Concrete curing agent

A technology of concrete curing agent and leveling agent, applied in the field of concrete curing agent, can solve the problems of inability to effectively block water evaporation, poor curing effect, low protection rate, etc., to reduce shrinkage cracks, prevent water loss, reduce The effect of drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

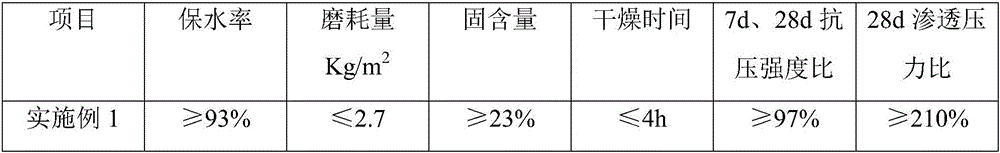

Embodiment 1

[0021] A concrete curing agent, the concrete curing agent comprises:

[0022] Styrene-acrylic emulsion 22Kg, acrylamide solution 9Kg, sodium silicate solution 7Kg, organic silicon solution 8Kg, methyl methacrylate 3Kg, polyethylene glycol monomethyl ether acrylate 2Kg, polyethylene glycol 4Kg, polyvinyl alcohol 3Kg, Styrene 5Kg, methyl acrylate 6Kg, butyl methacrylate 6Kg, butyl acrylate 3Kg, ethyl methacrylate 6Kg, ammonium thiosulfate 3Kg, EPDM rubber 3Kg, butyl citrate 0.7Kg, soda ash 1Kg , gypsum powder 0.5Kg, periodate lignin 0.1Kg, surfactant 0.1Kg, defoamer 0.2Kg, leveling agent 0.3Kg and benzyl alcohol 1Kg;

[0023] Wherein, the weight percentage concentration of styrene-acrylic emulsion is 25%, the weight percentage concentration of acrylamide is 15%, and the weight percentage concentration of sodium silicate solution is 25%;

[0024] The number-average molecular weight of polyethylene glycol is 500-1000, and the number-average molecular weight of polyethylene glycol...

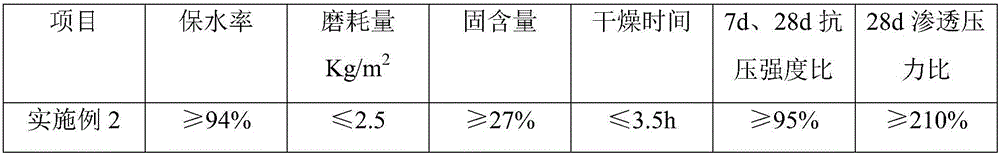

Embodiment 2

[0034] A concrete curing agent, the concrete curing agent comprises:

[0035] 20Kg of styrene-acrylic emulsion, 7Kg of acrylamide solution, 7Kg of sodium silicate solution, 6Kg of organic silicon solution, 1Kg of methyl methacrylate, 1Kg of polyethylene glycol monomethyl ether acrylate, 3Kg of polyethylene glycol, 1Kg of polyvinyl alcohol, Styrene 4Kg, methyl acrylate 6Kg, butyl methacrylate 5Kg, butyl acrylate 3Kg, ethyl methacrylate 4Kg, ammonium thiosulfate 1Kg, EPDM rubber 1Kg, butyl citrate 0.7Kg, soda ash 1Kg , gypsum powder 0.5Kg, periodate lignin 0.1Kg, surfactant 0.1Kg, defoamer 0.2Kg, leveling agent 0.3Kg and benzyl alcohol 1Kg;

[0036] Wherein, the weight percentage concentration of styrene-acrylic emulsion is 25%, the weight percentage concentration of acrylamide is 15%, and the weight percentage concentration of sodium silicate solution is 25%;

[0037] The number-average molecular weight of polyethylene glycol is 500-1000, and the number-average molecular weigh...

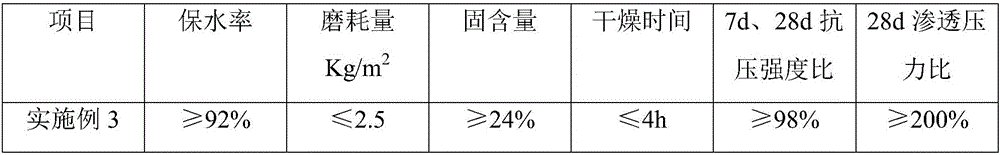

Embodiment 3

[0047] A concrete curing agent, the concrete curing agent comprises:

[0048] 25Kg of styrene-acrylic emulsion, 10Kg of acrylamide solution, 9Kg of sodium silicate solution, 8Kg of organic silicon solution, 3Kg of methyl methacrylate, 3Kg of polyethylene glycol monomethyl ether acrylate, 5Kg of polyethylene glycol, 3Kg of polyvinyl alcohol, Styrene 6Kg, methyl acrylate 8Kg, butyl methacrylate 7Kg, butyl acrylate 5Kg, ethyl methacrylate 6Kg, ammonium thiosulfate 3Kg, EPDM rubber 3Kg, butyl citrate 0.7Kg, soda ash 1Kg , gypsum powder 0.5Kg, periodate lignin, surfactant 0.1Kg, defoamer 0.2Kg, leveling agent 0.3Kg and benzyl alcohol 1Kg;

[0049] Wherein, the weight percentage concentration of styrene-acrylic emulsion is 25%, the weight percentage concentration of acrylamide is 15%, and the weight percentage concentration of sodium silicate solution is 25%;

[0050] The number-average molecular weight of polyethylene glycol is 500-1000, and the number-average molecular weight of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com