Patents

Literature

1786results about How to "Simple process route" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

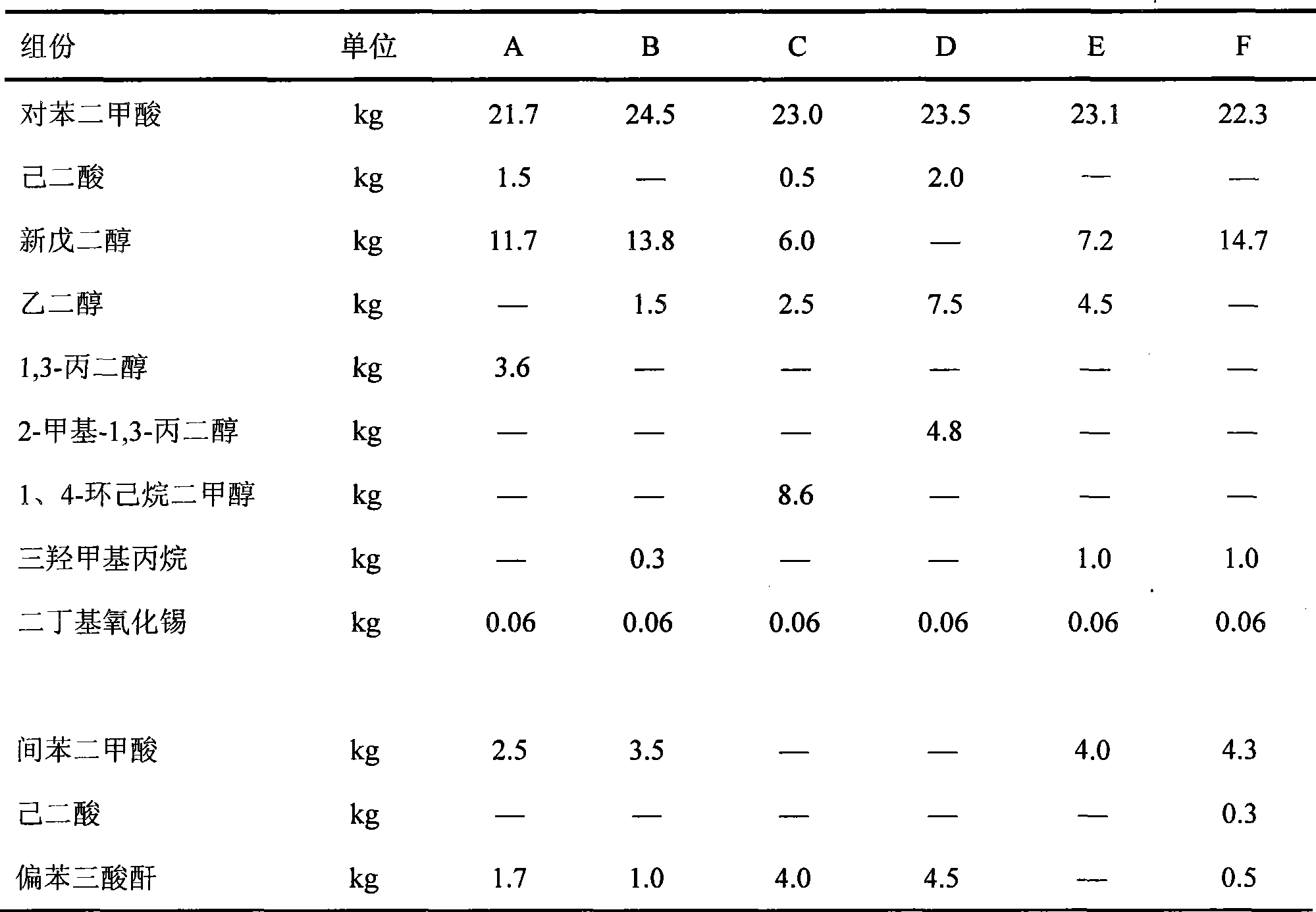

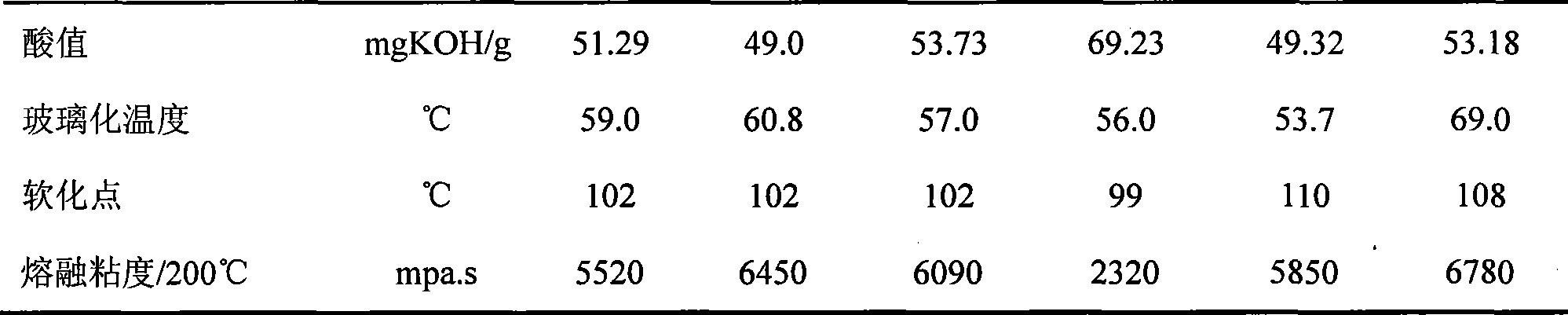

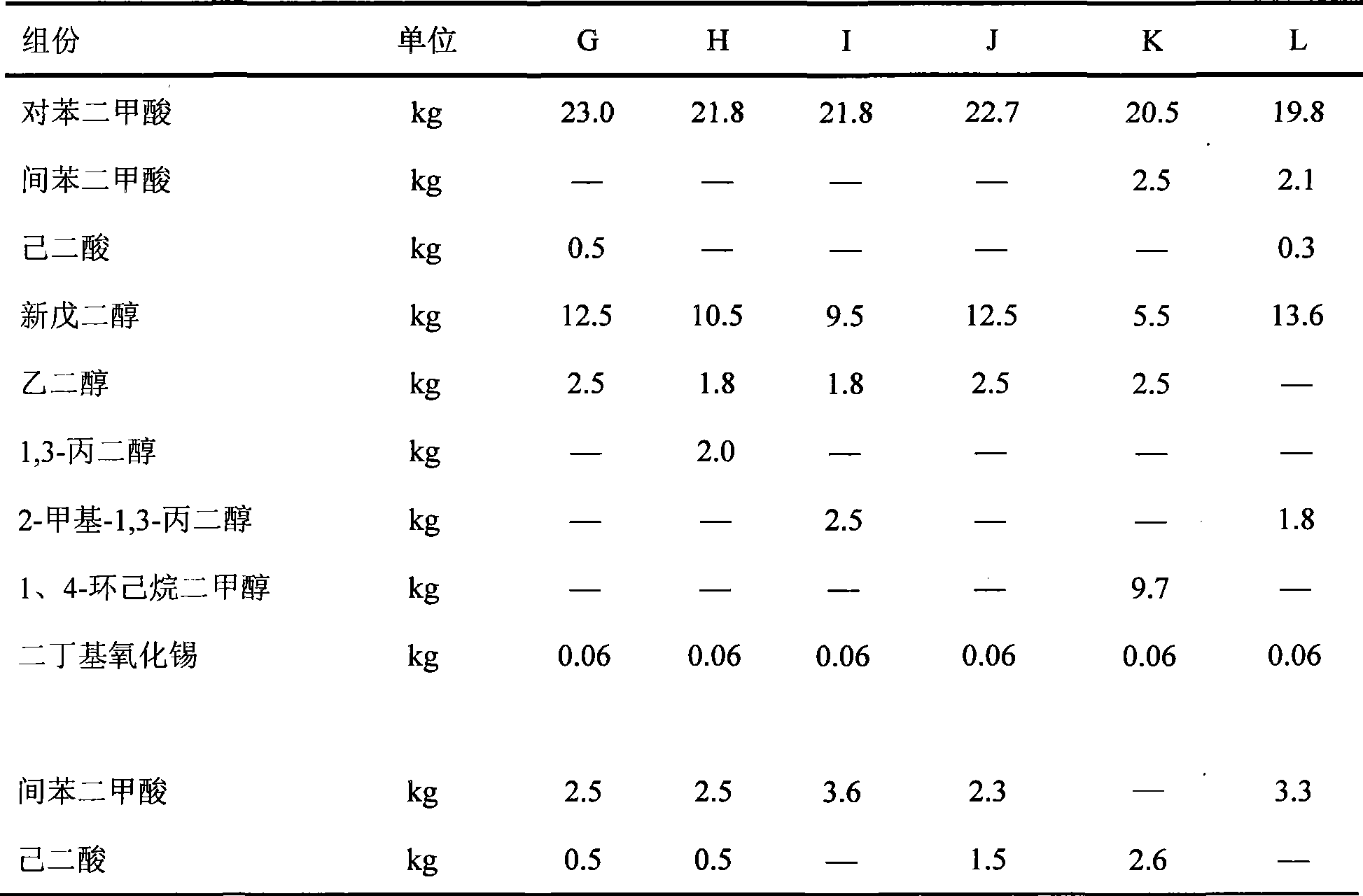

Polyester resin with high acid value and low acid value for environment-friendly dry blended low-gloss powder coating and preparation method thereof

InactiveCN101445591ASuitable glass transition temperatureHigh softening pointPowdery paintsPolyester coatingsPolyolAcid value

The invention discloses a polyester resin with a high acid value and a low acid value for an environment-friendly dry blended low-gloss weather-resistant powder coating. The polyester resin is made from the following raw materials by weight percentages by virtue of esterification and condensation reaction: 15%-60% of polyol, 30%-65% of polyacid, 0%-5% of a branching agent, 5%-15% of an acidolysis agent and 0.01%-0.15% of an esterification catalyst. The invention further discloses a preparation method of the polyester resin with the high acid value and the low acid value for the environment-friendly dry blended low-gloss weather-resistant powder coating. Thepolyester resin with the high acid value and the polyester resin with the low acid value have the characteristics of proper glass transition temperature, proper softening point and good storage stability. A powder coating made by curing beta-hydroxyalkyl amide with the polyester resin has the advantages of excellent deglossing effect and good mechanical properties.

Owner:GUANGZHOU QINGTIAN INDAL

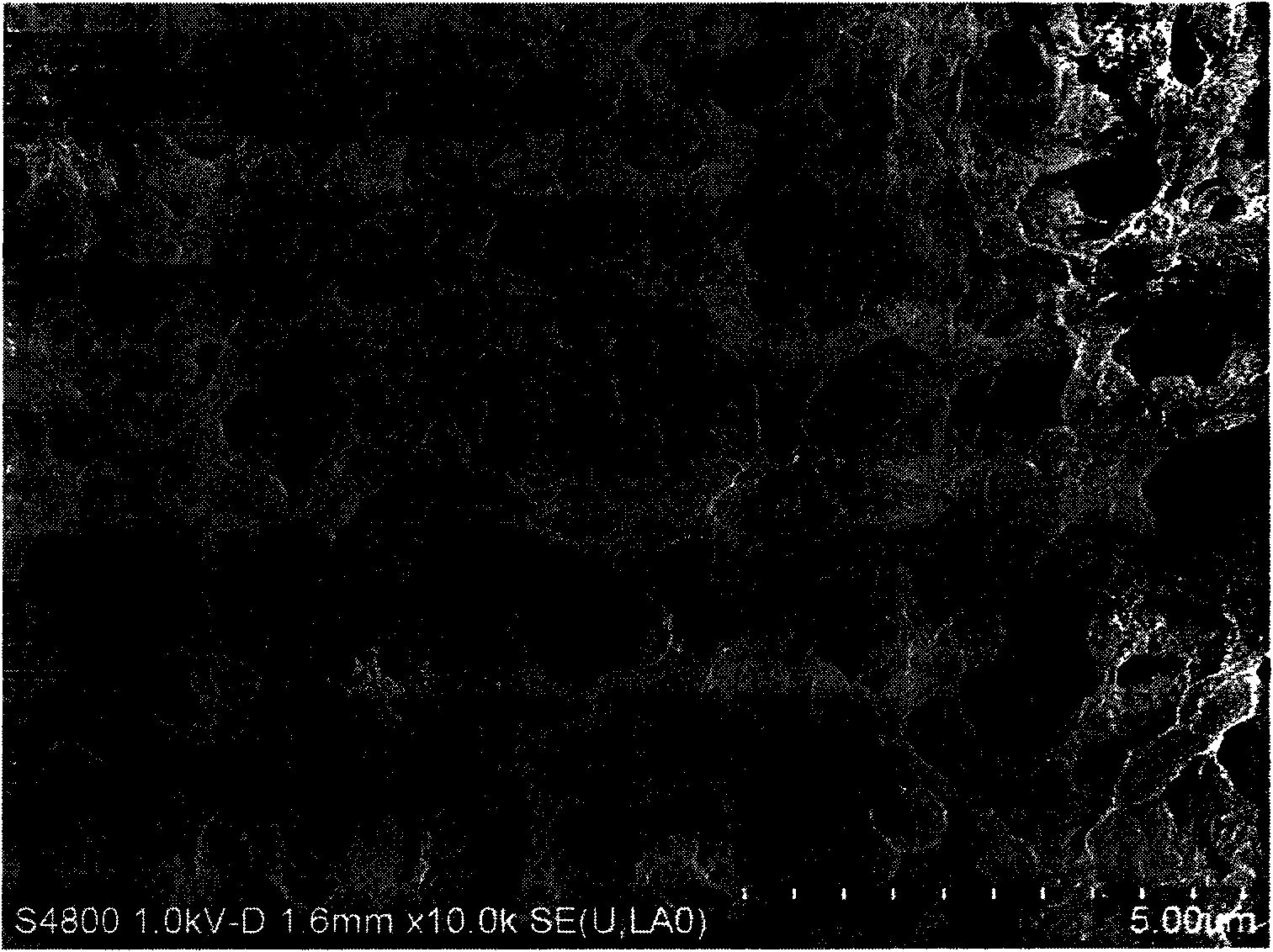

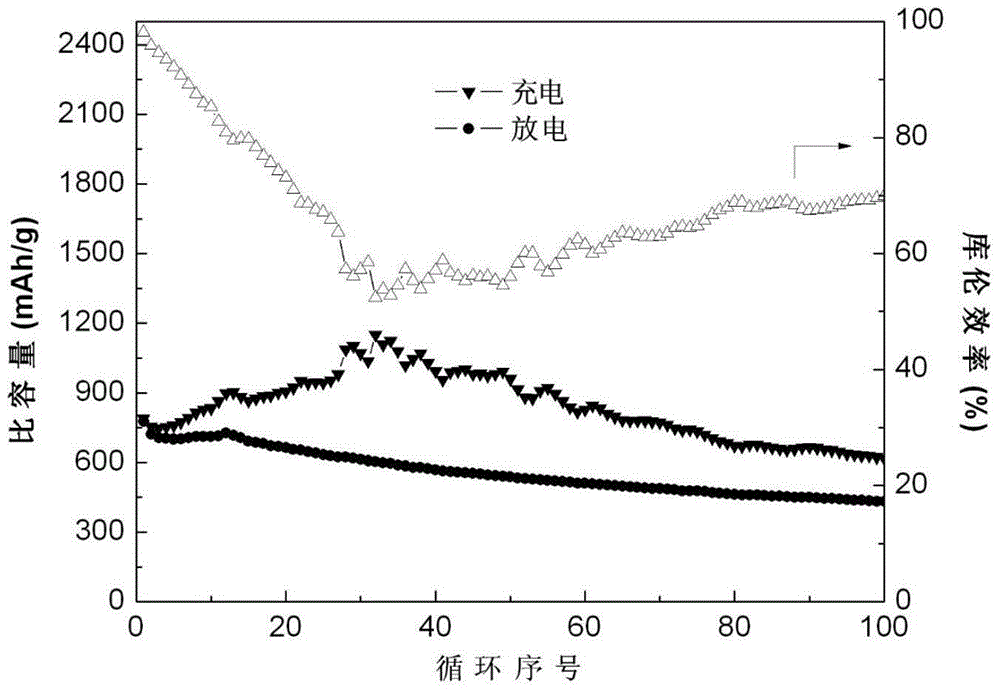

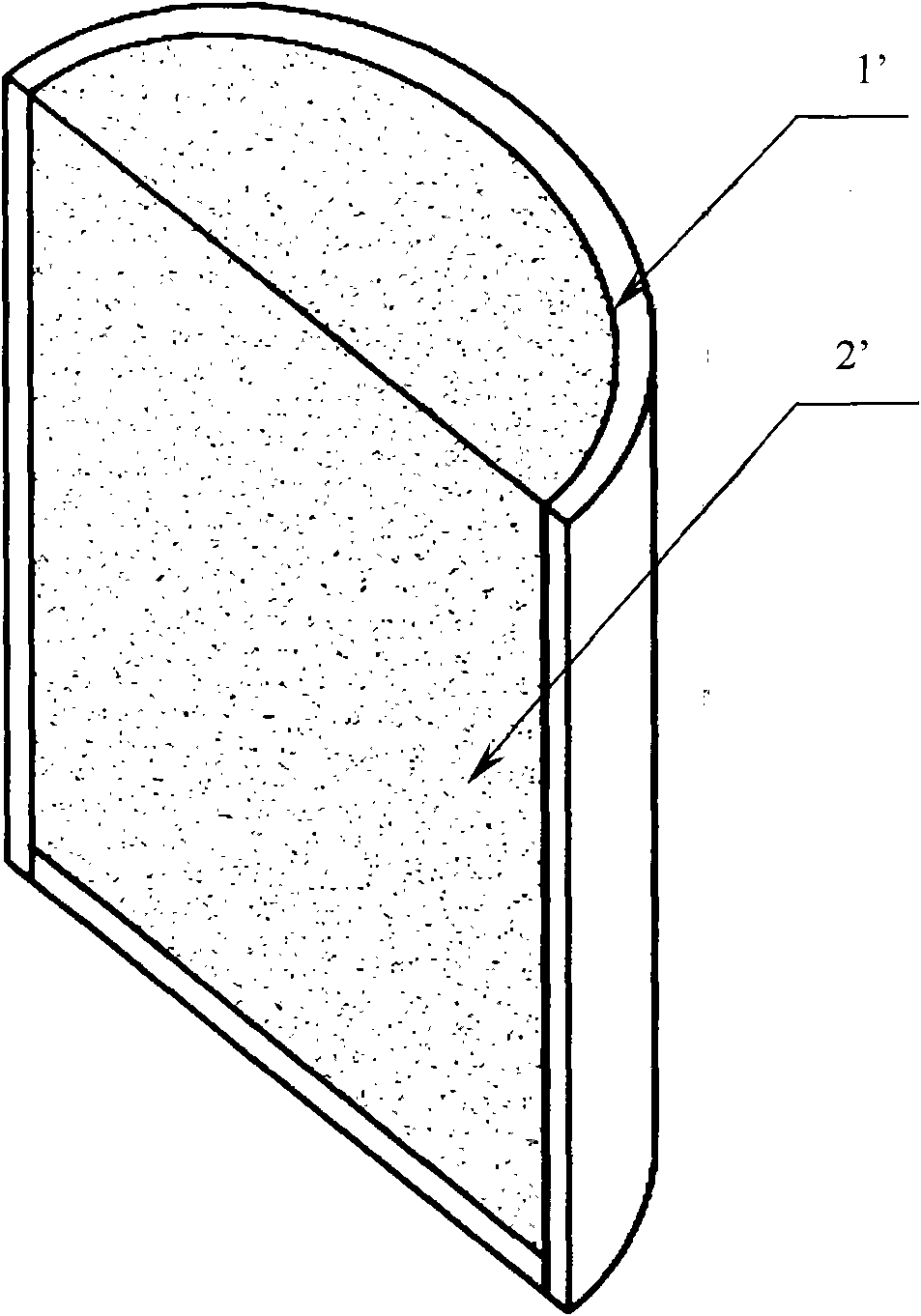

High-liquid absorbing rate micro-nano structure polymer electrolyte membrane and preparation method thereof

