Potassium-sodium-manganese-iron-based Prussian-blue electrode material, and preparation method and application thereof

A potassium-sodium-manganese-based, Prussian blue technology, applied in nanotechnology, battery electrodes, circuits, etc. for materials and surface science, can solve the problem of memory effect affecting the use of lead-acid batteries, safety problems, and environmental pollution. , to achieve the effect of easy industrialized continuous production, low cost, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

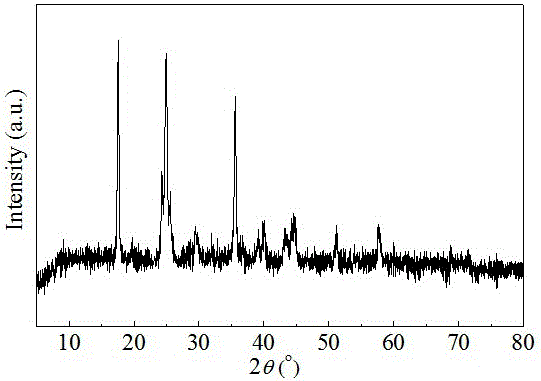

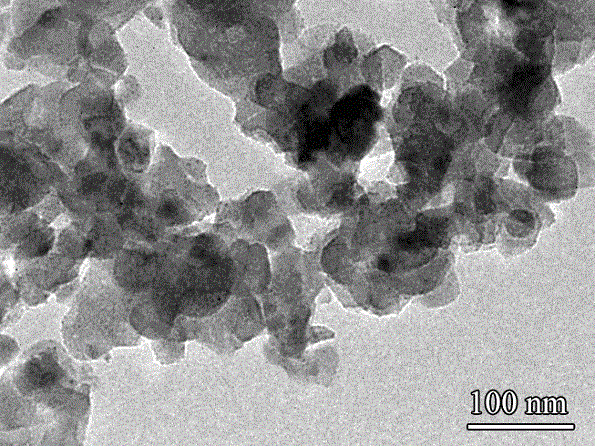

[0028] Put 0.8g of manganese chloride and 1.0g of sodium citrate into a 500mL beaker, add 200mL of deionized water, stir until dissolved to obtain solution A. Put 1.7g of potassium ferricyanide in a 500mL beaker and add 200mL of deionized water, stir until dissolved to obtain solution B. Then solution B was added to solution A, aged at room temperature for 12 hours, washed three times with water, washed three times with alcohol, and dried to obtain K x Na y MnFe(CN) 6 . K produced x Na y MnFe(CN) 6 See the XRD pattern of figure 1 , the resulting K x Na y MnFe(CN) 6 The TEM image is shown in figure 2 .

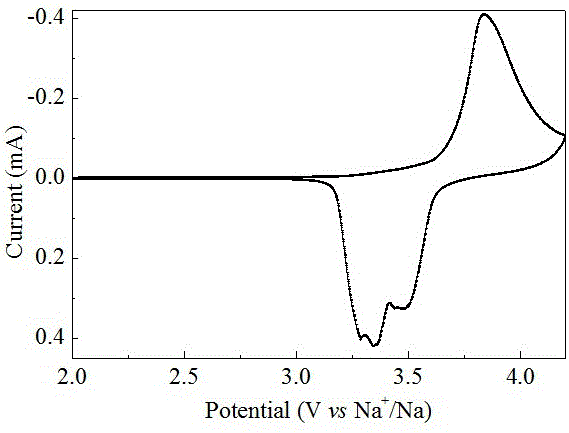

[0029] K prepared with this example x Na y MnFe(CN) 6 , Conductive carbon black and binder polyvinylidene fluoride are mixed in a mass ratio of 80:10:10, and deionized water is used as a solvent, coated on the aluminum foil, and vacuum-dried for 12 hours. Then use sodium perchlorate, PC, EC as the electrolyte, and the sodium sheet as the counter electrode...

Embodiment 2

[0031] Put 1.2g of manganese chloride and 2.6g of sodium citrate into a 500mL beaker and add 200mL of deionized water, stir until dissolved to obtain solution A. Put 1.7g of potassium ferricyanide in a 500mL beaker and add 200mL of deionized water, stir until dissolved to obtain solution B. Then add solution A (B) to solution B (A), age at 50°C for 12 hours, wash with water three times, wash with alcohol three times, and dry to obtain K x Na y MnFe(CN) 6 . K produced x Na y MnFe(CN) 6 See the XRD pattern of Figure 5 .

[0032] K prepared with this example x Na y MnFe(CN) 6 , Conductive carbon black and binder polyvinylidene fluoride are mixed in a mass ratio of 80:10:10, and deionized water is used as a solvent, coated on the aluminum foil, and vacuum-dried for 12 hours. Then use sodium perchlorate, PC, EC as the electrolyte, and sodium sheet as the counter electrode to carry out CV and constant current charge and discharge tests. The CV curve is shown in I...

Embodiment 3

[0034]Put 60g of manganese sulfate and 50g of sodium citrate in a container, add 5L of deionized water, stir until dissolved to obtain solution A. Put 150g of sodium ferrocyanide in a container and add 5L of deionized water, stir until dissolved to obtain solution B. Then add solution B to solution A, age at 30°C for 20 hours, wash with water three times, wash with alcohol three times, and dry to obtain K x Na y MnFe(CN) 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com