Patents

Literature

187 results about "Ammonium thiosulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium thiosulfate (ammonium thiosulphate in British English) is an inorganic compound with the formula (NH₄)₂S₂O₃. It is white crystalline solid with ammonia odor, readily soluble in water, slightly soluble in acetone and insoluble in ethanol and diethyl ether.

Protein-based wood adhesive and preparation method thereof

InactiveCN102719217ANo health damageAvoid decompositionNon-macromolecular adhesive additivesProtein adhesivesPolyvinyl alcoholAdhesive

The invention discloses a protein-based wood adhesive which is characterized by being made of the following raw materials in part by weight: 100 parts of water, 5 to 50 parts of protein-containing raw materials, 10 to 14 parts of polyamide epichiorobydrin (PAE), 5 to 15 parts of modifier, 1 to 15 parts of acidity regulator, 0 to 15 parts of stabilizer, 0 to 10 parts of humectant, 0 to 10 parts of anti-freeze, 0.1 to 10 parts of preservatives, 0 to 10 parts of mold inhibitor, 0 to 10 parts of enzyme inhibitor, and 0 to 10 parts of filling. The protein-containing raw materials contain over 10% of coarse protein, and the modifier is one of or a mixture of several of polyacrylamide, polyvinyl alcohol, polyvinyl acetate, borax, ammonium thiosulfate, carbamide and isocyanate. The invention also discloses a preparation method of the protein-based wood adhesive. The invention adopts common chemical materials and adopts a break-through normal-temperature material-mixing technique, which uses water as solvent. The adhesive has the advantages of high stickiness, evenness and convenience in adhesive application and stable product quality.

Owner:马晓平

Fertilizer specially used for rice and preparation method thereof

ActiveCN103964971AIncrease profitEasy to breatheFertilizer mixturesPotassiumMagnesium ammonium phosphate

The invention discloses a fertilizer specially used for rice and a preparation method thereof. The fertilizer comprises an organic fertilizer and an inorganic fertilizer, wherein the inorganic fertilizer is prepared from the following raw materials: urea, monoammonium phosphate, potassium chloride, lime nitrogen, magnesium ammonium phosphate, zinc sulfate, boric acid, a sterilizing agent, urea formaldehyde, diatomite, ATS and dicyandiamide; the urea formaldehyde containing ammonium thiosulfate and dicyandiamide serves as a coating, and the diatomite is attached to the outer side of the coating; the other raw materials are contained in the coating. The organic fertilizer is prepared from the following raw materials: sterilizing agent decoction dregs, chicken manure, bagasse, xylitol residue, cottonseed cake and plant ash. The fertilizer can meet the requirement of the whole rice growth period after being applied once, manual labor is saved, the soil aeration, fertilizer absorption and water retention characteristics can be improved, steady growth of rice plants is promoted, and the yield is increased by 10-20 percent per mu.

Owner:JINAN BADUN FERTILIZER

Method for comprehensively utilizing phosphate fertilizer by-product

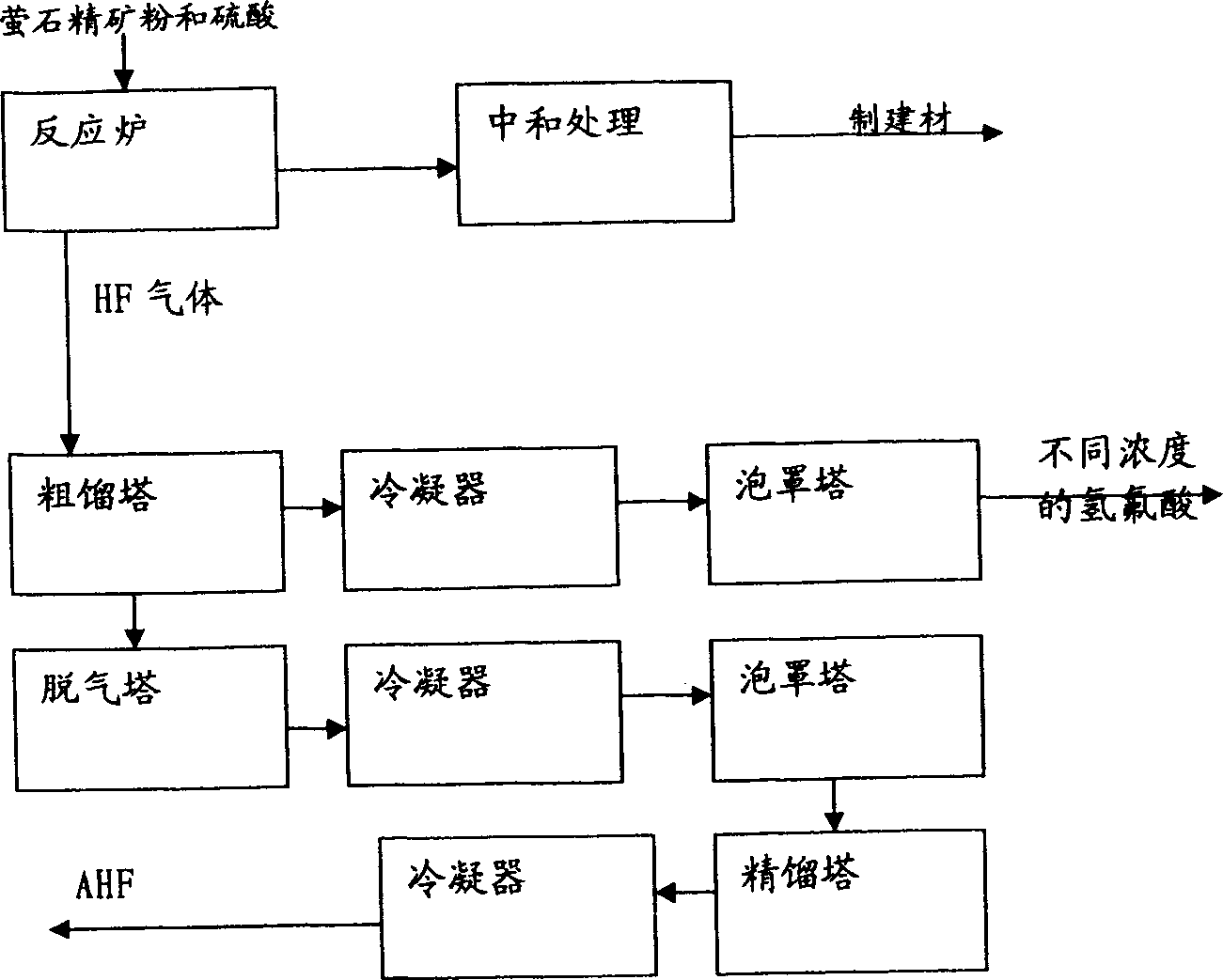

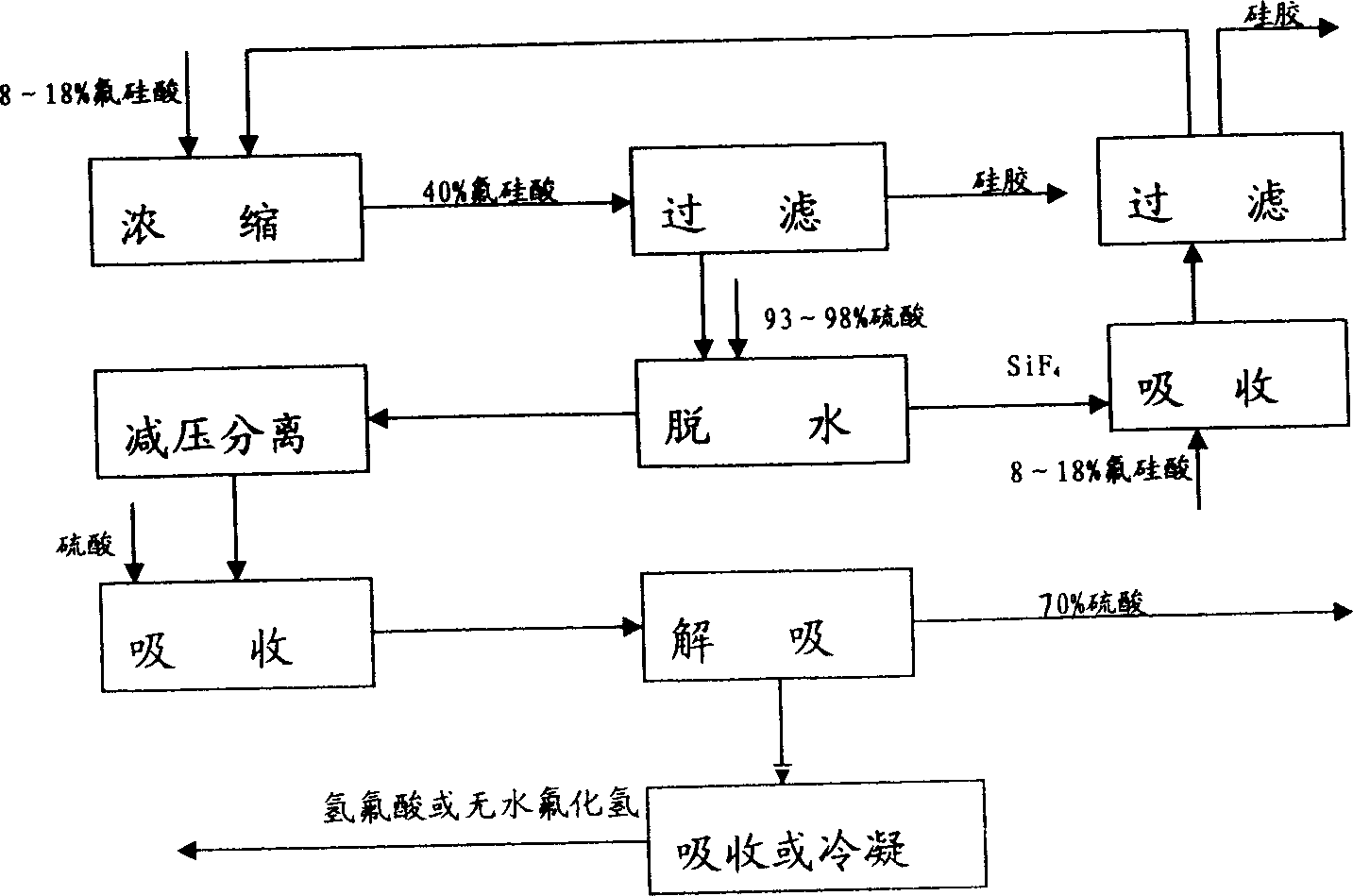

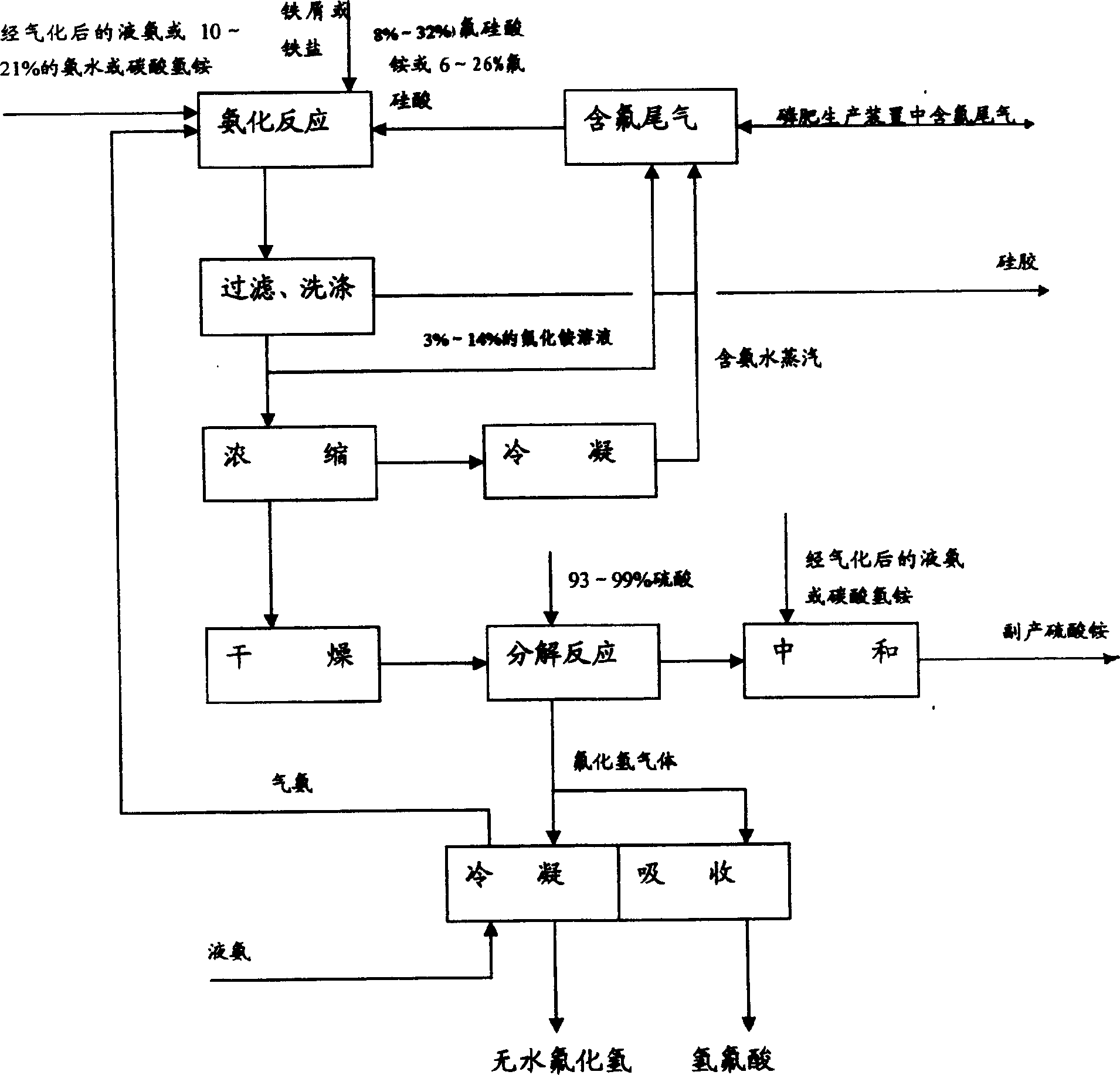

InactiveCN1554570AReasonable designReduce material requirementsSolid waste disposalFluorine/hydrogen-fluorideIron saltsAmmonium fluorosilicate

The method of comprehensively utilizing phosphate fertilizer by-product includes utilizing ammonium fluoride solution of 3-14% concentration to absorb side product fluorine containing tail gas ammonium fluorosilicate solution; adding iron scrap or iron salt to fluorosilicic acid as one other by-product to eliminate phosphorus; adding liquid ammonia, ammonia water or ammonium bicarbonate; filtering, washing, and eliminating silica precipitate; returning ammonium fluoride solution to phosphate fertilizer absorbing system, concentration and drying to obtain ammonium hydrogen fluoride; reacting solid ammonium hydrogen fluoride and sulfuric acid at high temperature to obtain HF gas, absorbing HF gas to obtain hydrofluoric acid, purification and condensation to obtain anhydrous HF; and mixing the mixture of ammonium sulfate and ammonium bisulfate with ammonium bicarbonate or ammonia in a mixer, curing and crushing to ammonium sulfate fertilizer.

