Method for extracting salt from coking desulphurization waste solution and special device thereof

A technology of coking desulfurization waste liquid and special equipment, which is applied in chemical instruments and methods, thiocyanic acid, inorganic chemistry, etc., can solve the problems of temperature being affected by environmental changes, prolonging the product processing route, and direct entry of concentrated liquid, etc., to achieve product Wide market, low operating costs, and the effect of preventing transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for extracting salt from coking desulfurization waste liquid, comprising the following steps:

[0028] Under the conditions of 80-85°C and vacuum degree of 0.095Mpa, heat the coking desulfurization waste liquid and react for 2-4 hours to decompose polysulfides to remove sulfur and ammonia, and add 1-2% activated carbon equivalent to the volume of the coking desulfurization waste liquid Adsorb the precipitated sulfur and ammonia, as well as impurities in the solution, to obtain a clear night, the pH of the clear liquid is less than 7; heat and evaporate the concentrated clear liquid to obtain a concentrated liquid; under normal pressure or negative pressure of 0.03Mpa, use Ultrafiltration material, at 80-85°C, heat-filter the concentrate at a constant temperature to remove fine sulfur particles to obtain a clean concentrate; the clean concentrate is cooled and crystallized in a crystallizer, firstly controlled at 70°C, crystallized ammonium sulfate, and separated...

Embodiment 2

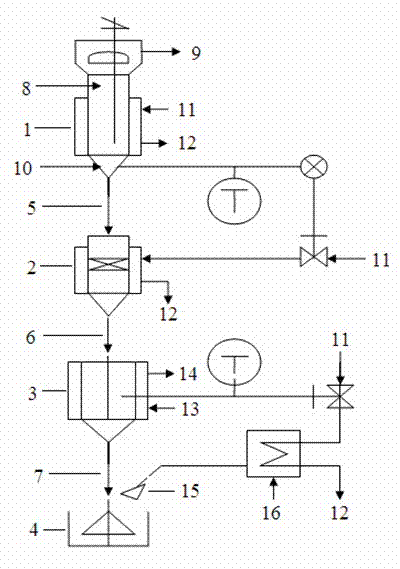

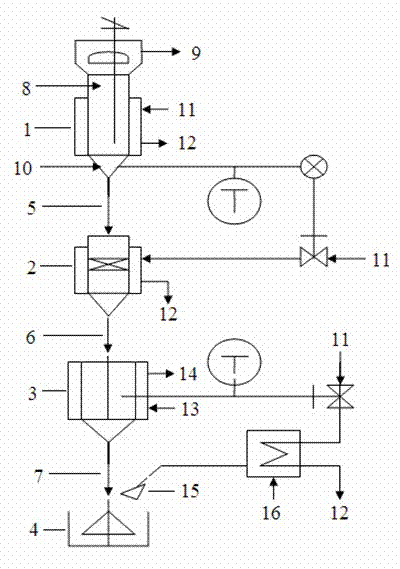

[0030] As shown in the drawings, it is a special device for the method of extracting salt from coking desulfurization waste liquid of the present invention. The device includes an evaporation concentrator 1, a constant temperature ultrafilter 2, a cooling crystallizer 3, a constant temperature washing separator 4, and a vacuum evaporator. The bottom of the evaporation concentrator 1 is provided with a concentrate discharge pipe 5, and the concentrate discharge pipe 5 is connected to the top inlet of the constant temperature ultrafilter 2; a net concentrate discharge pipe 6 is arranged at the bottom of the constant temperature ultrafilter 2, and the net concentration The liquid discharge pipe 6 is connected with the cooling crystallizer 3; the crystallization slurry discharge pipe 7 is arranged at the bottom of the cooling crystallizer 3, and the crystallization slurry discharge pipe 7 is connected with the constant temperature washing separator 4.

[0031] During the operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com