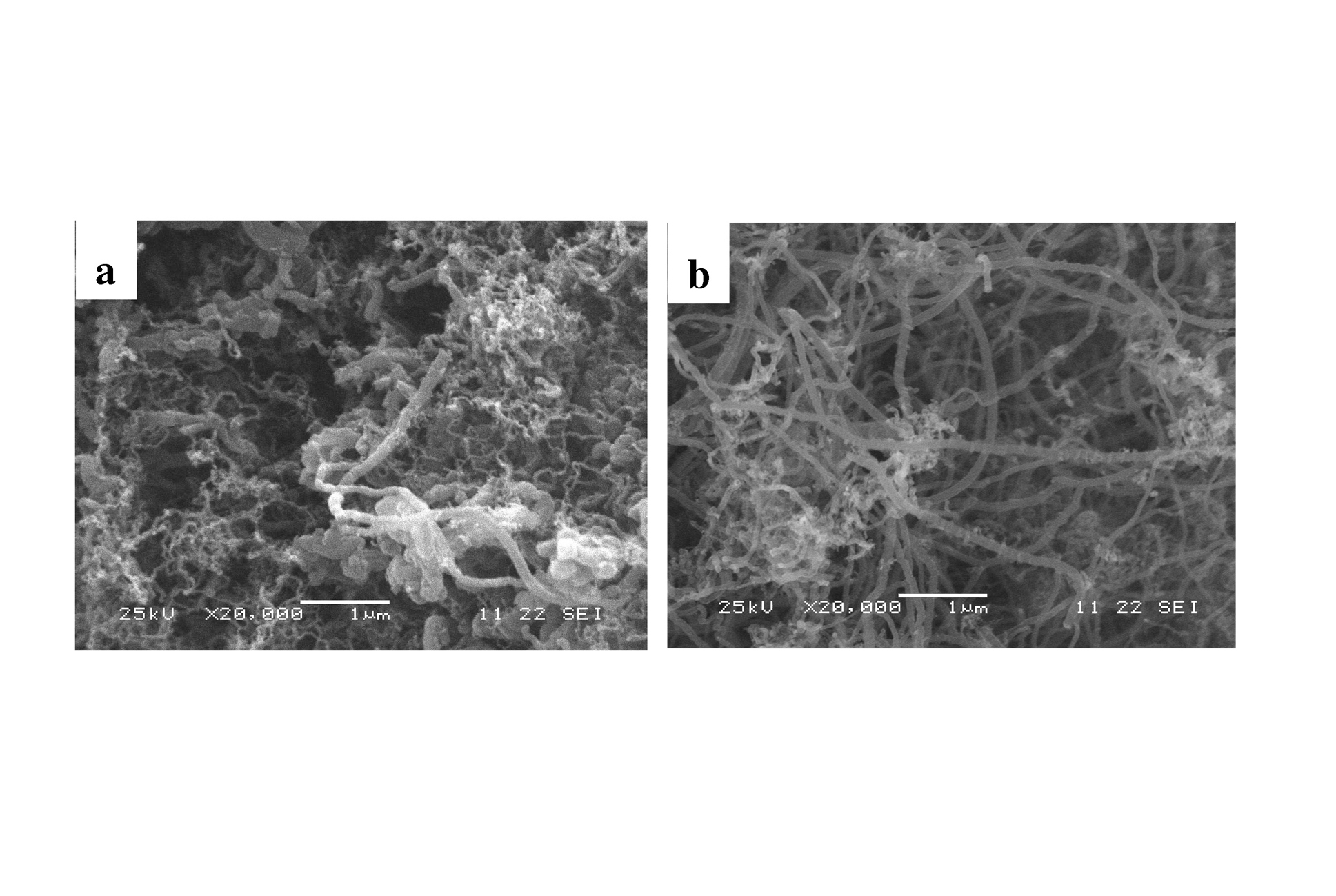

InactiveCN101626097AHigh liquid absorptionPromote absorptionSecondary cellsMicro nanoPolymer science

The invention discloses a preparation method of a high-liquid absorbing rate micro-nano structure polymer electrolyte membrane, wherein the membrane is prepared by polymer material being packed on a support frame. The method comprises the following steps of: by being processed, the polymer membrane has a micro-nano structure, forms holes with micron level and nanometer level, and forms a netty distribution hole structure with the nanometer holes of the support frame; and the polymer which is crossly linked layer by layer is packed on the special support frame to form a special netty micro-nano structure polymer electrolyte membrane. The polymer membrane of the micro-nano structure can absorb large numbers of electrolyte, greatly increase liquid-absorption rate, and improve the affinity of diaphragm to the electrolyte; the netty micro-nano structure leads the electrolyte to be kept in the membrane well, leads lithium ion in the polymer electrolyte membrane to be evenly distributed, leads the concentration to be to balanced, and lead the current density in the battery to be evenly when discharging electricity; and the special support frame guarantees the mechanical capability of the membrane. The preparation technology of the polymer electrolyte membrane has simple route and easily obtained raw material, can be operated under a normal condition, and does not need harsh production environment. The polymer lithium ion battery prepared by the membrane has good electrochemistry capability.

Owner:CHANGSHA HIGH TECH INDAL DEV ZONE CAISHENG NEW ENERGY TECH

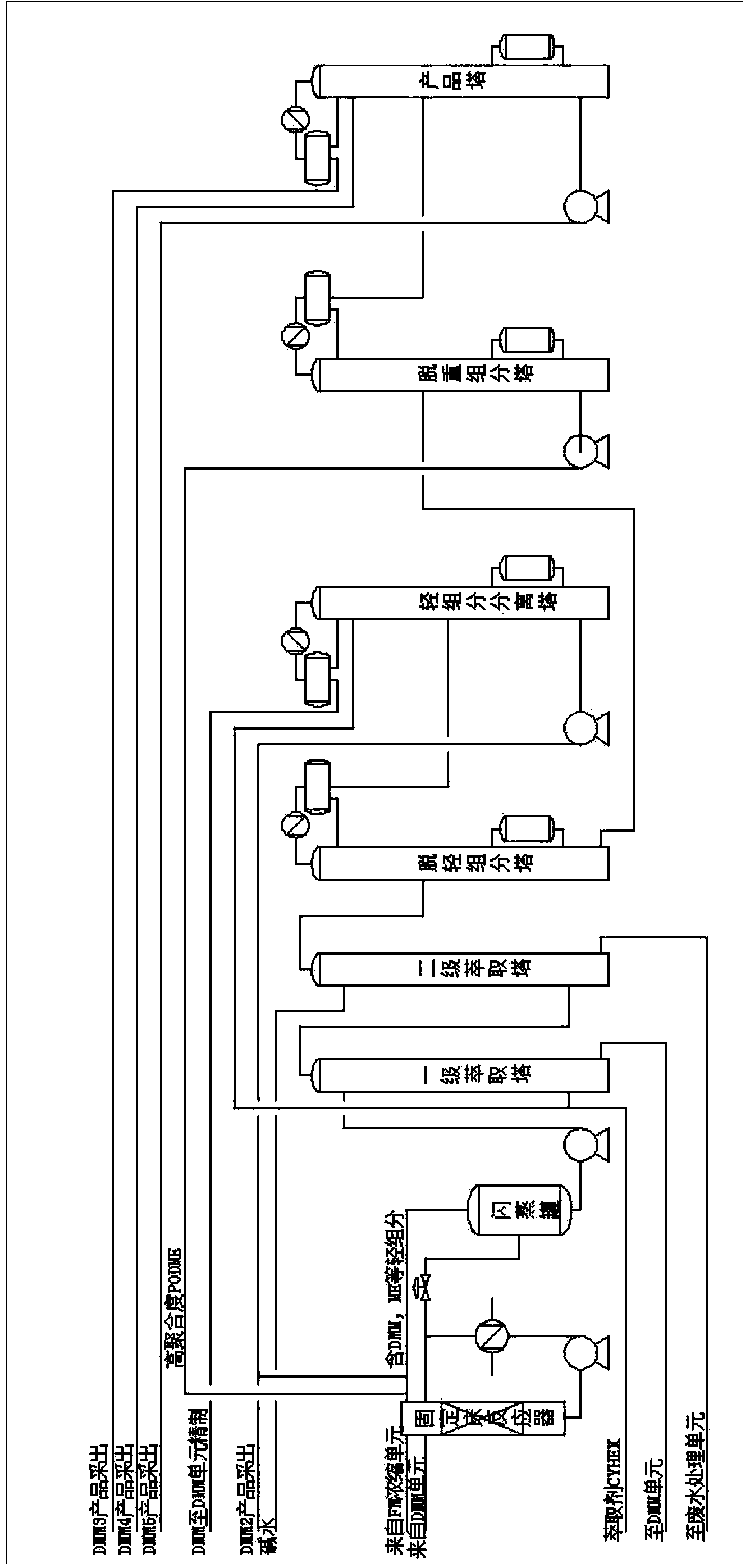

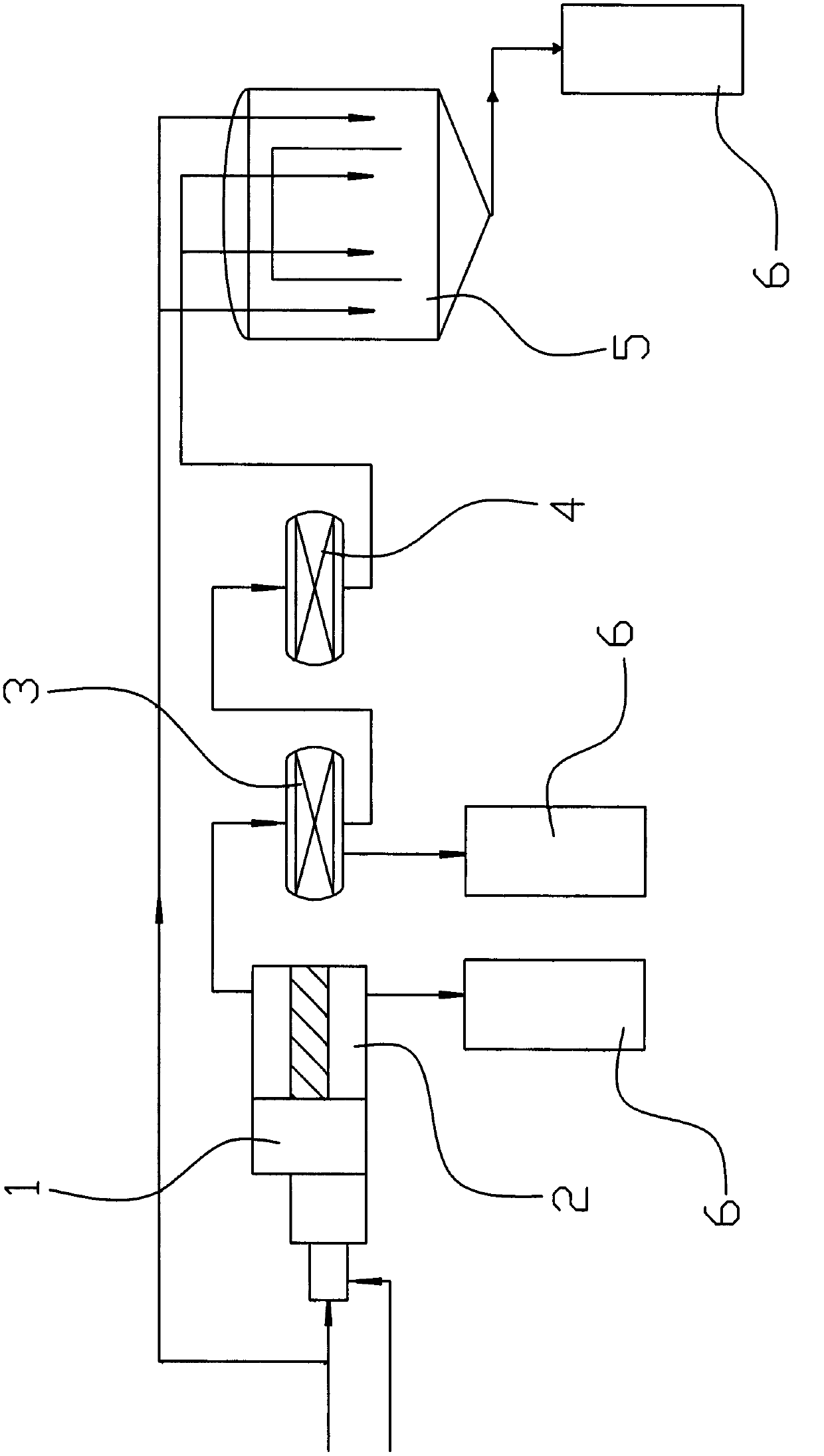

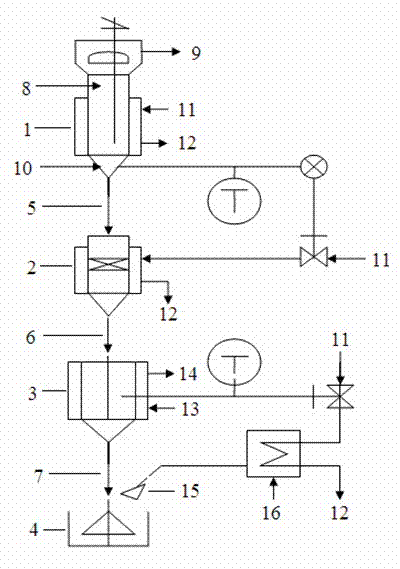

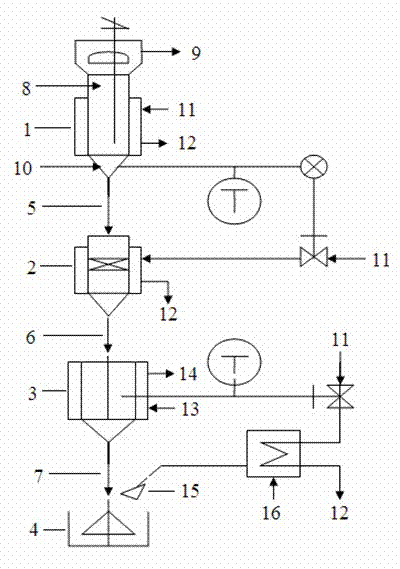

Process unit and method for preparing polymethoxy dimethyl ether

ActiveCN103626640AEasy to makeInexpensive to adoptOrganic chemistryOrganic compound preparationPtru catalystSolid acid

The invention discloses a process unit and method for preparing polymethoxy dimethyl ether. According to the method, cheaper and more accessible methylal formaldehyde are used as raw materials, and a solid acid resin with longer service life is used as a catalyst to synthesize the polymethoxy dimethyl ether. By using the cheaper and more accessible methylal formaldehyde are used as the raw materials, the complete process workshop and process route are simple; and the catalyst adopts the solid acid resin which has the advantages of low cost, simple preparation process and longer service life.

Owner:JIANGSU KAIMAO PETROCHEM TECH

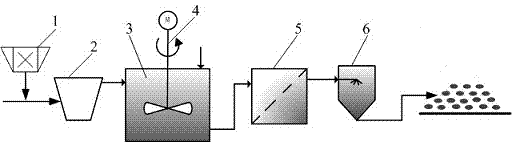

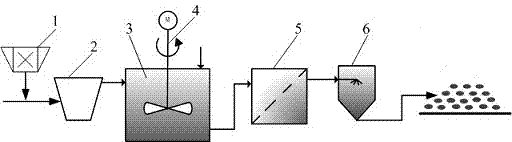

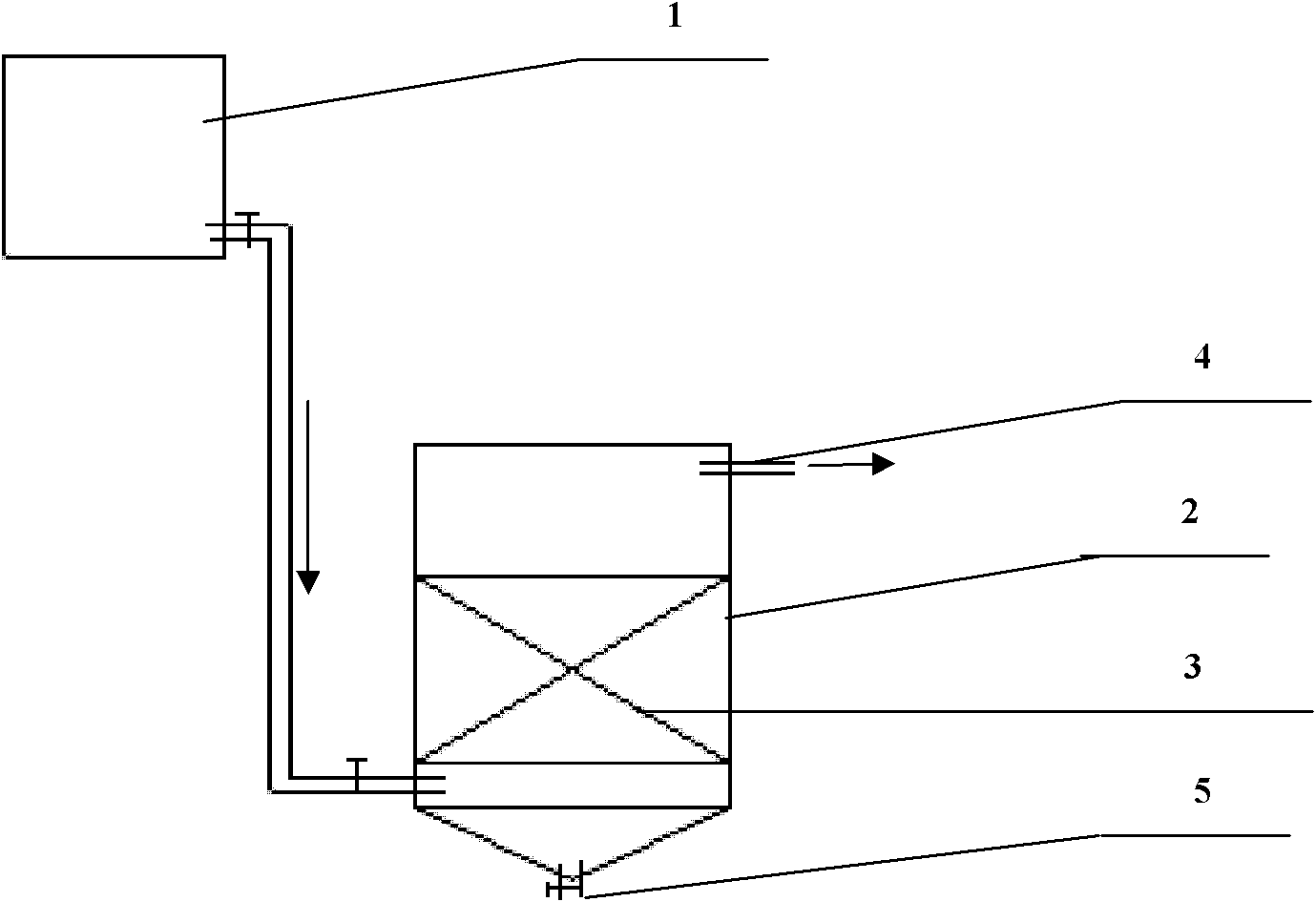

Method and device for preparing formed sludge fuel

InactiveCN102212403AImprove dehydration effectImplement resourcesSludge treatment by de-watering/drying/thickeningBiofuelsSludgeSolid fuel

The invention discloses a process method for preparing a derived solid fuel by using sludge, and the method comprises the following steps: feeding dehydrated wet sludge with the moisture content of 70-85% and biomass at a weight ratio of 50:(1-10) into a tempering kettle, introducing less water, evenly stirring, adding a tempering agent the mass of which is 0-20% of that of dried solid sludge, stirring for 2-10 minutes continuously, removing most of water by a dehydrator, forming, and naturally drying for 24 hours, thus obtaining the derived sludge solid fuel. The invention also discloses a device for preparing a formed sludge fuel. The device comprises a straw crusher, a feeder, the tempering kettle, the stirrer, the fuel hydrator and a fuel forming machine, wherein the stirrer is positioned at the top of the tempering kettle, a stirring shaft is coincident with the axis of the tempering kettle and inserted into the tempering kettle, the outlet of the straw crusher is connected with the inlet of the feeder, the outlet of the feeder is connected with the inlet of the tempering kettle, the outlet of the tempering kettle is connected with the inlet of the fuel dehydrator, and the outlet of the fuel dehydrator is connected with the inlet of the fuel forming machine.

