Ceramic formula and preparation method for ceramic product

A technology of ceramics and formulations, applied in the field of ceramic materials, can solve problems such as the limitation of kiln floor space, and achieve the effects of improving production efficiency and enterprise benefits, reducing investment in technological transformation, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

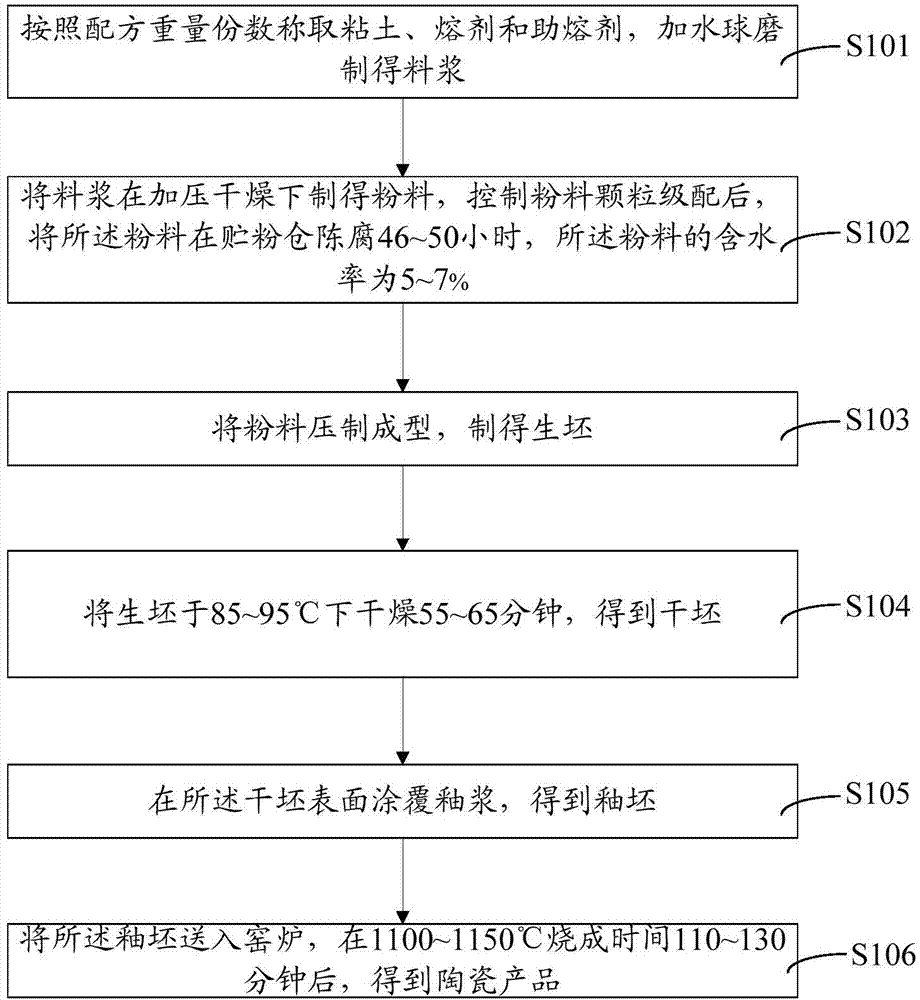

[0065] see figure 1 , the preparation method of the ceramic green body of an embodiment, comprises the following steps:

[0066] Step S101: Weigh the clay, flux and flux according to the weight of the formula, add water and ball mill to obtain a slurry; the process parameters of the slurry are: 1-1.5% of the residue after passing through a 250-mesh sieve, and a moisture content of 35-38% %, the viscosity is 150~200mpa.s

[0067] The uniform mixing of pulverized raw materials can make the particles of clay, flux and flux smaller, and the uniform mixing ensures the fineness of the slurry, making the size of the ceramic body shrink, and the firing temperature and performance are stable. Preferably, the clay, flux and flux can be ground by ball milling for 8-10 hours, wherein the total mass of clay, flux and flux: mass of ball stone: mass of water = 1:2:0.6. Ball milling is carried out in a closed machine, using wet grinding method to avoid flying dust and high grinding efficien...

Embodiment 1

[0085] Ceramic formula in the present embodiment, the raw material of ceramic formula comprises following component by weight part:

[0086] 30 parts of Zisha shale, 25 parts of Niuxi village clay, 25 parts of Zijinshan shale, 3 parts of limestone, and 17 parts of industrial waste. The nearby clay is Niuxi village clay, and the shale is Zijinshan shale.

[0087] Among them: clay (55 parts): Zisha shale, Niuxi Village clay, the weight ratio of Zisha shale to Niuxi Village clay is 1.2.

[0088] Flux (25 parts): Purple Mountain Shale.

[0089] Flux (20 parts): limestone, ceramic fragments, the weight ratio of the mass of limestone to ceramic fragments is 0.18.

[0090] Taking the preparation of ceramic floor tiles as an example, it includes the following steps:

[0091] Weigh the clay, flux and flux according to the parts by weight of the formula, put the clay, flux and flux into the ball mill for ball milling for 9 hours, wherein the total mass of clay, flux and flux: the qua...

Embodiment 2

[0101] The raw materials of the ceramic formula in this embodiment include the following components in parts by weight: 30 parts of purple sand shale, 30 parts of Niuxi village pottery clay, 20 parts of Zijinshan shale, 1 part of limestone, 19 parts of industrial waste residue (including ceramic fragments 3 parts, 16 parts of industrial waste). The nearby clay is Niuxi village clay, and the shale is Zijinshan shale.

[0102] Among them: clay (60 parts): Zisha shale, Niuxi Village clay, the weight ratio of Zisha shale to Niuxi Village clay is 0.67.

[0103] Flux (20 parts): Purple Mountain Shale

[0104] Flux (20 parts): limestone, ceramic fragments, the weight ratio of the mass of limestone to ceramic fragments is 0.33.

[0105] Taking flower pot preparation as an example, it includes the following steps:

[0106] Weigh the powder materials such as clay, flux and flux according to the weight of the formula, put the clay, flux and flux powder into the ball mill, fill the bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com