonia and nitrogen in water sample

InactiveCN103592413ASimple and fast operationThe result is accurateAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorColor changesBottle

The invention discloses a reagent for quickly testing the content of ammonia and nitrogen in a water sample. The reagent comprises three packages A, B and C, wherein the package A comprises the following raw materials: 400 g to 600 g sodium salicylate, 400 g to 600 g sodium potassium tartrate and 10 g to 20 g sodium nitroprusside, the reagent is added into a mortar to be fully ground and then is sub-packaged to be 100 mg per tube; the package B comprises the following raw materials: 100 g to 200 g sodium hydroxide, the volume of a volumetric flask is set to be 1000 ml, and the reagent is sub-packaged to be 10 ml per flask; the package C is a sodium hypochlorite solution of 10 ml per bottle. A method for quickly testing the content of ammonia and nitrogen in the water sample comprises the following steps: when the water sample is tested, adding 0.05-0.1 ml of the reagent B into a tube of the package A, adding 2-4 ml of the water sample to be tested and 0.05-0.1 ml of the reagent C in sequence, shaking well, standing at the room temperature of 25 DEG C for 5-10 minutes, observing the color change, and comparing with a standard color card to read out the ammonia and nitrogen concentration of the water sample to be tested.

Owner:山东益源环保科技有限公司

Surface metallization treatment method for carbon fibers

InactiveCN106906646AImprove surface roughnessEnhanced interfacial bondingCarbon fibresLiquid/solution decomposition chemical coatingFiberSodium acetate

The invention belongs to the technical field of surface treatment of non-metallic materials, and particularly relates to a surface metallization treatment method for carbon fibers. The method comprises steps as follows: the carbon fibers are subjected to surface degumming, roughening treatment, sensitizing treatment and activating treatment firstly and then are subjected to pre-plating, a pre-plating solution is a mixed solution of nickel metal salt, sodium acetate, sodium potassium tartrate and sodium hypophosphite, the carbon fibers are subjected to chemical plating finally, and a chemical plating solution is a mixed solution of nickel metal salt, sodium acetate, sodium citrate and hypophosphite. According to the surface metallization treatment method for the carbon fibers, problems of strict experiment conditions, complicated operation and higher equipment requirements of a conventional surface metallization treatment method for the carbon fibers are solved, the process route of the method is simple, raw materials are easily available, the production cost is low, and pollution is prevented.

Owner:KUNMING UNIV OF SCI & TECH

g-C3N4/ZnO nano-sheet multi-level heterogeneous structure photocatalyst and preparation method thereof

ActiveCN107185580ASimple preparation processLow costCatalyst activation/preparationHydrogen productionLevel structureZinc Acetate Dihydrate

The invention discloses a g-C3N4 / ZnO nano-sheet multi-level heterogeneous structure photocatalyst and a preparation method thereof. The method is characterized in that acidized carbon nitride, sodium potassium tartrate, zinc acetate and urea are adopted as raw materials, and the g-C3N4 / ZnO nano-sheet multi-level heterogeneous structure photocatalyst is obtained by using a liquid-phase precipitation-phase conversion technology; the self-assembly of the multi-level structure and the g-C3N4 loading are completed in one step; and the method comprises: dissolving acidized carbon nitride in water, sequentially adding a certain amount of sodium potassium tartrate, zinc acetate and urea, carrying out a reaction for 3-12 h at a temperature of 70-90 DEG C, cooling through an ice bath, carrying out centrifugation, drying, and carrying out roasting phase transformation to obtain the g-C3N4 / ZnO nano-sheet multi-level heterogeneous structure photocatalyst. According to the present invention, the used precursor is the inexpensive zinc acetate, the preparation process is simple, and the cost is low; and the prepared g-C3N4 / ZnO nano-sheet multi-level heterogeneous structure photocatalyst has characteristics of high catalytic efficiency and good photocatalytic activity.

Owner:东营睿港投资服务有限责任公司

Sambucus chinensis culture soil and preparation method thereof

InactiveCN105175121ALow costImprove survival rateBio-organic fraction processingOrganic fertiliser preparationPhylum CyanobacteriaBiotechnology

The invention relates to sambucus chinensis culture soil. The culture soil is prepared from the following components in parts by weight: 100-250 parts of sludge, 50-70 parts of coal residues, 30-35 parts of plant ash, 20-28 parts of cyanobacteria, 12-24 parts of orange peels, 20-30 parts of watermelon peels, 25-35 parts of mushroom dregs, 15-30 parts of goose manure, 12-22 parts of pig manure, 8-13 parts of goose feather, 20-22 parts of bacterial powder, 15-18 parts of animal urine, 9-12 parts of calcium dihydrogen phosphate, 6-12 parts of ammonium hydrogen carbonate, 12-14 parts of rape seed cake powder, 5-8 parts of sodium potassium tartrate, 2-4 parts of zinc sulfate, 1-5 parts of calcium carbonate, 18-22 parts of bacillus subtilis and 13-26 parts of a trichoderma viride strain agent.