Owner:JIANGSU XINFA ENVIRONMENTAL PROTECTION TECHCO

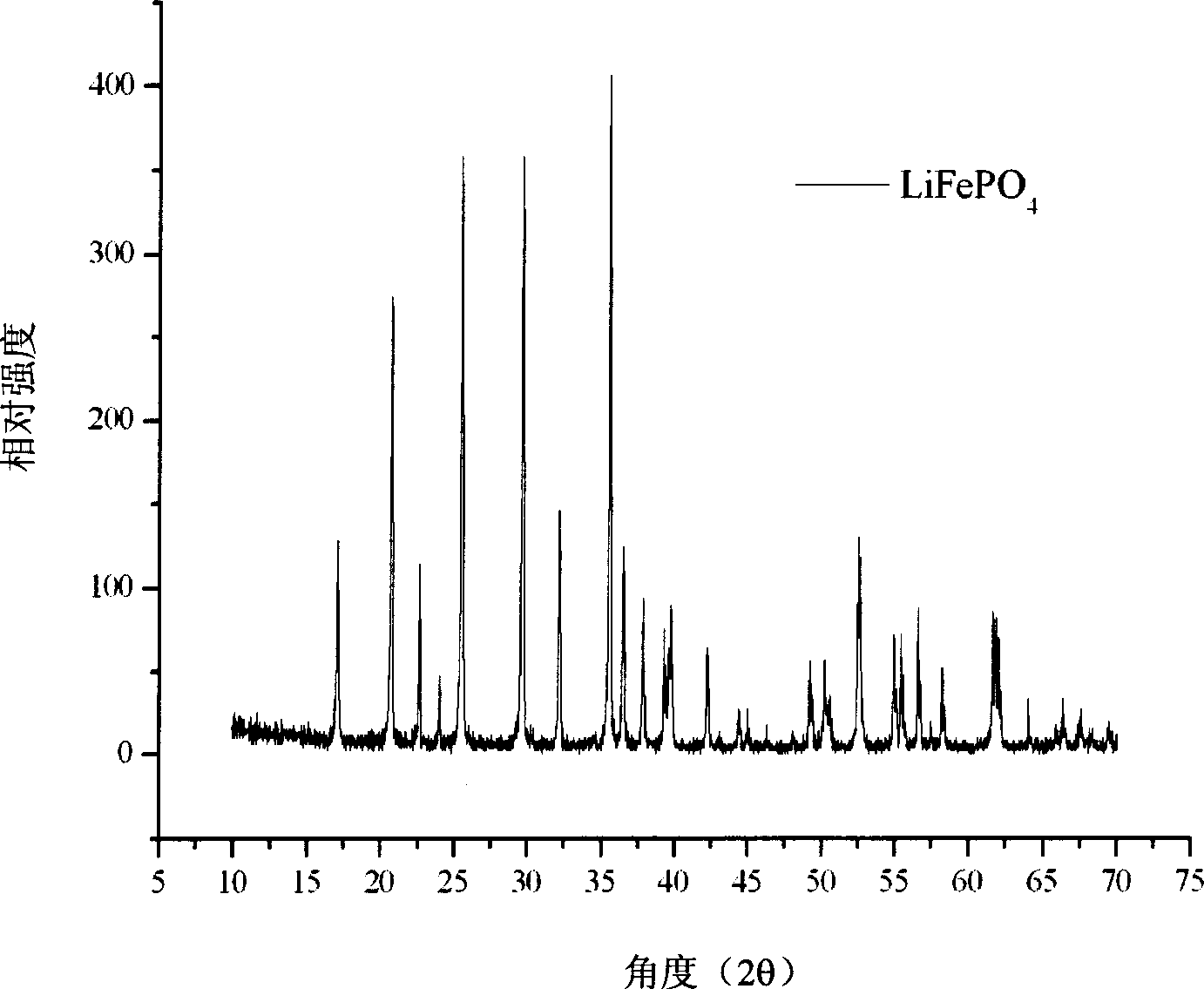

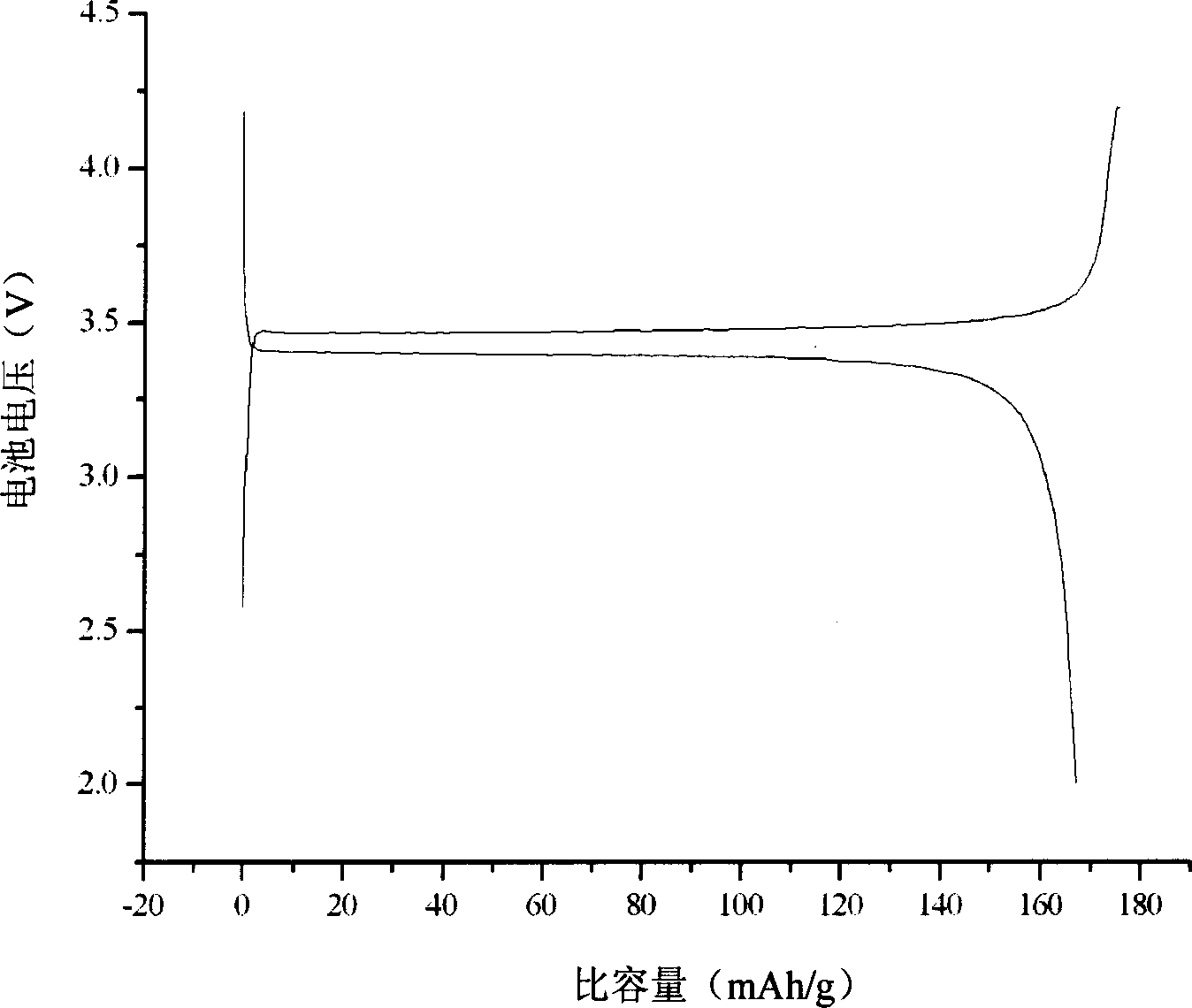

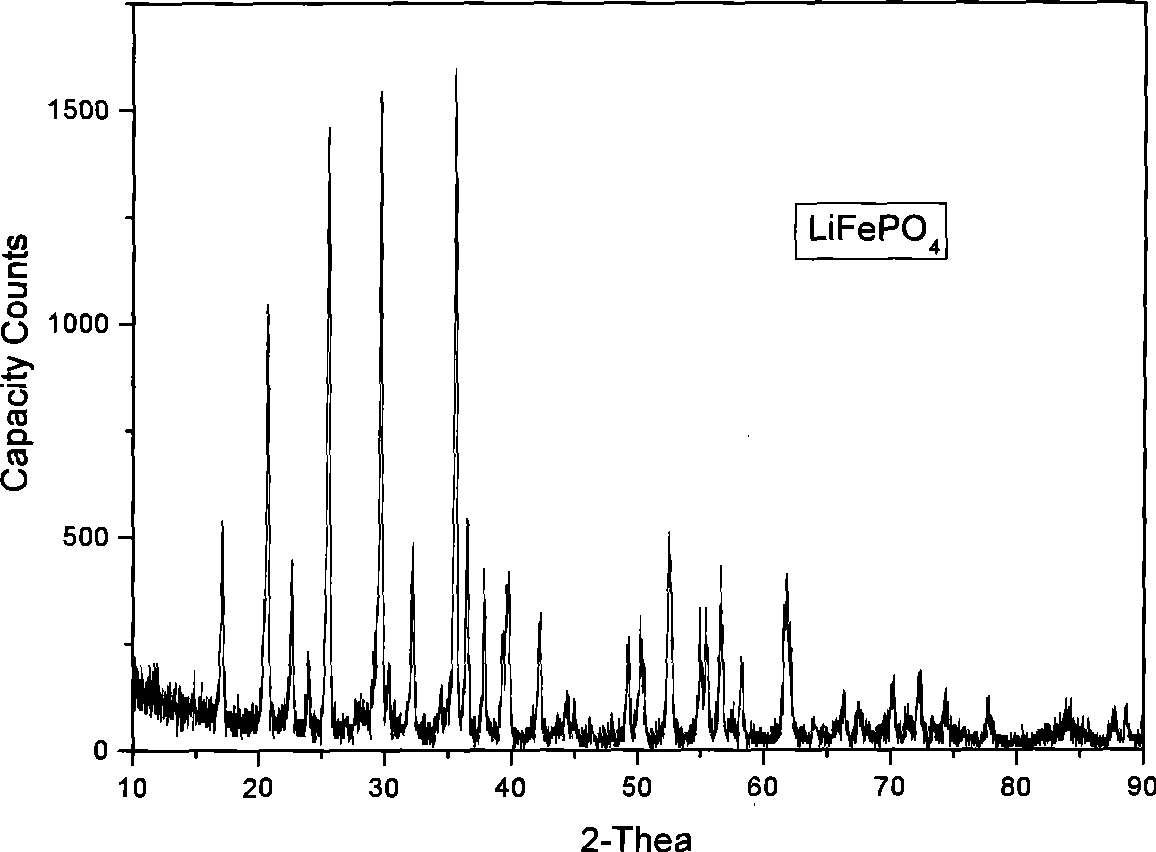

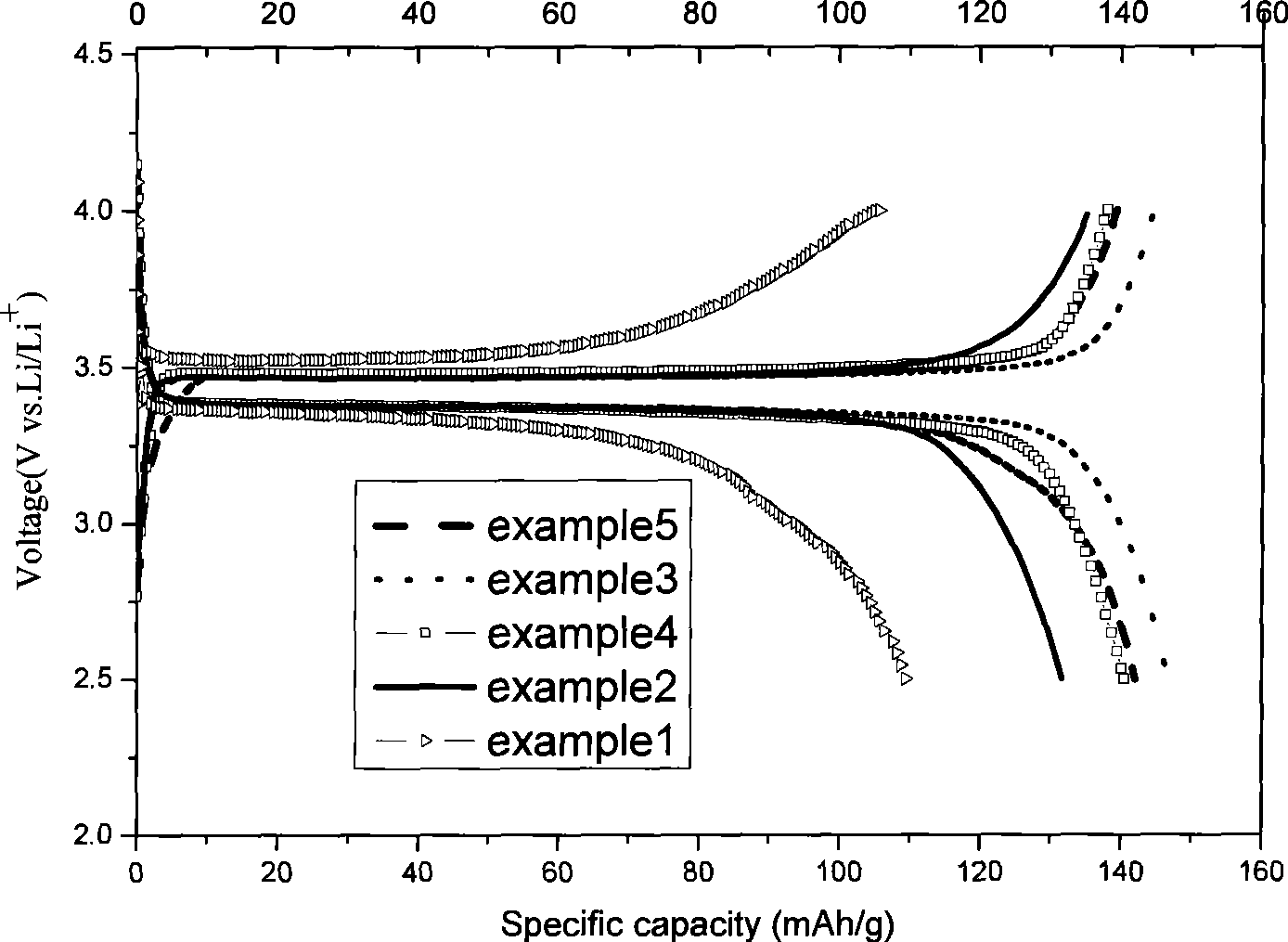

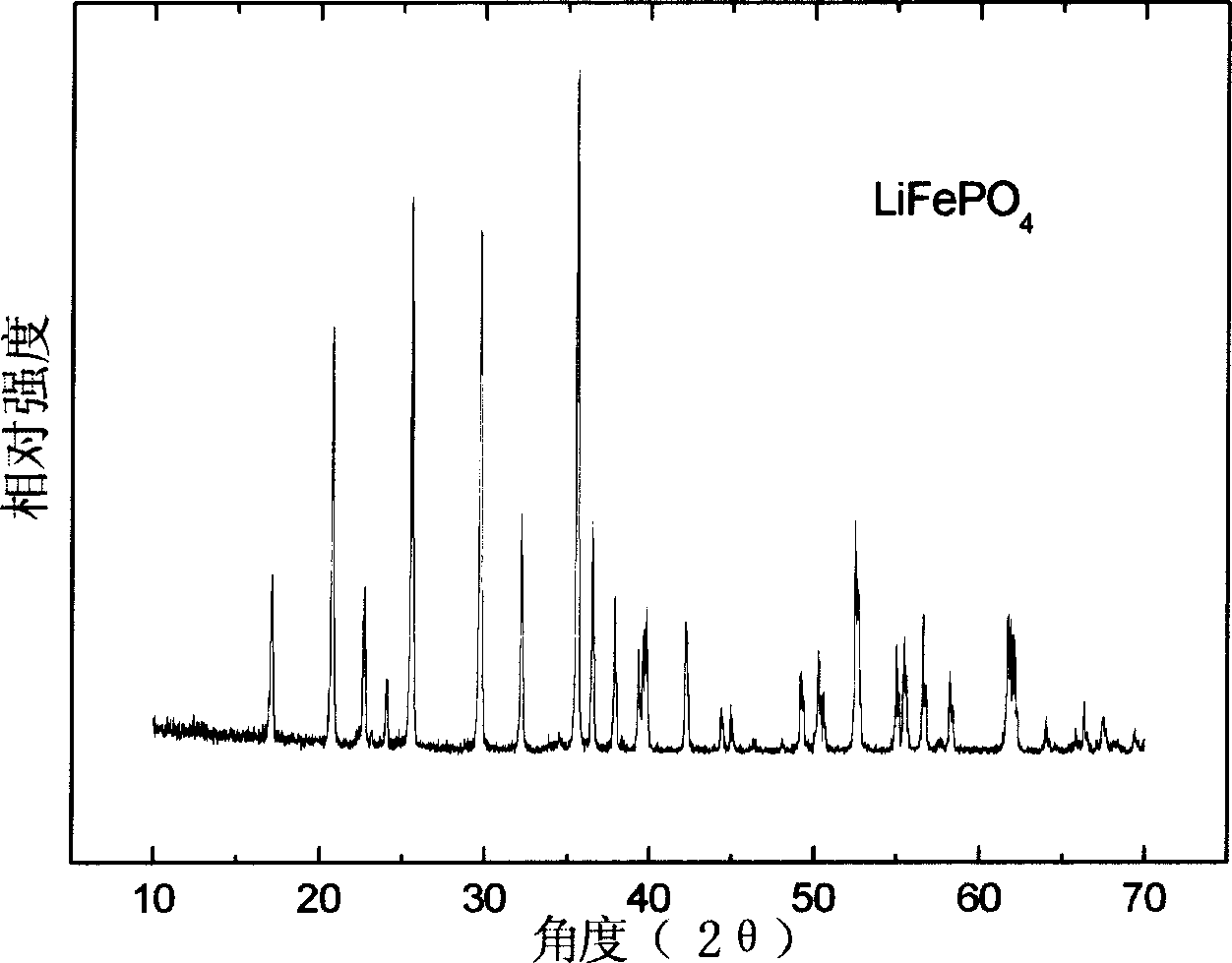

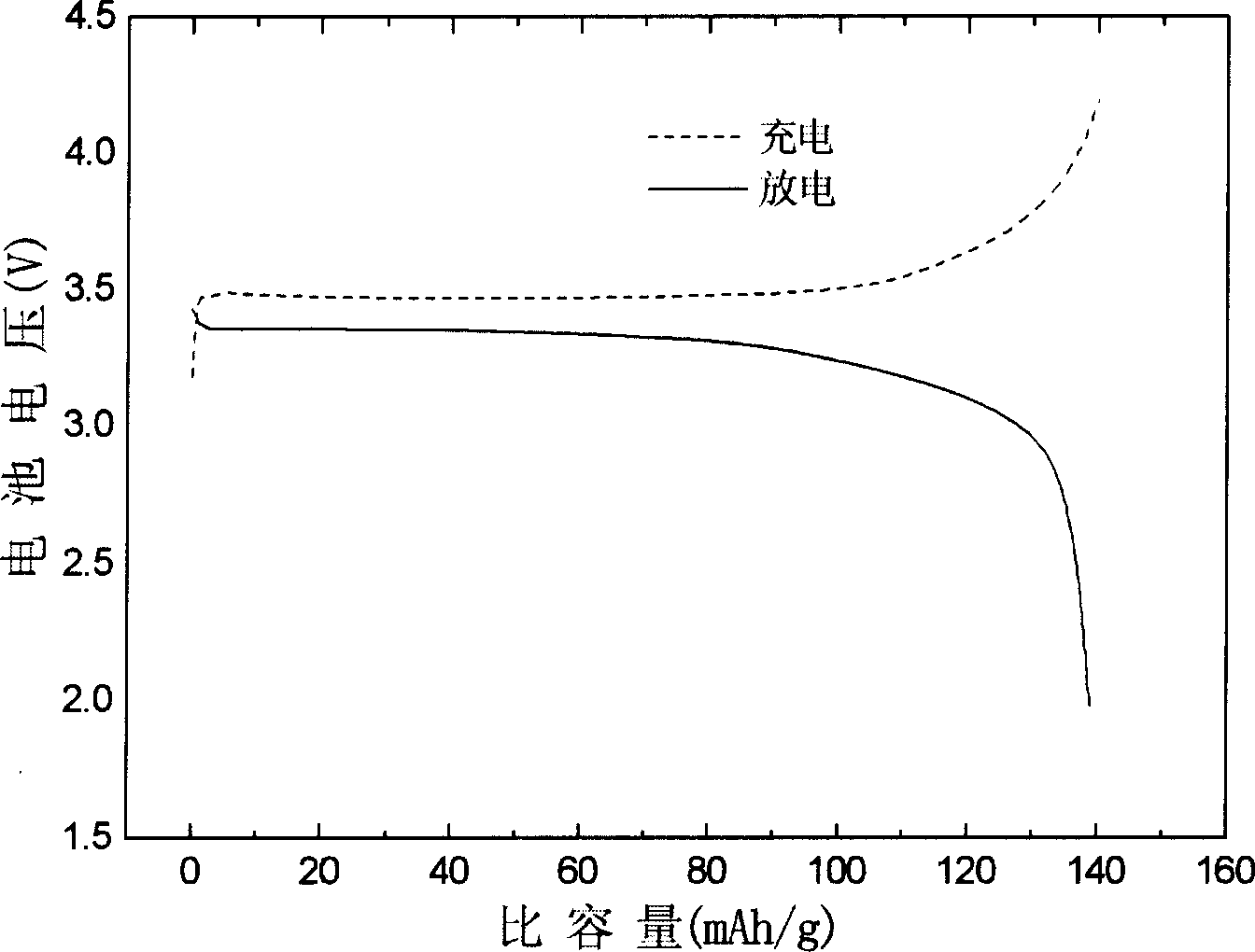

Process for preparing lithium ferrous phosphate coated with carbon

InactiveCN1821062ALow costReduce processing costsCell electrodesPhosphorus compoundsPhosphatePhosphoric acid

The preparation process of carbon coated lithium ferrous phosphate adopts ferric phosphate as one material and through reduction inside solution and high temperature heat treatment. Thus obtained carbon coated lithium ferrous phosphate has excellent crystal structure, and exhibits excellent electrochemical performance in lithium battery. It has discharge capacity at 0.2 C current up to 167 mAh / g, approaching the theoretical value 170 mAh / g. The present invention has low cost and simple technological path, and is suitable for large scale production.

Owner:SHANGHAI JIAO TONG UNIV

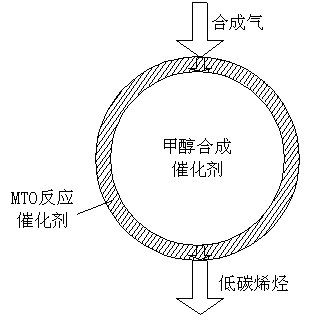

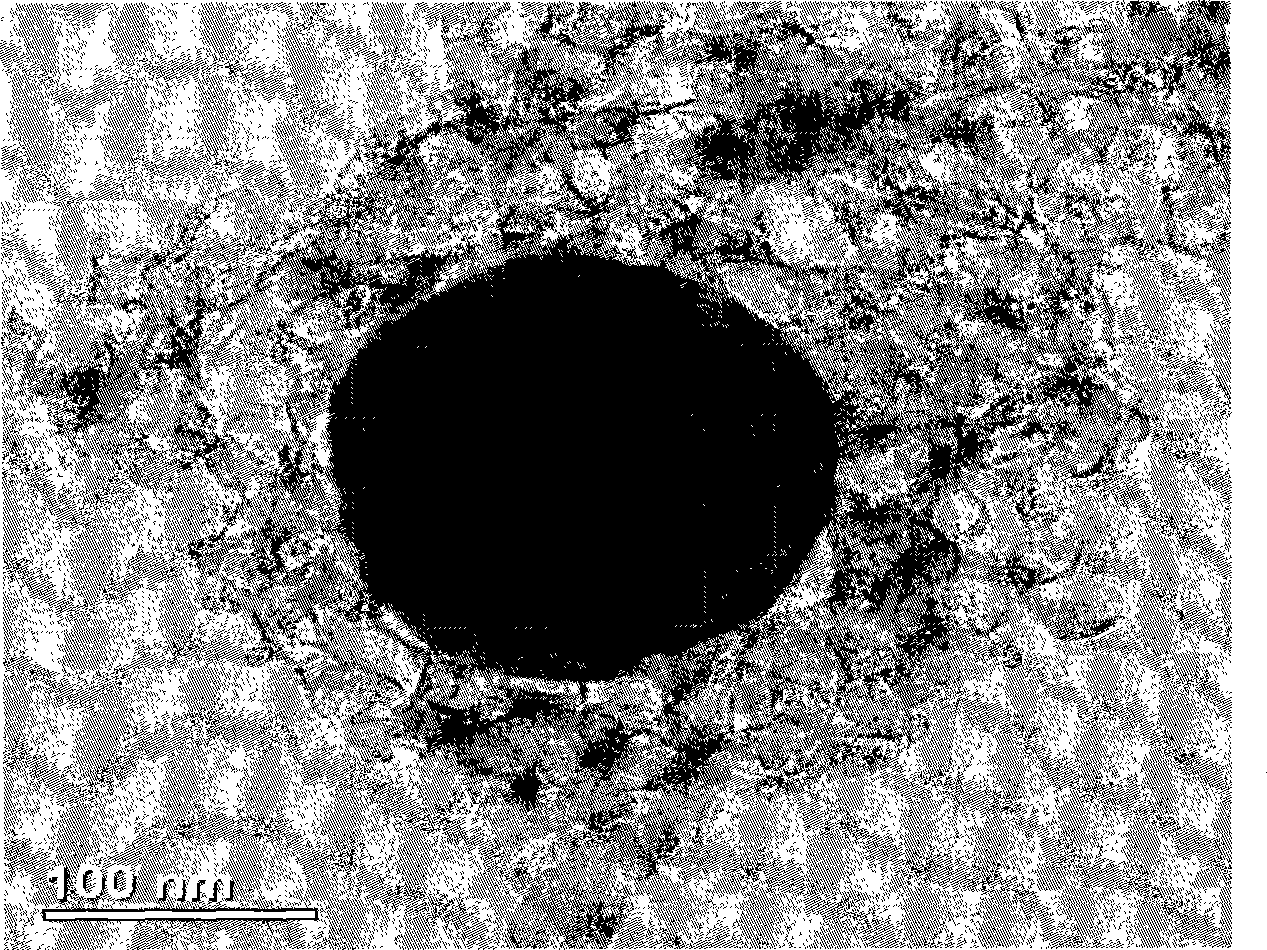

Core-shell structure catalyst and method for preparing low-carbon olefin by using synthetic gas one-step method

InactiveCN103071528AInhibition of coke inactivationImprove conversion rateHydrocarbon from carbon oxidesMolecular sieve catalystsSyngasAlkane

The invention discloses a core-shell structure catalyst and a method for preparing low-carbon olefin by using a synthetic gas one-step method. The core-shell structure catalyst couples methanol synthesis reaction and MTO (Methanol To Olefin) reaction together, so that synthetic gas is converted into the low-carbon olefin in one step. The core-shell structure catalyst takes a methanol synthesis catalyst as a core and an MTO reaction catalyst as a shell. The method for preparing the low-carbon olefin in one step on the core-shell structure catalyst comprises the following processes of: enabling reaction gas to firstly permeate through a shell catalyst pore channel to enter a core catalyst for reaction to generate methanol, enabling the generated methanol to be in contact with an active center of a shell catalyst in the process of dispersing the shell catalyst and reacting to generate the low-carbon olefin. The core-shell structure catalyst and the method have the benefits that the process route is simplified, the reaction equilibrium of the methanol synthesis reaction is broken through, and the conversion rate of CO (Carbonic Oxide) is improved; a shell simultaneously restrains the contact of the generated olefin with the core catalyst and prevents the generated olefin from being catalyzed into alkane by the catalyst; and a unique pore channel structure of the shell also has an effect of molecule screening, so that the generation of high-carbon products is reduced.

Owner:ZHEJIANG UNIV

Method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur

ActiveCN104208992AHigh activityReduce energy consumptionDispersed particle separationSulfur preparation/purificationCombustionLiquid state