Owner:云南三环化工有限公司 +1

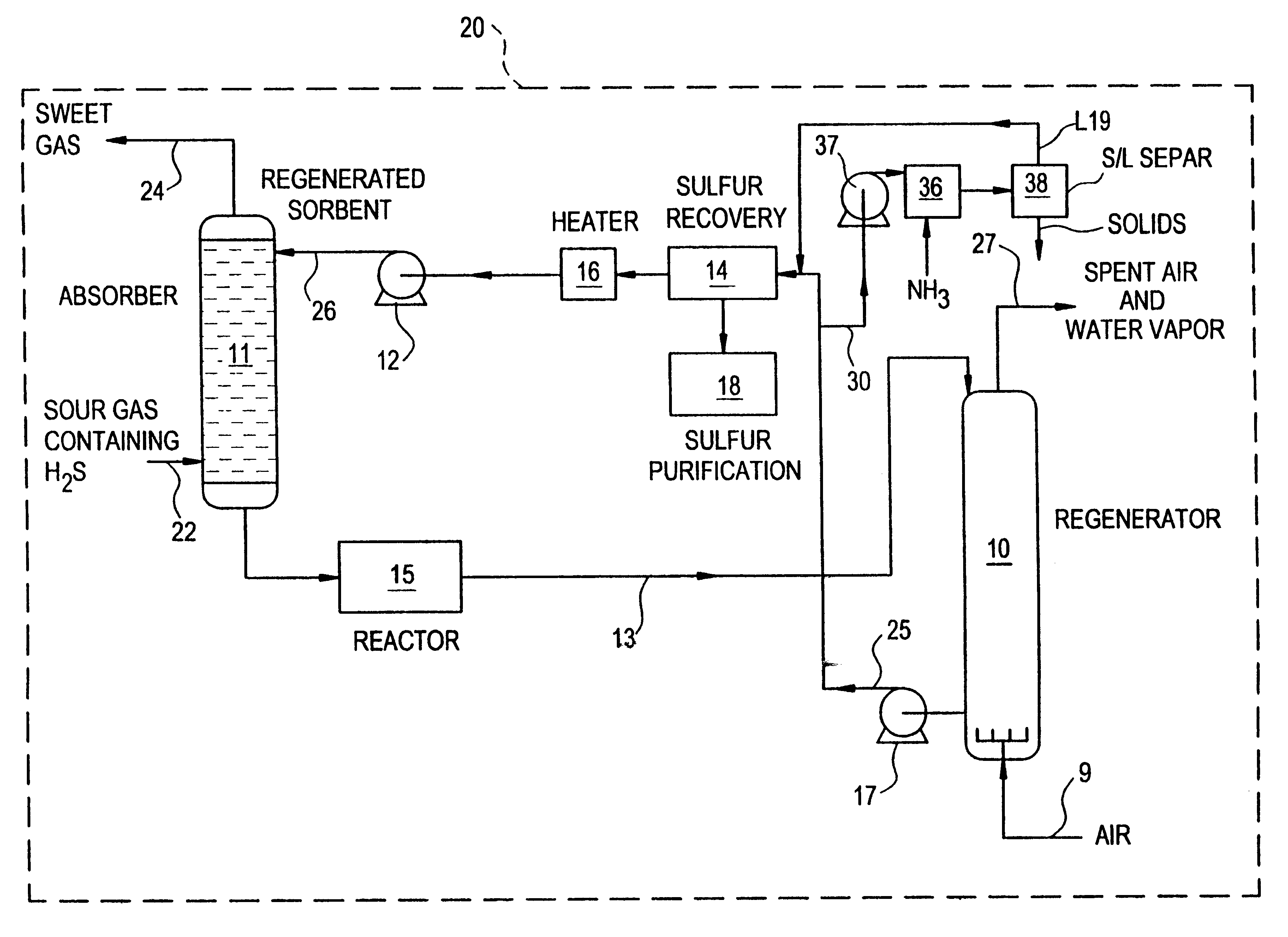

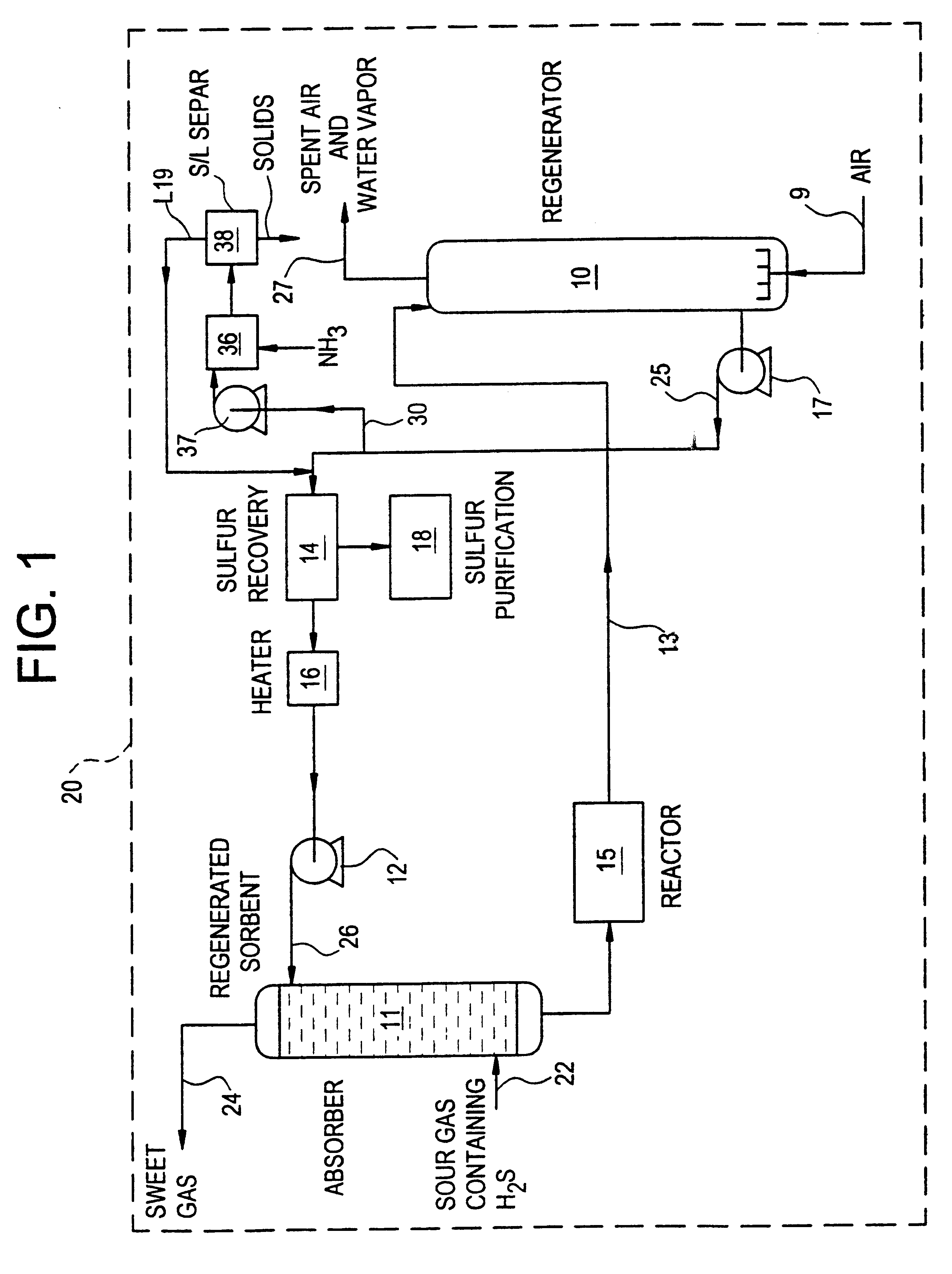

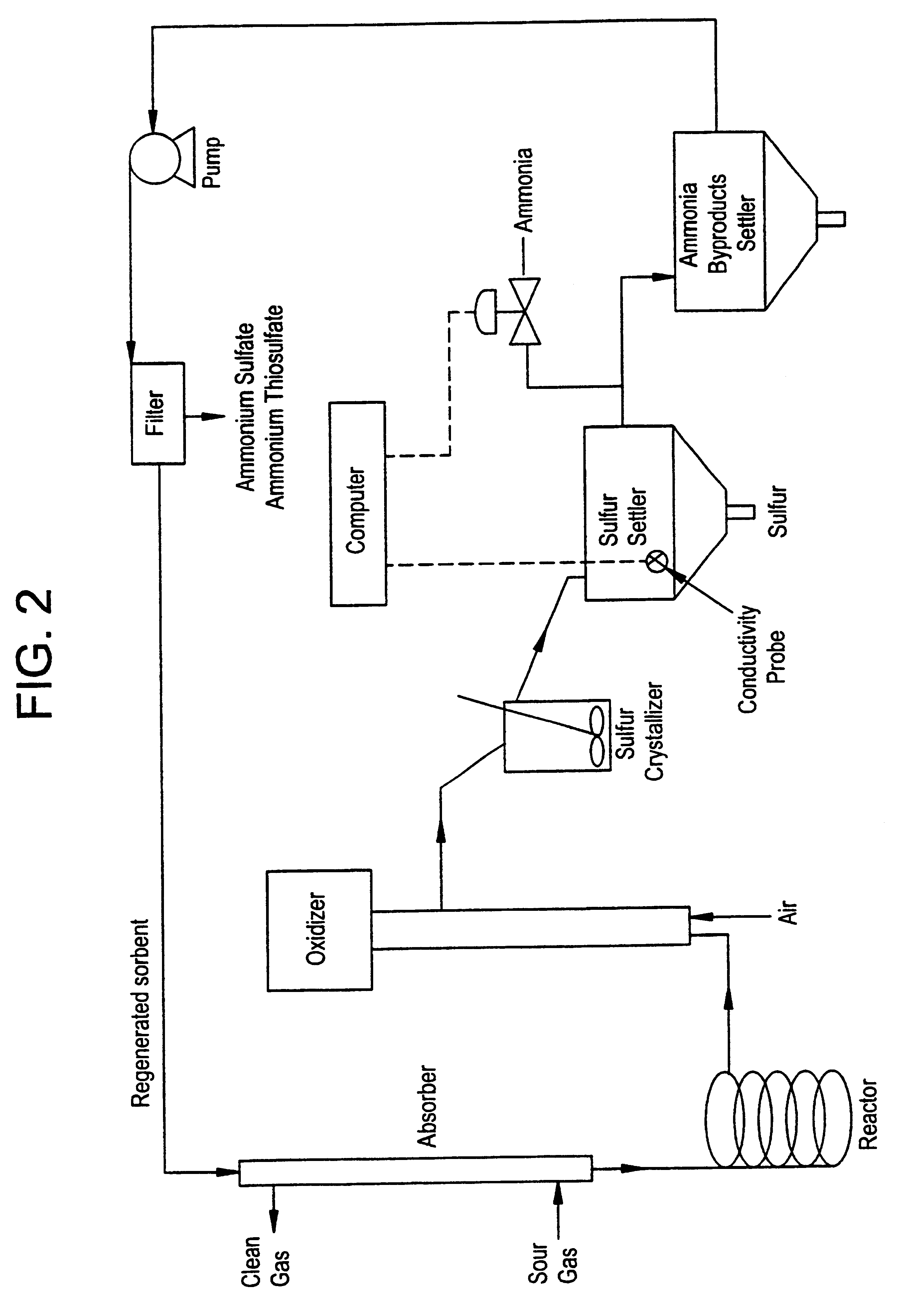

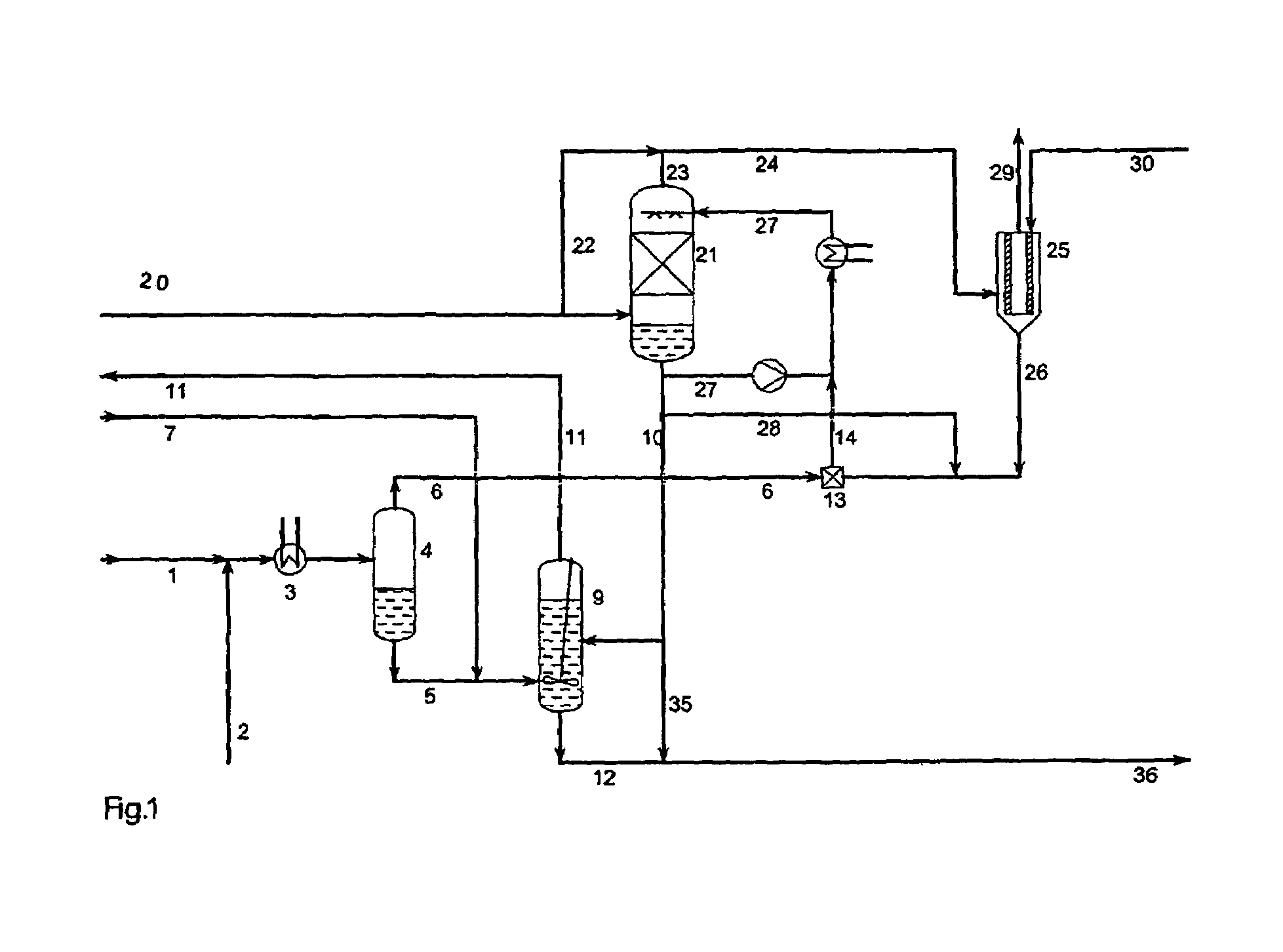

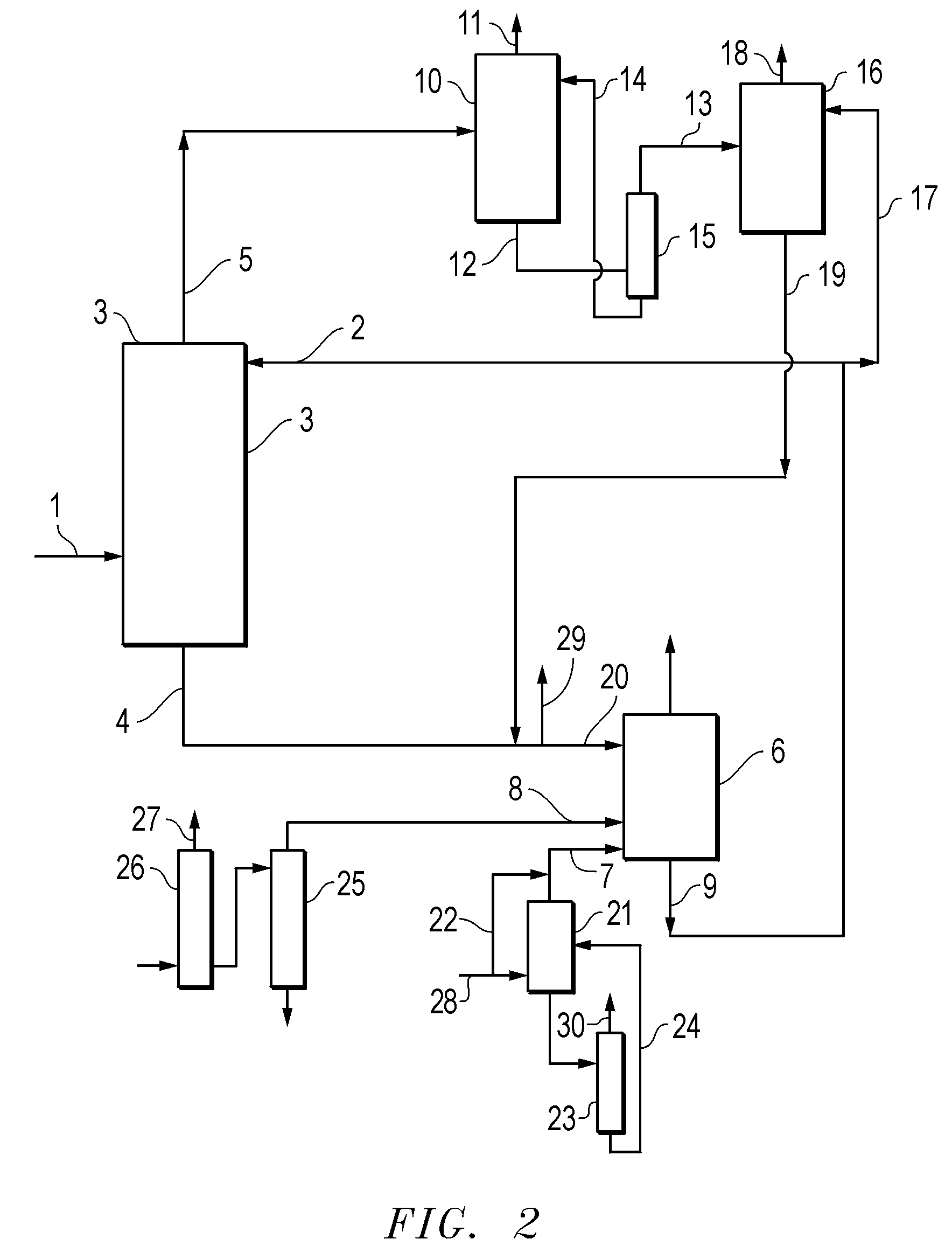

Regeneration method for process which removes hydrogen sulfide from gas streams

InactiveUS6544492B1Removal process is favorableAvoid problemsThiosulfates/dithionites/polythionitesHydrogen sulfidesThio-Sulfide

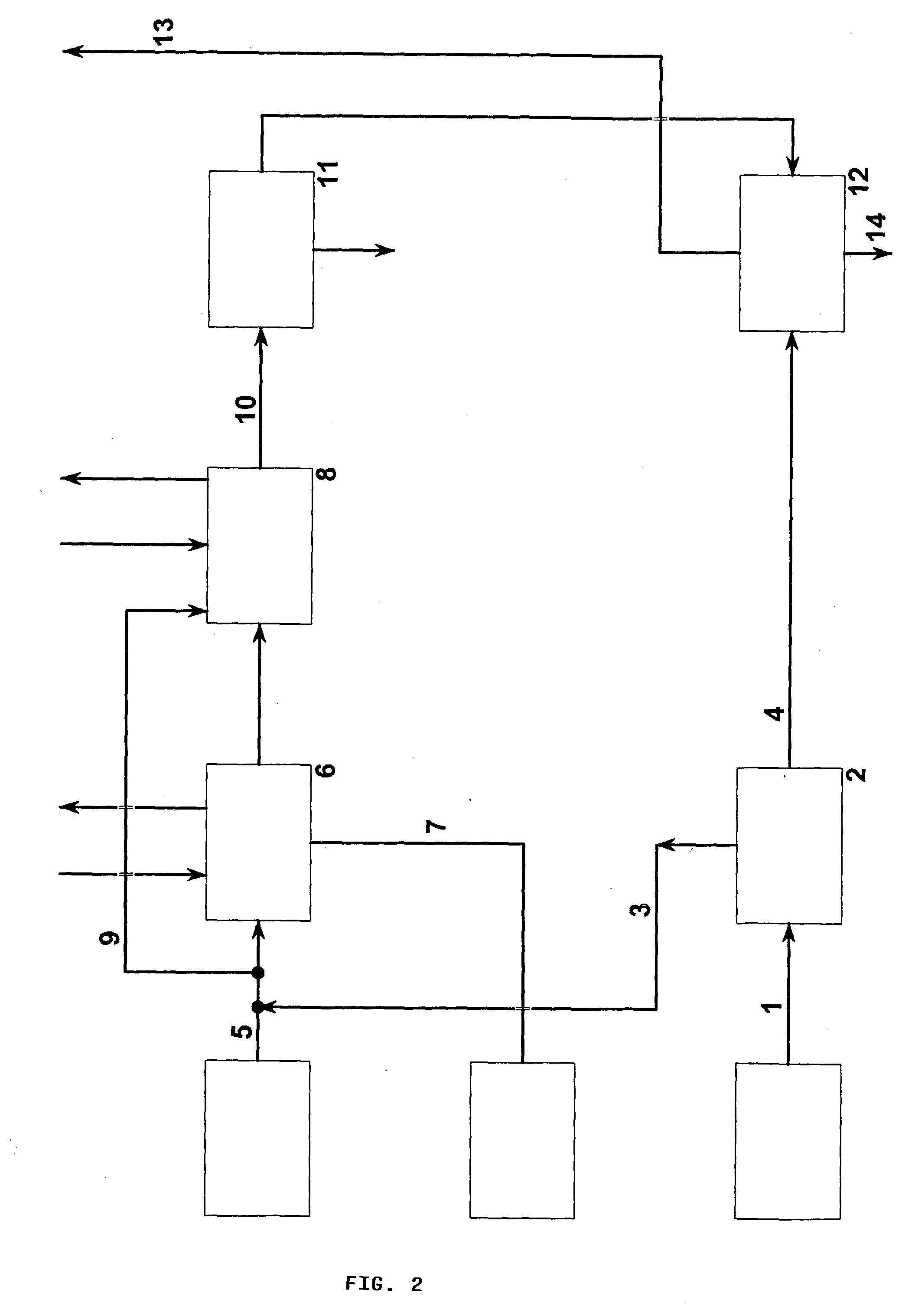

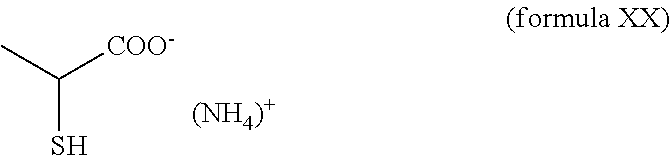

A process is provided for the removal of hydrogen sulfide out of a gaseous stream (22), such as a natural gas, by contacting the hydrogen sulfide containing gas with a sorbing liquid (26) containing a tertiary amine so that the hydrogen sulfide is sorbed into the liquid in absorber (11) and transferring the sorbing liquid / hydrogen sulfide mixture to a reactor (15) where the tertiary amine promotes the conversion of the hydrogen sulfide into polysulfide via reaction with sulfur; transferring the polysulfide solution from the reactor (15) to a regenerator (10) where polysulfide is converted into elemental sulfur via reaction with air (9); transferring at least a portion of the solution (25) containing elemental sulfur, as well as sulfate and thiosulfate species, into a mixture (36) where it is contacted with gaseous ammonia which reacts with the sulfate and thiosulfate species to produce ammonium sulfate and ammonium thiosulfate which are removed from the solution while the remaining portion of solution (25) is transferred to a sulfur recovery unit (14). That portion of the solution which has been subjected to ammonium sulfate and ammonium thiosulfate removal is rejoined with that portion of the solution (25) being forwarded to sulfur recovery unit (14). The solution from the sulfur recovery unit (14) is recycled back to the absorber (11).