Owner:合肥科友生物科技有限公司

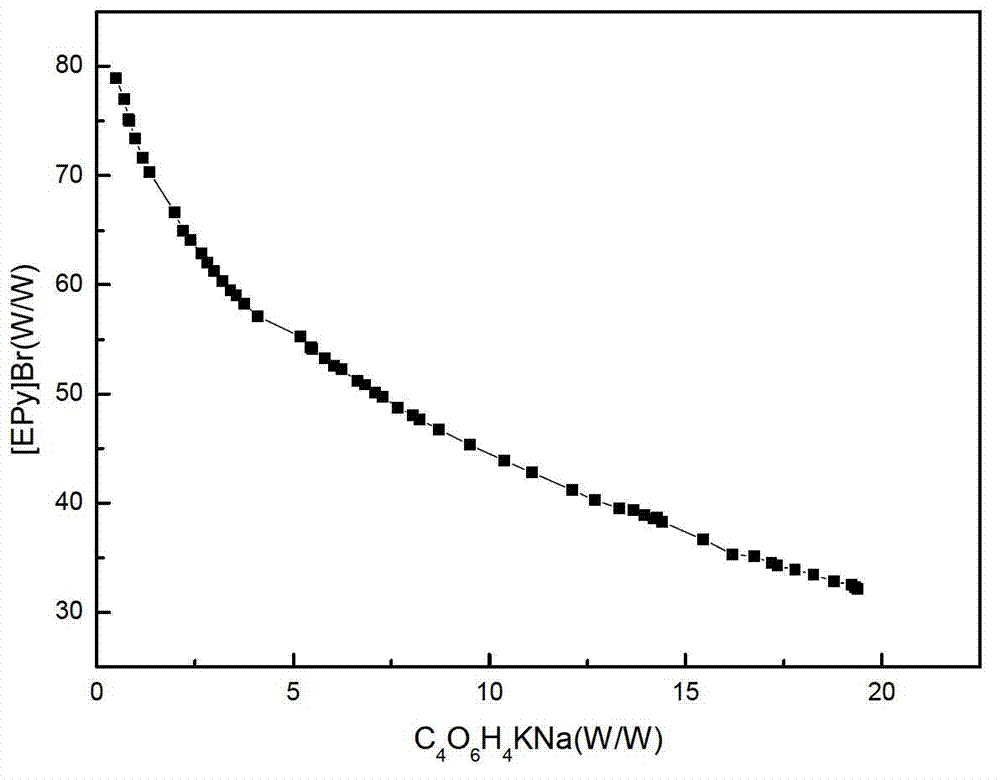

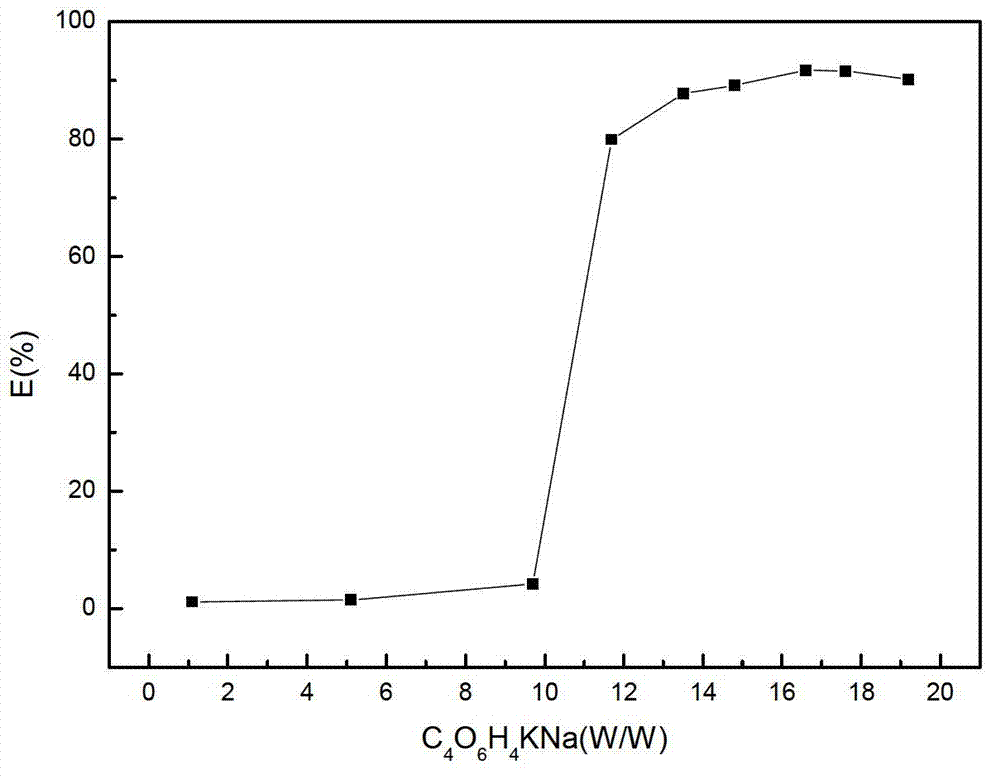

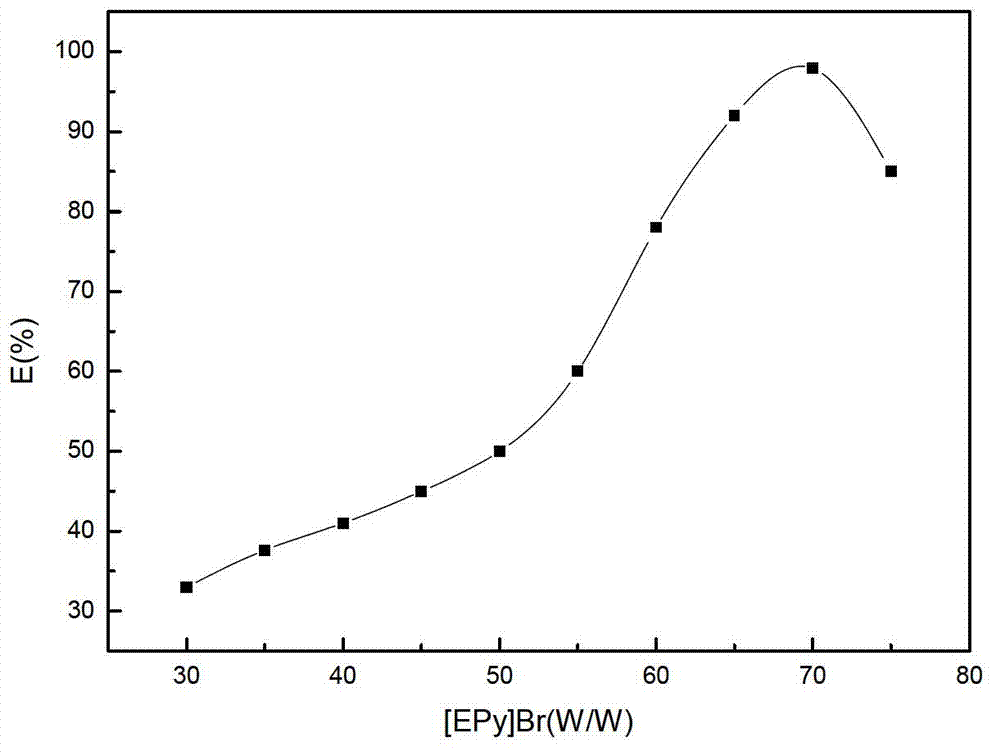

Method for separating and enriching trace phthalates by using pyridine type ionic liquid aqueous two-phase system

InactiveCN103245550AOvercome emulsificationOvercome timePreparing sample for investigationPotassium sodium tartrateSodium potassium tartrate

The invention discloses a new method for separating and enriching trace phthalates in the environment by using a pyridine type ionic liquid aqueous two-phase system. The method comprises the following steps of: evenly mixing 39-49 g of brominated N-ethylpyridine ionic liquid with 7.96-10.89 g of sodium potassium tartrate salt, thereby obtaining an aqueous two-phase extraction system; adding the aqueous two-phase extraction system to 2 ml of to-be-tested dibutyl phthalate aqueous solution, and then carrying out oscillating extraction once to three times in a constant-temperature oscillator under the conditions of a temperature in the range from 15 to 25 DEG C and a pH value in the range from 5.0 to 5.9, wherein the time of extraction each time is 2.5-3 hours; and then standing for phase separation after extraction. The extraction rate of the method for dibutyl phthalate is capable of reaching 98.9%. The method has the characteristics of wide linear range, low detection limit, low relative standard deviation and high yield in sample measurement. Besides, the method is capable of meeting the state requirements for detection of residual phthalates, is quite simple to operate, and is suitable for quantitative analysis of trace and ultra-trace phthalates in the environment.