The invention discloses a method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur. The method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur sequentially comprises the following steps: introducing the acid gas into a combustion furnace to be mixed with air introduced by the other pipeline so as to carry out a combustion reaction; introducing the gas reacted in the combustion furnace into a cooler to be cooled to 230-250 DEG C, after cooling, separating the cooled liquid sulfur at a liquid outlet, introducing mixed gas in the combustion furnace into a catalyst reactor, enabling hydrogen sulfide to react with sulfur dioxide in the catalyst reactor so as to generate sulfur and water, and separating the generated liquid sulfur at the liquid outlet of the catalyst reactor; introducing the mixed gas in the catalyst reactor into a hydrogenation reactor and enabling the sulfur dioxide to react with hydrogen in the hydrogenation reactor; introducing the gas in the hydrogenation reactor into a hydrogen sulfide absorption device and preparing the hydrogen sulfide into elemental sulfur under the action of an alkaline solution, a complex catalyst and the introduced air. The method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur has the advantages of short process route, high quality of produced sulfur and low energy consumption, is capable of fully removing SO2 gas and is green and environmentally friendly.

Owner:NINGBO RES & DESIGN INST OF CHEM IND

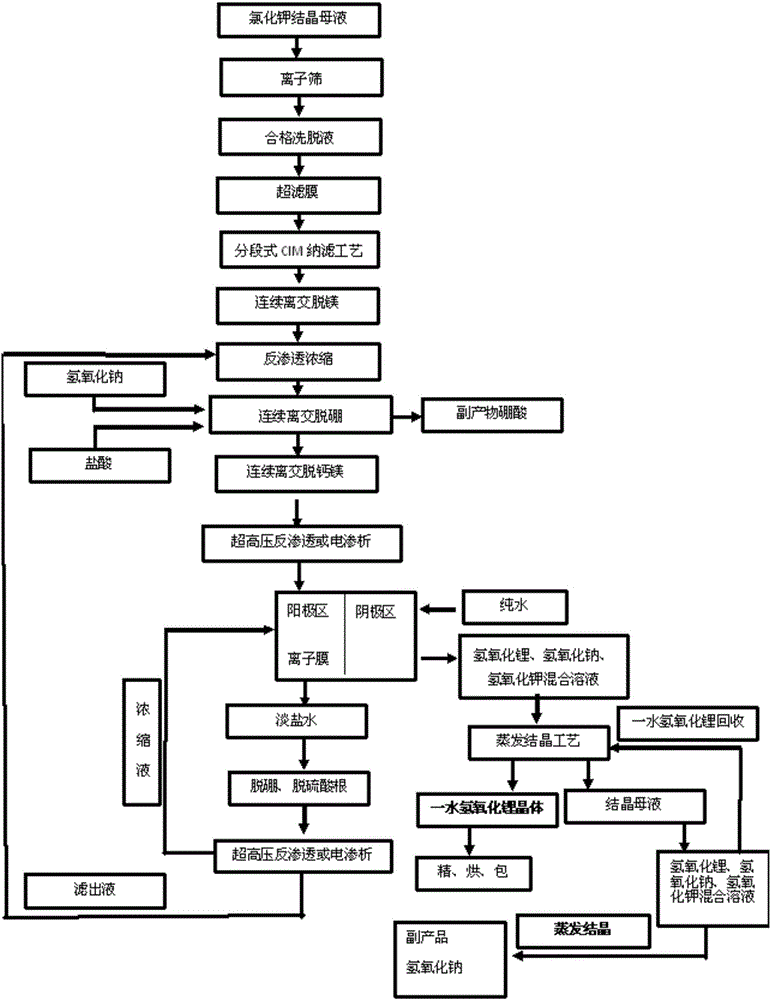

Production method of high-purity lithium hydroxide

ActiveCN106011917AHigh yieldReduce consumptionCellsBoron-oxygen compoundsLithium hydroxideUltrafiltration

The present invention relates to a production method of high-purity lithium hydroxide. A crystallization mother liquor waste water is obtained after production of potassium chloride by using a salt lake bittern as the raw material, a magnesium-lithium ratio of the crystallization mother liquor waste water is 200-500:1, an eligible eluant is obtained through ion sieve adsorption and elution of the crystallization mother liquor waste water, and after treatment of the eluant through the ultrafiltration membrane technology, the sectional type nanofiltration technology, the external regeneration continuous hybridization technology and the reverse osmosis technology, a reverse osmosis concentrated solution is obtained. In the reverse osmosis concentrated solution, the content of magnesium ions is <=300 ppm, the content of lithium ions is 4-6 g / L, the content of sodium ions is 3-5 g / L, the content of calcium ions is <=5 ppm, the content of sulfate ions is 1-30 ppm and the content of boron is <=400 ppm. According to the production method provided by the present invention, the reverse osmosis concentrated solution is used as the raw material, the process comprises ultrahigh pressure reverse osmosis continuous hybridization for boron-removing, continuous hybridization for sulfate radical removing, ion-exchange membrane electrolysis, and crystallizing evaporation, and by using the hybridization boron-removing technology, the ion-exchange membrane electrolysis technology and the crystallizing evaporation technology, the high-purity lithium hydroxide is obtained, with the byproducts being the boric acid and sodium hydroxide. The process is continuous, controllable, high in extraction rate, low in production cost and easy to industrialize.