Owner:URS

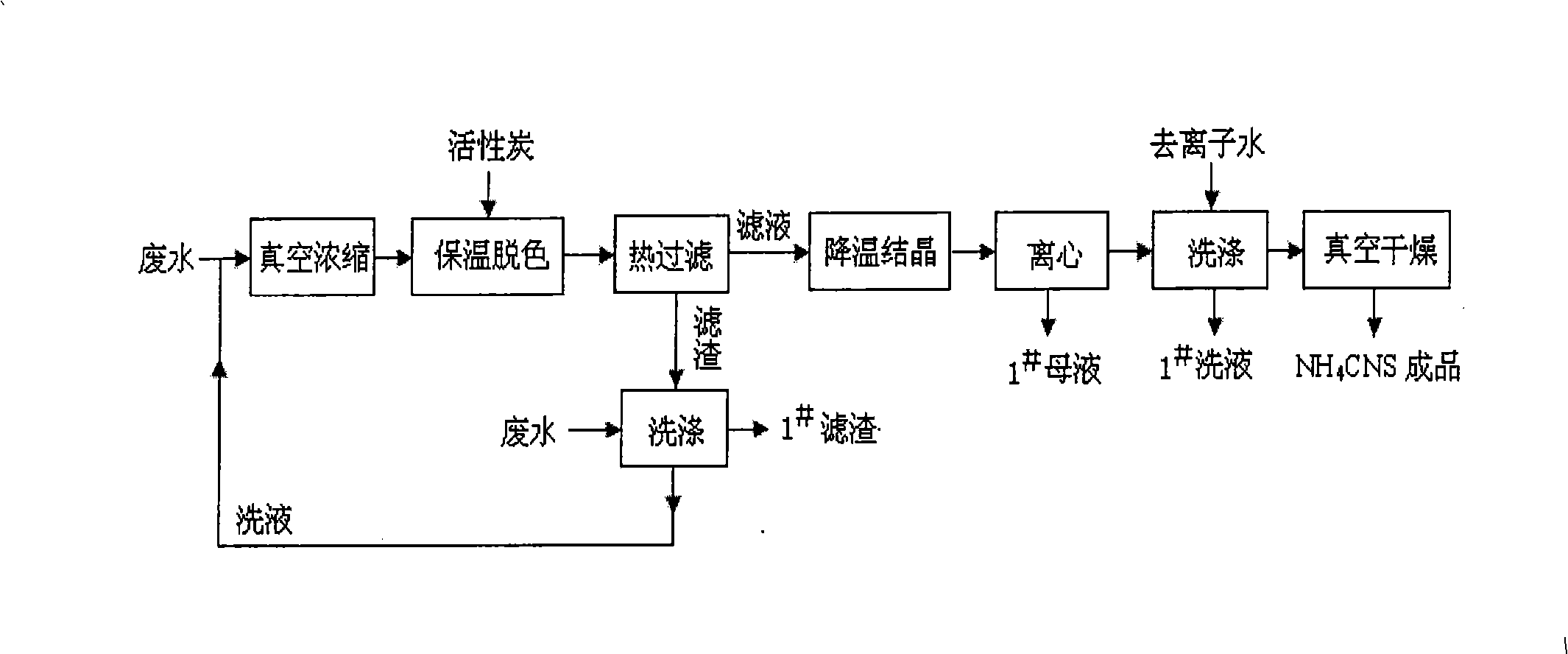

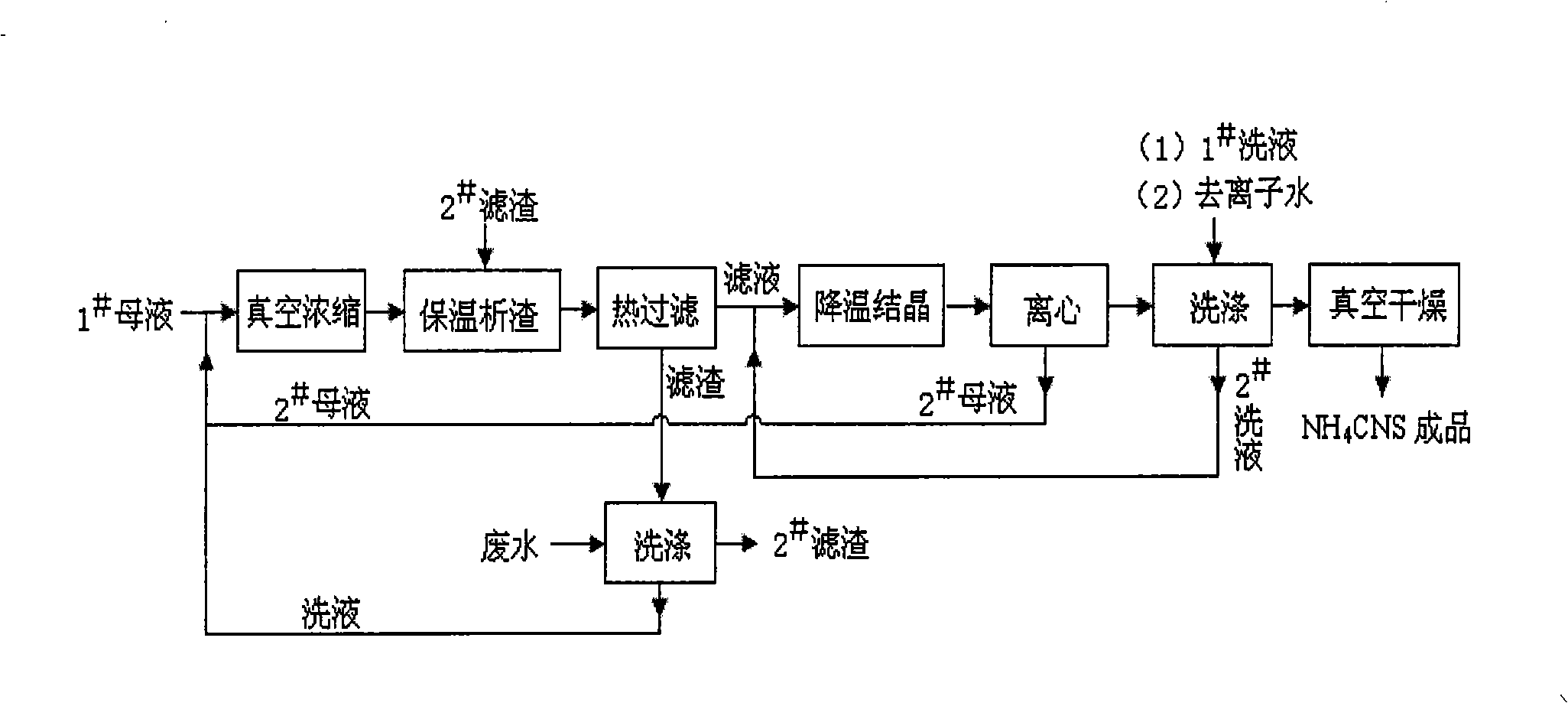

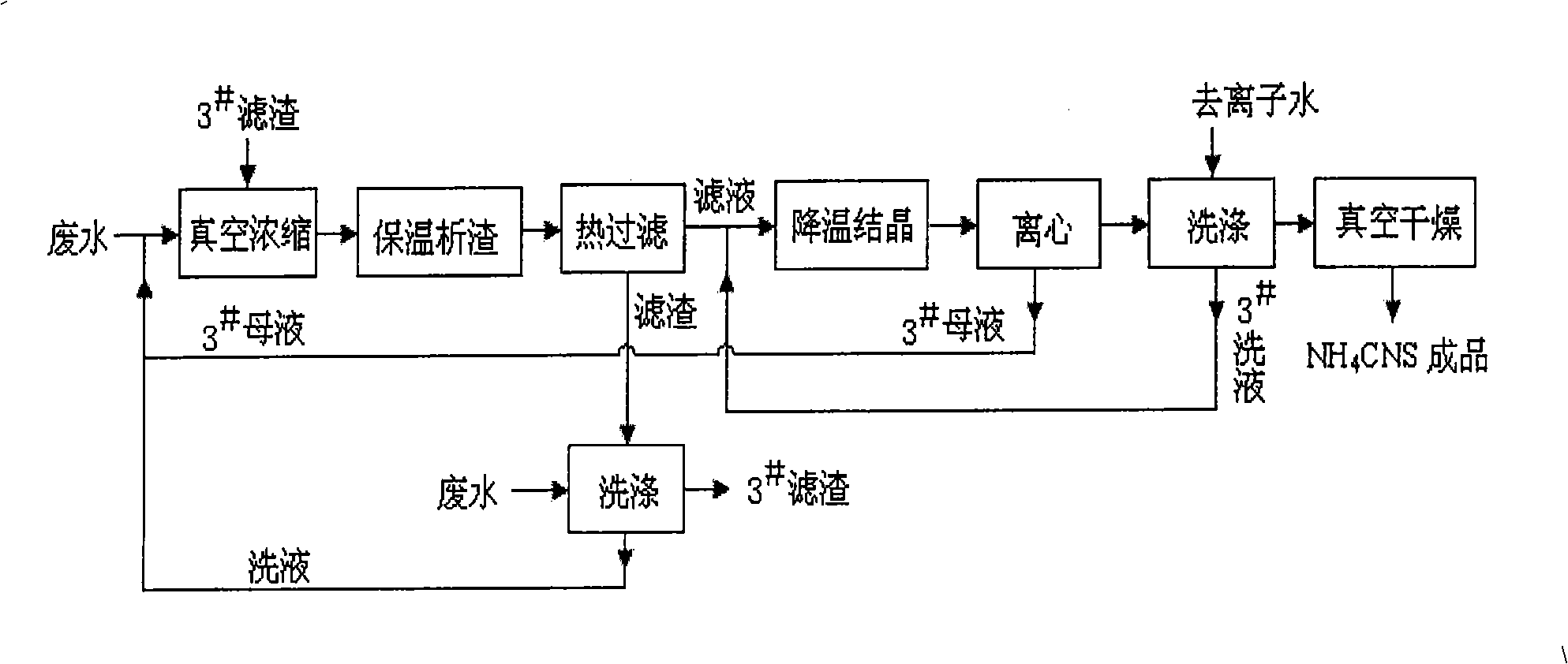

Method for recovering thiocyanate from coke oven gas desulfuration and decyanation wastewater

ActiveCN102424401AMeet the requirements of green circular economyEasy to handleThiocyanic acidPersulfateThiocyanate

The invention discloses a method for recovering thiocyanate from coke oven gas desulfuration and decyanation wastewater. The method comprises the steps of: adding persulfate or sulfuric acid to polyamine salt wastewater for reacting with ammonium thiosulfate so as to generate ammonium sulfate and ammonium sulfite, and further oxidizing into ammonium sulfate and sulfur, thus the wastewater is changed into a two-component mixed liquid which contains ammonium thiocyanate and ammonium sulfate and is easy to separate by crystallization from a three-component mixed liquid, and high-efficiency separation is realized. The purity of the obtained ammonium thiocyanate crystal can reach 99%.

Owner:江苏燎原环保科技股份有限公司

Method for extracting salt from coking desulphurization waste solution and special device thereof

InactiveCN102161541AEffective interceptionAvoid diversionThiocyanic acidWater/sewage treatment bu osmosis/dialysisFiltrationDecomposition

The invention discloses a method for extracting salt from coking desulphurization waste solution and a special device thereof. The method comprises the following steps of: heating raw material waste solution for decomposition, adsorbing and decolorizing, then heating, evaporating and concentrating to obtain concentrated solution, performing heat filtration at constant temperature to remove fine sulfur particles, cooling and crystallizing in a crystallizer, filtering at constant temperature, separating filtrate to obtain crystals, washing the crystals to obtain high-purity ammonium thiocyanate, dissolving mixed salt crystals in ammonium sulfate mother liquor, regulating the acidity to be below 20 percent, preheating to ensure that the temperature is between 90 and 110 DEG C, blowing air oroxygen, performing oxidative transformation for 1min to obtain ammonium sulfate transformation liquid, and adding ammonium sulfate production mother liquor to obtain an ammonium sulfate product. By the method, a high-purity product can be extracted from the waste solution through one-time operation, so that processing and treatment times are reduced; solid-phase impurities are effectively intercepted and prevented from transferring to the crystals at constant temperature; and the mixed salt is subjected to oxidative transformation treatment, all ammonium thiosulfate is transformed into the ammonium sulfate product with high nitrogen content, the process is simple, operation cost is low, and product marketing is broad.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

Acid pickling promotor for iron and steel

The acid pickling promoter for iron and steel consists of inorganic salt as reducing agent 10-80 wt%, organic metal ion chelating chelating agent 1-20 wt%, synergist 1-20 wt% and water 10-50 wt%. The acid pickling promoter is suitable for being added into acid pickling liquid to promote the elimination of dense oxide scale on the surface of steel, shapes and other iron and steel product. It can raise the surface quality of silicon steel plate after being acid pickled, shorten acid pickling period, reduce acid consumption and improve acid pickling environment.

Owner:HUAZHONG UNIV OF SCI & TECH +2

Method of separating multi-ammonium compound salt

InactiveCN101012065ANon-flammableNon-explosiveThiosulfates/dithionites/polythionitesThiocyanic acidAmmonium compoundsWastewater