Owner:CHANGAN UNIV

High-strength automotive wire cable material

ActiveCN104045941AEliminate odorEasy to processPlastic/resin/waxes insulatorsCalcium silicatePhosphorous acid

The invention discloses a high-strength automotive wire cable material. The high-strength automotive wire cable material is prepared from the following components in parts by weight: 100 parts of SG3 type PVC (poly vinyl chloride) resin, 30 parts of rare earth calcium-zinc compound stabilizer, 3 parts of dioctyl terephthalate, 12 parts of nano calcium carbonate, 12 parts of commercial calcium-zinc stabilizer, 1.2 parts of polyethylene wax, 3 parts of ACR impact resistance modifier, 0.2 part of bisphenol A, 2 parts of nano barium sulfate and 0.6 part of silicone powder; the silicone powder is nanocrystalline silicon dioxide powder coated with silicone; the rare earth calcium-zinc compound stabilizer is prepared from 5 parts by weight of yttrium oxide, 1 part by weight of indium oxide, 15 parts by weight of tartaric acid, 3 parts by weight of sodium potassium tartrate, 32 parts by weight of calcium silicate, 38 parts by weight of zinc stearate, 2 parts by weight of phosphorous acid and 10 parts by weight of silicone powder. Heat-resistant grade of the PVC cable material is 105 DEG C, the cable material still has good processability under high-speed processing condition, and the obtained cable has excellent abrasion resistance performance.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Preparation method of iron tetroxide-carbon nanotube lithium battery negative electrode material

InactiveCN109119625AOvercome the disadvantage of poor conductivityImprove lithium battery performanceMaterial nanotechnologySecondary cellsCarbon nanotubeSodium potassium tartrate

The invention discloses a preparation method of an iron tetroxide-carbon nanotube lithium battery negative electrode material, and the preparation method comprises the following steps: 1. dispersing apurchased carbon nanotube in concentrated nitric acid (65%-68% by mass), carrying out high-temperature acid treatment, and cleaning and drying for standby; 2, dispersing the acid-treated carbon nanotubes into deionize water; 3, adding ferric chloride hexahydrate, urea and polyvinylpyrrolidone into the mixed solution obtain in the step 2, adding sodium potassium tartrate as a reducing agent, and fully stirring and dissolving; and 4, pouring the mixed liquid obtain in the step 3 into a stainless steel reaction kettle lined with polytetrafluoroethylene, sealing and heating, washing and drying toobtain a nano composite material. The metal oxide nanomaterial is bonded to the surface of a carbon material with a large specific surface area. The structural stability of the carbon material can withstand the stress caused by volume change and the shortcomings of poor conductivity of nano-metal oxide active materials are overcome, so that the composite material has excellent lithium electricalproperties.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Fertilizer special for iodine-rich crops and preparation method of fertilizer

The invention discloses a fertilizer special for iodine-rich crops. The fertilizer is prepared from the following raw materials in parts by weight: 34-42 parts of slaked lime, 20-30 parts of rapeseed cake powder, 12-18 parts of peanut cake powder, 10-13 parts of canal mud, 8-10 parts of nori powder, 6-8 parts of ammonium bicarbonate, 6-8 parts of kelp powder, 6-8 parts of sodium potassium tartrate, 4-5 parts of citric acid, 3-6 parts of zinc sulfate powder, 3-4 parts of copper sulfate powder, 4-6 parts of sodium tripolyphosphate, 5-6 parts of zinc sulfate, 3-4 parts of EM agent, 4-5 parts of soil modifier and a proper amount of water. The fertilizer disclosed by the invention not only contains various nutrient elements essential for ordinary crops, but also is rich in iodine, so that iodine-rich crops can be high in quality and yield; meanwhile, the fertilizer is relatively low in preparation cost, good in product quality, small in operation labor, free of environment pollution, capable of improving the water-retaining fertilization capability, has a function as a soil improver and is applicable to large-scale popularization and application; the method is simple and easy to operate.

Owner:内蒙古森农生物科技有限公司

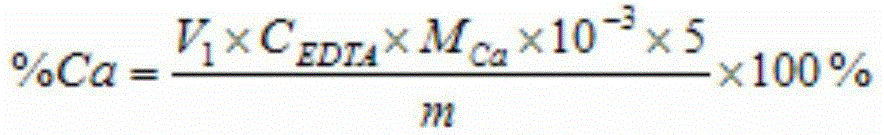

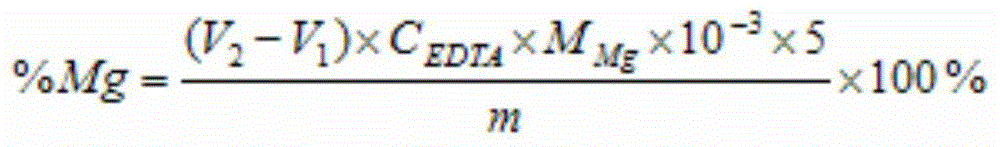

Method for rapidly analyzing calcium and magnesium in iron ore

InactiveCN106841511AGuaranteed constant volumeSimple methodChemical analysis using titrationCysteine thiolateIronstone

The invention discloses a method for rapidly analyzing calcium and magnesium in iron ore. The method comprises the following steps: (1) weighing an iron ore sample, wetting with water, adding concentrated hydrochloric acid, concentrated nitric acid, hydrofluoric acid and concentrated sulfuric acid, heating for decomposing the sample, heating for evaporating till white smoke nearly disappears, cooling, adding hydrochloric acid, heating till a solid is completely dissolved, taking down, cooling, transferring to a volumetric flask, and supplementing to a constant volume with water; (2) moving a solution with the constant volume to a glass beaker, diluting to a certain volume with water, adding sodium potassium tartrate, L-cysteine, a potassium hydroxide solution and a mixture of a calcium reagent and potassium sulfate, titrating with an EDTA standard solution to an end point, and calculating the content of the obtained calcium; (3) moving the solution with the constant volume to the glass beaker, diluting with water, adding the sodium potassium tartrate, the L-cysteine, an ammonia water-ammonium chloride buffer solution and neolan blue K-naphthol green B, and titrating with the EDTA standard solution to an end point; (4) calculating the content of the obtained magnesium by a subtraction method. The method is simple, convenient, fast and easy to master, and has relatively good practicality.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

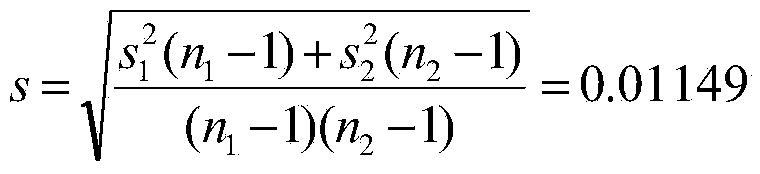

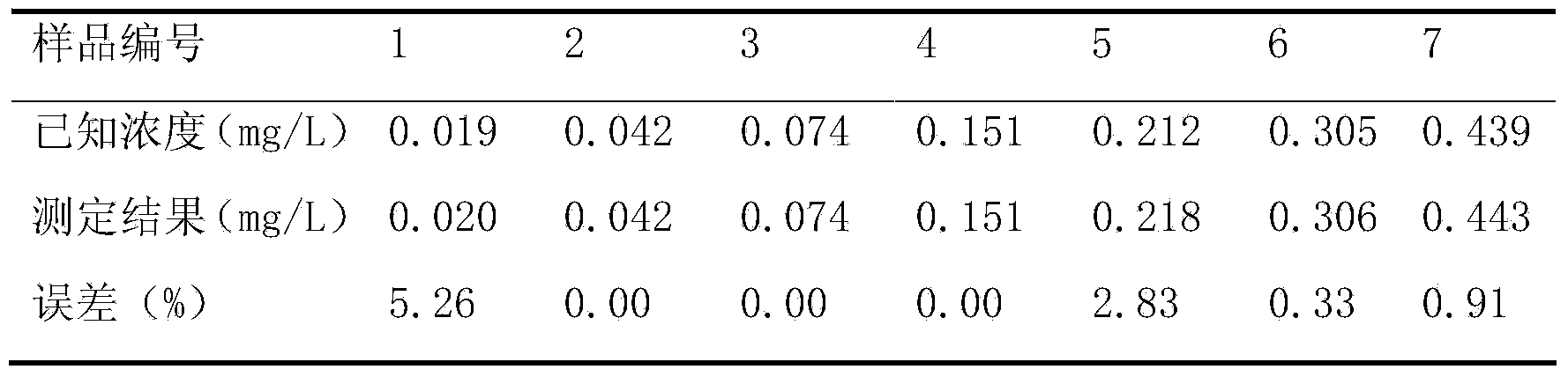

Method for measuring ammonia nitrogen in seawater

InactiveCN104076032AEasy to operateShort timeMaterial analysis by observing effect on chemical indicatorPolyvinyl alcoholColloid