Owner:启迪清源(上海)新材料科技有限公司

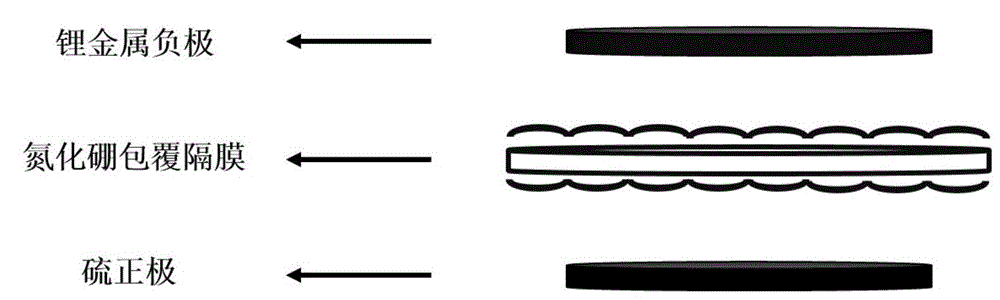

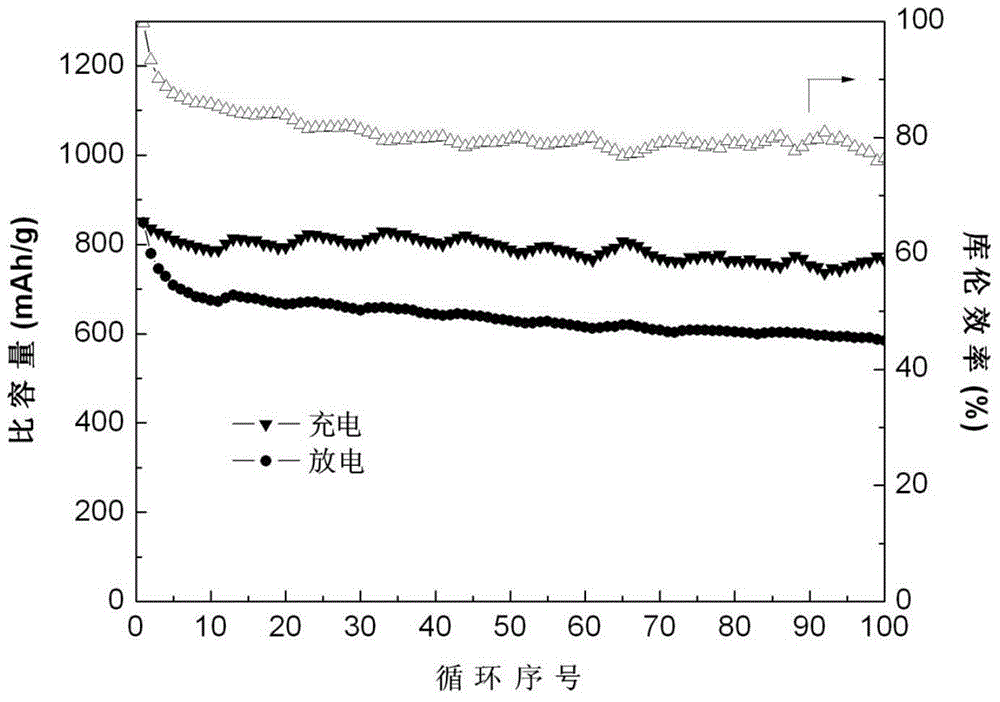

Production method of boron nitride coated diaphragm of lithium-sulfur battery

ActiveCN104993083AIncrease capacityImprove Coulombic efficiencyLi-accumulatorsCell component detailsHexagonal boron nitrideBoron nitride

The invention relates to a production method of a boron nitride coated diaphragm of a lithium-sulfur battery. The diaphragm is produced from a commercial polypropylene diaphragm, two sides of the diaphragm are uniformly covered with hexagonal boron nitride, and the characteristics of hexagonal boron nitride 'white graphite' are used, so lithium ions are allowed to pass, shuttle of polysulfide anions is obstructed, a reaction of a lithium negative electrode with the polysulfide anions is inhibited, formation of lithium dendrites, lithium sulfide precipitate and fixed lithium is prevented, the capacity, the coulombic efficiency and the cycle stability of the lithium-sulfur battery are improved, the growth of the negative electrode metal dendrite in the cycle process is effectively inhibited, and the safety of the battery is improved. The method has the advantages of simple process route and clear purpose, and the produced diaphragm has multiple functions, and can greatly overcome disadvantages of present technologies.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

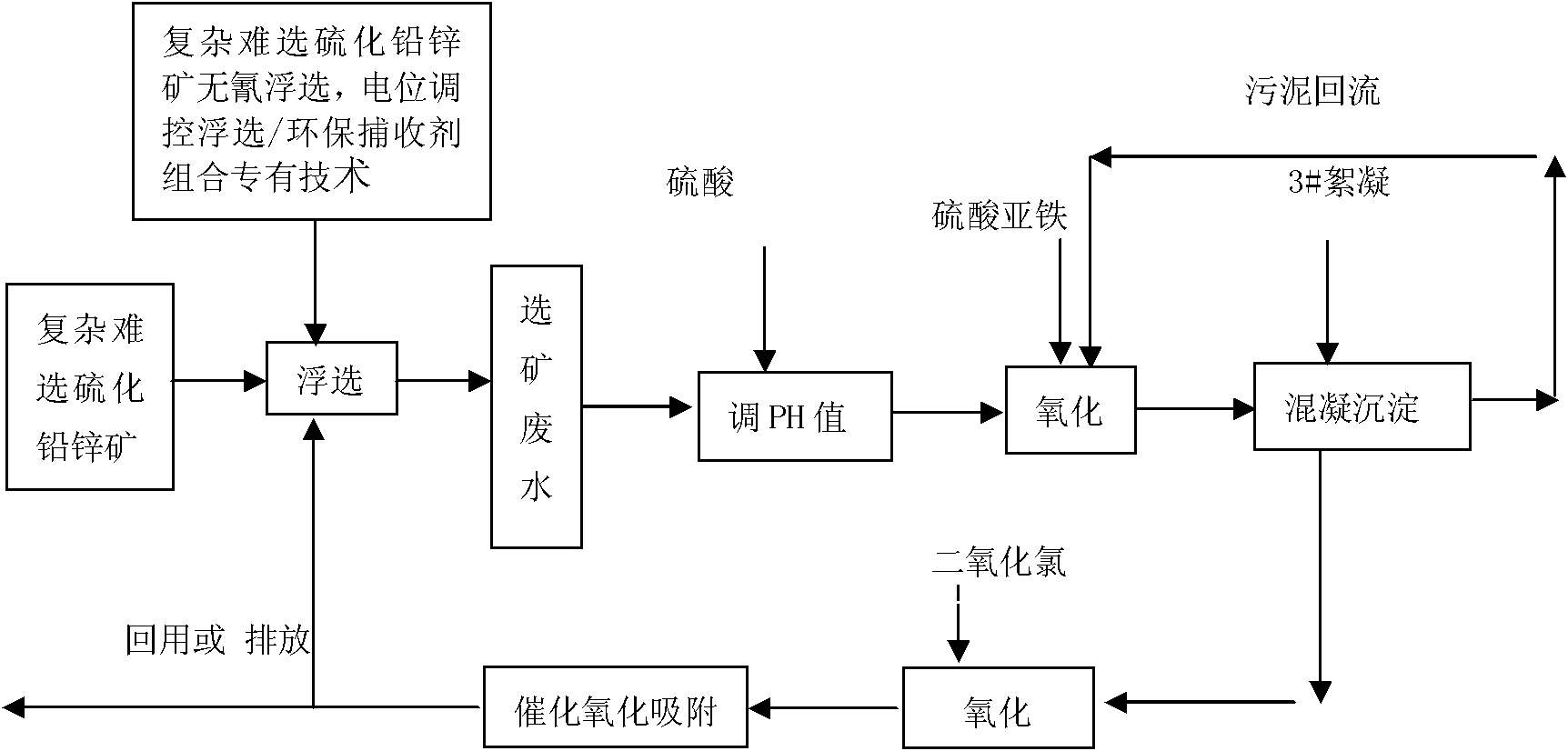

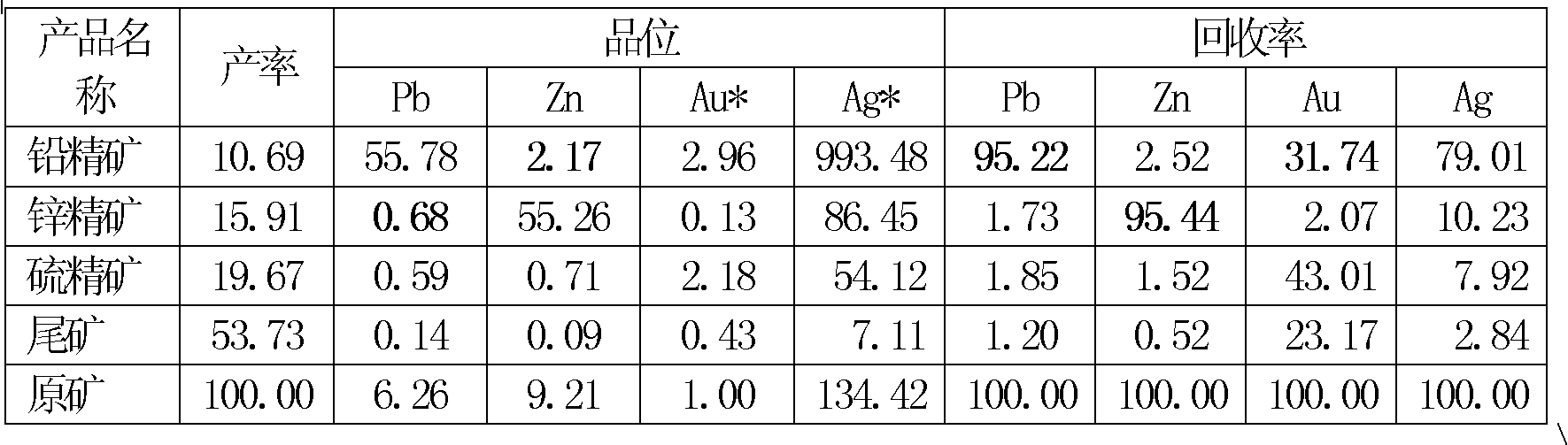

Method for treating and recycling lead-zinc sulfide ore dressing wastewater

ActiveCN101913720AEliminate the effects ofExtended service lifeWaste water treatment from quariesMultistage water/sewage treatmentActive carbonNovel technique

The invention provides a technique for treating and recycling lead-zinc ore dressing wastewater and aims to solve the problems of influence on the ore dressing index due to the recycling of the ore dressing wastewater for production and environmental pollution caused by drainage. The novel technique for treating and recycling the lead-zinc sulfide ore dressing wastewater comprises the steps of: adjusting the pH value of the total wastewater of an ore dressing plant; adding ferrous sulfate and flocculant into the wastewater to perform oxidation-coagulation treatment; and oxidizing the treated water by using chlorine dioxide, and performing catalytic oxidation and adsorption by using an active carbon bed, so that the treated water reaches the relevant discharge standard of China; and totally recycling the treated water by adopting the combined application of potential-controlled flotation and an environmental-protection collector. Compared with the field process technique, the method saves the cyanide flotation process and improves the recovery rates of lead, zinc and gold. The method provides whole technical integration of the combined application technique of the potential-controlled flotation and the environmental-protection collector and the wastewater treatment technique for the treatment and recycling of the lead-zinc ore dressing wastewater, and realizes recycling of the ore dressing wastewater.

Owner:HUNAN HERMES SAFE ENVIRONMENT PROTECTION SCI

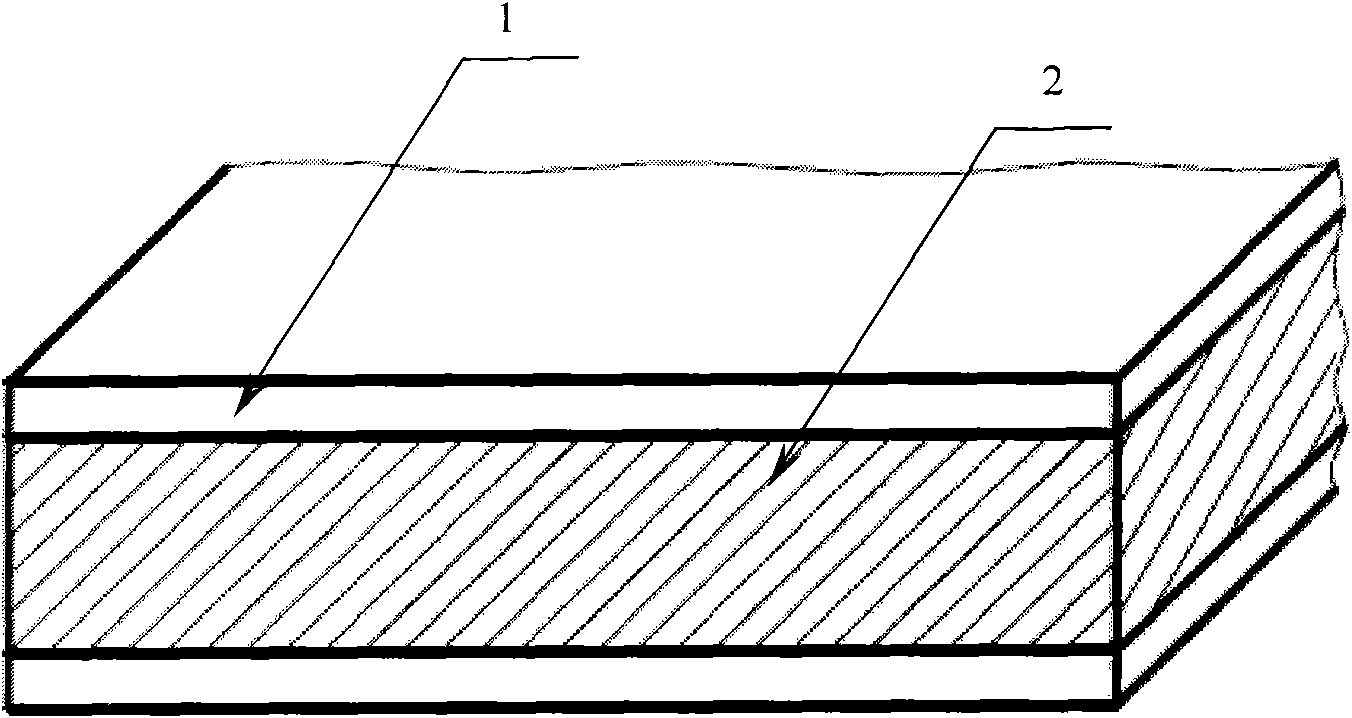

Aluminium-plated particle reinforced aluminum-matrix composite material and preparation method thereof

InactiveCN102114719AEnhanced powder densificationImprove mechanical propertiesMetal layered productsSurface layerElectromagnetic shielding

The invention belongs to the technical filed of particle reinforced aluminum-matrix composite materials and in particular relates to an aluminium-plated particle reinforced aluminum-matrix composite material and a preparation method thereof. The aluminium-plated particle reinforced aluminum-matrix composite material is characterized in that the surface layer of the aluminium-plated particle reinforced aluminum-matrix composite material is made of pure aluminium, and the core interlayer of the aluminium-plated particle reinforced aluminum-matrix composite material is composed of a particle reinforced aluminum-matrix composite material. The aluminium plating of the aluminium-plated particle reinforced aluminum-matrix composite material is realized in the process of carrying out vacuum hotpressing or hot isostatic pressing by using a powder metallurgic method. The method disclosed by the invention comprises the following steps: carrying out powder densification on particle reinforced aluminum-matrix composite materials through vacuum hotpressing or hot isostatic pressing, and simultaneously, carrying out metallurgical bonding on an aluminum die-sleeve and a composite material blank at high temperature and high pressure so as to obtained the aluminium-plated particle reinforced aluminum-matrix composite material. The aluminium-plated particle reinforced aluminum-matrix composite material can be subjected to one or more subsequent processing such as extrusion, forging, rolling and heat treatment so as to obtain various aluminium-plated particle reinforced aluminum-matrix composite materials with different specifications and properties. The aluminium-plated particle reinforced aluminum-matrix composite material can be applied to occasions with anticorrosion or electromagnetic shielding demands.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Chitin oligose preparing process

InactiveCN1847267AImprove efficiencySimple process routeOligosaccharidesFermentationBiotechnologyDegradative enzyme

The present invention relates to chitin oligose preparing process, and is especially enzyme generating fermentation process to degrade chitin colloid for preparing bioactive chitin oligose. The preparation process has simple technological path, effective inhibition of further degradation of bioactive chitin oligose, reuse of degrading enzyme and other advantages, and is suitable for industrial production. The preparation process includes: culturing Aeromonascaviae strain to obtain fermented liquid, centrifugally separating the fermented liquid to obtain enzyme supernatant; preparing chitin colloid; compounding chitin colloid buffer solution in an enzyme reactor and adding abacterial enzyme liquid for enzymolysis to obtain enzymolyzed chitin oligose liquid; four stages of membrane separation to obtain concentrate and spray drying to obtain bioactive chitin oligose product.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

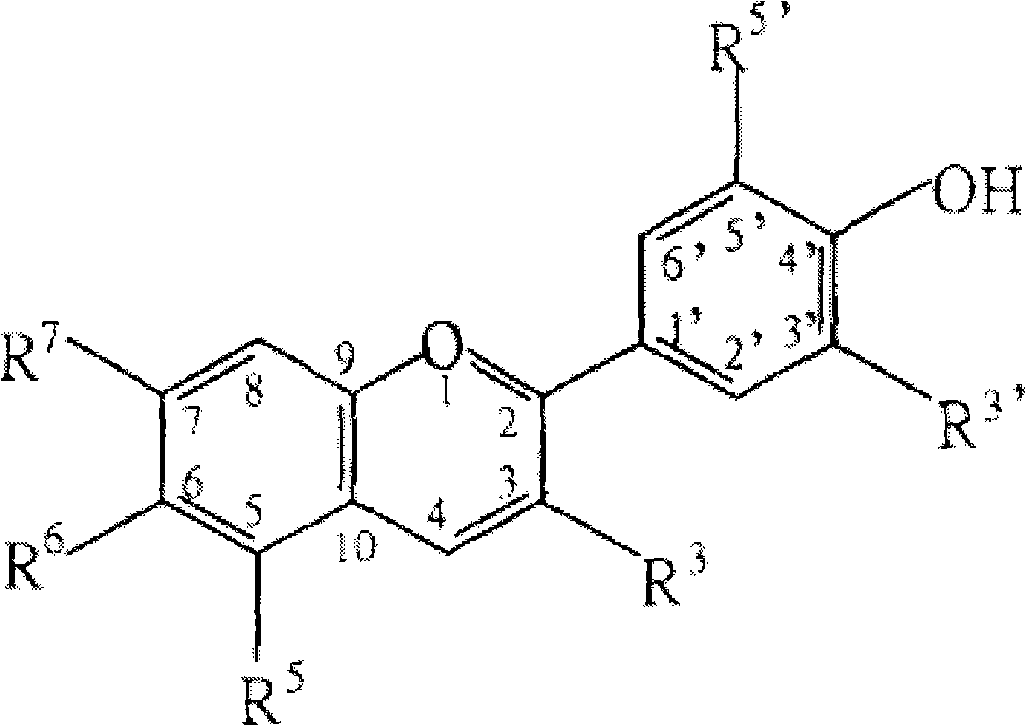

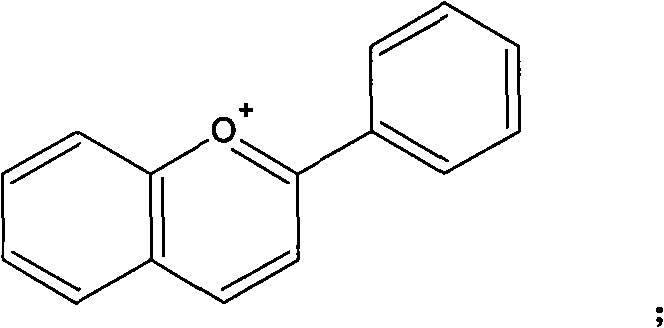

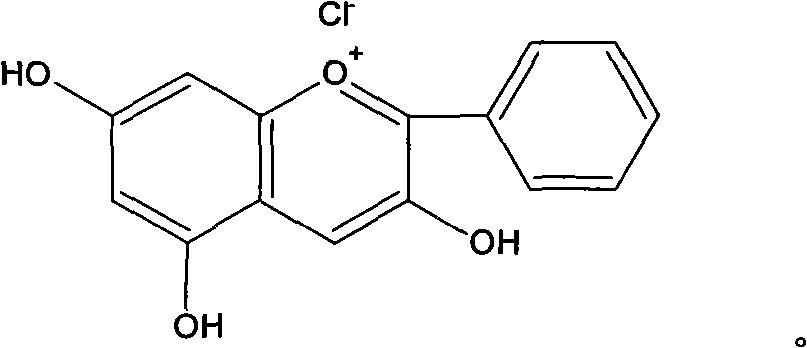

Separating, purifying and inspecting method of anthocyanin in blueberry wine dregs

InactiveCN102321062AMaintain biological activityImprove antioxidant capacityOrganic chemistryColor/spectral properties measurementsFreeze-dryingSlurry

The invention relates to a separating, purifying and inspecting method of anthocyanin in blueberry wine dregs, which belongs to the technical field of functional active constituent extraction and purification. In the separating method, blueberry wine dregs or frozen blueberry wine dregs are ground into slurry or are freeze-dried and crushed into powder; and the slurry or the powder is separated in a warm extraction method in an acidified ethanol solution, and blueberry anthocyanin coarse extracting liquid is obtained through reduced pressure concentration. The blueberry anthocyanin coarse extracting liquid is purified and concentrated to prepare a blueberry anthocyanin concentrated solution. The concentrated solution is freeze-dried to obtain blueberry wine dreg anthocyanin freeze-dried powder. In the invention, the anthocyanin is separated out from waste produced by blueberry wine, which shows the research and development of simple, efficient, environment-friendly and low-cost production technology; and the content of the anthocyanin in the blueberry anthocyanin freeze-dried powder is 10-40%. The anthocyanin concentrated solution or coarse extracting liquid can be directly manufactured into oral liquid, tablets and other functional foods. The anthocyanin freeze-dried powder can be manufactured into food stain with an obvious antioxidation to be widely used in the fields of beverages, wines and the like.