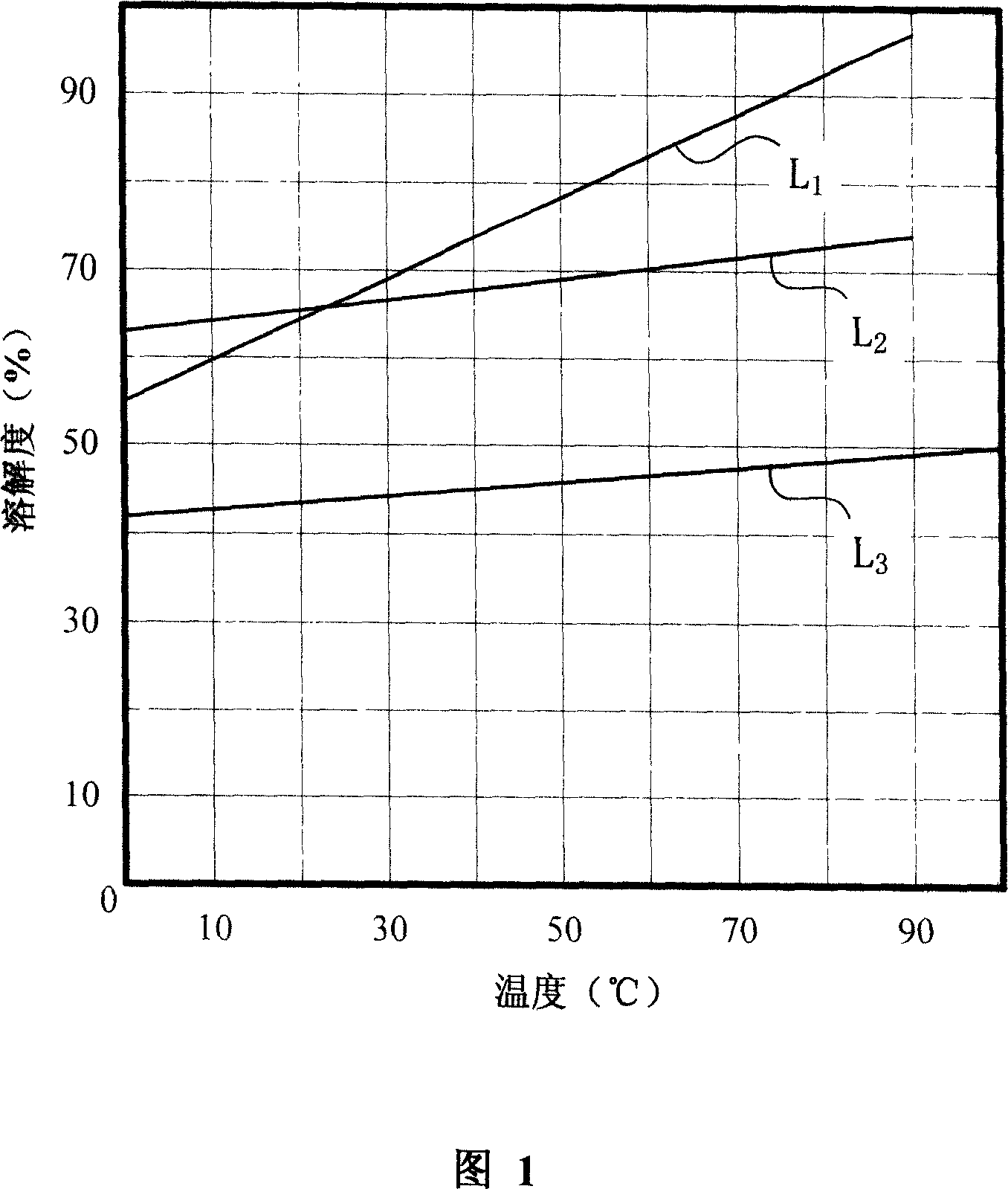

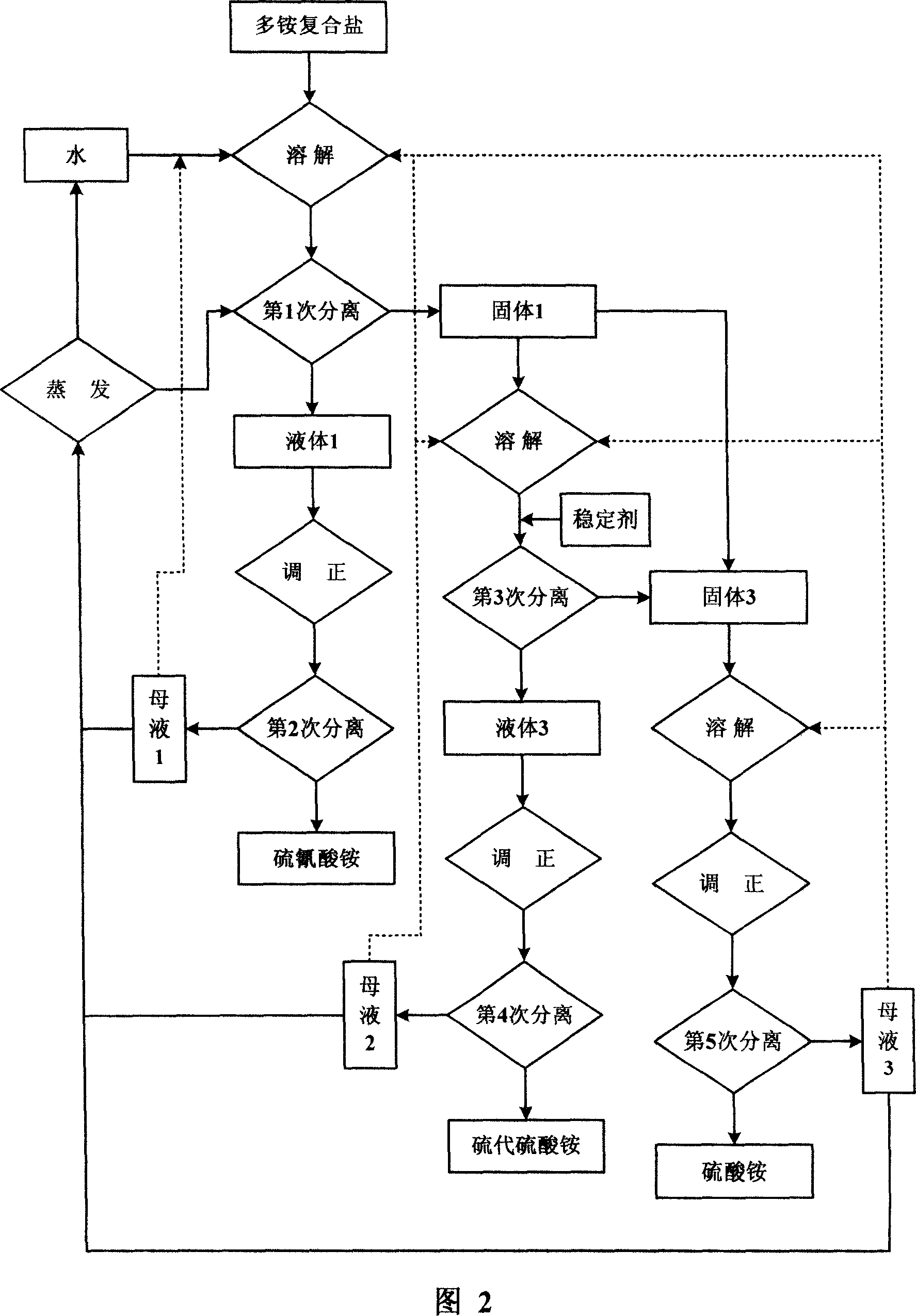

The invention discloses a separating method of multi-ammonia composite salt, which comprises the following steps: separating ammonia thiocyanate under low temperature (0-25 deg.c); enriching ammonium thiosulfate and ammonium sulfate under middle temperature (40-65 deg.c); separating ammonium sulfate under high temperature (80-90 deg.c); separating enriched ammonium thiosulfate at 20-40 deg.c; dissolving, crystallizing and separating solid from liquid for several times under different temperature to separate ammonium thiocyanate, ammonium thiosulfate and ammonium sulfate one by one.

Owner:苏州久王环保科技股份有限公司

Repair method for mercury-polluted soil

InactiveCN105414166AImprove adsorption capacityAchieve the purpose of repairContaminated soil reclamationSodium BentonitePhytoremediation

The invention discloses a repair method for mercury-polluted soil. The repair method comprises the following steps: ploughing up surface soil with a depth of 25-30 centimetres away from ground surface, of the mercury-polluted soil, air-drying, grinding and sieving to obtain pre-treated surface soil; forming a passivator from 40-55 parts of bentonite, 5-15 parts of hydroxyapatite, 3-8 parts of ammonium thiosulphate and 8-16 parts of calcium hydroxide in parts by mass; adequately and uniformly mixing the passivator with the treated surface soil according to an added amount which is 2-5% of the mass of the surface soil, of the passivator, standing for 10-20 days until mercury with a content of 70% in the surface soil is fixed, and completing passivator repair; and levelling the surface soil, planting Indian mustard, dissolving calcium thiocyanate in water and uniformly spraying the solution into the peripheral soil of the root systems of Indian mustard during the vigorous growth period of Indian mustard, and finally harvesting Indian mustard. The repair method disclosed by the invention is simple to operate, low in cost, short in remediation period, and suitable for application of repair for large-area mercury-polluted soil plants.

Owner:陕西清扬环境科技有限公司

Method for promoting restoration of mercury contaminated soil plant

InactiveCN101786098AFacilitate absorption and transportImprove repair efficiencyContaminated soil reclamationPhytoremediationAmmonium thiosulfate

The invention discloses a method for promoting restoration of mercury contaminated soil plant by using ammonium thiosulfate, which comprises the following steps of: 1) planting rape into mercury contaminated soil; 2) after the rape grows for 2-3 months, adding ammonium thiosulfate solution into the soil, wherein 2-6g of the ammonium thiosulfate is added in per kilogram of soil; and 3) harvesting the plant after the ammonium thiosulfate is added for 3-10 days. The ammonium thiosulfate adopted by the method is pollution-free for the soil, simple in technique and low in cost, has good restoration effect for the mercury contaminated soil, and is applicable to resorting large-area mercury contaminated soil plant.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Method for treating ammonia desulfurization waste liquid by oxidation method

InactiveCN103030207AEasy to separateSimple processDispersed particle separationThiocyanic acidThio-Catalytic oxidation

The invention provides a method for treating ammonia desulfurization waste liquid by an oxidation method, and belongs to the technical field of desulfurization waste liquid treatment. According to the method, oxidation reaction is conducted by blowing air or oxygen into the ammonia desulfurization waste liquid; ammonium thiosulfate in the desulfurization waste liquid is oxidized into ammonium sulfate in the oxidation reaction process; ammonium thiocyanate is not oxidized, but continues to be reserved in the desulfurization waste liquid; and then ammonium thiocyanate is extracted through evaporation and secondary crystallization. The method is suitable for treating desulfurization waste liquid generated in a gas desulfurization and decyanation technological process by a catalytic oxidation method, and suitable for waste liquid treatment in the desulfurization technology field of hydrogen sulfide such as coke oven gas, natural gas, coalbed methane and refinery gas. With the adoption of the method, ammonium thiosulfate salt in the waste liquid can be converted to ammonium sulfate salt, ammonium thiocyanate salt can be protected, and ammonium sulfate salt and ammonium thiocyanate salt can be separated and purified from the waste liquid into a product.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for extracting ammonium sulfate from ammonia desulphurization wastewater by oxidation process

The invention provides a method for extracting ammonium sulfate from ammonia desulphurization wastewater by an oxidation process, and belongs to the technical field of treatment of desulphurization waste solutions. The method comprises the steps of: carrying out oxidation reaction in a manner of blowing air or oxygen into the ammonia desulphurization wastewater, wherein in the oxidization reaction, ammonium thiosulfate in the desulphurization wastewater is oxidized into ammonium sulfate, ammonium thiocyanate is not oxidized and further maintained in the desulphurization wastewater; and then extracting ammonium sulfate in an evaporation or crystallization manner. The method disclosed by the invention is suitable for treatment of the desulphurization wastewater produced in the air desulfurization and cyanide-removal processes by a catalytic oxidation method. The method is suitable for treatment of waste liquor in the field of the desulfurization process of hydrogen sulfide containing gases such as coke even gas, natural gas, coal bed gas and refinery gas. By using the method disclosed by the invention, ammonium thiosulfate salt in the wastewater can be transformed into ammonia sulfate salt, ammonium thiocyanate is protected, and the ammonium thiosulfate salt and the ammonium thiocyanate can be separated from the wastewater and purified to obtain the products.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Process for recycling inorganic salt from wastewater for desulfurization and decyanation of coke oven gas

ActiveCN101402461AHigh recovery rateEasy to operateThiosulfates/dithionites/polythionitesThiocyanic acidCatalytic oxidationNo production

The invention provides a process for reclaiming inorganic salt from wastewater in the desulphurization and decyanation of coal gas of a coke furnace. The process aims at reclaiming ammonium thiocyanate (NH4CNS), ammonium thiosulfate ((NH4)2S2O3) and ammonium sulphate ((NH4)2SO4) from wastewater produced by a liquid-phase catalytic oxidation, desulphurization and decyanation process taking ammonia as an alkaline resource. In particular, the process comprises that the wastewater and a mother solution with the ratio of NH4CNS to (NH4)2S2O3 more than or equal to 1.0 (wt) and the ratio of NH4CNS to (NH4)2S2O3 less than 1.0 (wt) are separated to obtain finished products of NH4CNS, (NH4)2S2O3 and (NH4)2SO4 through a targeted process. The process is easy to operate and control parameter, has high salt reclaiming rate and high product quality, reaches the aim that the wastewater can be fully treated and has no production of three wastes, and has good economic and social benefits.

Owner:JINNENG SCI & TECH

Method for extracting ammonium thiocyanate from ammonia-process desulfurization waste liquid by oxidation process

InactiveCN103011201AEasy to separateSimple processThiocyanic acidMultistage water/sewage treatmentLiquid wasteEvaporation

The invention discloses a method for extracting ammonium thiocyanate from ammonia-process desulfurization waste liquid by an oxidation process, and belongs to the technical field of treatment of the desulfurization waste liquid. According to the method, an oxidation reaction is implemented by a way of blowing air or oxygen into ammonia-process desulfurization waste liquid; by the oxidation reaction, ammonium thiosulfate in the desulfurization waste liquid is oxidized into ammonium sulfate, but ammonium thiocyanate is not oxidized and is still reserved in the desulfurization waste liquid; and the ammonium thiocyanate is extracted by ways of evaporation and secondary crystallization. The method disclosed by the invention is applicable to the treatment of the desulfurization waste liquid which is generated from the process of desulfurization and decyanation of the gas by a catalytic oxidation process, and is suitable for the waste liquid treatment in the field of desulfurization process of hydrogen sulfide-containing gases such as coke oven gas, natural gas, coal-bed methane and refinery gas. By the method, the ammonium thiosulfate salt in the waste liquid is converted into the ammonium sulfate salt and the ammonium thiocyanate salt is protected, and the ammonium thiosulfate salt and the ammonium thiocyanate salt are separated from the waste liquid and purified into products.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Production technique for extracting ammonium thiosulfate and ammonium thiocyanate from desulfurization waste liquor

InactiveCN101850952ASolving Recycling ProblemsEmission reductionThiosulfates/dithionites/polythionitesThiocyanic acidOrganic solventEconomic benefits

The invention discloses a production technique for extracting ammonium thiosulfate and ammonium thiocyanate from a desulfurization waste liquor, which comprises the following steps: settling, filtering, decoloring, concentrating, crystallizing, separating, drying a sulfur-containing waste liquor generated in a desulfurization production process of HPF in a coke-oven plant, and finally, recovering ammonium thiocyanate and ammonium thiosulfate by using a mixed organic solvent. The invention is a production technique for comprehensively treating waste water generated in the prior HPF desulfurization technique, and the mixed organic solvent is used for separating ammonium thiocyanate and ammonium thiosulfate. The invention effectively solves the problem of waste water recovery in the desulfurization process, reduces discharge and environmental pollution of waste water, recovers important chemical raw materials (ammonium thiocyanate and ammonium thiosulfate), and can increase the economic benefit.

Owner:QINGDAO CHUTIAN ENERGY SAVING TECH

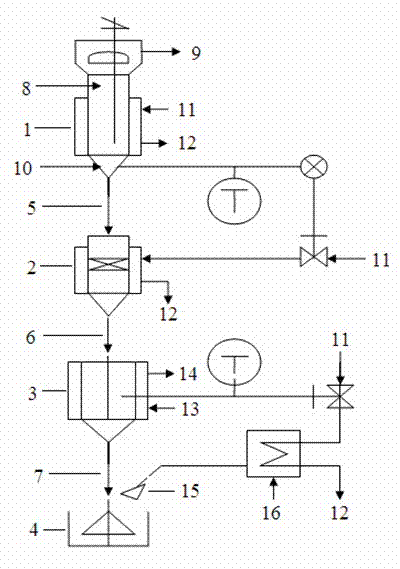

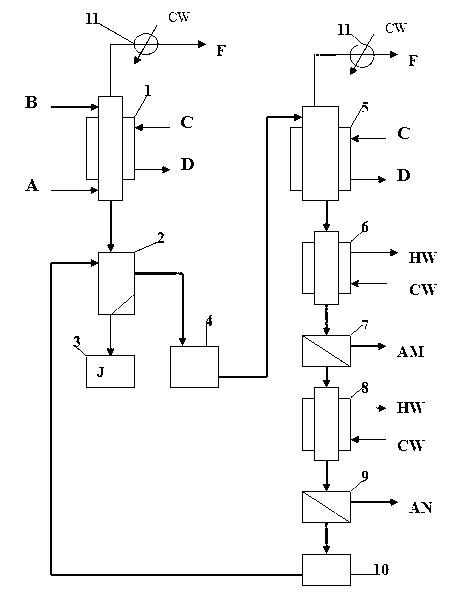

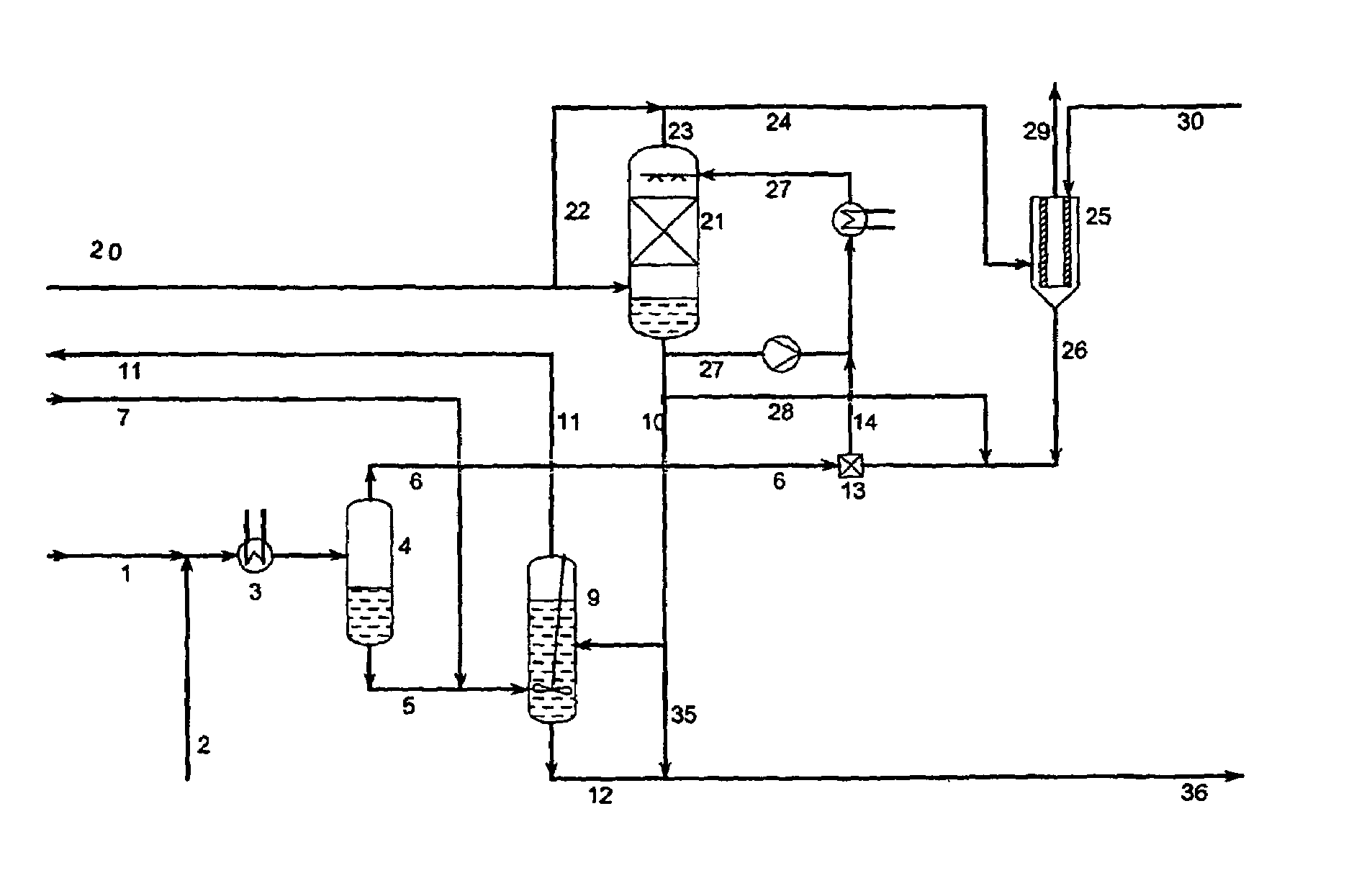

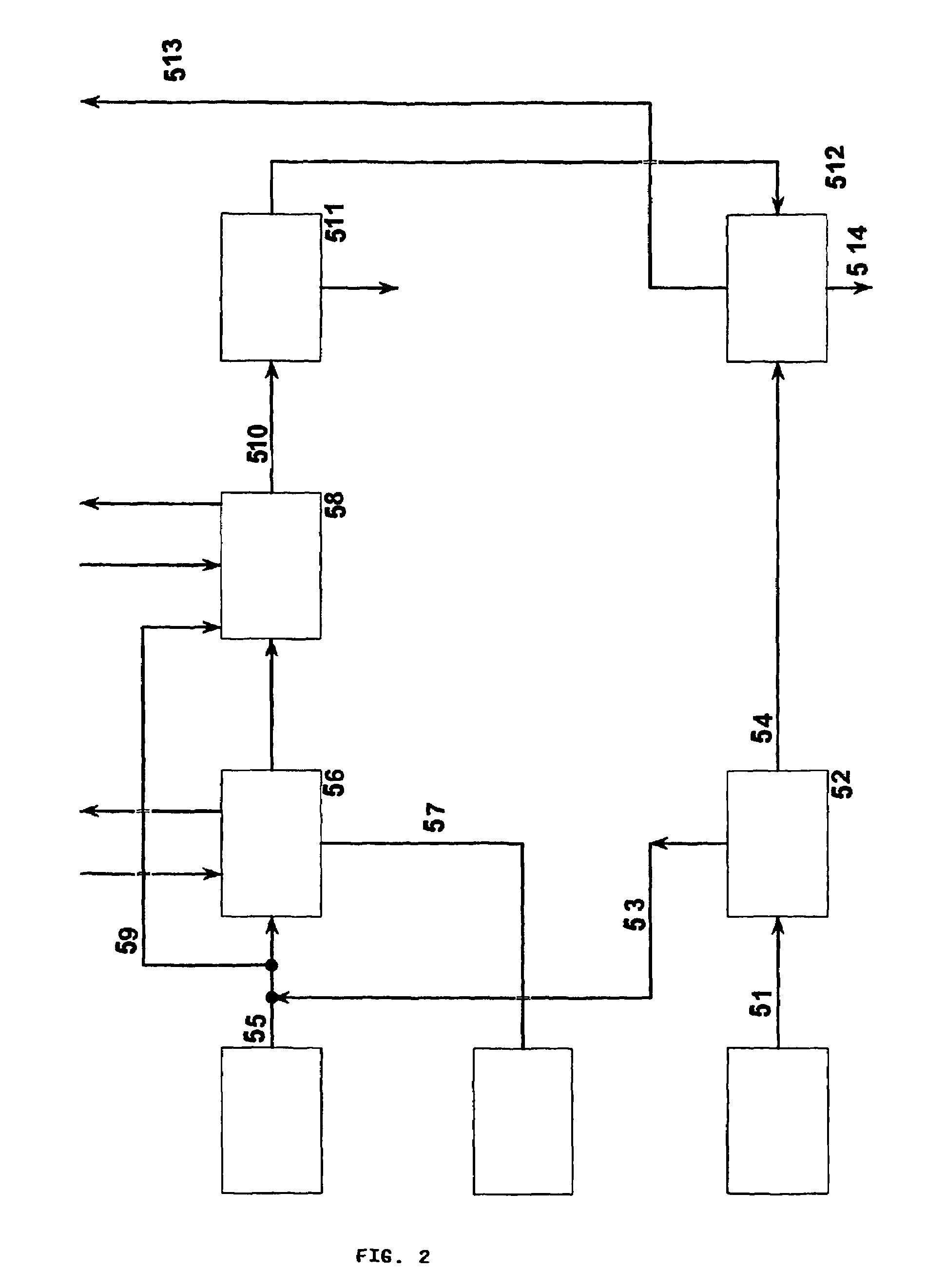

Process for production of ammonium thiosulphate

InactiveUS20030223930A1Speed up the processThiosulfates/dithionites/polythionitesSulfite preparationAqueous solutionAmmonium thiosulfate