The invention discloses a method for measuring ammonia nitrogen in seawater, and belongs to the technical field of detection. The method comprises the steps of A, extracting a seawater sample from a sea area to be detected; B, removing interference impurities from the seawater through sodium potassium tartrate and polyvinyl alcohol together, covering calcium and magnesium ions in the seawater through a sodium potassium tartrate solution, enabling the water sample to be in a clarified state through a colloid protection effect of the polyvinyl alcohol (PVA), and directly measuring the ammonia nitrogen in the seawater through a Nessler's reagent method; C, adding a developing agent for different time periods, measuring an absorbency value of the developing agent, and determining the optima developing time according to the change of the absorbency value along with the time; D, implementing a method for quickly measuring the ammonia nitrogen in a polluted seawater system through the conventional Skalar san++ flow injection analyzer serving as a support based on the principle of a Nessler's reagent colorimetric method.

Owner:ZHEJIANG OCEAN UNIV

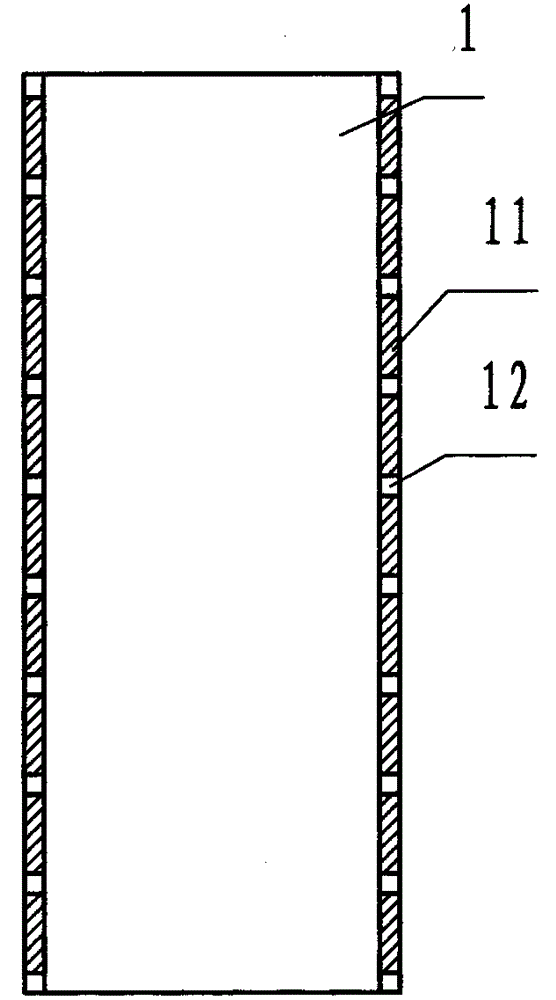

Preparation method for electromagnetic shielding silicone rubber

The invention provides a preparation method for electromagnetic shielding silicone rubber. The preparation method comprises the following steps: an ethylenediamine tetraacetic acid disodium solution is mixed with a sodium potassium tartrate solution so as to obtain a first mixed solution; a solution containing divalent nickel ions is mixed with the first mixed solution so as to obtain a second mixed solution; the second mixed solution is mixed with a hydrazine solution as to obtain a third mixed solution; copper powder is mixed with the third mixed solution so as to obtain nickel-plated copper powder; banburying and vulcanization are sequentially performed on crude silicone rubber, a vulcanizing agent and the nickel-plated copper powder, so that the electromagnetic shielding silicone rubber is obtained. According to the electromagnetic shielding silicone rubber prepared through the preparation method, the silicone rubber is filled with the nickel-plated copper powder, since the nickel-plated copper powder has good electrical conductivity and migration resistance and nickel has good magnetic conductivity, the prepared electromagnetic shielding silicone rubber has the electrical conductivity and magnetic conductivity at the same time. Therefore, the electromagnetic shielding effect is good.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Biological organic slow release fertilizer and preparing method thereof

InactiveCN106220313AFertilizer effect time is longImprove water holding capacityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiseasePolyvinyl alcohol

The invention discloses a biological organic slow release fertilizer and a preparing method thereof. The fertilizer is prepared from, by weight, 35-45 parts of calcium magnesium phosphate fertilizer, 20-25 parts of potash fertilizer, 6-12 parts of sodium potassium tartrate, 15-20 parts of glutinous rice flour, 3-4 parts of citric acid, 2-4 parts of polyvinyl alcohol, 15-20 parts of coal gangue, 15-20 parts of decomposed coal, 12-15 parts of medical stone, 8-12 parts of spent mushroom compost, 2-4 parts of carboxymethylcellulose, 4-6 parts of konjac glucomannan, 1-2 parts of sodium selenite, 0.5-1.5 parts of diammonium phosphate, 2-4 parts of ferrous sulfate, 0.5-1.0 part of potassium sulphate, 4-6 parts of germanium oxide and 6-8 parts of xanthan gum. The slow release fertilizer can meet the nutrient requirement of plants in the whole growth period, has long effective period and high water holding capacity, contains nitrogen, phosphorus, potassium and multiplex trace elements, and can achieve nutrient balance. Furthermore, soil loosening can be achieved, soil fertility can be improved, the utilization rate of the fertilizer can be increased, and disease resistance and drought resistance of crops can be improved.