Owner:吉林云尚保健食品有限公司

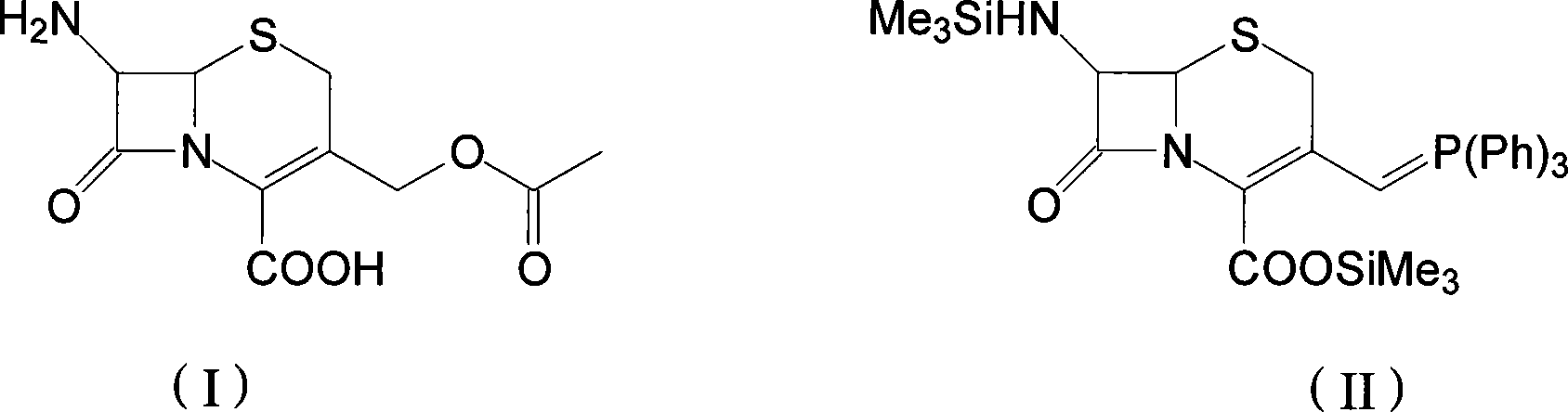

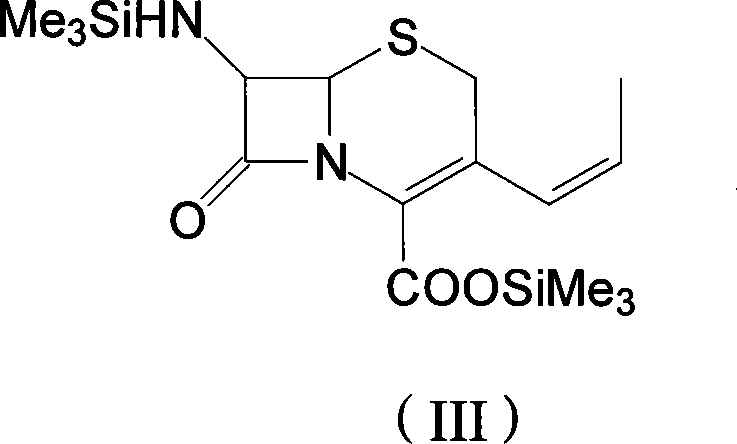

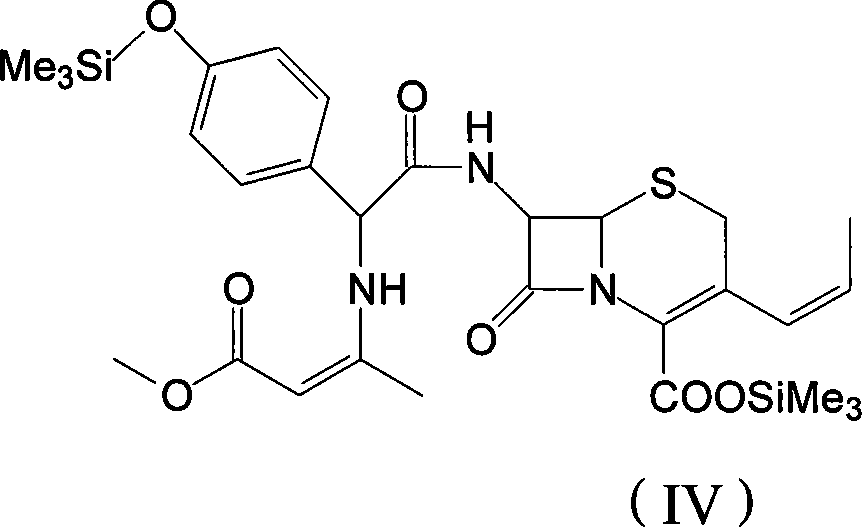

Method for preparing cephalosporin propylene

The invention discloses a preparation method of cefprozil, which comprises: 7-amin cethalosporanic acid (7-ACA) reacts with triphenyl phosphine to get 7- trimethylsilyl amino-3-triphenyl phosphate methylene-4-cethalosporanic acid trimethylsilyl ester through silanization protection and iodination reagent replacing under the condition of catalyst existing; WITTIG reaction is made for the product and acetaldehyde to get 7-trimethylsilyl amino -3-(propenyl-1-alkenyl)-4-cethalosporanic acidtrimethylsilyl ester; then the compound reacts with D-para hydroxybenzene glycine dane potassium salt to geta compound (6R, 7R)-7-[(2R)-2- ethoxycarbonyl-1-methyl - ethylene amino (4-trimethylsilyl oxyphenyl) acetamido group(amide)]-8-oxo-3- (1- propenyl)-5-thio-1- heterobicycle [4.2.0] octylene-2-ene-2-carboxylic acid trimethylsilyl ester; hydrolytic treatment is then used to get the cefprozil. The invent adopts the method of one pot and can participate in next reaction without separating intermediateproducts. The preparation method of cefprozil has the advantages of low cost, convenient operation and high overall yield, adapting to demands of industrial production.

Owner:南通康鑫药业有限公司

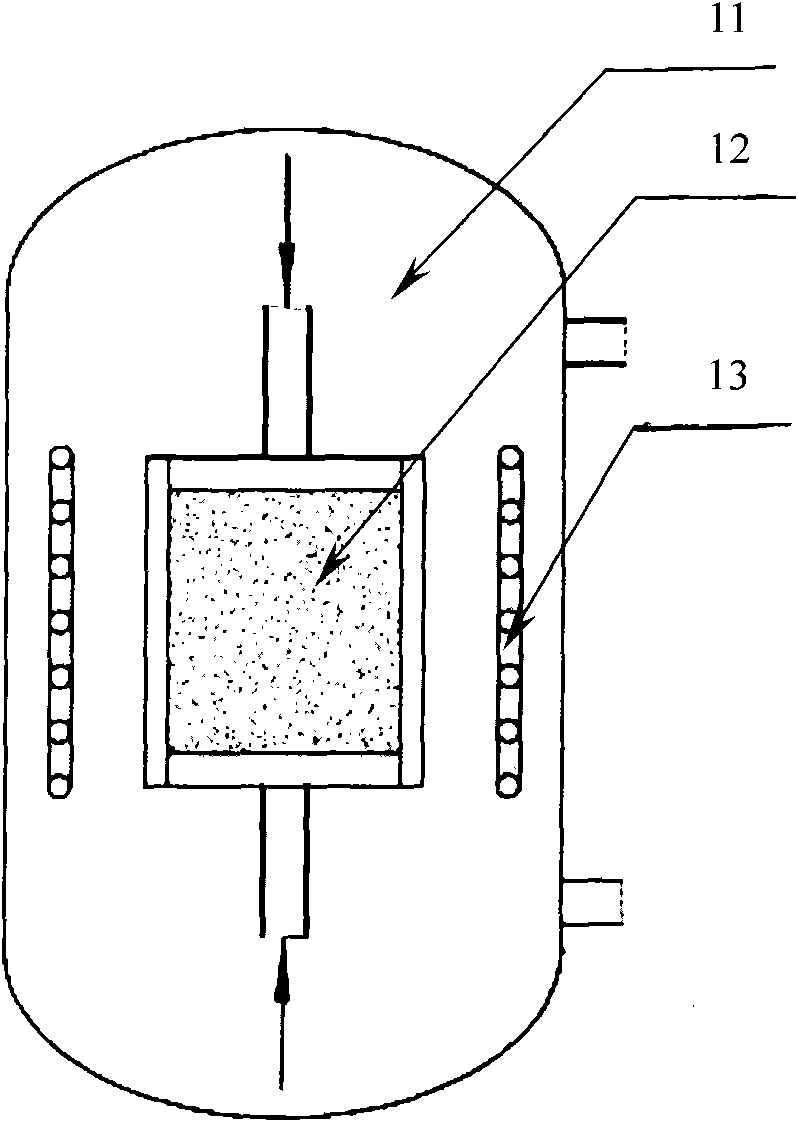

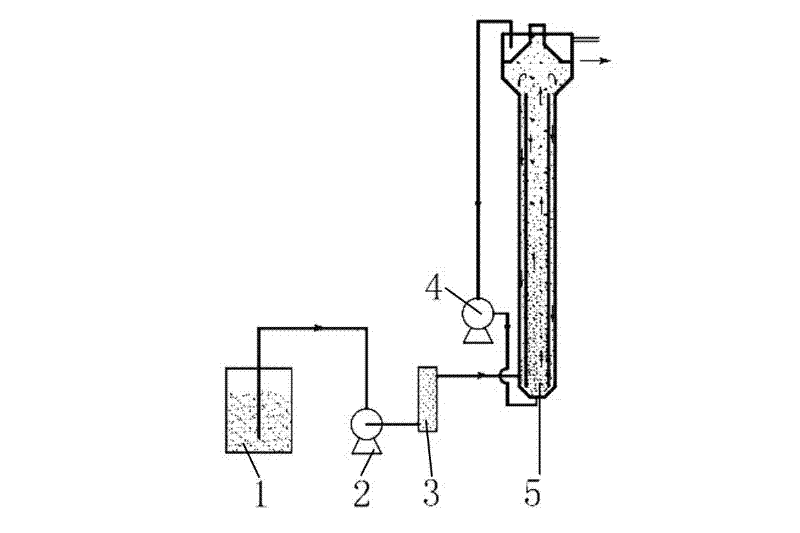

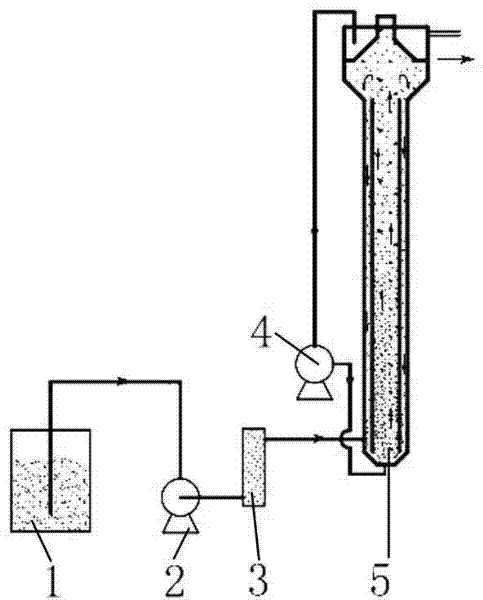

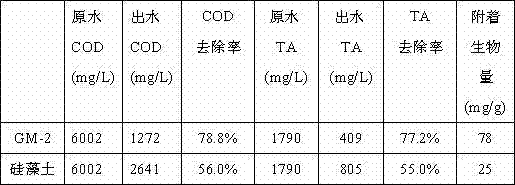

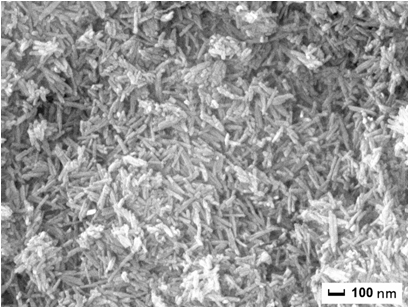

Multi-hole foam glass carrier for fast mass transfer biological fluidized bed and preparation method and application thereof

InactiveCN102515551AEvenly distributedImprove chances of interphase contactTreatment with anaerobic digestion processesBiocompatibilityFoam glass

The invention relates to a multi-hole foam glass carrier for a fast mass transfer biological fluidized bed and a preparation method and application thereof, which belong to sewage disposal technology. The multi-hole foam glass carrier is prepared by using waste glass as a raw material to be composited with volcanic rocks, coal ash, coal gangue, furnace clinker, iron powder, aluminum powder, binding agents, foaming agents, foam stabilizer and fluxing agents by weight, and multi-hole foam glass is obtained by stages of preheating, fast sintering, foaming, fast cooling and annealing. The preparation process of the multi-hole foam glass carrier is simple in route, easy to control and low in cost, and the prepared carrier is stable in performance, high in porosity, large in specific surface area, resisting in impact, good in mechanical performance, high in biocompatibility, favorable to efficient fixing of the microorganism, and suitable to the fast mass transfer biological fluidized bed. The multi-hole foam glass carrier solves the problem that biological immobilization carriers in the prior art are easy to abrade, small in bio-film formation amount, low in mass transfer effects and the like in the fast mass transfer biological fluidized bed. The preparation method opens up new approaches for preparing the biological carriers, and fills blank spaces in using of foam glass materials in sewage disposal.

Owner:NANJING UNIV OF TECH

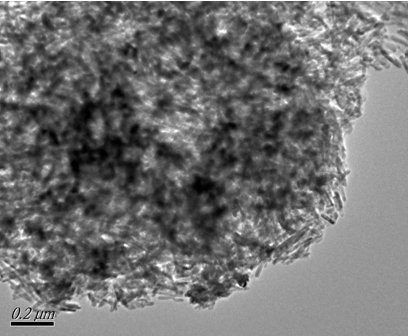

Graphene/hydroxyapatite nano composite and preparation method thereof

InactiveCN102569749AImprove surface topographyLarge specific surface areaMaterial nanotechnologyCell electrodesO-Phosphoric AcidBiological materials

The invention relates to a graphene / hydroxyapatite nano composite and the preparation method thereof, particularly relates to a hydrothermal method for preparing graphene / hydroxyapatite nano composite through the assistance of amino acid, and belongs to the field of nano composite and biological material. According to the invention, graphene oxide is placed in deionized water for ultrasonic dispersion, and calcium chloride anhydrous is added for stirring, so as to form mixed solution A; amino acid is added into dilute phosphoric acid for stirring so as to form solution b, the dilute hydrochloric acid solution is used for adjusting the solution to enable the PH value to be 7.5 to 8.5, finally the mixed solution A and the mixed solution B are mixed to transfer into a polytetrafluoroethylene reaction kettle for hydro-thermal reaction, and after the reaction is finished, the composite can be obtained through centrifugating, cleaning and vacuum drying the product. The invention has the advantages that the operating process is relatively simple, the structure is controllable, the surface appearance is better, the specific surface area is larger, the dimension is even, and the like.

Owner:JIANGSU UNIV

Method for separation and extraction of 1, 3-propylene glycol and its byproducts from fermentation liquid

InactiveCN1634823ASimple process routeReduce energy consumptionOrganic compound preparationHydroxy compound preparationHigh concentrationSolubility

The present invention discloses a process for separation and extraction of 1,3-propylene glycol by fermentation method, which belongs to biochemical separation technical field. A rectification is carried out to separate alcohol in the fermentation liquor, then solids and dissolved protein are separated from the fermentation liquor by composite flocculation of cation type flocculant and non-ion type flocculant. The pH value of the obtained clear liquid is regulated by an acid, and an extraction is performed with an aldehyde. An aldolisation between 1,3-propylene glycol, 2,3-butanediol, glycerine and an aldehyde is carried out to obtain a cyclic acetal to be separated from water phase, salts and other solubility impurity are separated from 1,3-propylene glycol, 2,3-butanediol and glycerine along with the water phase. The acetal hydrolysis applies reacting rectification with solid acid catalyst, can obtain high concentration 1,3-propylene glycol, 2,3-butanediol and glycerine mixture, which is separated again by subsequent common rectification. Excessive aldehyde in the extract phase is recovered by rectification. The invention has the advantages of simple extraction and separation process, low energy consumption, high product recovery, less equipment investment and less land occupation.

Owner:TSINGHUA UNIV

Method for preparing bis(trifluoromethanesulfonyl)imide metal salt

InactiveCN101456832ANo pollution in the processHigh puritySecondary cellsSulfonic acid amide preparationImideAlkali metal oxide

The invention discloses a method for preparing bis(trifluoromethylsulfonyl)imide metallic salt. The method comprises the following steps: trifluoromethane halogenated sulfonyl, liquid ammonia and organic amine alkali as raw materials are used to generate a mixture solvent containing bis(trifluoromethylsulfonyl)imide quaternary ammonium salt by a nonpolar inert solvent; the mixture containing the bis(trifluoromethylsulfonyl)imide quaternary ammonium salt is distilled to reclaim the solvent so as to obtain a bis(trifluoromethylsulfonyl)imide quaternary ammonium salt solid; the bis(trifluoromethylsulfonyl)imide quaternary ammonium salt solid reacts with alkali metal oxide in an aqueous solution to generate a mixture of the bis(trifluoromethylsulfonyl)imide metallic salt; and finally, the target product is prepared by the obtained mixture of the bis(trifluoromethylsulfonyl)imide metallic salt through decompressed dehydrating, decompressed drying and other steps. The process has a simple route, and does not pollute the environment. The purity of the bis(trifluoromethylsulfonyl)imide metallic salt prepared by the method is more than 99 percent, and the yield is over 90 percent.