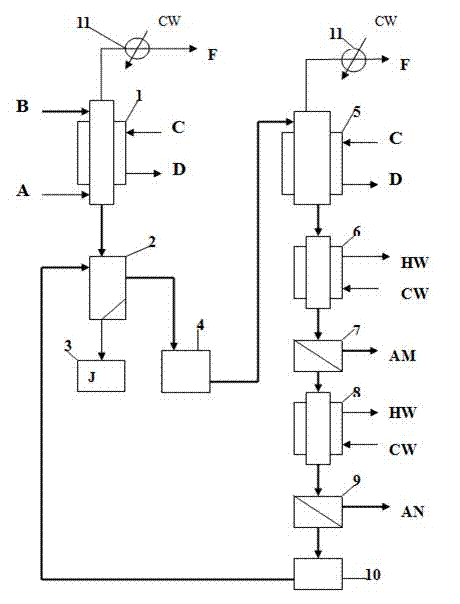

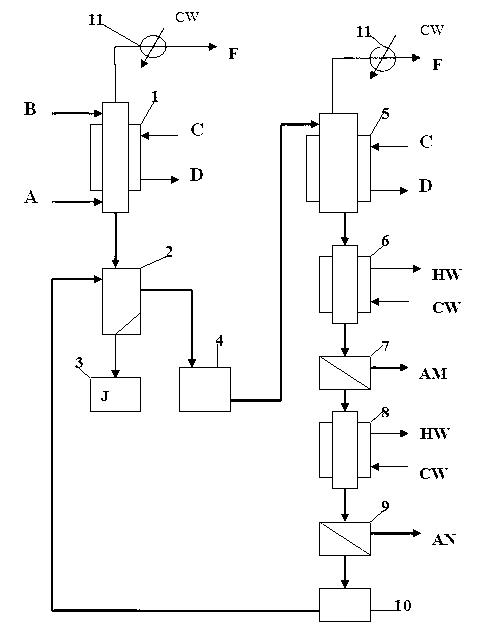

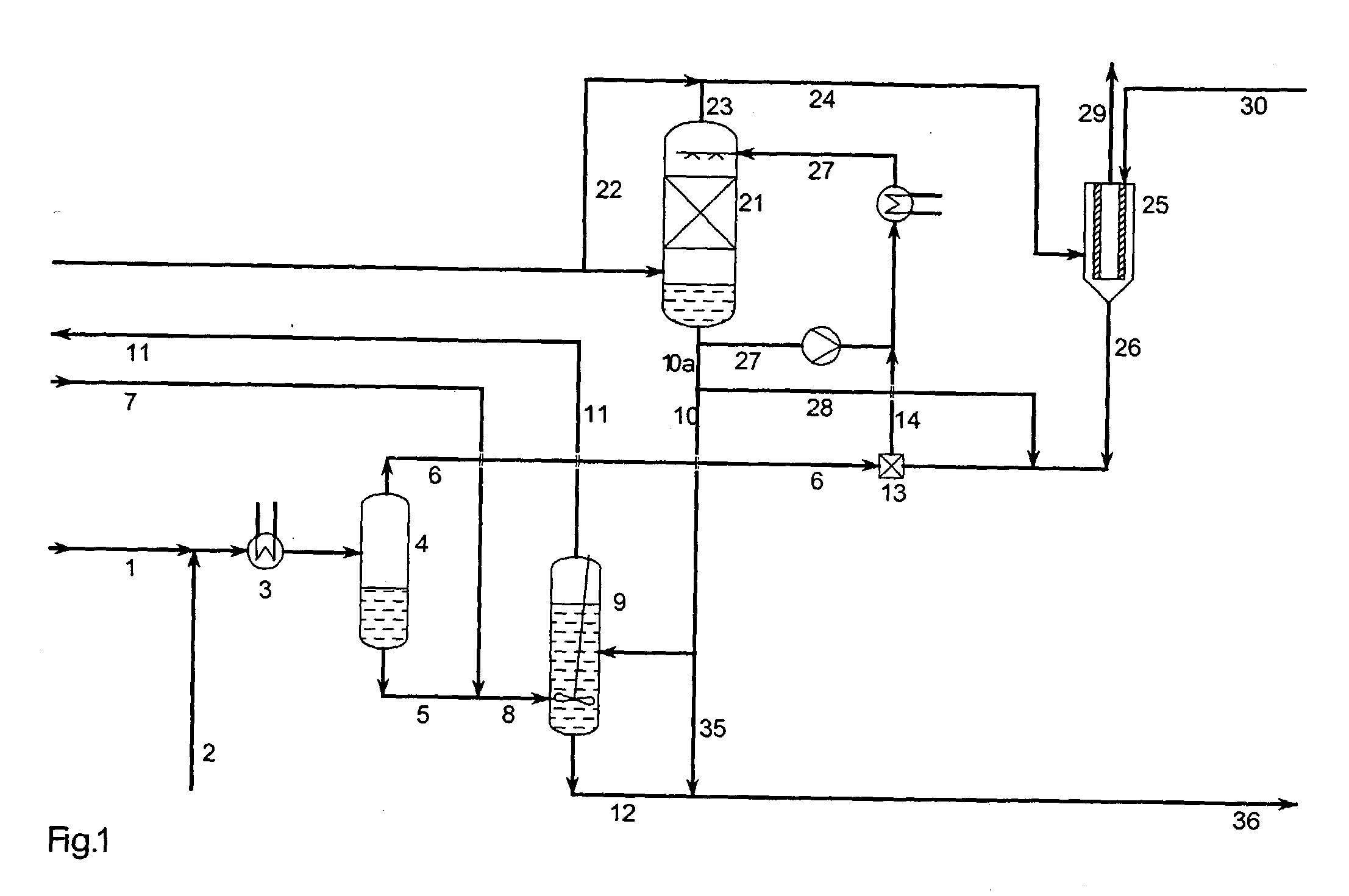

A process for continuous production of ammonium thiosulphate, (NH4)2S2O3 (ATS) from NH3, H2S and SO2 comprising steps of: (a) partial condensation in a partial condenser 4 of a first gaseous or partial liquid feed stream comprising H2O, H2S and NH3 with a molar H2S:NH3 ratio <0.4; (b) passing the aqueous condensate comprising NH4HS and NH3 from the partial condenser 4 to a reactor 9 in which said condensate is contacted with a third feed gas stream 7 comprising H2S and with an aqueous solution 10 comprising NH4HSO3 and (NH4)2SO3 under formation of an aqueous solution of (NH4) 2S2O3; (c) passing the gas stream comprising NH3 and H2S from the partial condenser 4 to a mixing device 13 in which said gas stream is completely dissolved in the water drained off from the aerosol filter 25; (d) passing a second feed gas stream 20 comprising approximately 2 / 3 mole SO2 per mole of NH3 contained in the first feed stream to a SO2 absorber 21 and the aerosol filter 25; (e) passing the aqueous solution produced in mixing device 13 to the SO2 absorber 21; (f) passing the off gas from the absorber 21 to the aerosol filter 25 and (g) adding to the aerosol filter 25 a balance amount of water required for obtaining approximately 40-65 wt % (NH4)2S2O3 in the aqueous of solution of (NH4)2S2O3 being withdrawn from the reactor 9.

Owner:HALDOR TOPSOE AS

Decolorization of dyed keratin fibers

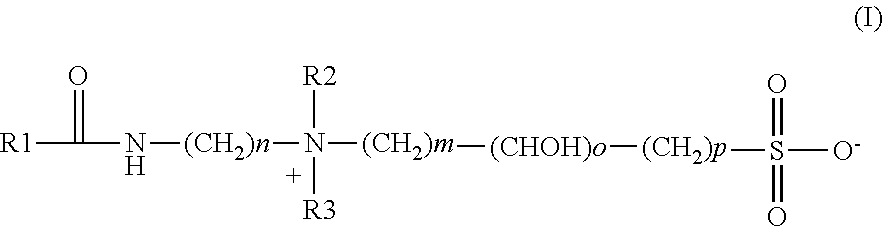

The invention relates to agents for the reductive decolorization of dyed keratin fibers, in particular human hair, containing in an aqueous cosmetic carrier (a) one or more reduction agents from the group consisting of sodium dithionite, zinc dithionite, potassium dithionite, sodium sulfite, sodium hydrogen sulfite, potassium sulfite, potassium hydrogen sulfite, ammonium sulfite, sodium thiosulfate, potassium thiosulfate, ammonium thiosulfate, hydroxymethanesulfinic acid, aminomethanesulfinic acid, cysteine, thiolactic acid, sulfanylacetic acid (thioglycolic acid), and / or ascorbic acid, and (b) one or more zwitterionic surfactants, each of which has at least one quaternary ammonium group and a grouping of —SO3— as structural units.

Owner:HENKEL KGAA

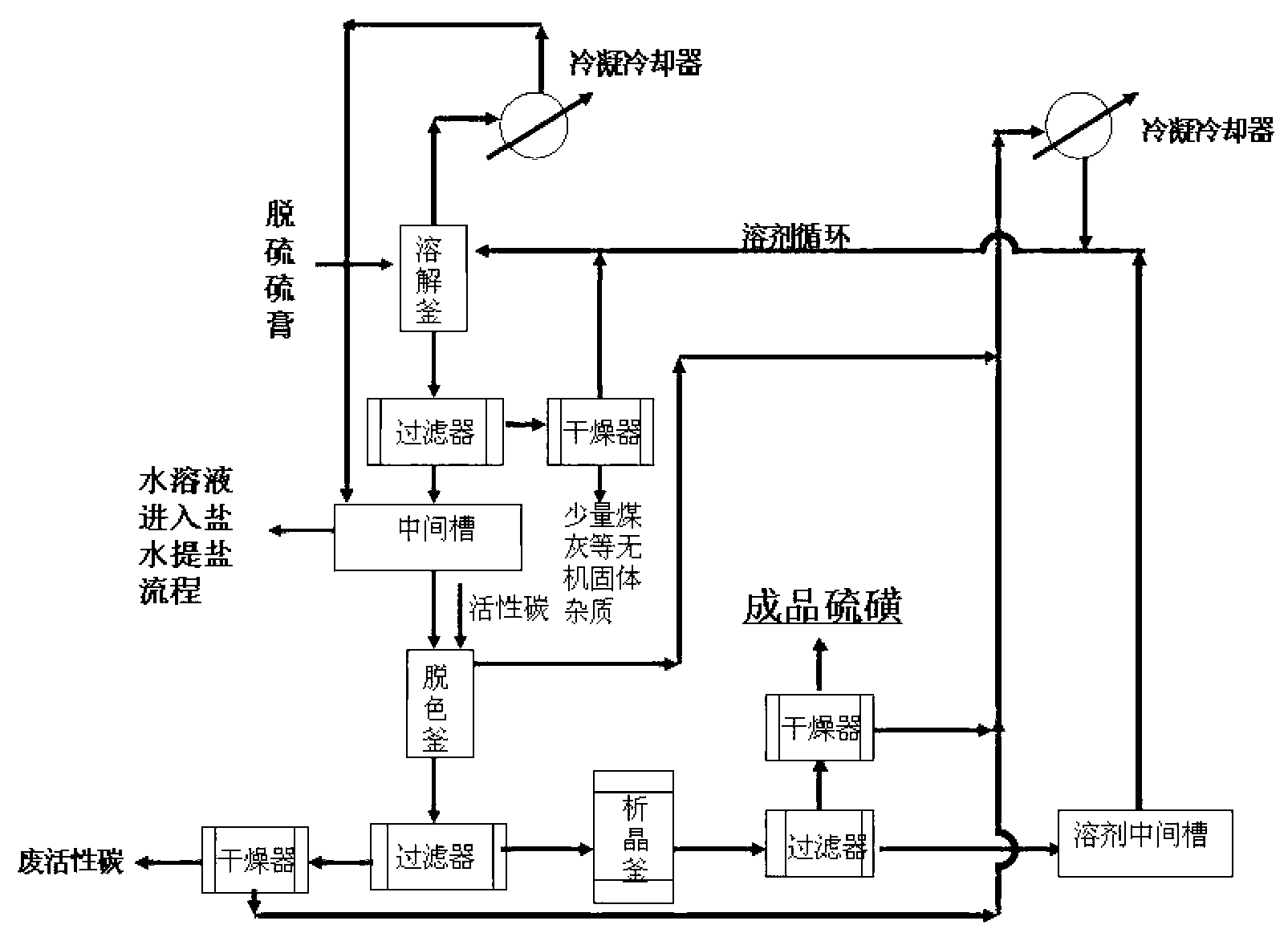

Method for processing sulfur paste as coke oven gas desulfuration by-product

ActiveCN103264991AThorough treatmentNo secondary pollutionCalcium/strontium/barium sulfatesThiosulfates/dithionites/polythionitesResource utilizationImpurity

The invention relates to a method for processing sulfur paste as a coke oven gas desulfuration by-product. The method is characterized in that a sulfur paste processing procedure comprises the steps of dissolving sulfur and removing impurities, decoloring and removing impurities, lowering temperature and crystallizing, drying the product and the like; and a waste liquid treatment procedure comprises the steps of decoloring and removing impurities, carrying out vacuum concentration on filtrate containing salt, separating ammonium thiocyanate, concentrating the ammonium thiocyanate ethyl alcohol filtrate for crystallization, drying an ammonium thiocyanate product, separating ammonium sulfate, concentrating the ammonium thiosulfate filtrate for crystallization, drying the ammonium thiosulfate product, and the like. The method can be used for thoroughly processing the sulfur paste and the waste liquid containing sulfur, the recycling rate of the product is high, no mixed salt and waste water are discharged without cause secondary pollution, so that the method is clean and environment-friendly. The method also has the outstanding characteristics of strong adaptive capacity, large production elasticity, high resource utilization ratio and the like.