Owner:赵浩

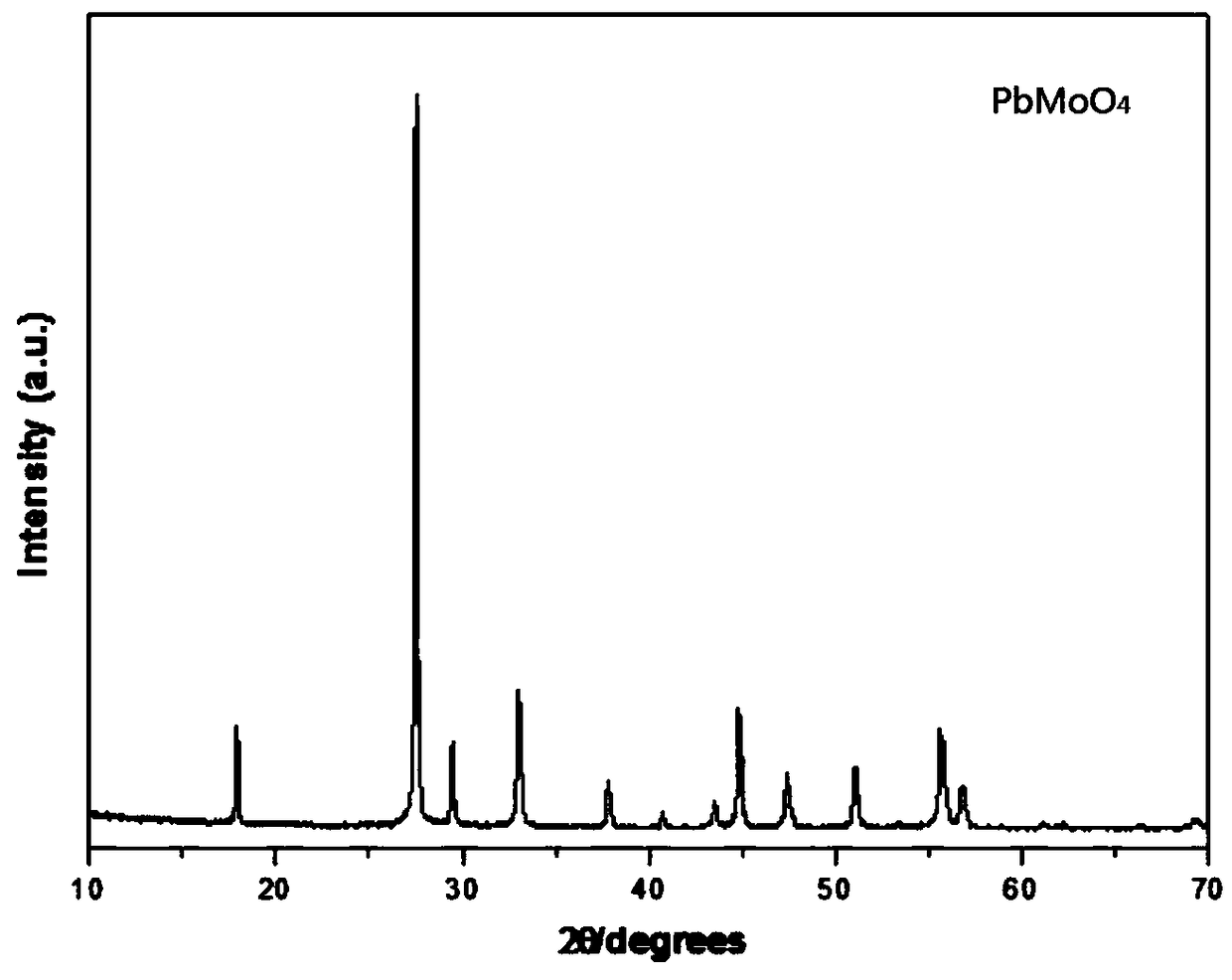

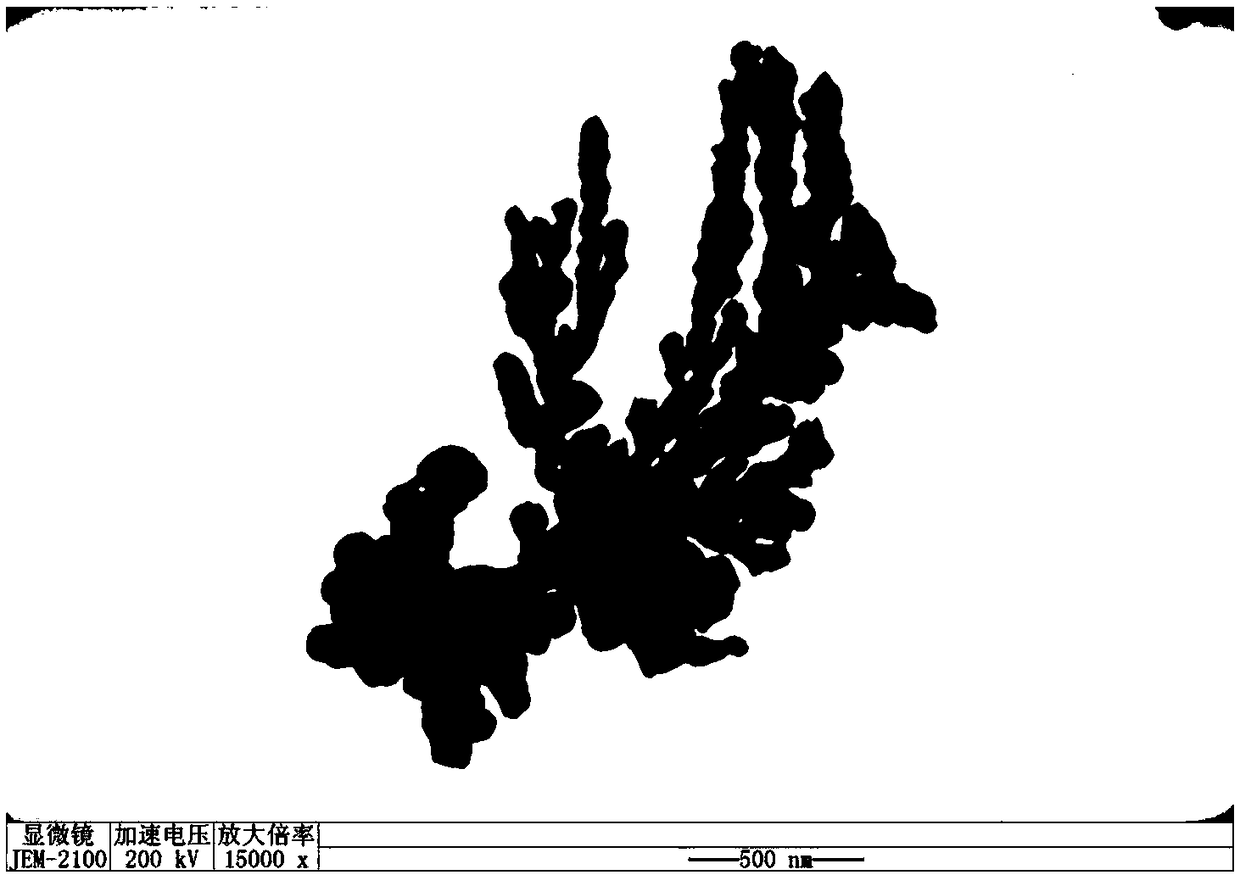

Preparation method of lead molybdate dendritic crystal

ActiveCN109231270AHigh crystallinityShape is easy to controlMolybdeum compoundsLead nitrateAcousto-optics

The invention discloses a preparation method of lead molybdate dendritic crystal. Firstly a sodium molybdate solution, a lead nitrate solution, a sodium potassium tartrate solution, a polyvinylpyrrolidone solution are prepared, and then the lead nitrate solution is mixed with the sodium potassium tartrate solution to obtain a lead tartrate precipitation solution, the sodium molybdate solution is mixed with the polyvinylpyrrolidone solution, the lead tartrate precipitation solution is mixed with a mixed solution of sodium molybdate and polyvinylpyrrolidone, then water is evaporated, an obtainedprecursor is placed in a corundum crucible, and microwave reaction is performed for 10 to 30 minutes to obtain the lead molybdate dendritic crystal. The preparation method of the lead molybdate dendritic crystal, provided by the invention, has the advantages of controllable morphology, simple process, low cost and the like, industrial production is easy to realize, and the obtained lead molybdatedendritic crystal has very good application prospects in the fields such as optical fiber, luminescent materials, acousto-optic devices and photocatalysts.

