Surface metallization treatment method for carbon fibers

A technology of surface metal and treatment method, applied in the field of carbon fiber surface metallization treatment, can solve the problems of high equipment requirements, complicated operation, harsh experimental conditions, etc., and achieve the effects of easy availability of raw materials, simple process route and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

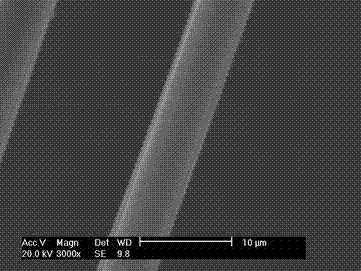

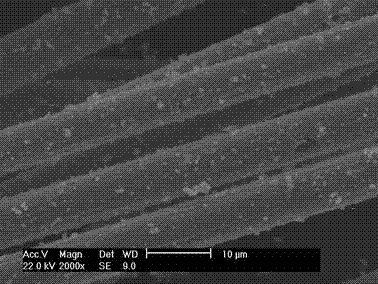

Image

Examples

Embodiment 1

[0044] Step 1, pre-processing

[0045] Step 1.1 Degumming on the surface: Burn the carbon fiber at a high temperature at 400°C for 40 minutes;

[0046] Step 1.2: Coarse treatment: immerse the degummed carbon fiber in a 20wt% nitric acid solution and boil it for 40 minutes;

[0047] Step 1.3 Sensitization treatment: immerse the roughened carbon fiber in a stannous chloride sensitizing solution for 5 min. The components of the stannous chloride sensitizing solution are stannous chloride, hydrochloric acid and tin. Dosage: chlorine Stannous: 15g / L, hydrochloric acid: 35g / L, tin: 5g / L;

[0048] Step 1.4 activation treatment: immerse the sensitized carbon fiber in a palladium chloride activation solution for 8 min. The palladium chloride activation solution is a mixture of palladium chloride and hydrochloric acid. The dosage is: palladium chloride: 0.3g / L, Hydrochloric acid: 30ml / L to obtain pretreated carbon fiber;

[0049] Step 2, pre-plating

[0050] The pre-plated carbon fiber obtained ...

Embodiment 2

[0055] Step 1, pre-processing

[0056] Step 1.1 Degumming on the surface: Burn the carbon fiber at a high temperature at 450°C for 30 minutes;

[0057] Step 1.2: Coarse treatment: immerse the degummed carbon fiber in a 25wt% nitric acid solution and boil it for 30 minutes;

[0058] Step 1.3 Sensitization treatment: immerse the roughened carbon fiber in a stannous chloride sensitizing solution for sensitization for 7 minutes. The components of the stannous chloride sensitizing solution are stannous chloride, hydrochloric acid and tin. Dosage: chlorinated Stannous: 20g / L, hydrochloric acid: 40g / L, tin: 3g / L;

[0059] Step 1.4 Activation treatment: immerse the sensitized carbon fiber in a palladium chloride activation solution for 5 min. The palladium chloride activation solution is a mixture of palladium chloride and hydrochloric acid. The dosage is: palladium chloride: 0.1g / L, Hydrochloric acid: 20ml / L, the pretreated carbon fiber is obtained;

[0060] Step 2, pre-plating

[0061] The p...

Embodiment 3

[0065] Step 1, pre-processing

[0066] Step 1.1 Degumming on the surface: Burn the carbon fiber at a high temperature at 500°C for 50 minutes;

[0067] Step 1.2: Coarse treatment: immerse the degummed carbon fiber in a 30wt% nitric acid solution and boil it for 50 minutes;

[0068] Step 1.3 Sensitization treatment: immerse the roughened carbon fiber in a stannous chloride sensitizing solution for sensitization for 6 min. The components of the stannous chloride sensitizing solution are stannous chloride, hydrochloric acid and tin. Dosage: chlorine Stannous: 10g / L, hydrochloric acid: 30g / L, tin: 4g / L;

[0069] Step 1.4 activation treatment: immerse the sensitized carbon fiber in a palladium chloride activation solution for 8 min. The palladium chloride activation solution is a mixture of palladium chloride and hydrochloric acid. The dosage is: palladium chloride: 0.5g / L, Hydrochloric acid: 35ml / L to obtain pretreated carbon fiber;

[0070] Step 2, pre-plating

[0071] The pre-plated carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com