Owner:张建利

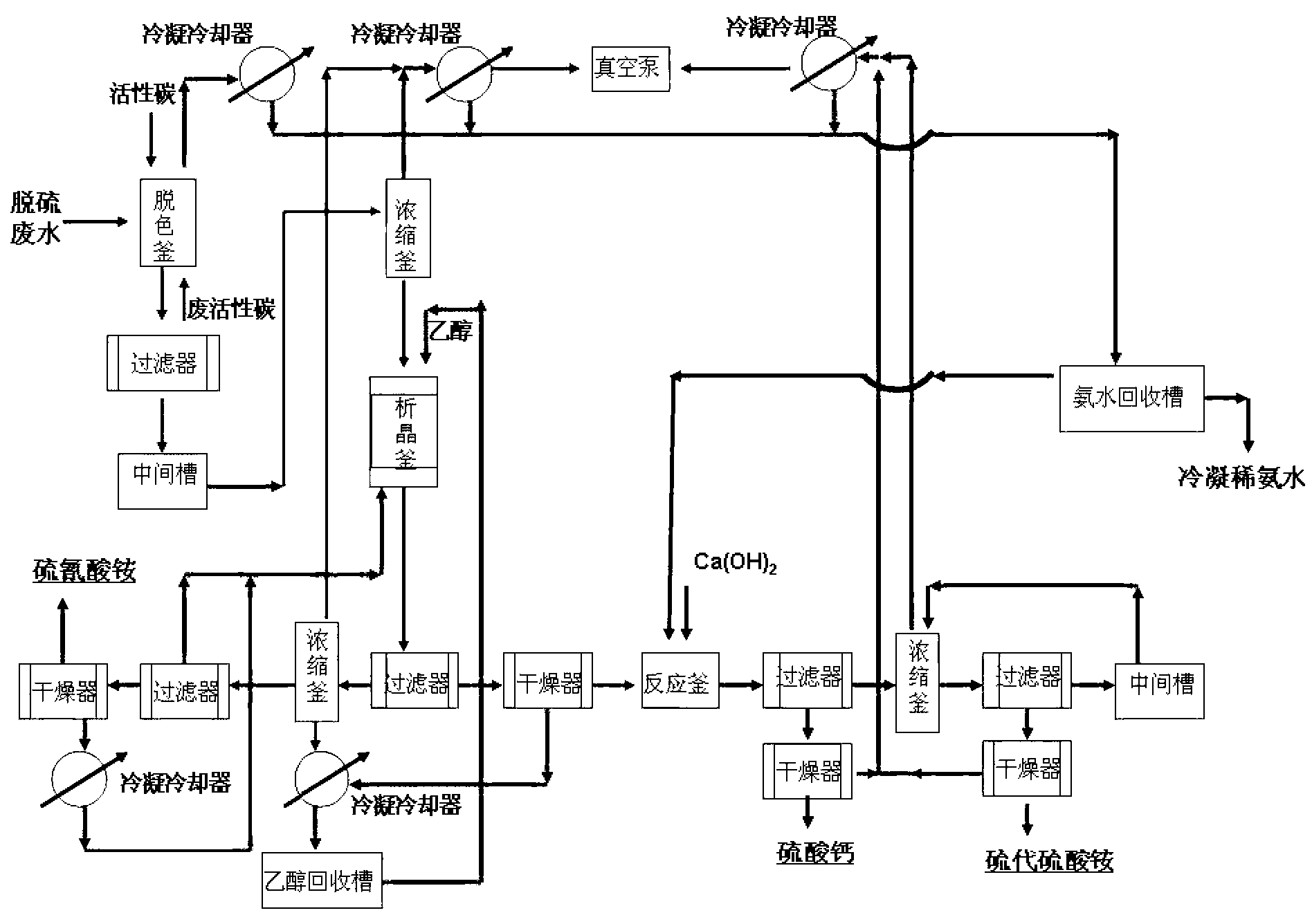

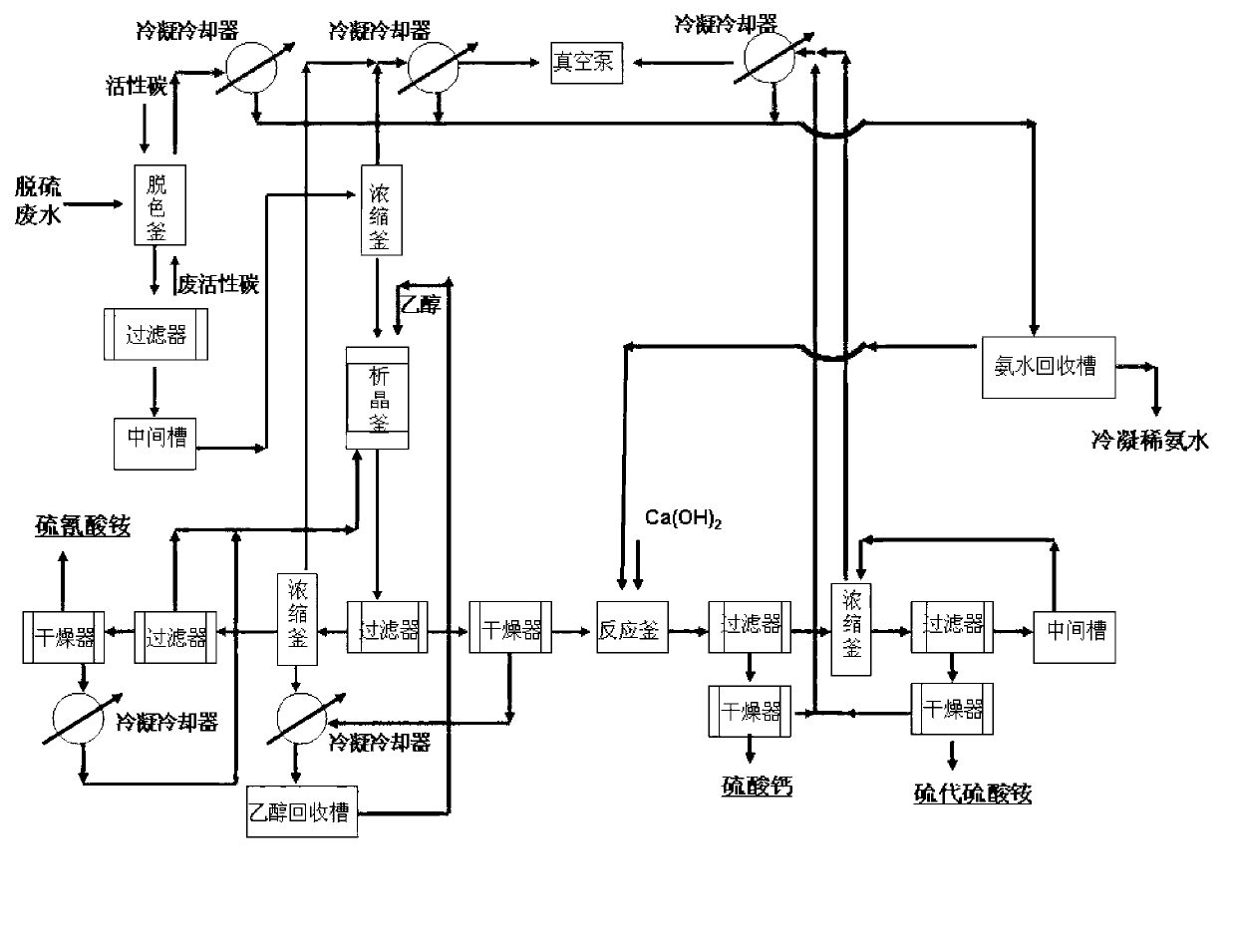

Method for extracting two secondary salts from desulfurized salt-containing waste liquid of coke oven gas

ActiveCN103274367AThorough treatmentNo secondary pollutionThiosulfates/dithionites/polythionitesThiocyanic acidLiquid wasteResource utilization

The invention relates to a method for extracting two secondary salts from a desulfurized salt-containing waste liquid of coke oven gas. The waste liquid treatment and secondary salt extraction process comprises the following steps: decolorizing, removing impurities, performing reduced pressure concentration on the salt-containing filtrate, separating ammonium thiocyanate, concentrating and crystallizing the ammonium thiocyanate ethanol filtrate, drying the ammonium thiocyanate product, separating ammonium sulfate, concentrating and crystallizing the ammonium thiosulfate filtrate, drying the ammonium thiosulfate product and the like. According to the invention, the desulfurized waste liquid is thoroughly treated, the products are high in recovery rate, no mixed salts or waste water is discharged, no secondary pollution is caused, and the process is clean and environment-friendly. Meanwhile, the invention also has the remarkable characteristics of high adaptability, high production elasticity, high resource utilization rate and the like.

Owner:张建利

Preparation method of sulfuration-type hydrogenation catalyst

ActiveCN103801335ASimple production processReduce manufacturing costPhysical/chemical process catalystsRefining to eliminate hetero atomsAmmonium thiosulfateMetal

The invention discloses a preparation method of a sulfuration-type hydrogenation catalyst. The preparation method is as follows: using a carrier precursor and ammonium thiosulfate and an auxiliary agent for kneading, molding and drying, loading a hydrogenation active metal component, and then performing heat treatment to obtain the sulfuration-type hydrogenation catalyst. The method is simple in preparation process and low in cost. The prepared sulfuration-type hydrogenation catalyst is good in sulfuration effect and high in hydrogenation activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

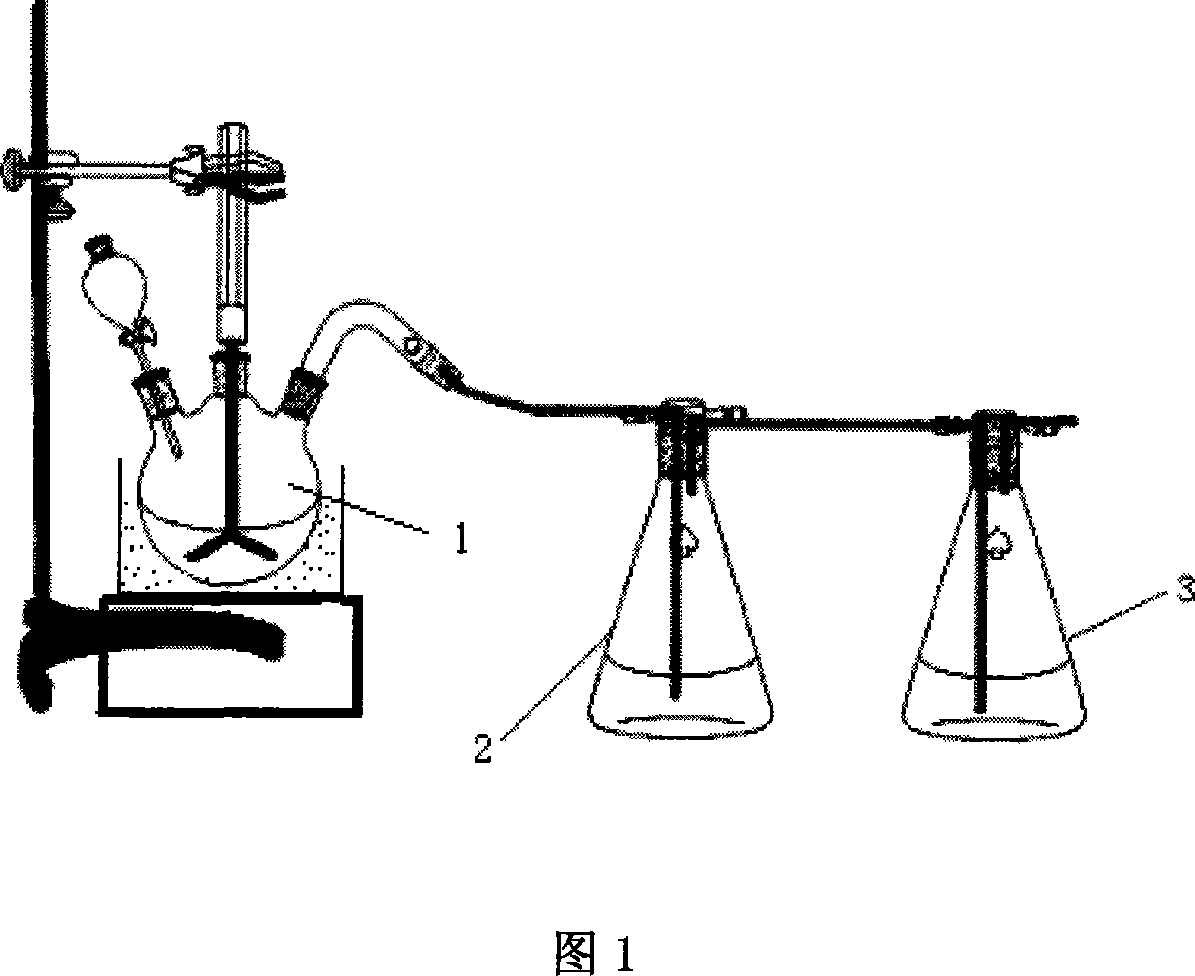

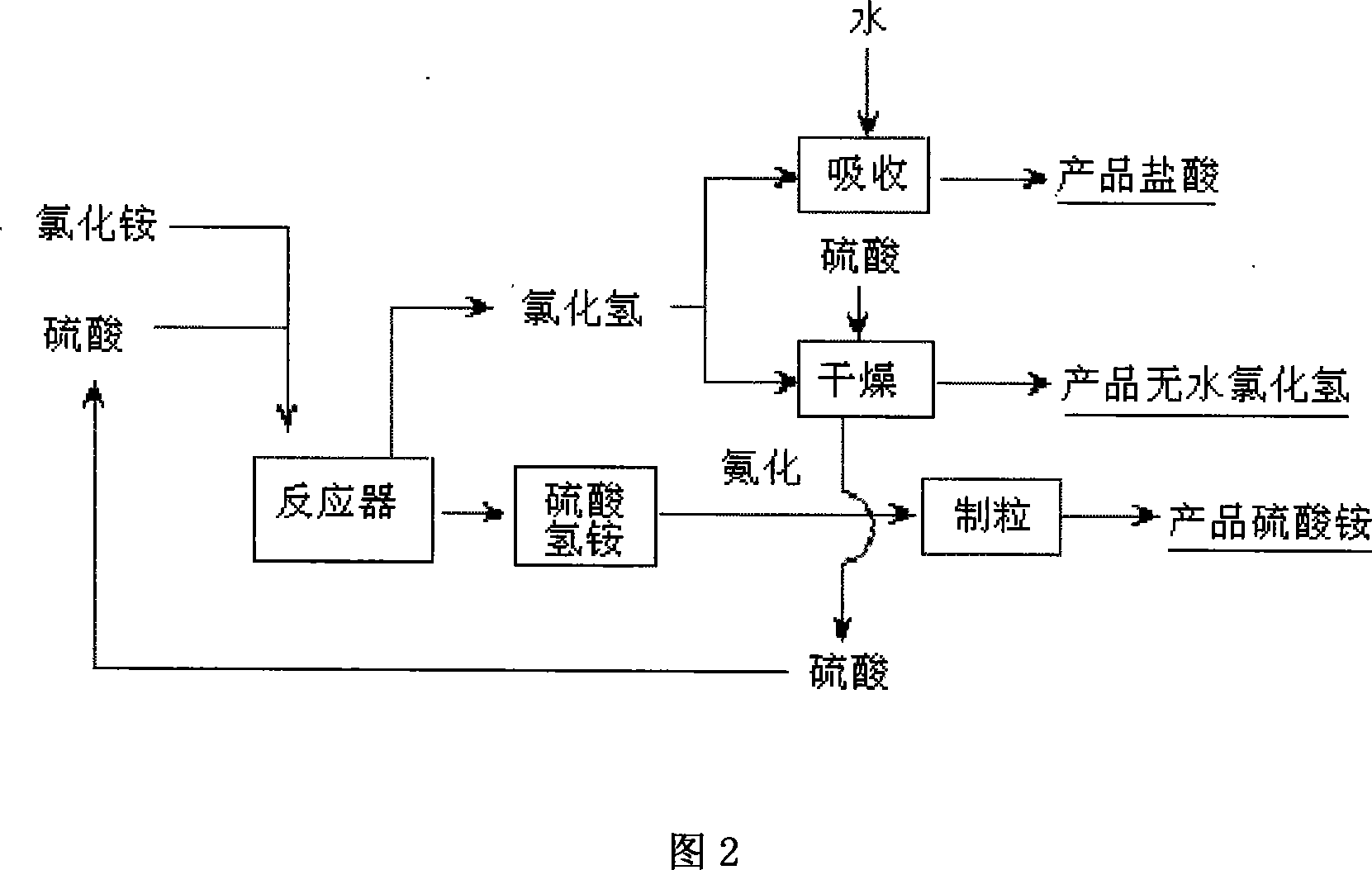

Method for producing ammonium bisulfate and hydrogen chloride by using ammonium chloride and sulfuric acid

InactiveCN101134579ARaise the gradeEffective consumptionChlorine/hydrogen-chlorideAmmonium sulfatesReaction temperatureNitrogen

The present invention relates to solid-liquid reaction process of solid ammonium chloride and sulfuric acid to obtain high grade ammonium bisulfate and hydrogen chloride gas, and the process has molar ratio between ammonium chloride and sulfuric acid of 1 to 0.9-1.1, concentration of sulfuric acid of 93-98 wt%, reaction temperature of 60-130 deg.c and reaction time of 5-60 min. The process may have ammonium chloride as the by product of sodium carbonate producing process and industrial sulfuric acid as the material. The produced hydrogen chloride gas may be absorbed with water to produce hydrochloric acid or further desorbed and refined to obtain anhydrous hydrogen chloride, and the produced ammonium bisulfate may be aminated to obtain ammonium sulfate. The process is simple, has easy control and no waste discharge, and provides one new way for best utilization of nitrogen element and chlorine element in ammonium chloride.