Owner:LUOYANG INST OF SCI & TECH

Culture soil for Chinese herbaceous peony and preparation method of culture soil

The invention relates to culture soil for Chinese herbaceous peony. The culture soil is composed of the following components in parts by weight according to a formula: 130-250 parts of sludge, 80-90 parts of yellow phosphorus furnace slag, 30-40 parts of blue algae, 20-45 parts of argy wormwoods, 16-36 parts of mulberry leaves, 15-25 parts of peach leaves, 20-40 parts of fishbone meal, 20-30 parts of egg shells, 18-28 parts of locusts, 16-18 parts of glycine, 7-17 parts of glutamic acid, 38-58 parts of pigsty manure, 20-25 parts of quick lime, 12-24 parts of carboxymethyl cellulose, 8-14 parts of nanometer rock phosphate powder, 8-20 parts of potassium sulfate, 13-26 parts of urea, 8-16 parts of sodium potassium tartrate and 5-10 parts of bacillus subtilis.

Owner:合肥科友生物科技有限公司

Manufacturing method of paraffin-control anti-scale anticorrosion alloy suction aid

InactiveCN105298402AIncrease contact areaSave work timeDrilling rodsCleaning apparatusMaterials scienceSodium hydroxide

The invention discloses a manufacturing method of a paraffin-control anti-scale anticorrosion alloy suction aid. The method includes: making steel J55 or N80 into the suction aid, making nitrates or sulfates or chlorides of silver, copper, zinc, tin, nickel, iron, manganese and rare-earth into an electroplating liquid I, preparing an electroplating liquid II by using sodium potassium tartrate as a complex, adjusting pH of the electroplating liquid II to 12-13.5 by using sodium hydroxide to obtain an electroplating liquid III, electroplating the suction aid in the electroplating liquid III by using metallic titanium or graphite as a positive electrode and the suction aid as a negative electrode, and performing thermal treatment at 300-600 DEG C to obtain the finished paraffin-control anti-scale anticorrosion alloy suction aid. The aid is capable of degrading paraffin, colloid and asphaltene in crude oil, preventing the precipitation and condensation of sulfates or carbonates of calcium, magnesium, barium and strontium, and preventing paraffin jamming and scale jamming on the wall of a suction pump, a sucker rod or a suction pipe.

