Patents

Literature

455 results about "China clay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of acid extracting aluminium from high-silicon alumina-containing raw mineral materials

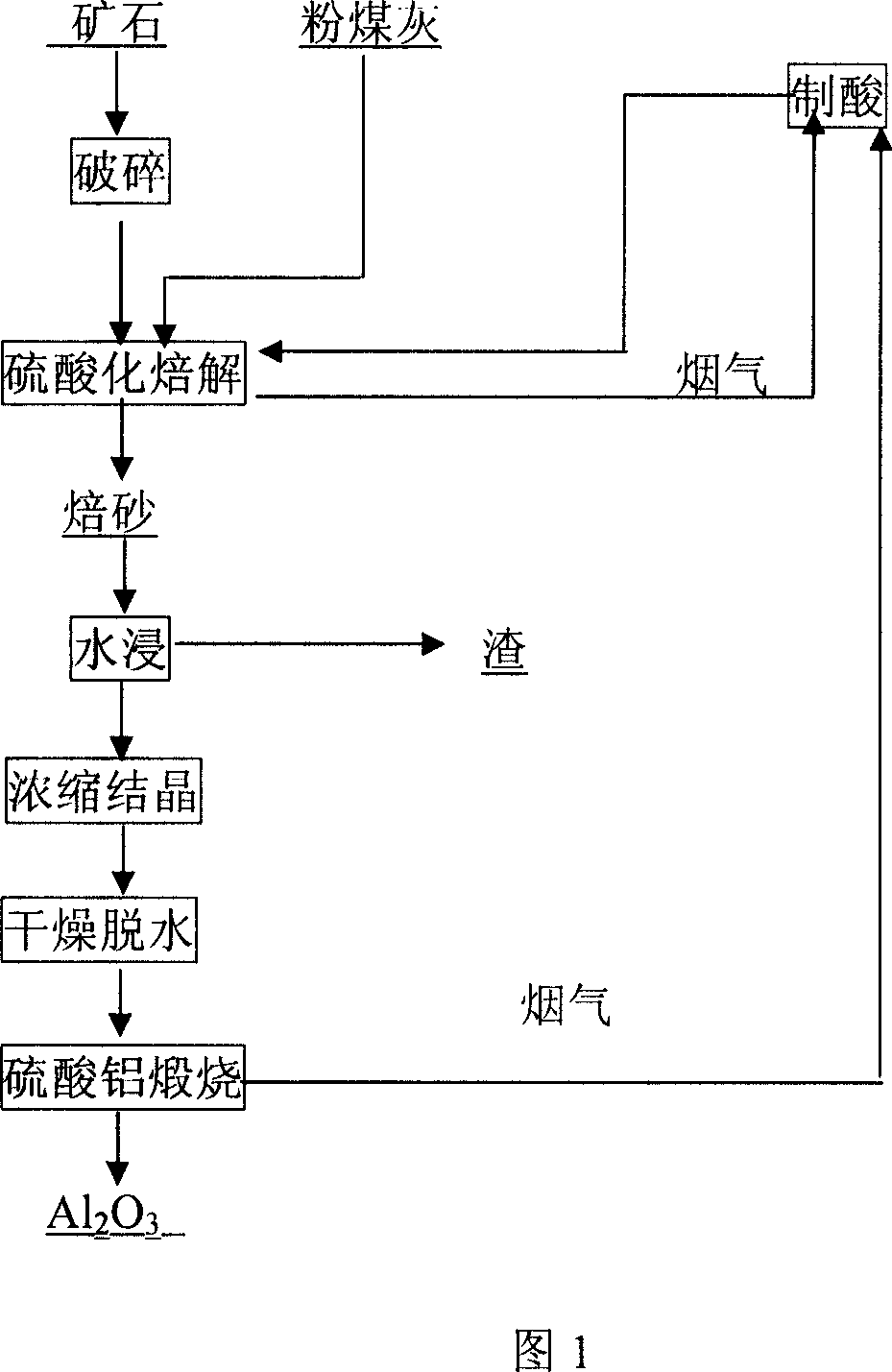

The invention relates the method of extracting aluminium from high-silicon siliceous mineral. The method comprises the following steps: mixing the aluminous ore and sulfuric acid, baking, leaching with water, filtering leachate, getting aluminium sulphate solvent, thickening filter liquor, separating out aluminium sulphate, drying, dewatering, getting anhydrous aluminium sulphate; calcining aluminium sulphate, and getting Al2O3. The invention can extracte aluminium from high-silicon siliceous mineral, coal gangue, coal ash, China clay, andalusite, feldspath, ganister, nepheline and vermiculite without baking. The method has the advantages of simple technology, little corrosion, easy operation and high recovery ratio.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

