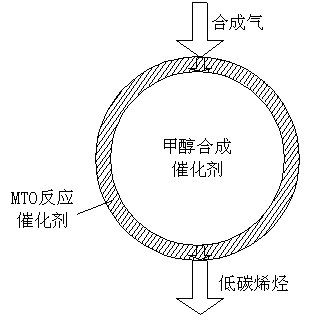

Core-shell structure catalyst and method for preparing low-carbon olefin by using synthetic gas one-step method

A technology of core-shell structure and low-carbon olefins, which is applied in the direction of molecular sieve catalysts, hydrocarbon production from carbon oxides, chemical instruments and methods, etc., can solve the problems of low self-sufficiency rate and large consumption demand, so as to prolong the service life and reduce high Carbon product generation, effect of increasing the yield of the target product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Mix the nitric acid solution of copper, zinc and aluminum with Na 2 CO 3 Solution co-precipitation, suction filtration, drying and roasting to obtain copper-zinc-aluminum oxide;

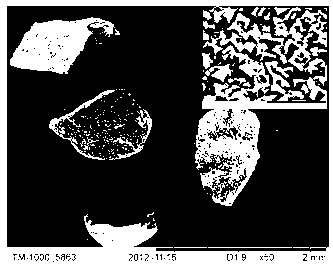

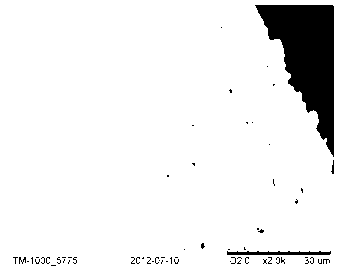

[0026] 2) Press Al 2 o 3 :P 2 o 5 : SiO 2 :TEAOH:H 2 The molar ratio of O was 0.3:1:0.2:2:100 to prepare a synthetic liquid, and reacted hydrothermally at 150°C for 20 hours to obtain molecular sieve crystal seeds. Coat the seed crystal on the surface of the copper-zinc-aluminum oxide carrier, put the seed-coated carrier into the synthesis solution and crystallize at 170°C for 100 hours to prepare the core-shell of copper-zinc-aluminum oxide coated with SAPO-17 molecular sieve membrane Structural catalyst, the obtained core-shell structure catalyst sees figure 2 , whose cross-sectional view is shown in image 3 , the thickness of the molecular sieve film is 6 microns, and the pore size of the shell film is 0.4 nm;

[0027] 3) Add the prepared core-shell structure catalyst into th...

Embodiment 2

[0030] 1) Mix the nitric acid solution of copper, zinc and cobalt with Na 2 CO 3 solution co-precipitation, suction filtration, drying and roasting to obtain copper-zinc-cobalt oxide;

[0031] 2) Press Al 2 o 3 : SiO 2 :TPAOH:EtOH:H 2 The molar ratio of O was 2:1:0.01:5:300 to configure the synthesis solution, and hydrothermally reacted at 180°C for 10 hours to obtain molecular sieve seeds. Coat the seed crystal on the surface of the copper-zinc-cobalt oxide carrier, put the seed-coated carrier into the synthesis solution and crystallize at 190°C for 50 hours to prepare the modified ZSM-5 molecular sieve membrane-coated copper-zinc-cobalt oxide Core-shell structure catalyst, molecular sieve membrane thickness 15 microns, shell membrane pore size 0.5nm;

[0032] 3) Add the prepared core-shell structure catalyst into the reaction tube, and reduce it with hydrogen diluted with nitrogen, wherein the volume percentage of hydrogen in the mixed gas is 5%;

[0033] 4) After the...

Embodiment 3

[0035] 1) Mix copper-zinc nitric acid solution, nickel-manganese-chromium hydrochloric acid solution with Na 2 CO 3 solution co-precipitation, suction filtration, drying and roasting to obtain copper zinc nickel manganese chromium oxide;

[0036] 2) Press Al 2 o 3 :P 2 o 5 : SiO 2 :TEAOH:H 2The molar ratio of O was 3:2:1.5:0.1:500 to configure the synthesis liquid, and hydrothermally reacted at 160°C for 40 hours to obtain molecular sieve seeds. Coat the seed crystal on the surface of the copper-zinc-nickel-manganese-chromium oxide support, put the seed-coated support into the synthesis liquid and crystallize at 165°C for 70 hours to prepare SAPO-34 molecular sieve membrane-coated copper-zinc-nickel-manganese-chromium oxide The core-shell structure catalyst of the material, the molecular sieve film thickness is 1 micron;

[0037] 3) Add the prepared core-shell structure catalyst into the reaction tube, and reduce it with hydrogen diluted with nitrogen, wherein the volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com