Aluminium-plated particle reinforced aluminum-matrix composite material and preparation method thereof

An aluminum-based composite material, particle-reinforced aluminum technology, applied in chemical instruments and methods, layered products, metal layered products, etc. The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

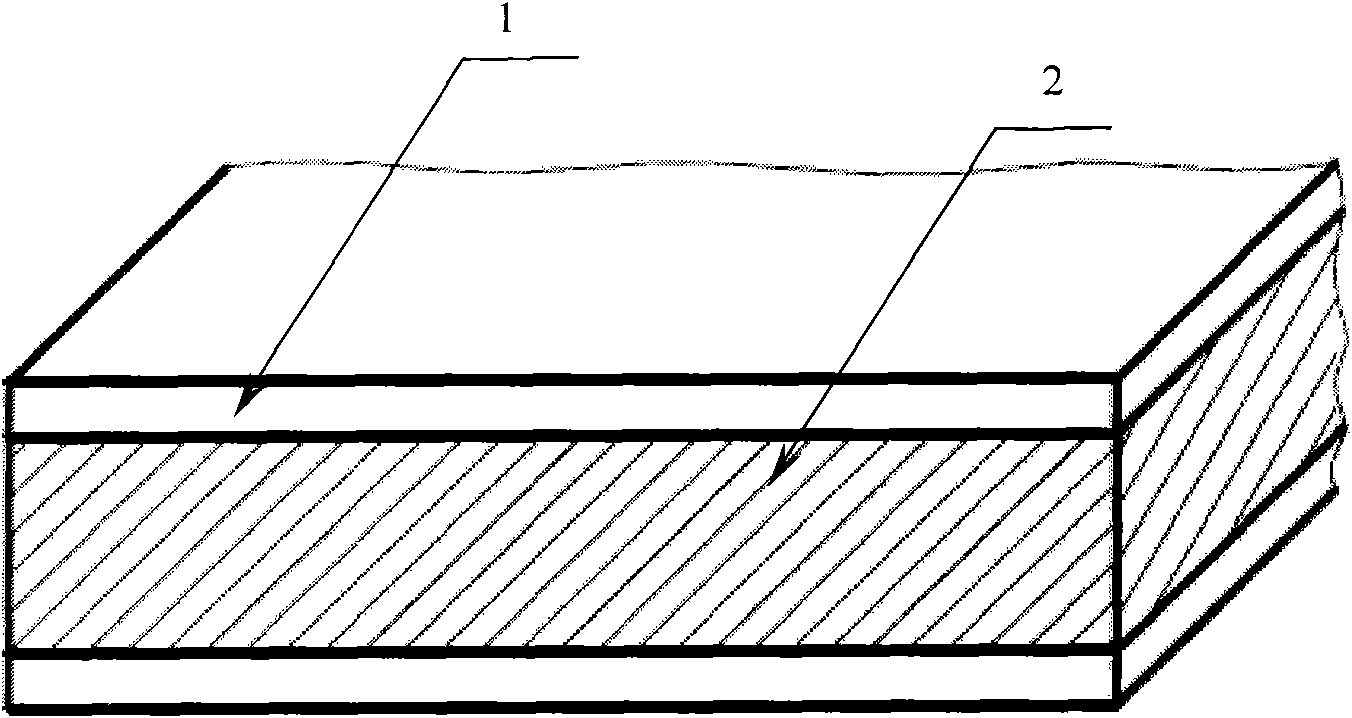

[0034] The aluminum-coated particle reinforced aluminum-based composite material prepared in this embodiment, such as figure 1 As shown, the surface layer is the surface pure aluminum layer 1, the core particle reinforced aluminum matrix composite material layer 2 is 37% vol. Aluminum 6061).

