Shrinkage-compensating rapid repairing material for bridge expansion joints

A technology for compensating shrinkage and repairing materials, which is applied in the field of bridge expansion joints with compensating shrinkage and quick repairing materials, can solve problems such as difficult maintenance of fast-hardening concrete, and achieve the effect of enhancing its own internal curing effect, enhancing volume stability and reducing cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

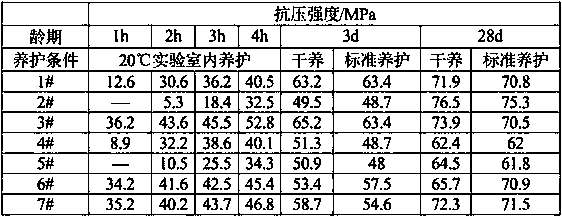

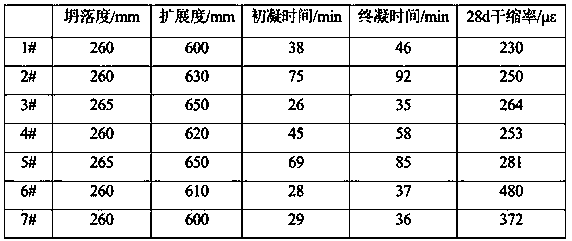

[0034] Example 1 Preparation of 1# Bridge Expansion Joint Compensating Shrinkage Rapid Repair Material

[0035] The mass ratio of the raw materials used is: 25 parts of cement (42.5 grade ordinary Portland cement and rapid hardening sulfoaluminate cement prepared at a mass ratio of 1:6), 2 parts of gypsum powder, 3 parts of silica powder, expansion agent ( Light-burned magnesia expansion agent and calcium oxide expansion agent are prepared at a mass ratio of 1:5) 4 parts, 30 parts of quartz sand, 36 parts of crushed stone, 0.05 part of water reducer, retarder (sodium gluconate and tartaric acid by mass Ratio 3:1) 0.05 parts, super absorbent resin 0.05 parts, lithium carbonate 0.01 parts, defoamer 0.005 parts, water-binder ratio 0.25.

[0036] During construction, first chisel away the concrete at the cracked part of the expansion joint of the bridge, rinse and clean the pit, if no clear water is seen; put all the raw materials into the mixing pot and dry mix for three minutes,...

Embodiment 2

[0037] Example 2 Preparation of 2# Bridge Expansion Joint Compensating Shrinkage Rapid Repair Material

[0038] The mass ratio of the raw materials used is: 40 parts of cement (grade 42.5 ordinary portland cement and rapid hardening sulfoaluminate cement prepared at a mass ratio of 3:1), 2 parts of gypsum powder, 3 parts of silica powder, expansion agent ( 2 parts of light-burned magnesia expansion agent and calcium oxide expansion agent according to the mass ratio of 1:2), 30 parts of quartz sand, 36 parts of crushed stone, 0.1 part of water reducer, retarder (sodium gluconate and tartaric acid by mass Ratio 2:1) 0.05 parts, super absorbent resin 0.08 parts, lithium sulfate 0.01 parts, defoamer 0.005 parts, water-binder ratio 0.25.

[0039] Construction method is the same as embodiment 1.

Embodiment 3

[0040] Example 3 Preparation of 3# Bridge Expansion Joint Compensating Shrinkage Rapid Repair Material

[0041]The mass ratio of raw materials used is: 30 parts of cement (grade 42.5 ordinary Portland cement and rapid hardening sulfoaluminate cement prepared at a mass ratio of 2:1), 2 parts of gypsum powder, 3 parts of silica powder, expansion agent ( 2 parts of light-burned magnesia expansion agent and calcium oxide expansion agent according to the mass ratio of 1:2), 25 parts of quartz sand, 40 parts of crushed stone, 0.05 parts of water reducer, retarder (sodium gluconate and tartaric acid by mass Ratio 2:1) 0.15 parts, super absorbent resin 0.05 parts, lithium carbonate 0.01 parts, defoamer 0.005 parts, water-binder ratio 0.25.

[0042] Construction method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com