Owner:关良玉

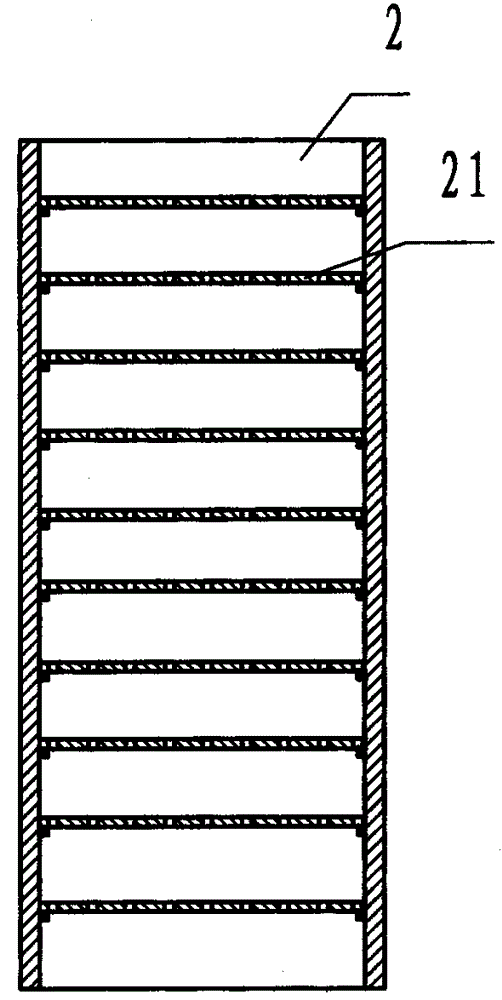

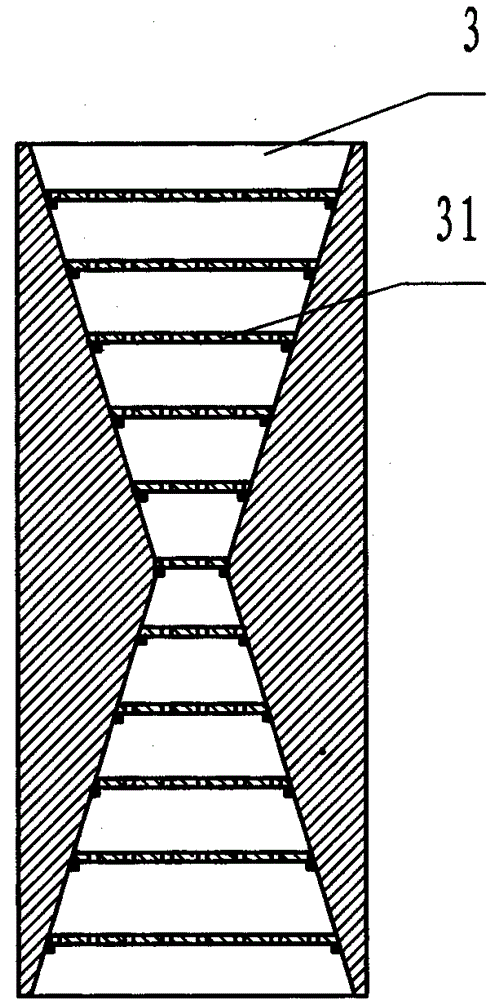

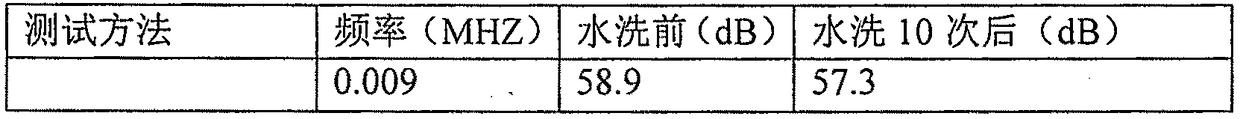

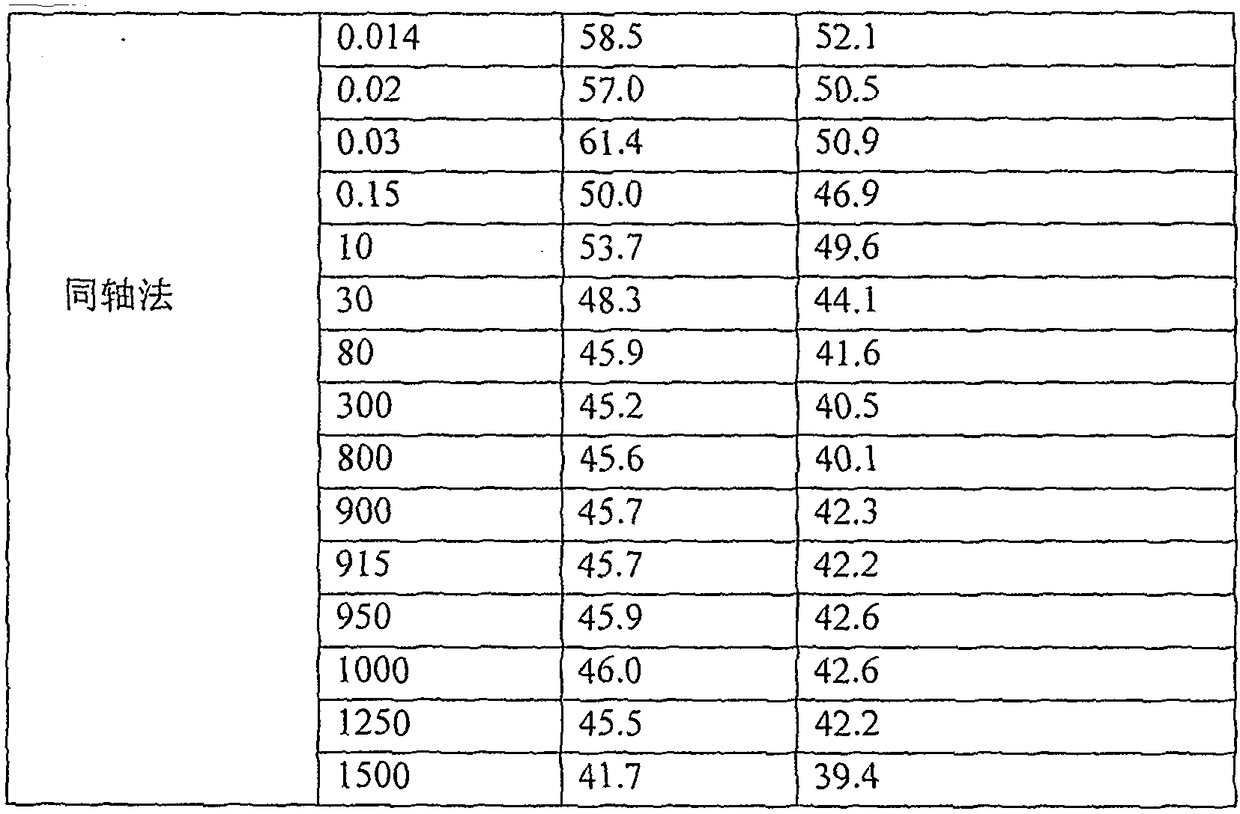

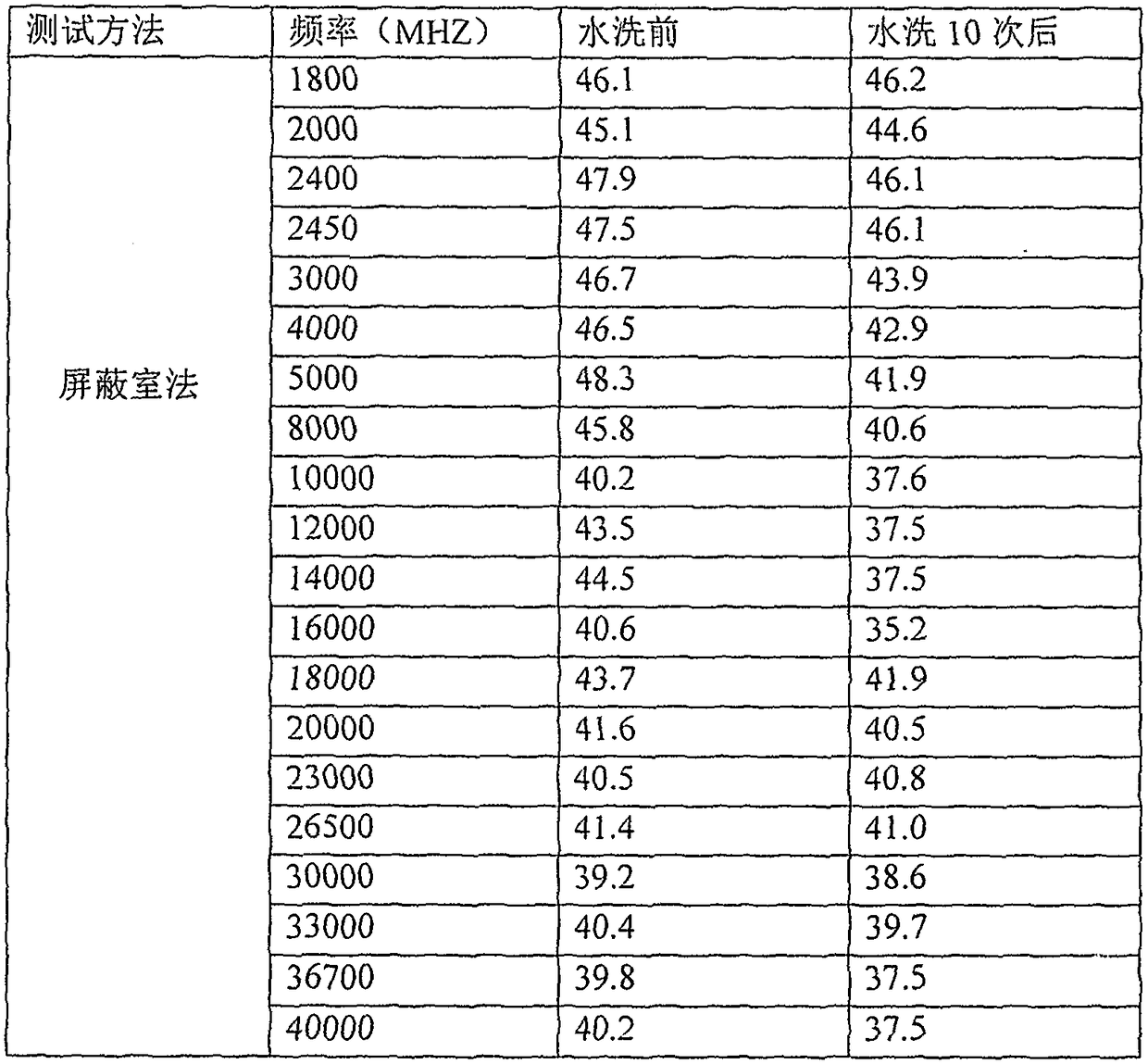

Production method of washable electromagnetic shielding fabric

InactiveCN108625157AImprove electromagnetic shielding performanceReduced electromagnetic shielding effectivenessFibre typesWater basedYarn

The invention provides a production method of washable electromagnetic shielding fabric. The production method comprises the following steps: (1), adding copper sulfate and a silver nitrate solution into water, then adding JFC and a dye-retarding agent, uniformly mixing, and adding sulfuric acid to adjust the PH value; (2), adding acrylic yarn or acrylic fabric into a prepared chemical reaction bath, adding a sodium thiosulfate solution, sodium sulfite and a sodium potassium tartrate solution, running in a container for 30min, then raising the temperature according to a temperature raising curve, preserving heat at 100 DEG C for 60min, reducing the temperature to 60 DEG C according to a temperature reducing rate of 1 DEG C / min, washing by using warm water, dewatering and drying; (3), coating the dried conductive acrylic yarn with graphene-based water-based electromagnetic shielding coating and weaving to obtain the washable electromagnetic shielding fabric, and coating the dried conductive acrylic fabric with the graphene-based water-based electromagnetic shielding coating. The shielding effectiveness of the washable electromagnetic shielding fabric produced by the production method provided by the invention can still meet using requirements after 10 times of washing.