Owner:ZHANGJIAGANG HUASHENG CHEM CO LTD

Vaccinium uliginosum cyanidin and separation and purification method thereof

InactiveCN101265252AGuaranteed AntioxidantMaintain biological activityOrganic chemistryBiotechnologyEngineering

The invention relates to an anthocyanidin made from Vaccinium uliginosum L. and separation and purification methods thereof, which belong to the technology field of active component extraction and purification and functional food development. The content of anthocyanidin in Vaccinium uliginosum L. is 29.8-40%, wherein the content of malvidin accounts for 4.68-5.48% of the anthocyanidin; and antioxidant activity of the anthocyanidin is as 7.8-15 times as that of Vc. The preparation method includes pre-treating raw material, cold soaking and concentrating, purifying and concentrating, and freeze dying. The ultrasonic and microwave-assisted cold soaking method is employed for separation, and an AB-8 macroporous resin static-dynamic combined absorption purification method is employed. The invention provides an environmental friendly, high-efficiency and low-cost separation and purification technology of anthocyanidin made from Vaccinium uliginosum L., which maintains product bioactivity such as antioxidant property of product and ideal separation effect, establishes the basis for wide utilization of abundant resource of Vaccinium uliginosum L. and industrialized development promotion of a series of Vaccinium uliginosum L. health food, and embodies great economic benefit and social benefit in deep processing of the Vaccinium uliginosum L.

Owner:吉林云尚保健食品有限公司

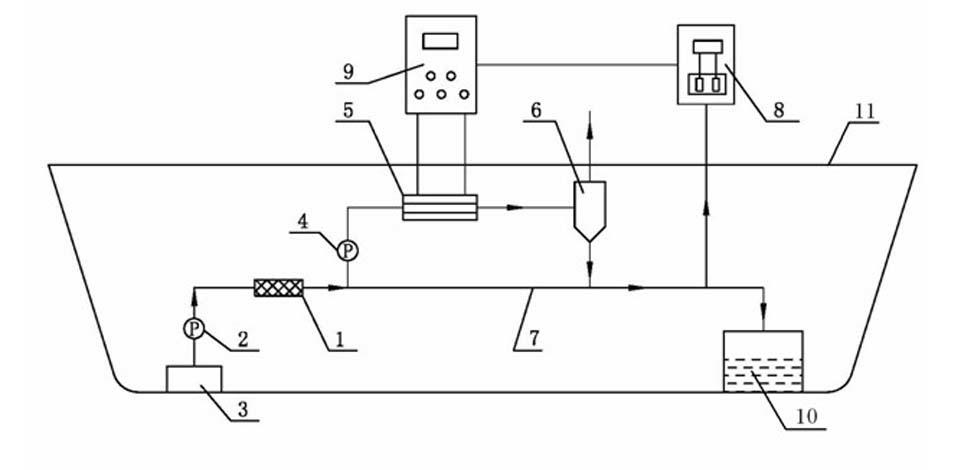

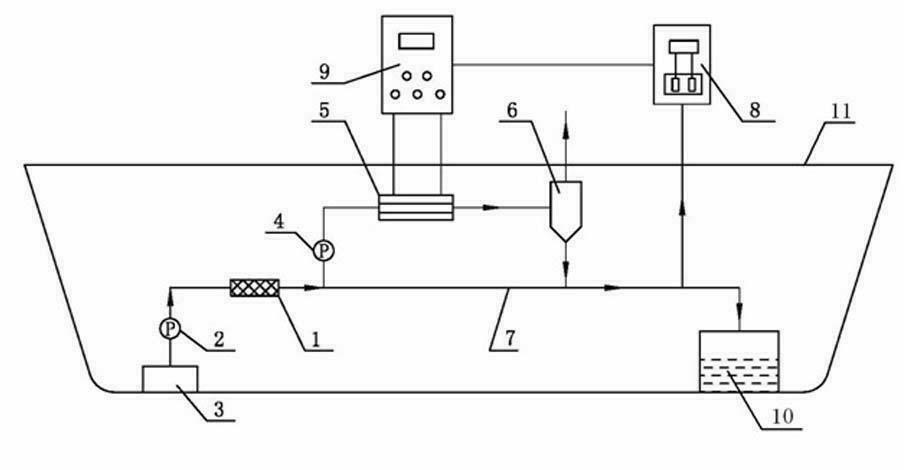

High-efficiency treatment method of ballast water in ship

InactiveCN102515400AReduce generationSimple process routeAuxillariesMultistage water/sewage treatmentSuspended particlesElectrolysis

The invention discloses a high-efficiency treatment method of ballast water in a ship and a device adopting the high-efficiency treatment method. The high-efficiency treatment method of ballast water in a ship comprises the following steps of 1, removing planktonts and suspended particles in ballast water by a high-efficiency filter, wherein the removed planktonts and the suspended particles have sizes of above 30 to 40 micrometers; 2, based on a branch electrolysis-based inactivation treatment technology, electrolyzing a part of seawater passing through an electrolysis unit into chlorine and hydrogen by the electrolysis unit, wherein the chlorine is fast dissolved in seawater to form sodium hypochlorite, and 3, feeding back the high-concentration sodium hypochlorite solution obtained by the step 2 to a ballast water feeding header pipe so that residual harmful aquatic organisms in the ballast water are killed. The high-efficiency treatment method of ballast water in a ship has the advantages that a technology of high efficiency filtration and branch electrolysis-based inactivation treatment and the equipment suitable for the technology are adopted; a technical flow is simple; a system volume is small; compared with the existing system, the device adopting the high-efficiency treatment method has a floor space reduced by above 30%; because of the utilization of branch electrolysis, a hydrogen generation amount is low so that hydrogen can be removed completely; a potential safety hazard is eliminated; installation is convenient; and safety and reliability are high.

Owner:SUNRUI MARINE ENVIRONMENT ENG

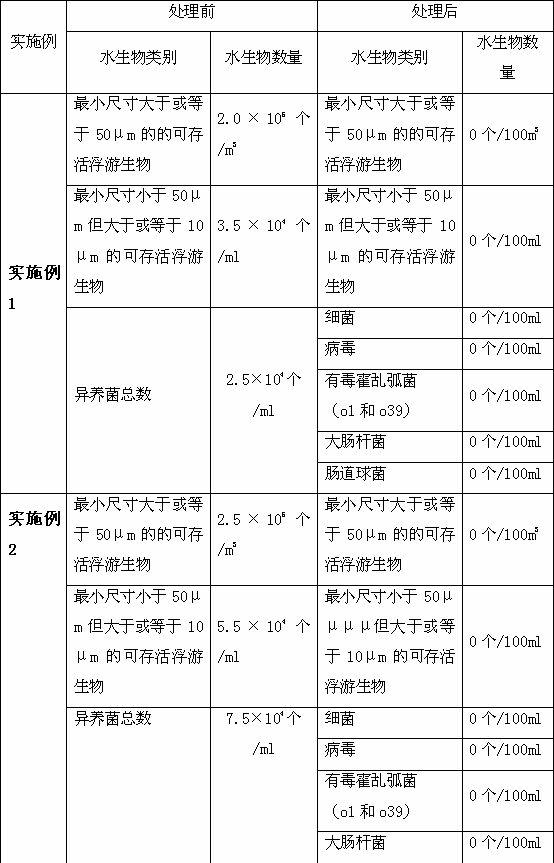

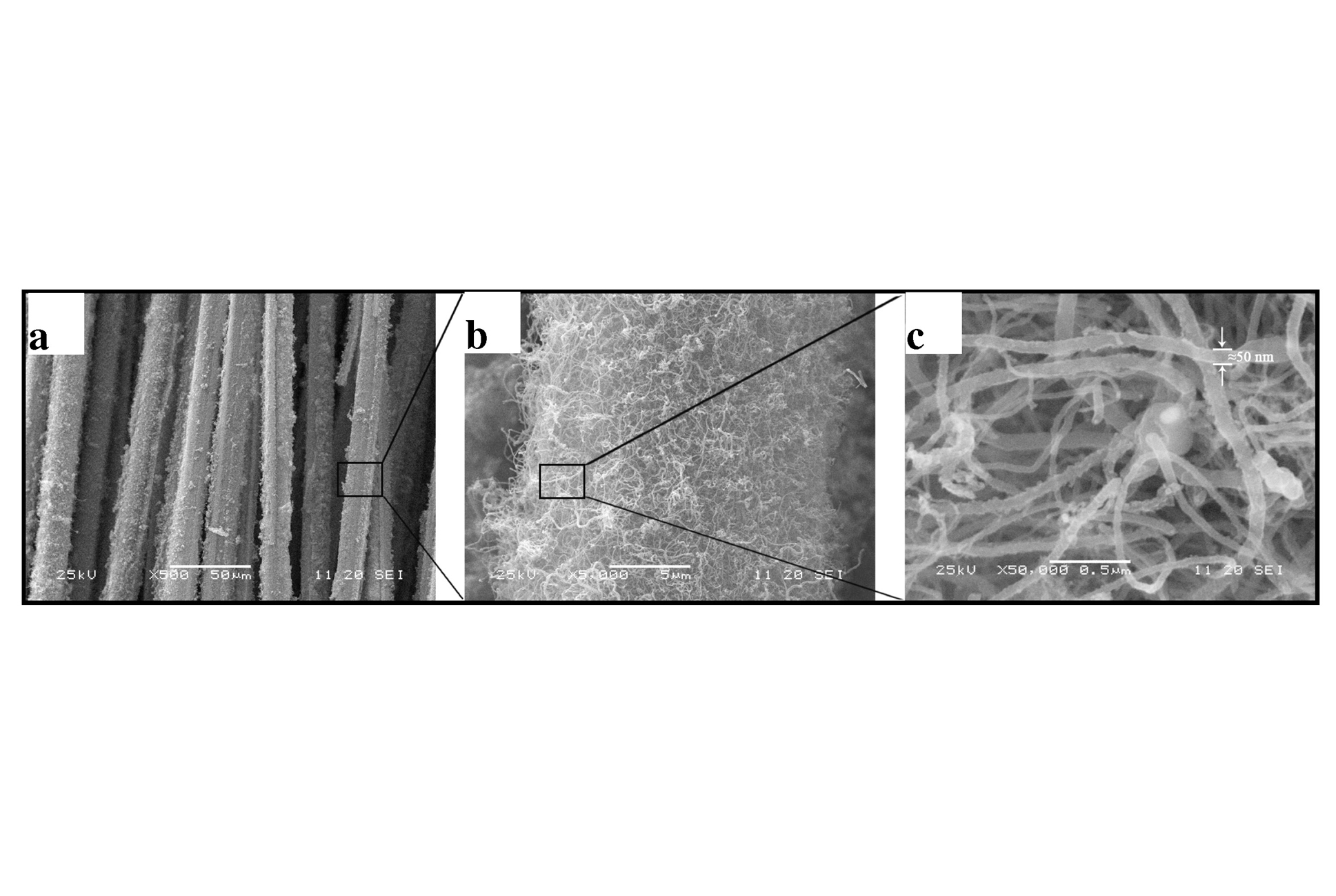

Silicon carbide fiber solid fabric for in-situ growing carbon nano tubes, composite material and preparation method thereof

The invention discloses a silicon carbide fiber solid fabric for in-situ growing carbon nano tubes, which is formed by mainly weaving silicon carbide fibers. In the invention, in-situ grown carbon nano tubes are uniformly distributed on the surfaces of the silicon carbide fibers and mutually wound to form a reticular structure. The preparation method comprises the following steps of: pretreating the silicon carbide fiber solid fabric; loading a Ni-La-Al composite catalyst by adopting a catalyst precursor vacuum impregnation-reduction method; and finally, carrying out chemical gas-phase deposition to ensure that the carbon nano tubes are in-situ grown on the silicon carbide fiber solid fabric. The invention also discloses a carbon nano tube-silicon carbide fiber mixed enhanced composite material which is prepared by using silicon carbide as a substrate and the silicon carbide fiber solid fabric as a reinforcement body by adopting a traditional precursor impregnation-conversion method. The silicon carbide fiber solid fabric has the advantages of uniform carbon nano tube dispersion, higher and controllable carbon nano tube content, good combination with fibers, and the like.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing antistatic polyacrylonitrile fibers from double-component nano electroconductive agent

InactiveCN102409422AImprove fill factorImprove conductivityElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentCarbon nanotubeSolvent

The invention discloses a method for preparing antistatic polyacrylonitrile fibers from a double-component nano electroconductive agent. The method comprises the following steps of: (1) compounding nano ATO (antimony tin oxide) with carbon nanotubes at a mass ratio of 1: (1-100) to obtain the double-component nano electroconductive agent, placing the double-component nano electroconductive agent,polyacrylonitrile and a dispersant in a spinning solvent, sufficiently stirring for dissolving polyacrylonitrile to obtain a blend solution, and treating in an ultrasonic dispersion device to prepare a blend spinning stock solution; and (2) passing through the blend spinning stock solution through a filtering and metering pump, and intruding to a coagulation bath composed of the spinning solvent and water through spinneret orifices to prepare the polyacrylonitrile fibers. The method has a simple process and high production efficiency, and can easily realize fiber production by adopting a conventional wet spinning process. By reasonable matching of different features and properties of nano ATO and carbon nanotubes, an electroconductive channel is formed in a polyacrylonitrile matrix, thus the electric conductivity of the polyacrylonitrile fiber is greatly improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

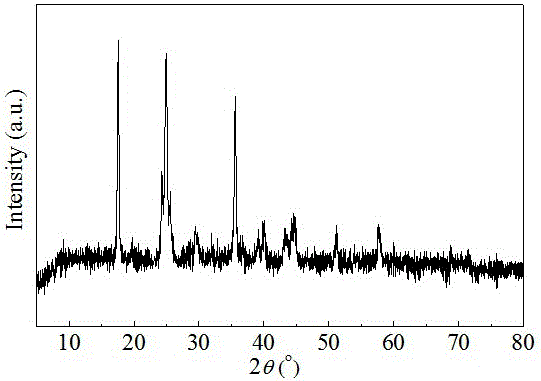

Method for preparing carbon-coating ferric phosphate lithium

ActiveCN101442117AImprove surface structureImprove electrochemical performanceElectrode manufacturing processesPhosphateNon oxidative

The invention discloses a method for preparing carbon-coated lithium iron phosphate (LiFePO4 / C). The method comprises the following steps: a, LiOH.H2O, reduced Fe powder and H3PO4 are weighed according to the molar ratio of 1:1:1 and are stirred in an aqueous solution so as to react for 2 to 10 hours under nitrogen protection; a carbon source is added to a reaction system, and an obtained suspension as a reaction product is subjected to spray drying through a high-speed centrifugal spray drying machine, so as to obtain a LiFePO4 / C precursor; and b, the LiFePO4 / C precursor is transferred to a tubular furnace in inert or non-oxidative atmosphere and treated for 6 to 24 hours at a temperature of between 200 and 750 DEG C, so as to obtain the LiFePO4 / C. As the method adopts the Fe powder as a raw material, the specific discharge capacity of a LiFePO4 / C anode material prepared by a coprecipitation method under the multiplying power between 0.1 and 2C is obviously improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

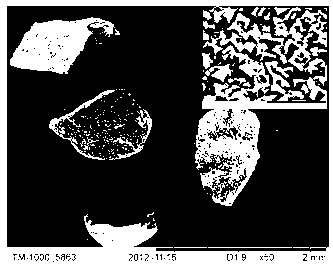

Method for preparing composite material of carbon coated lithium ferrous phosphate through iron phosphate

InactiveCN1915804AImprove completenessSuitable for industrial productionCell electrodesPhosphorus compoundsFerrous ammonium phosphatePhosphoric acid

This invention discloses a method for carbon-coated ferrous lithium phosphate composite material from ferric phosphate. The method comprises: (1) reducing Fe3+ of ferric phosphate into Fe2+ by a liquid-phase reducer; (2) reacting with NH4+ in the solution to obtain ferrous ammonium phosphate; (3) reacting with Li source at a high temperature and in inert atmosphere to obtain ferrous lithium phosphate; (4) coating with carbon to obtain carbon-coated ferrous lithium phosphate composite material. The method adopts Fe3+ as the raw material, thus reducing the costs of the raw material and the processing. The obtained composite material has such advantages as high purity and good electrochemical performance, and can be used as the cathode material of Li-ion batteries.

Owner:SHANGHAI JIAO TONG UNIV

Manufacture method of high-silicon aluminum content non-oriented silicon steel strip

ActiveCN102367547ASolving the problem of edge cracking in cold rollingSimple process routeMaterials preparationStress concentration

The invention discloses a manufacture method of a high-silicon aluminum content non-oriented silicon steel plate cold-rolled sheet, belonging to the field of material preparation and comprising the following components in parts by mass: 0.003 percent of C, 3.20 percent of Si, 0.60 percent of Mn, 0.008 percent of P, 0.001 percent of S, 1.10 percent of Al, 0.002 percent of Ti, not more than 0.03 percent of Ni, not more than 0.03 percent of Cr, not more than 0.03 percent of Cu and the balance of Fe or trace elements and unavoidable impurities. The manufacture method comprises the steps of: smelting in a converter, refining in a vacuum furnace, continuous-casting, thermal-rolling, normalizing, scouring and trimming, once-cold-rolling, intermediate-annealing, secondary-annealing, and annealing. A continuous casting blank is rolled into a strip, a hot-rolled strip enters a souring line for souring and trimmed on line after the scouring is finished; and the trimmed steel strip is subjected to normalization and annealing on a normalizing line and finally rolled and annealed. According to the invention, a stress concentrated part caused by trimming of the hot-rolled strip is released through the normalizing process, so that internal reasons causing cold rolling edge crack are eliminated and a cold rolling edge gap is completely removed.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for extracting salt from coking desulphurization waste solution and special device thereof

InactiveCN102161541AEffective interceptionAvoid diversionThiocyanic acidWater/sewage treatment bu osmosis/dialysisFiltrationDecomposition

The invention discloses a method for extracting salt from coking desulphurization waste solution and a special device thereof. The method comprises the following steps of: heating raw material waste solution for decomposition, adsorbing and decolorizing, then heating, evaporating and concentrating to obtain concentrated solution, performing heat filtration at constant temperature to remove fine sulfur particles, cooling and crystallizing in a crystallizer, filtering at constant temperature, separating filtrate to obtain crystals, washing the crystals to obtain high-purity ammonium thiocyanate, dissolving mixed salt crystals in ammonium sulfate mother liquor, regulating the acidity to be below 20 percent, preheating to ensure that the temperature is between 90 and 110 DEG C, blowing air oroxygen, performing oxidative transformation for 1min to obtain ammonium sulfate transformation liquid, and adding ammonium sulfate production mother liquor to obtain an ammonium sulfate product. By the method, a high-purity product can be extracted from the waste solution through one-time operation, so that processing and treatment times are reduced; solid-phase impurities are effectively intercepted and prevented from transferring to the crystals at constant temperature; and the mixed salt is subjected to oxidative transformation treatment, all ammonium thiosulfate is transformed into the ammonium sulfate product with high nitrogen content, the process is simple, operation cost is low, and product marketing is broad.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