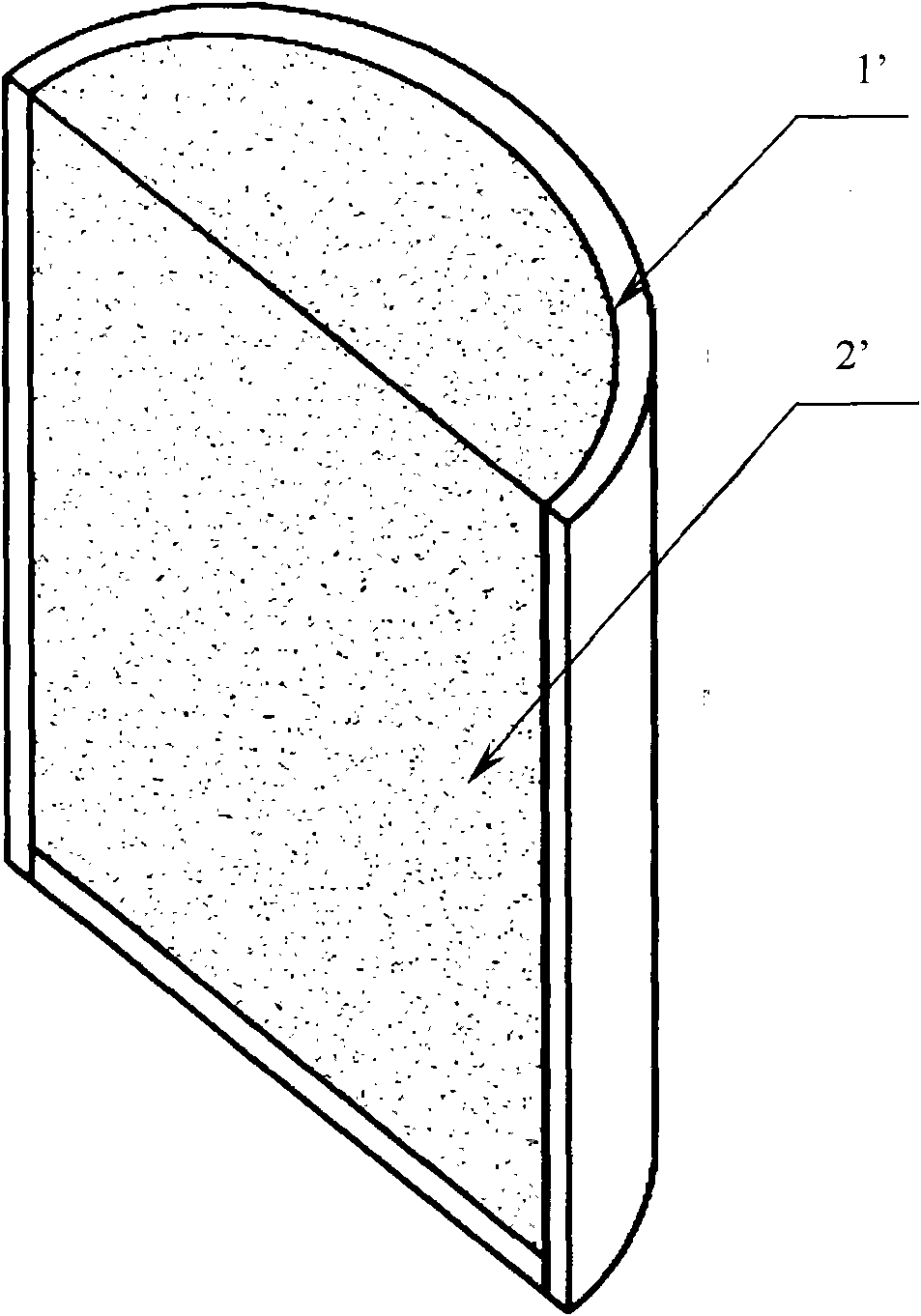

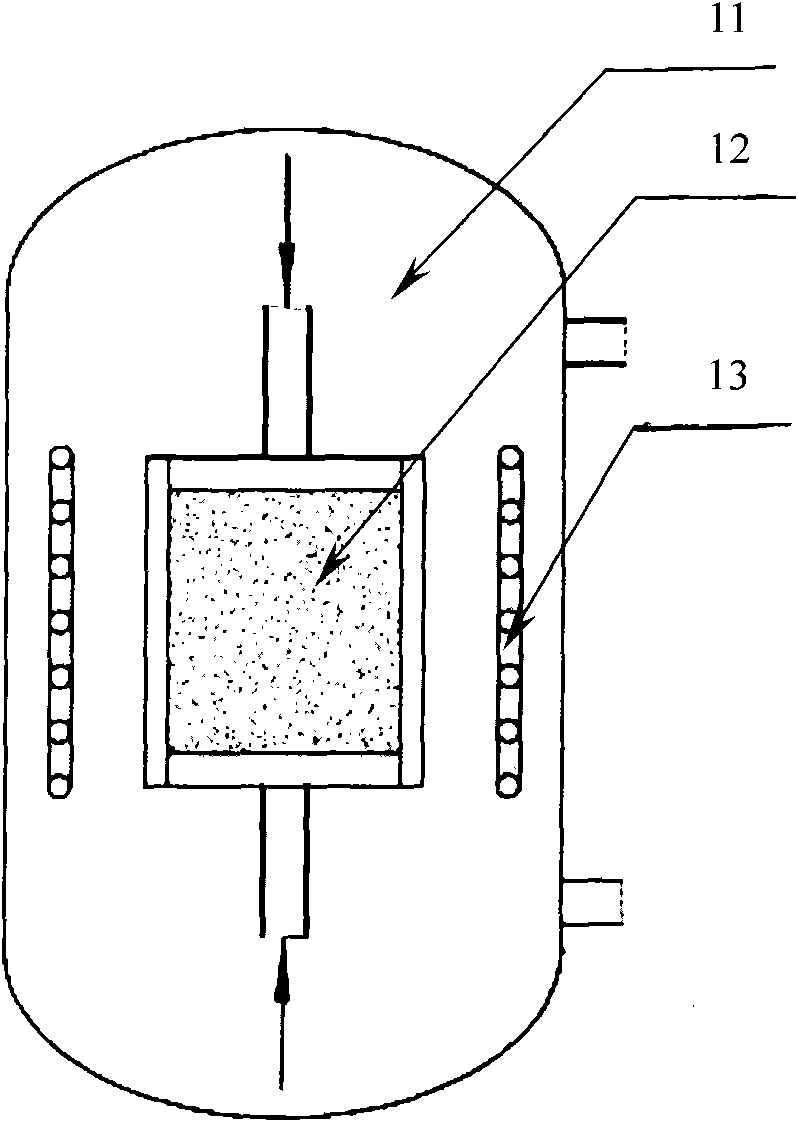

[0035] Its preparation method is as follows: figure 2 As shown, (1) put the uniformly mixed 37% vol.AlN / 6061 core particle reinforced aluminum matrix composite powder 2' into a barrel-shaped pure aluminum mold cover 1' with a wall thickness of 1 mm; (2) cover it After the pure aluminum cover plate is put into the steel mold as a whole; image 3 As shown, a heating element 13 is provided in the vacuum hot-press chamber 11, (3) the pure aluminum mold cover and the steel mold assembly 12 to be pressed are loaded into the vacuum hot-press chamber 11 to carry out Pressing, the process conditions are: pressure 30MPa, temperature 600°C, time 6h, after vacuum hot pressing, the steel mold is ...

Embodiment 2

[0037] The aluminum-coated particle reinforced aluminum-based composite material prepared in this embodiment, such as figure 1 As shown, the surface layer is the surface pure aluminum layer 1, and the core particle reinforced aluminum matrix composite material layer 2 is 25% vol.SiC p / 2009 (reinforcement particle SiC p The volume percentage is 25%, and the balance is the aluminum alloy matrix duralumin 2009).

[0038] Its preparation method is as follows: figure 2 As shown, (1) will mix uniformly 25% vol.SiC p / 2009 Core aluminum particle reinforced aluminum matrix composite material powder 2' is loaded into a barrel-shaped pure aluminum mold cover 1' with a wall thickness of 5mm; (2) After covering the pure aluminum cover plate, vacuumize it and degas it; Figure 4 As shown, a heating element 13' is arranged in the hot isostatic pressing chamber 11', (3) the pure aluminum die sleeve assembly 12' to be pressed with the particle-reinforced aluminum-based composite material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com