Owner:合肥爱家防辐射科技有限公司

Glass cleaning agent

InactiveCN104212652ANo smellNot corrosiveNon-ionic surface-active compoundsAnionic-cationic-non-ionic surface-active compoundsPolyphosphatePotassium

The invention discloses a glass cleaning agent which is prepared from the following components in parts by mass: 0.5-1 part of a fluorocarbon surfactant, 10-20 parts of an anionic surfactant, 5-10 parts of a nonionic surfactant, 1-3 parts of sodium potassium tartrate, 3-5 parts of sodium polyphosphate and 60-80 parts of deionized water, totaling 100 parts. The glass cleaning agent disclosed by the invention can exert a relatively strong cleaning and decontaminating effect with a relatively small dosage, so that the glass surface is bright and dustproof. The glass cleaning agent is simple in preparation method and easy to implement.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Low-slump-loss concrete pumping agent

The invention belongs to the technical field of concrete additives, and particularly relates to a low-slump concrete pumping agent, which is made of the following raw materials in parts by weight: 28-46 parts of calcium lignosulfonate, 10-22 parts of methyl cellulose, and potassium tartrate 10-16 parts of sodium, 5-11 parts of dodecyl betaine, 1-7 parts of hydroxyethylidene diphosphonic acid, and 1-7 parts of tributyl phosphate. The low-slump-loss concrete pumping agent of the invention has high slump-retaining properties, does not crystallize in normal use at 0°C or even lower temperatures, has strong adaptability to cement, adapts to different cement varieties, and has good fluidity.

Owner:张松波

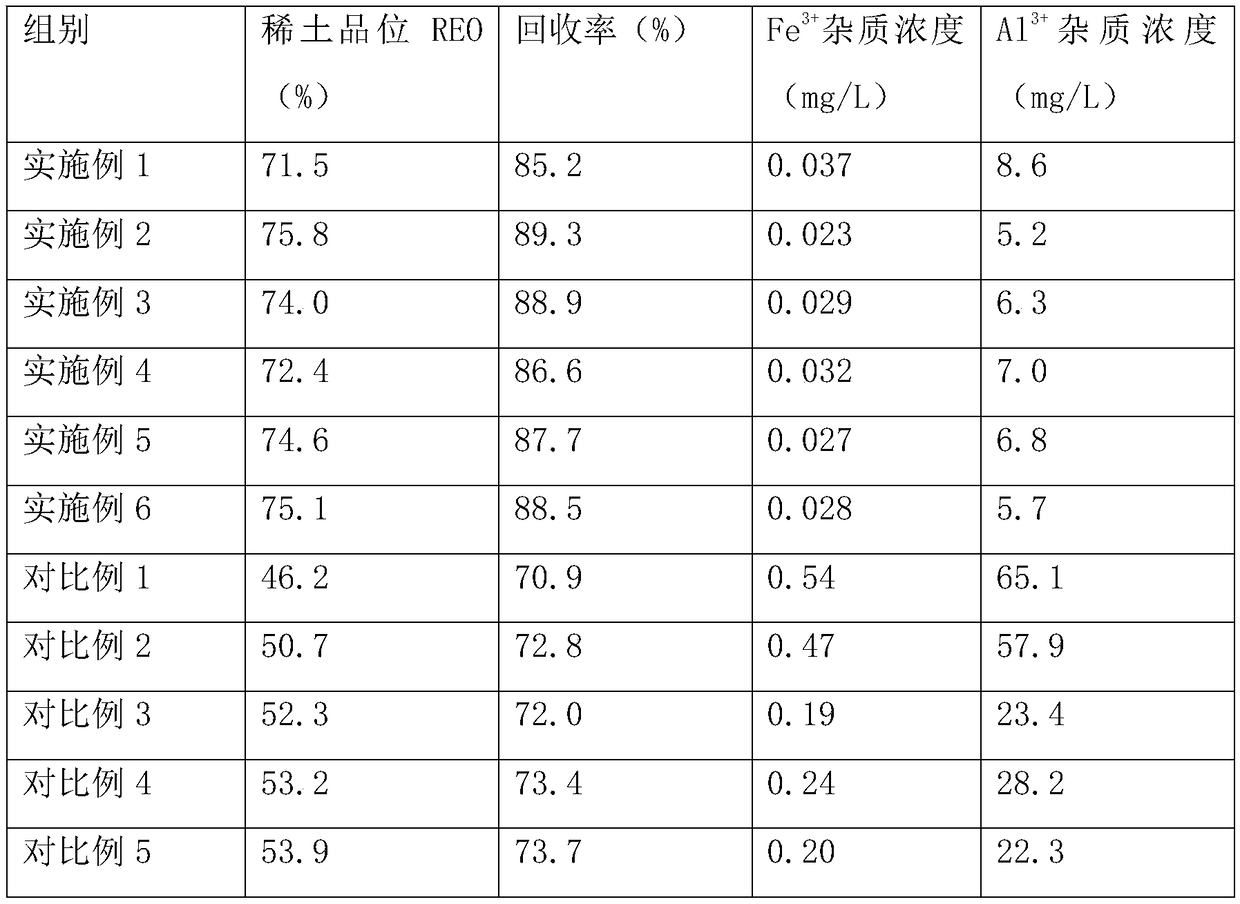

Rare-earth ore beneficiation method

ActiveCN109395887AGuarantee the effect of fine flotationHigh purityFlotationSodium-p-toluenesulfinateRare earth

The invention belongs to the technical field of rare-earth ore production, and provides a rare-earth ore beneficiation method. Three times rough flotation and three times fine flotation are adopted, NaOH, water glass and alkyl hydroximic acid used as a first collecting agent are added in the first rough flotation, on the basis of sodium hydroxide, a surfactant of sodium potassium tartrate, sodiump-toluenesulfonate and a sodium cocoyl methyl taurate mixture are added into a fifth collecting agent, on the basis of the sodium hydroxide, a non-ionic surfactant of dodecyl glucoside and a sodium dodecyl sulfate mixture are further added into a sixth collecting agent. By adopting the rare-earth ore beneficiation method, final concentrate of the rare-earth ore grade (REO) obtained is 70% or above, the recovery rate is 85% or above, the impurities are low, and the rare earth ore grade, the recovery rate and the purity are all high; and in addition, the method does not need complex equipment, and the feasibility is higher.

Owner:崔源发

High-activity chemical copper plating solution and chemical copper plating method

InactiveCN104561956AHigh activityGood bath stabilityLiquid/solution decomposition chemical coatingCopper platingBiological activation

The invention discloses a high-activity chemical copper plating solution and a chemical copper plating method. The high-activity chemical copper plating solution is characterized by mainly consisting of copper salt, a reducing agent, a complexant, a pH regulator and a combined additive, wherein the complexant is one or combination of several of ethylenediamine tetraacetic acid, sodium potassium tartrate, sodium citrate, N-(2-hydroxyethyl)ethylenediaminetriacetic acid, tetrahydroxypropyl ethylenediamine, triethanolamine and nitrilotriacetic acid; the combined additive is combination of N and / or S-containing additives. The high-activity chemical copper plating solution has the advantages of being high plating solution activity, low in operation temperature, good in stability and particularly suitable for the chemical copper plating of surfaces of nonmetal matrixes which are relatively weak in activation degree.

Owner:广东致卓环保科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com