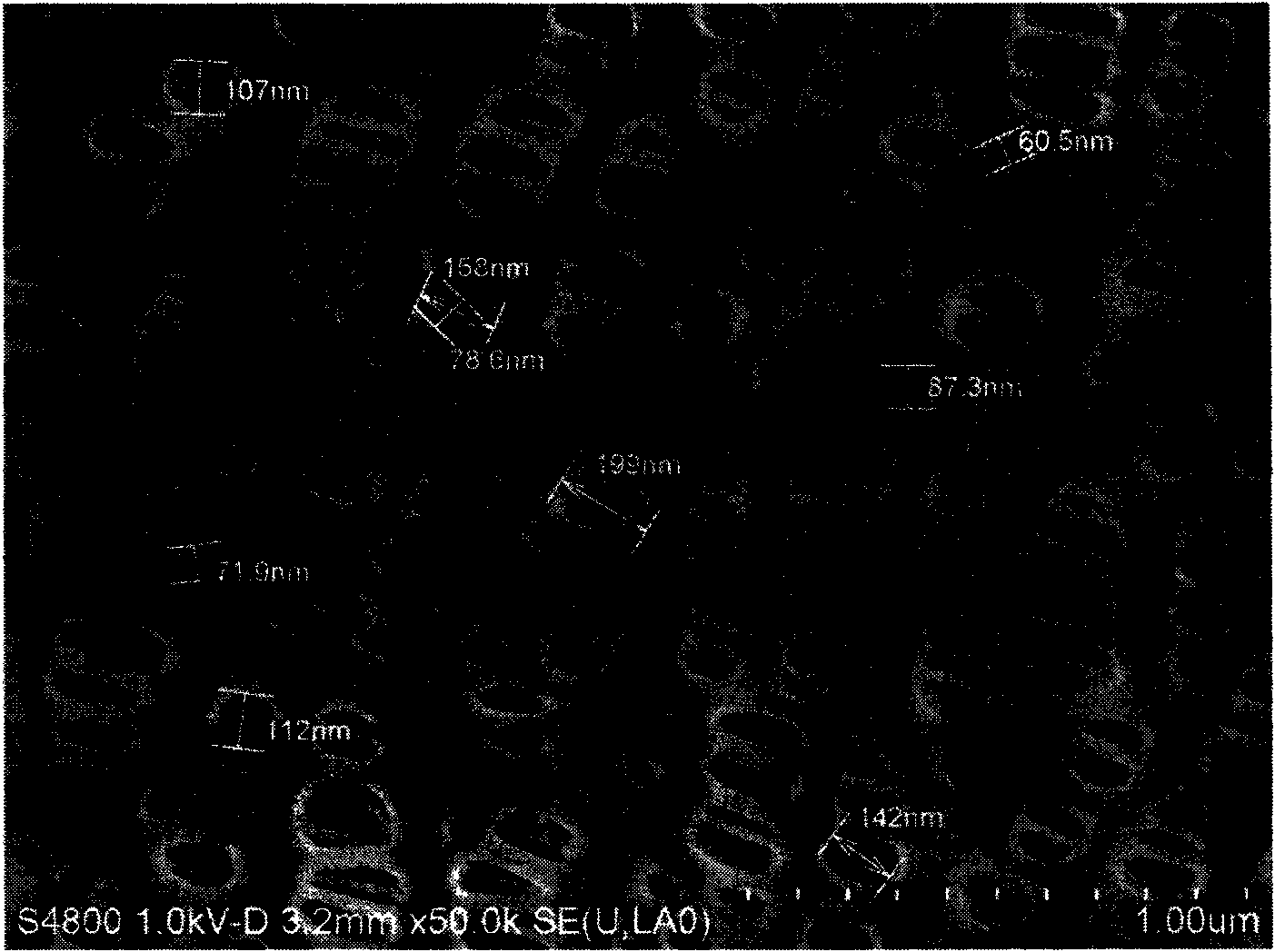

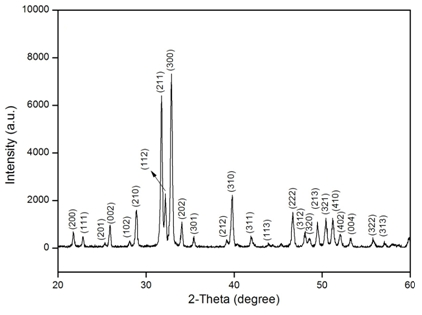

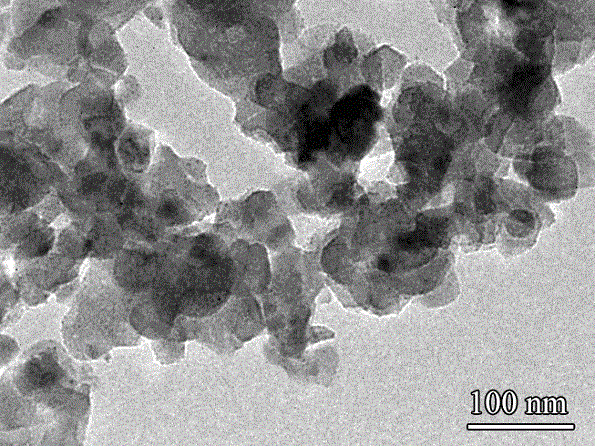

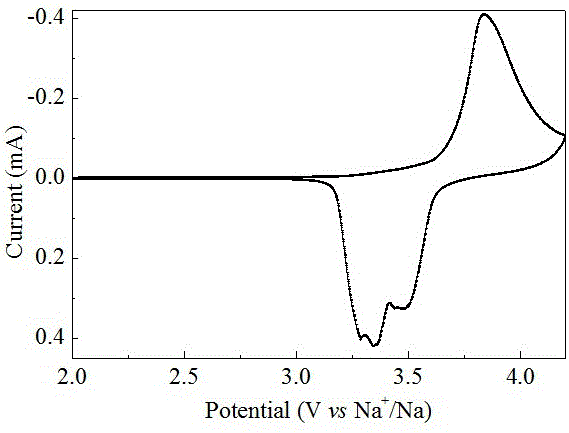

Potassium-sodium-manganese-iron-based Prussian-blue electrode material, and preparation method and application thereof

InactiveCN106549155AImproved magnification performanceImprove cycle stabilityMaterial nanotechnologyIron cyanidesNew energyManganese

The invention discloses a potassium-sodium-manganese-iron-based Prussian-blue electrode material, and a preparation method and application thereof, belonging to the technical field of synthesis of new-energy materials. According a technical scheme in the invention, the potassium-sodium-manganese-iron-based Prussian-blue electrode material has a general chemical formula of K<x>Na<y>MnFe(CN)<6>, wherein x and y are both more than 0 and less than 2; and the material has a cubic structure and a particle size of 10 to 200 nm. The invention also discloses the preparation method for the potassium-sodium-manganese-iron-based Prussian-blue electrode material and application of the material to the positive electrode of a sodium-ion battery. The potassium-sodium-manganese-iron-based Prussian-blue electrode material prepared in the invention has the cubic structure and a particle size of 10 to 200 nm; the nanometer three-dimensional structure of the material leads to increase in the specific surface area of the material and effective reduction in transfer distance of ions or electrons in the electrode material, so the rate performance and cycle stability of the electrode material are improved; and the electrode material has excellent electrochemical performance as a positive electrode material for the sodium-ion battery.

Owner:HENAN NORMAL UNIV

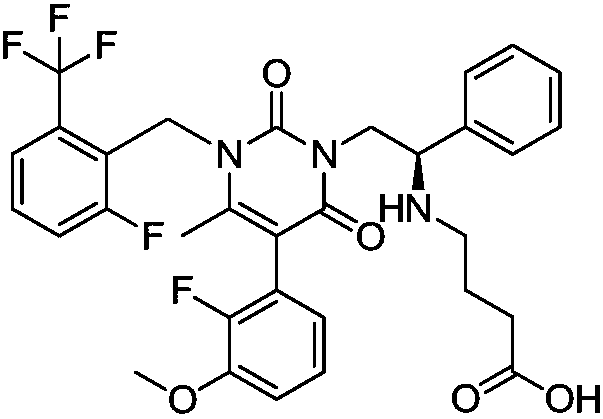

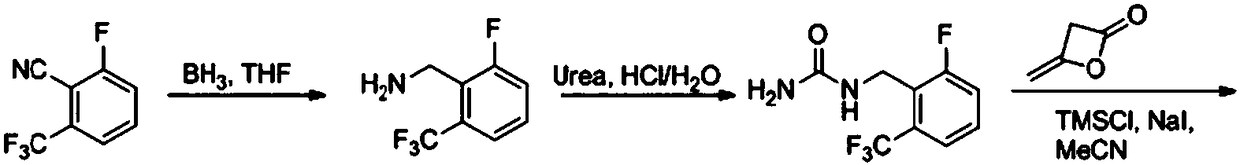

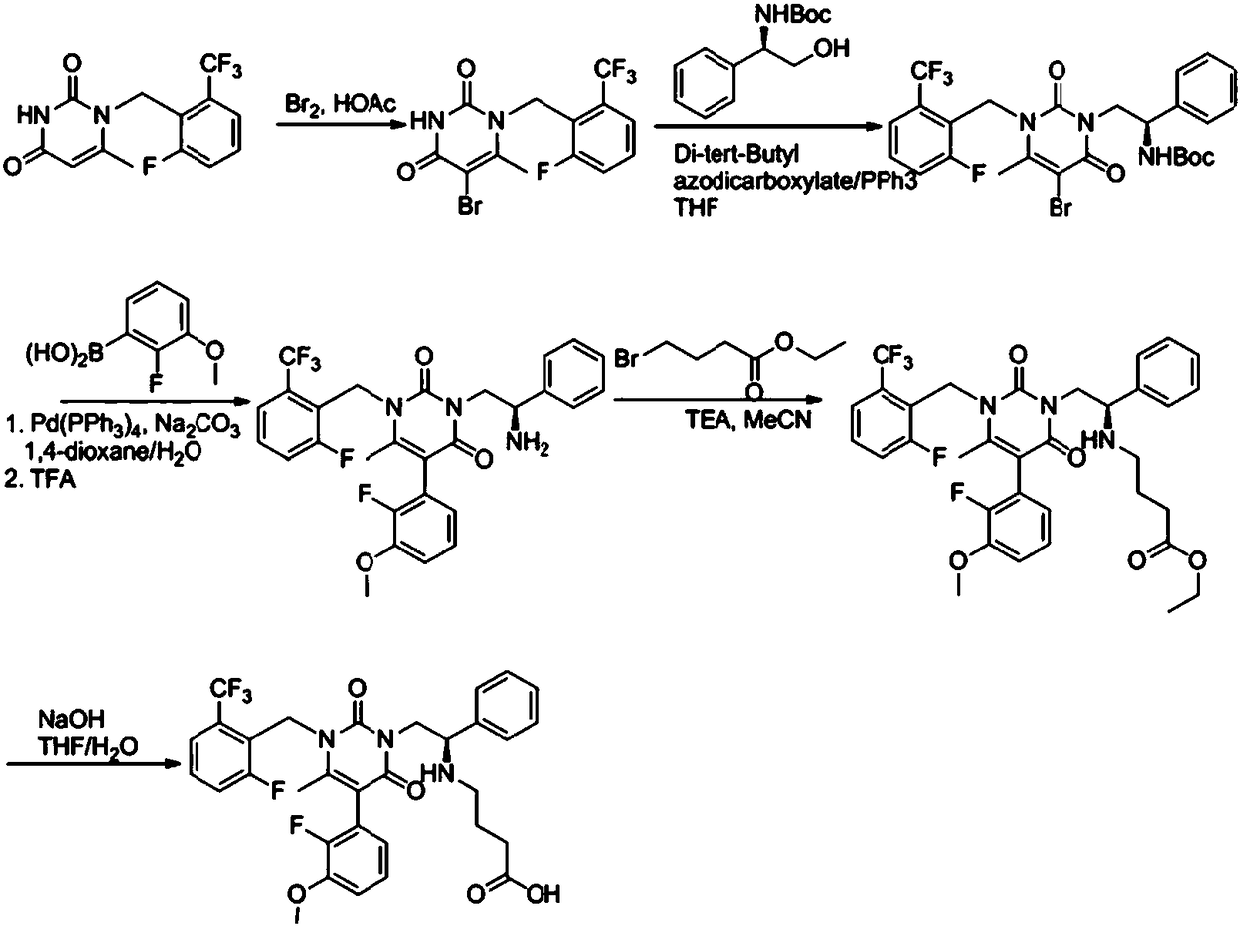

Elagolix synthesis method

The invention provides an elagolix synthesis method. The elagolix synthesis method comprises enabling a compound 5 and a compound 10 to participate in a condensation reaction to finish N-alkylation reaction to obtain a compound 11, and then implementing alkaline hydrolysis to obtain elagolix 12. The invention further discloses two synthesis methods of the compound 5: the method I comprises enabling a 5-bromine-6-methylpyrimidine-2,4(1H,3H)-diketone compound 1 and a 2-(brooethyl)-1-fluorin-3-(trifluoromethyl) benzene compound 2 to have a condensation reaction to obtain an intermediate 3, and then having a coupling reaction; the method II comprises enabling 1-halide-3-fluorin-2-anisole and acetoacetate 7 to have a coupling reaction to obtain a compound 8, and then having a condensation cyclization reaction with a compound 9; the improvements greatly shorten the route steps, the route efficiency is improved, the use of a noble metal catalyst is avoided, and the process cost is greatly lowered. The operation of the route is simple, the total yield is high, the purity of an obtained product is also relatively high, and the method is suitable for the enlarged production.

Owner:HANGZHOU CHEMINSPIRE TECH CO LTD

Microcapsule sustained release agent and preparation method and application thereof

InactiveCN102373110ASimple process routeMild conditionsEssential-oils/perfumesAnimal housingDispersityFirming agent

The invention provides a microcapsule sustained release agent and a preparation method and application thereof. The microcapsule sustained release agent is prepared by embedding essence with gelatin and Arabic gum, and is applied to sanitary towels or sanitary cushions or panty-shape diapers or pet cushions. The microcapsule sustained release agent consists of a core material and a wall material, wherein the wall material consists of natural high molecular gelatin, Arabic gum and a curing agent; the core material consists of essence and essential oil; the curing agent consists of tannic acid and glutaraldehyde; and microencapsulation is performed on the core material and the wall material in the ratio 1:2. The invention further provides a preparation method of the microcapsule sustained release agent. The preparation method comprises the following steps of: adding an emulsifier into Arabic gum for mixing; adding essence or essential oil into an emulsion for homogenizing and emulsifying; adding a gelatin solution into the emulsified emulsion; agglomerating into a capsule; curing with a curing agent; and drying to obtain a high-dispersity microcapsule sustained release agent. By adding the microcapsule sustained release agent into the space between a skin contact layer and a water-absorbing layer of a sanitary towel or sanitary cushion or panty-shape diaper or pet cushion, the effect of keeping fragrance for a long time can be achieved.

Owner:TIANJIN SINOSH NEW MATERIAL TECH

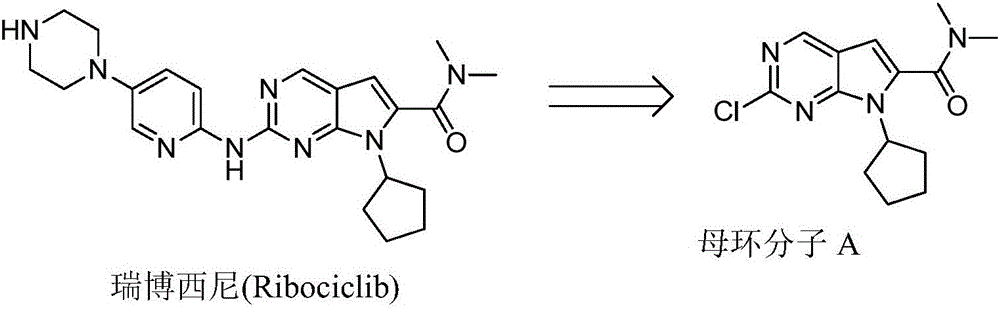

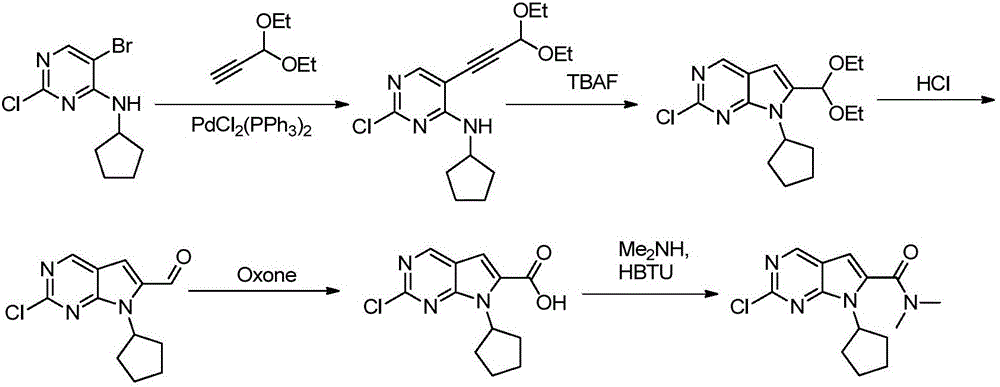

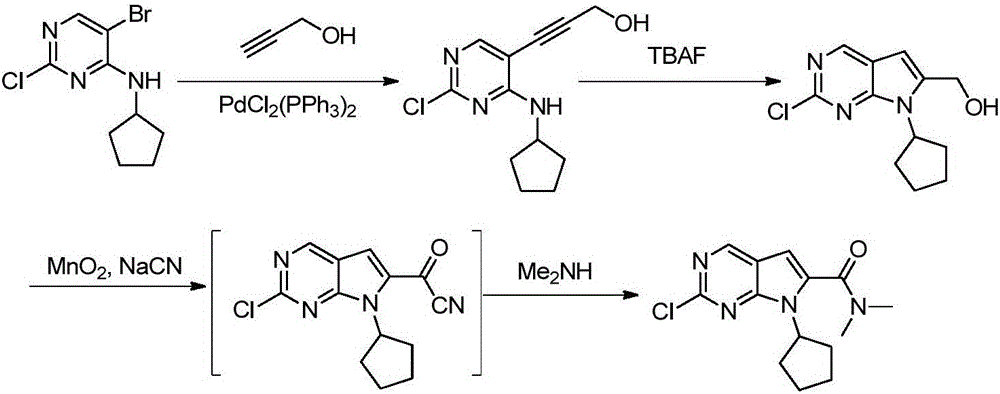

New synthesis method of ribociclib intermediate

ActiveCN106478641AEasy to operateImprove coupling conditionsOrganic chemistrySynthesis methodsSide chain

The invention discloses preparation of a ribociclib key intermediate A; propiolic acid ester or amide 2 is directly used as a Sonogashira coupling side chain, coupling conditions are optimized, an intermediate 3 is obtained with relatively high yield, the intermediate 3 is directly subjected to ring closing under simple conditions to complete construction of a mother ring molecule, to obtain a structural formula A or a precursor ester 4 of the structural formula A, and the precursor ester 4 is subjected to hydrolysis and condensation to obtain the structural formula A. The route has simple operation, reaction steps are shorted, the yield is relatively high, and the purity of the obtained product is relatively high, and the method is suitable for enlarged production, wherein the reaction route is described in the specification.

Owner:HANGZHOU CHEMINSPIRE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com