Owner:SICHUAN UNIV

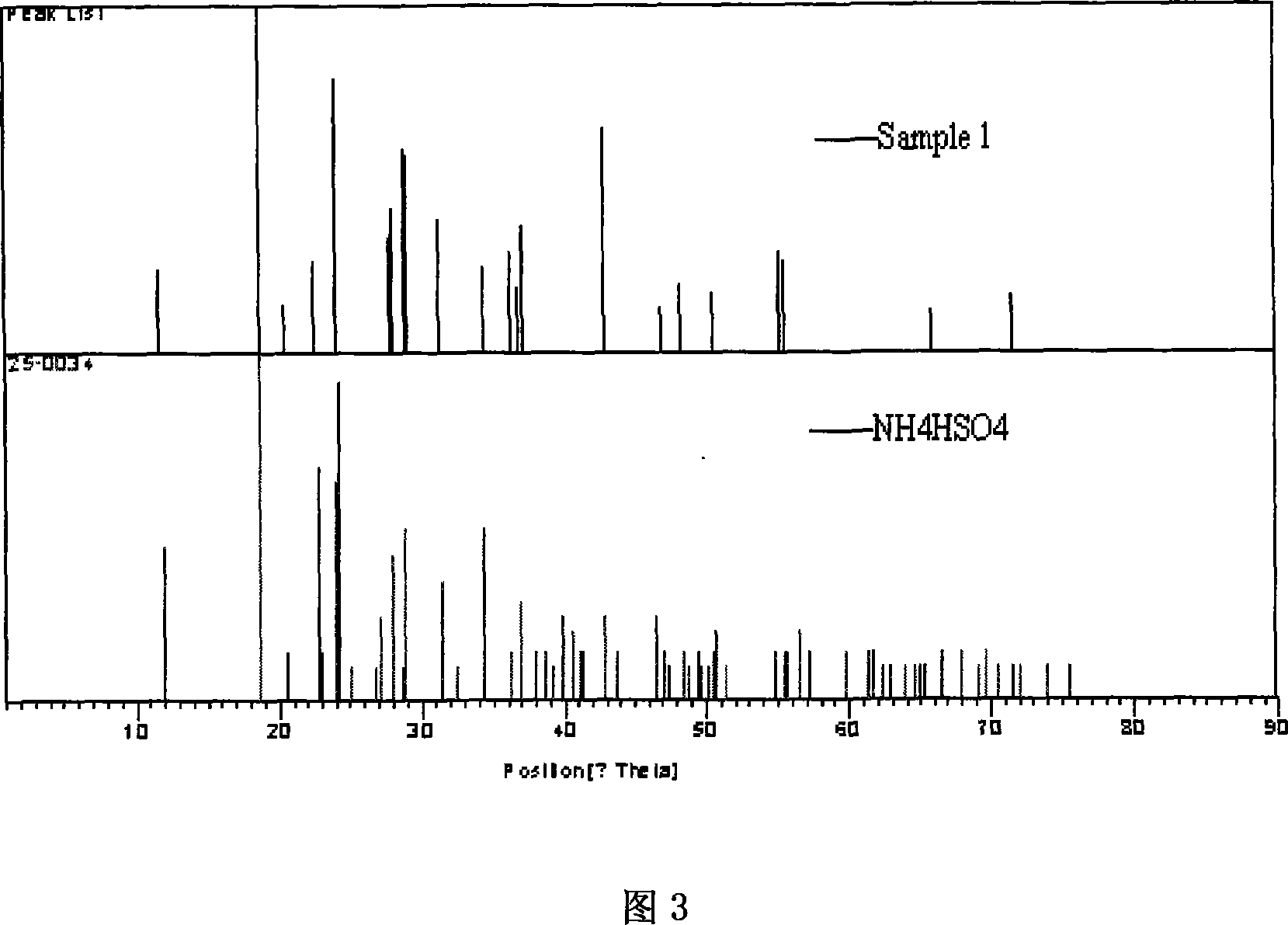

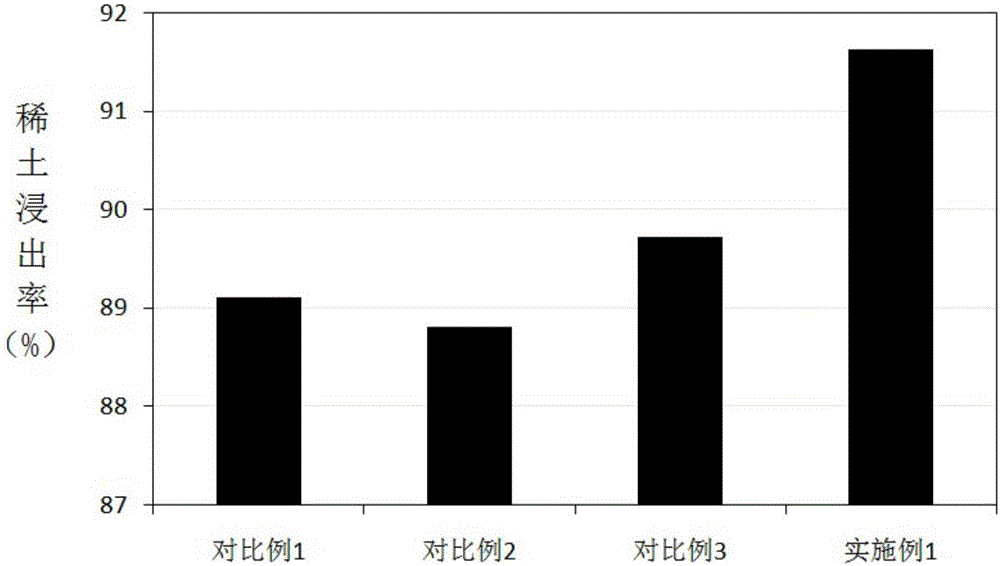

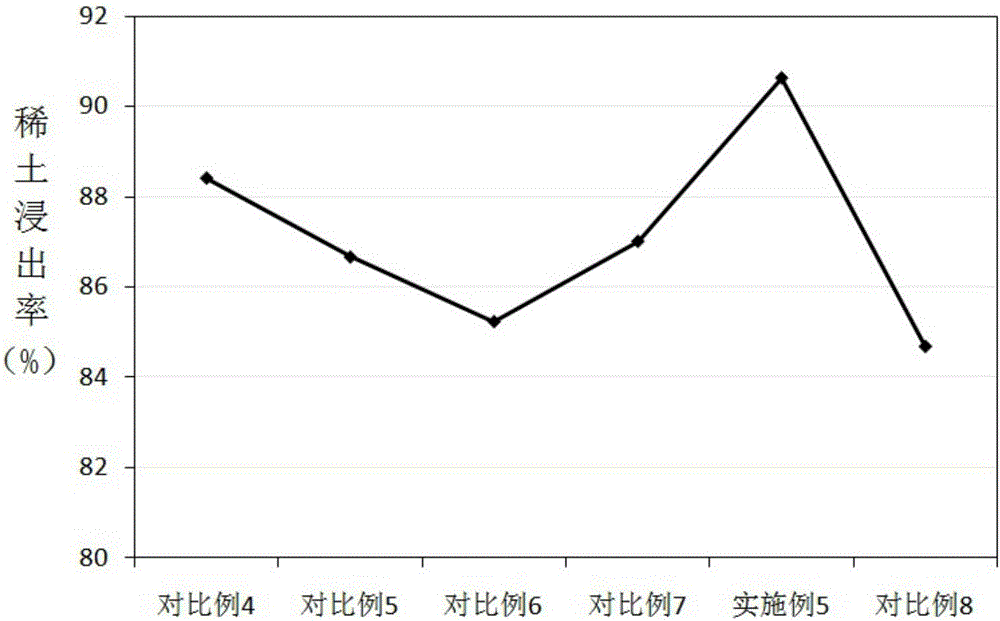

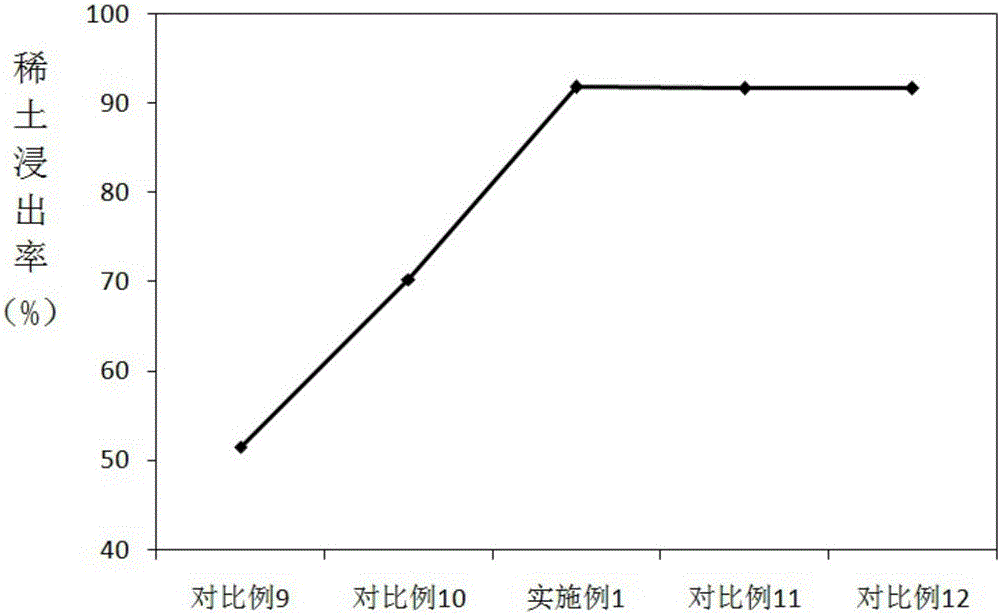

Rare earth ore leaching agent and leaching process

InactiveCN105821207AImprove leaching rateLow costProcess efficiency improvementSelective leachingRare earth ions

The embodiment of the invention relates to a rare earth ore leaching agent. The rare earth ore leaching agent comprises ammonium thiosulfate, ammonium sulfate and ammonium chloride. Rare earth ions are exchanged and desorbed through NH4+ in the three kinds of ammonium salt; through the positive synergistic effect of the ammonium thiosulfate, the ammonium sulfate and the ammonium chloride, the rare earth ore leaching agent in the embodiment can improve the rare earth ion leaching efficiency and reduce the content of aluminum and iron impurity ions in leaching liquid; and in addition, the agent cost is low, and the rare earth ore leaching agent can be used for the development and utilization of semi-weathering ionic adsorption type rare earth ore. A rare earth leaching process in the embodiment is simple, the high leaching rate and the high selective leaching of the rare earth ions can be achieved, and the rare earth ore leaching agent and leaching process are suitable for industrial large-scale use.

Owner:JIANGXI UNIV OF SCI & TECH +2

Sightseeing greenhouse succulents improvement matrix and preparation method thereof

InactiveCN104973959AFast rootingImproved soilBio-organic fraction processingOrganic fertiliser preparationSodium BentoniteManganese

The invention discloses a sightseeing greenhouse succulents improvement matrix and its preparation method. The matrix is prepared from the following raw materials, by weight, 30-50 parts of a light material, 40-60 parts of an organic matter, 4-8 parts of an inorganic fertilizer, 5-10 parts of bentonite, 0.5-1.5 parts of a microelement fertilizer and 0.5-1.5 parts of a plant protectant. The light material is one of components selected from vermiculite, perlite, ceramsite and volcanic or an arbitrary combination of two of the components. The organic matter is one of components selected from soybean cake, rape seed cake, cottonseed cake, leaf mould and bone meal or an arbitrary combination of two of the components. The inorganic fertilizer is obtained by mixing ammonium thiosulfate, monopotassium phosphate, potassium nitrate, ammonium phosphate and potassium sulphate. The microelement fertilizer is obtained by mixing ferrous sulphate, ammonium molybdate, manganese sulfate, zinc sulfate and copper sulphate. The plant protectant is obtained by mixing alpha-naphthylacetic sodium salt, diethyl aminoethyl hexanoateDA-6, 70 wt% of thiophanate-methyl and hymexazol. By the use of the improvement matrix, soil can be improved, fertilizers can be saved, the environment can be protected, and rooting speed of succulents can be raised.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

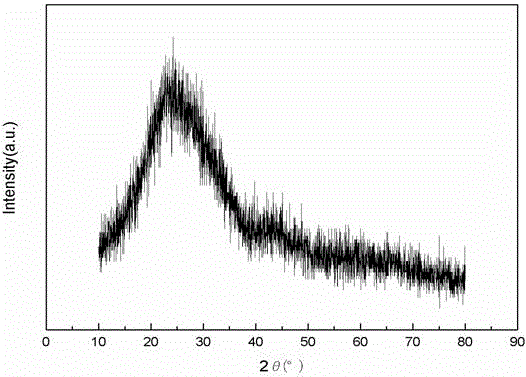

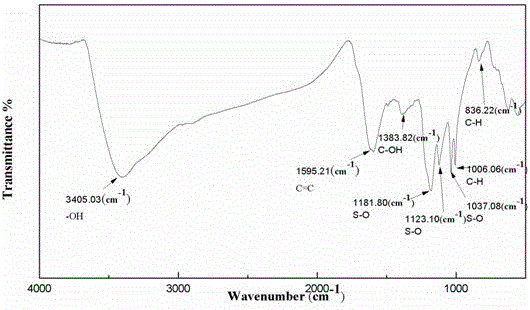

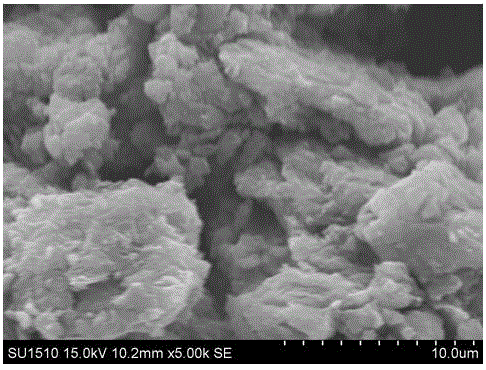

Method for preparing sulfonated graphene material

ActiveCN106379893ALow requirements for production equipmentMild conditionsCarbon compoundsArylSulfanilic acid

The invention discloses a method for preparing a sulfonated graphene material. The method comprises the following steps: taking reduced graphene oxide and sulfanilic acid aryl diazo salt as raw materials, and reacting, thereby obtaining the material. Graphene oxide is prepared by adopting an improved Hummers method, and the reduced graphene oxide is prepared by taking environmental-friendly ammonium thiosulfate as a reducing agent. The diazo salt is prepared from sulfanilic acid and is reacted with the reduced graphene oxide so as to prepare the functionalized sulfonated graphene. Only a low-temperature reaction is carried out in the whole experimental process, and the method adopts mild conditions, is easy to operate and control, high in safety and low in production equipment requirement and contributes to large-scale production.

Owner:TAIZHOU CITY GANG YANG RUBBER

Process for production of ammonium thiosulphate

InactiveUS7052669B2Thiosulfates/dithionites/polythionitesSulfite preparationAqueous solutionAmmonium thiosulfate

Owner:HALDOR TOPSOE AS

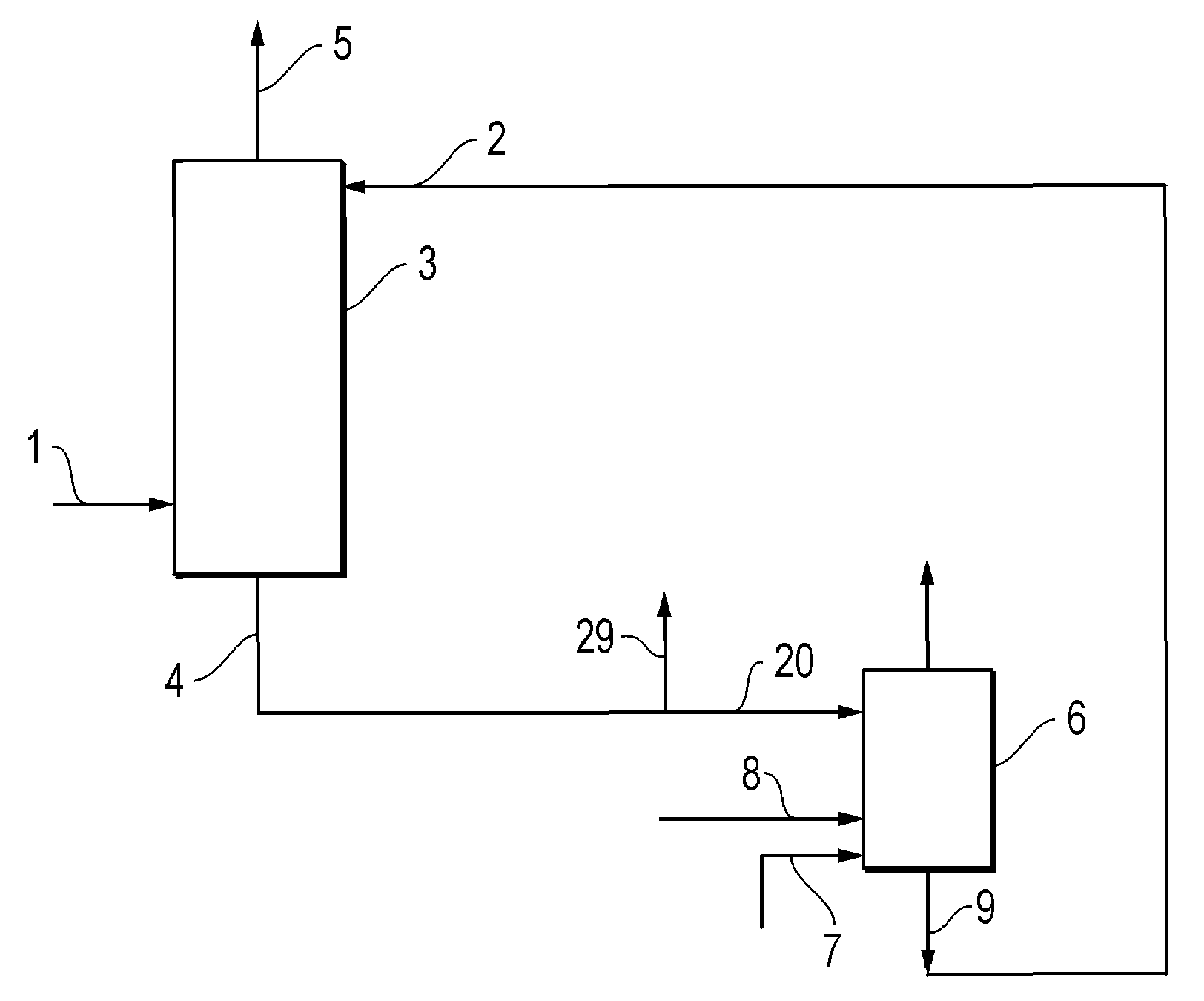

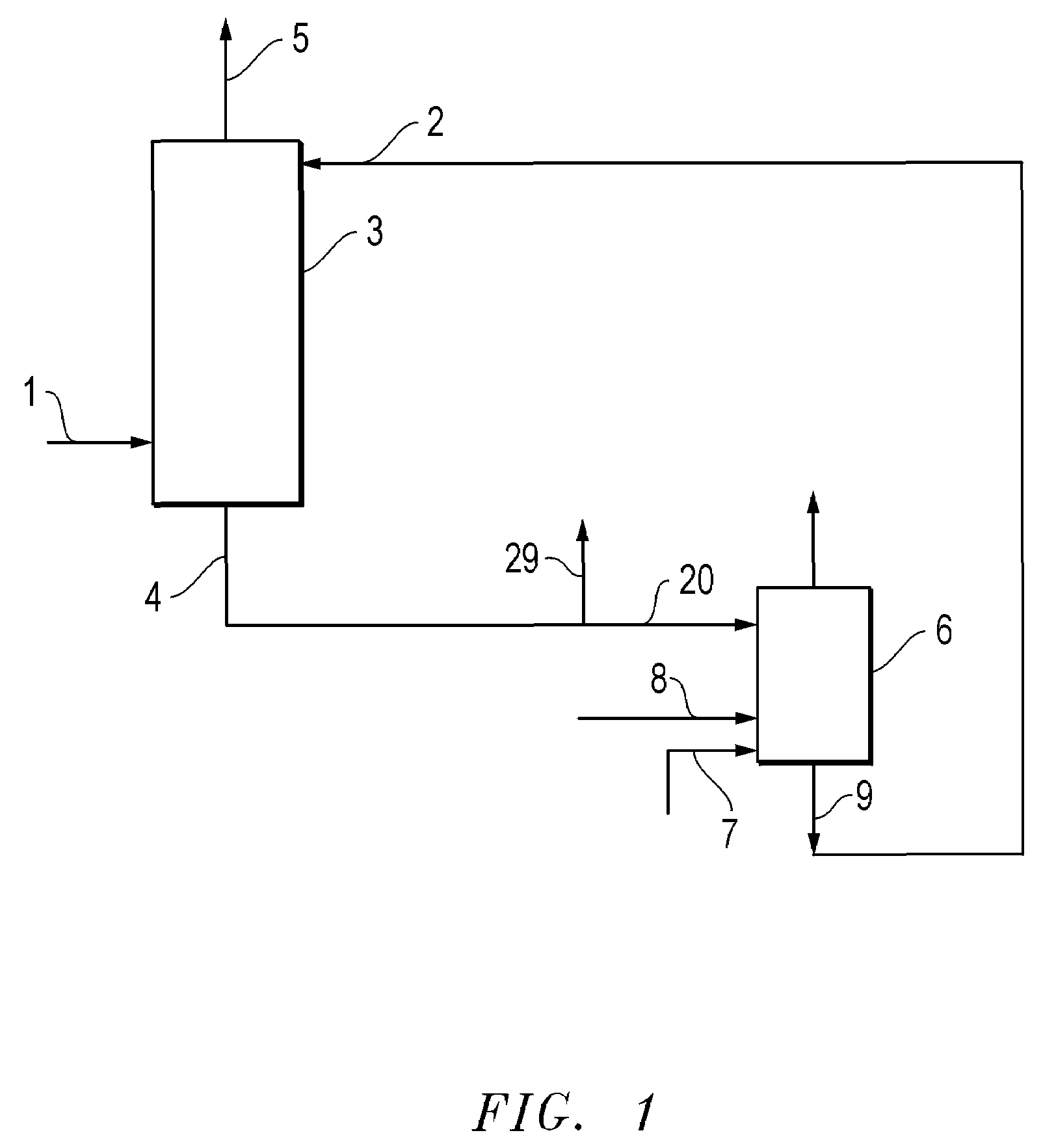

Process for treating a gas stream

ActiveUS7390470B2Efficient removalLow costCyanogen compoundsExhaust apparatusAmmonium bisulfateSulfur containing

Processes for selectively removing sulfur-containing compounds from a gas are described herein. The processes generally include contacting a first gas including carbon dioxide and hydrogen sulfide with a scrub solution including ammonium bisulfite and ammonium sulfite in a first contact zone to produce a first contact zone effluent liquid including ammonium thiosulfate and a first contact zone overhead gas including carbon dioxide.

Owner:THIOSOLV

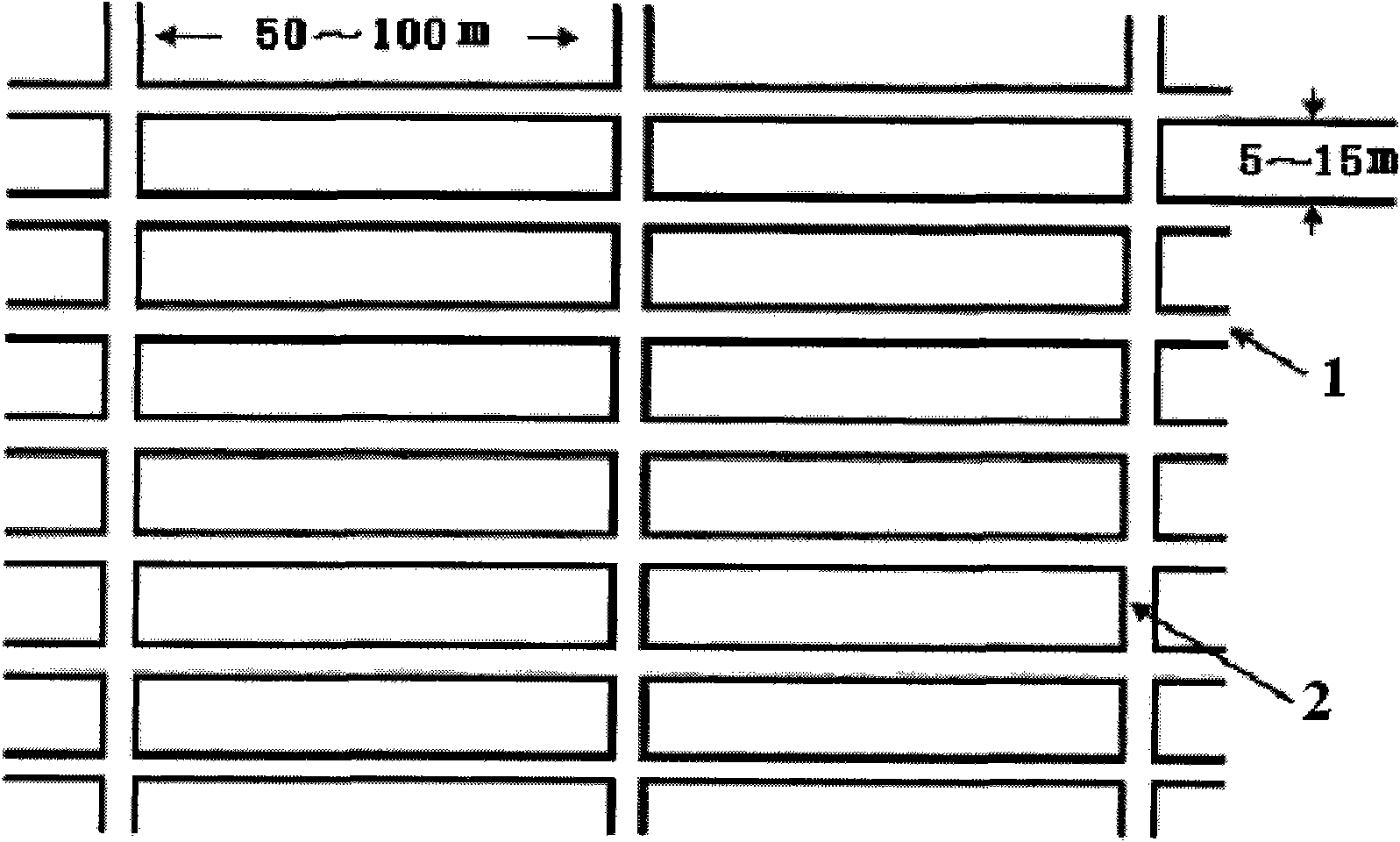

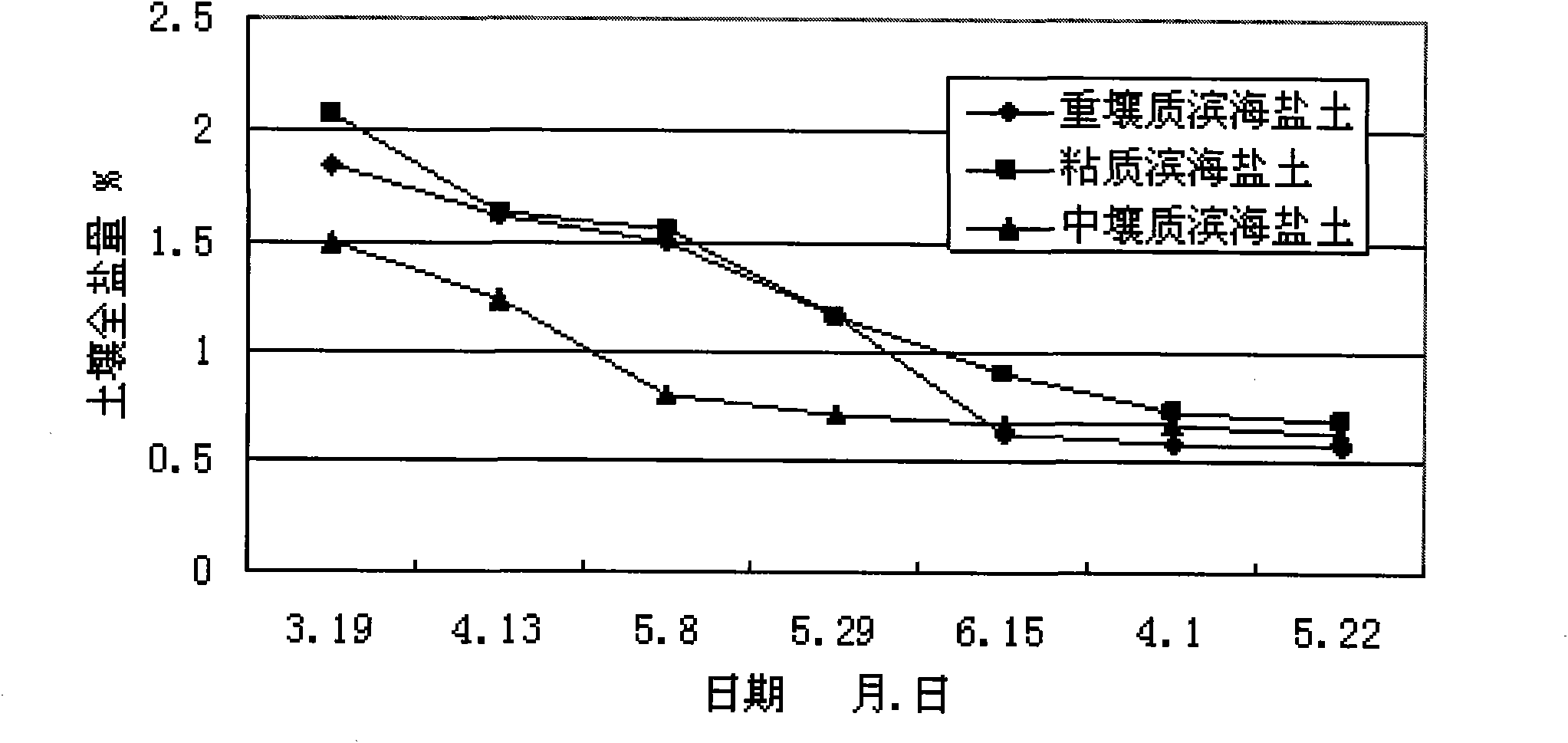

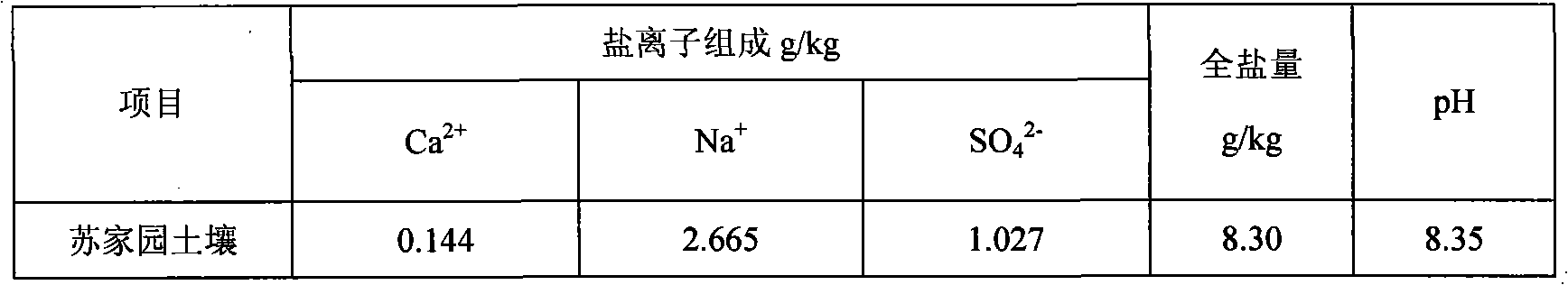

Calcium-rich saline water and method for irrigating calcium-rich saline water and reducing salt content in soil

InactiveCN101851513ARaise the ratioReduce the ratioOrganic fertilisersSoil-working methodsCalcium EDTAAmmonium sulfate

The invention discloses calcium-rich saline water and a method for irrigating calcium-rich saline water and reducing salt content in soil. The calcium-rich saline water comprises the following components in parts by weight: 2-3 parts of calcium sulfate and / or 2-5 parts of calcium nitrate, 0-5 parts of ammonium sulfate, 0-5 parts of sodium thiosulfate or ammonium thiosulfate and 1000 parts of fresh water of which the salinity is less than 1g / L or brackish water of which the salinity is 2g / L-5g / L or saline water of which the salinity is greater than 5g / L. In the invention, the experiment proves that when the calcium-rich saline water capable of improving Ca<2+> proportion and relatively reducing Na<+> content is used for irrigating saline soil, the salt content in the soil is reduced, and the proportion of Na<+> ions in salt ion composition in the soil is reduced, thereby ameliorating the negative effect on soil structure, permeability and other physical properties caused by high Na<+> content, so that the improved soil is beneficial to growth of certain plants.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

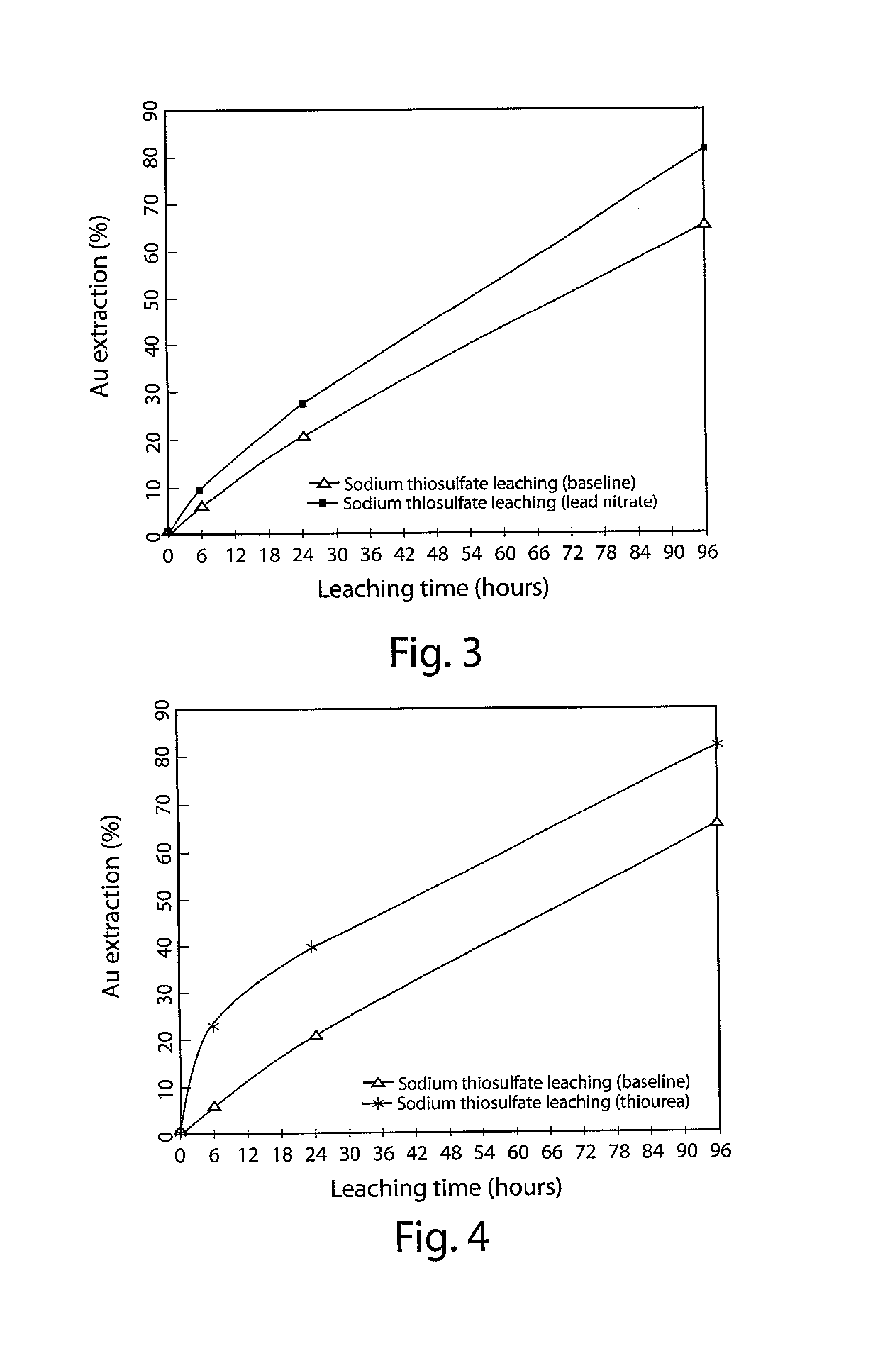

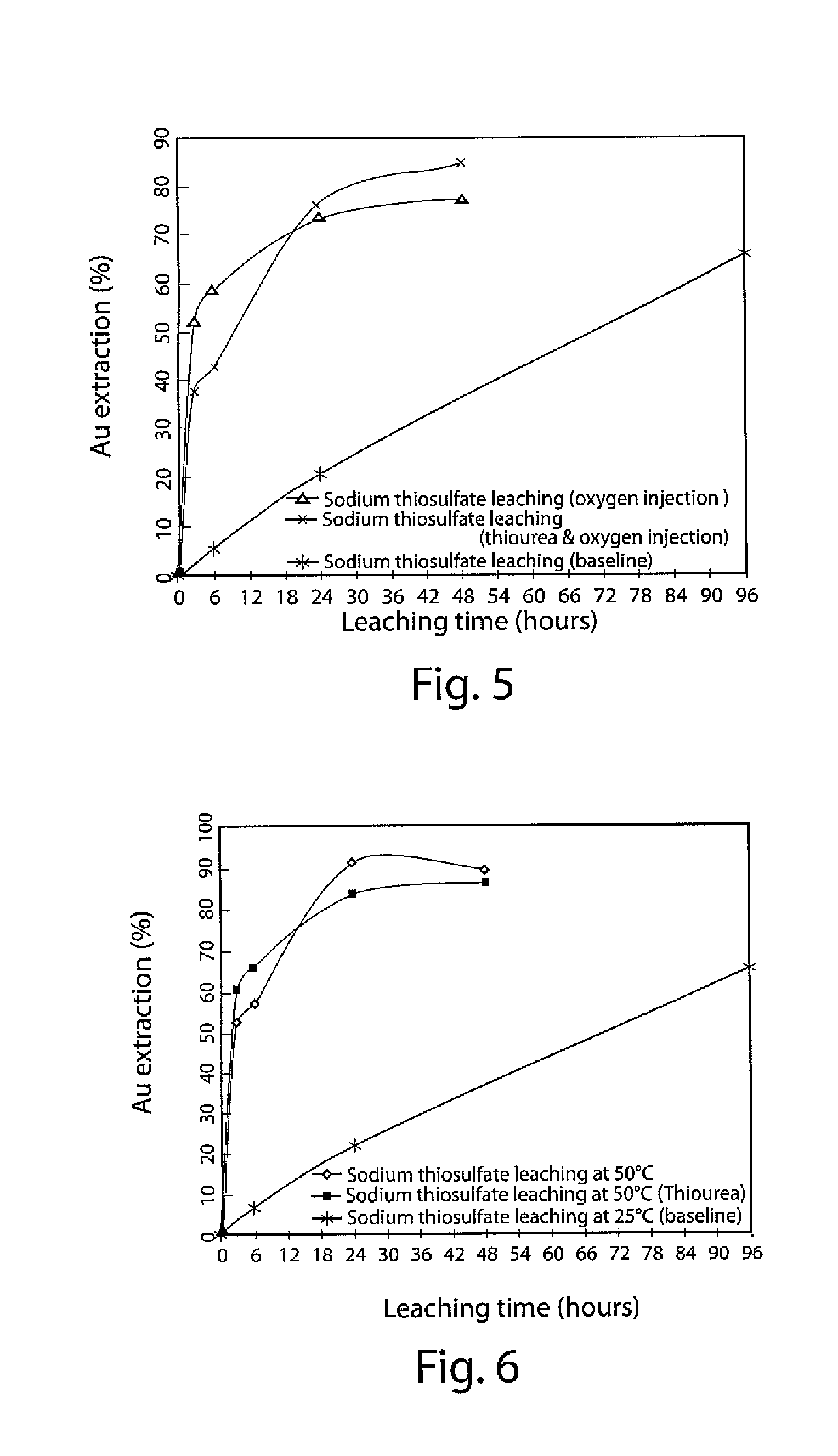

Process of leaching precious metals

ActiveUS20140212346A1Increase concentrationReduce usageProcess efficiency improvementLixiviantLead nitrate

The invention relates to modifications of a non-ammoniacal thiosulfate process of leaching precious metals (e.g. gold or silver) from precious metal-containing ores. The process involves leaching the ore with an aqueous lixiviant containing a soluble thiosulfate other than ammonium thiosulfate, a copper compound and an organic compound that serves as a copper ligand (i.e. a ligand-forming compound). Four modifications of this process are effective for increasing the amount of precious metal that can be extracted, reducing the consumption of materials, or for improving the rate of extraction. These four process, which may be used singly or in any combination, include (a) additions of soluble lead (e.g. as lead nitrate), (b) additions of thiourea, (c) increases in dissolved oxygen, and (d) increases of temperature at ambient pressure. This avoids the use environmentally harmful chemicals and allows for extraction from a variety of ores, e.g., containing substantial amounts of sulfides and / or quartz.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Concrete curing agent

The invention discloses a concrete curing agent, which comprises the following components in parts by mass: 20-25 parts of styrene-acrylic emulsion, 7-10 parts of acrylamide solution, 7-9 parts of sodium silicate solution, 6-9 parts of organic silicon solution 8 parts, 1-3 parts of methyl methacrylate, 1-3 parts of polyethylene glycol monomethyl ether acrylate, 3-5 parts of polyethylene glycol, 1-3 parts of polyvinyl alcohol, 4-6 parts of styrene , 6-8 parts of methyl acrylate, 5-7 parts of butyl methacrylate, 3-5 parts of butyl acrylate, 4-6 parts of ethyl methacrylate, 1-3 parts of ammonium thiosulfate, EPDM 1-3 parts of rubber, 0.7 parts of butyl citrate, 1 part of soda ash, 0.5 parts of gypsum powder, 0.1 part of periodate lignin, 0.1 part of surfactant, 0.2 part of defoamer, 0.3 part of leveling agent and benzene 1 part methanol. The curing agent disclosed by the invention can effectively prevent water loss inside the concrete, and is environmentally friendly and pollution-free.

Owner:CHINA ROAD & BRIDGE

Straw-based selective mercury removal material, preparation method and applications thereof

InactiveCN106237985AHigh removal rateFast removalOther chemical processesWater contaminantsNitrogen gasHigh selectivity

The present invention provides a straw-based selective mercury removal material preparation method, which comprises: (1) carrying out a steam explosion treatment on straws, and then treating at a temperature of 400-800 DEG C under vacuumizing and nitrogen atmosphere; (2) placing the product obtained in the step (1) into a reductive sulfur group-containing mixing liquid, carrying out stirring mixing, filtering, and drying, wherein the reductive sulfur group-containing mixing liquid is a mixing liquid of ammonium thiocyanate, ammonium thiosulfate and thioglycolic acid; and (3) mixing the product obtained in the step (2) and sublimed sulfur, heating under vacuumizing and nitrogen introducing conditions to achieve a temperature of 450 DEG C, maintaining for 2 h, carrying out program heating to 600-1000 DEG C, maintaining the vacuumizing and nitrogen introducing for 2 h, cooling, and grinding so as to obtain the straw-based selective mercury removal material. The invention further provides the mercury removal material prepared through the method and applications of the mercury removal material in mercury removal. According to the present invention, the straw-based selective mercury removal material has advantages of high mercury adsorption capacity, high mercury removal rate, rapid mercury removal, high selectivity, cheap and easily available raw materials, simple and feasible preparation process, environmental protection, economy, and good application prospect.

Owner:SICHUAN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com