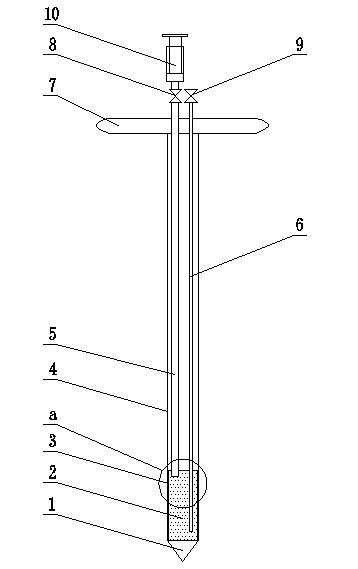

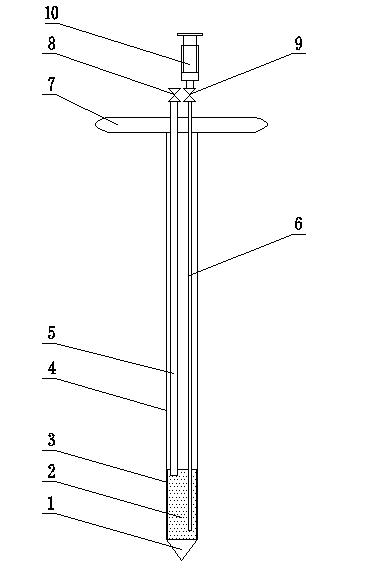

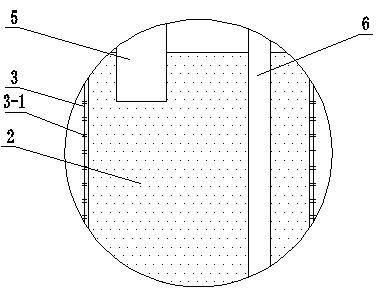

Triaxial creep tester of unsaturated soil

InactiveCN101592574AAvoid destructionSimple structureMaterial strength using tensile/compressive forcesInternal pressureRubber membrane

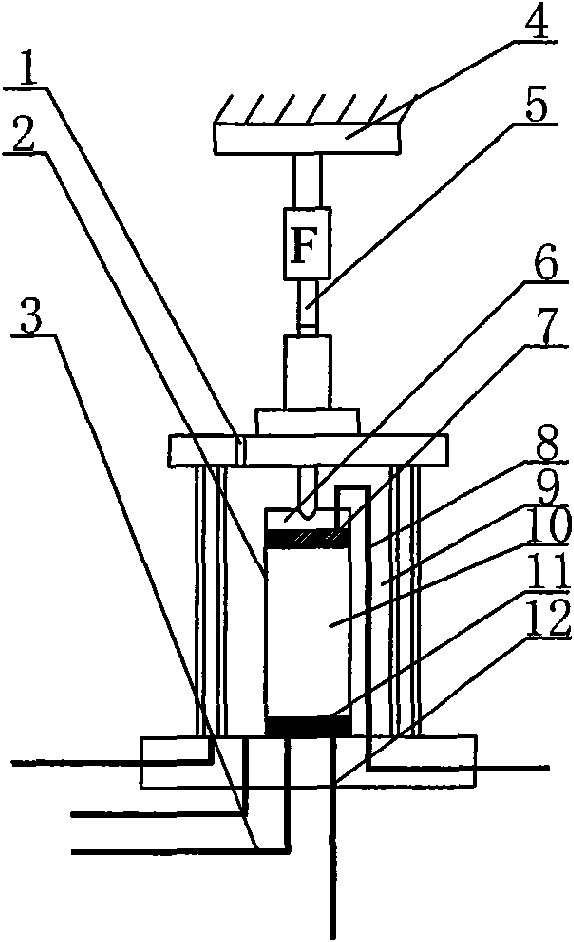

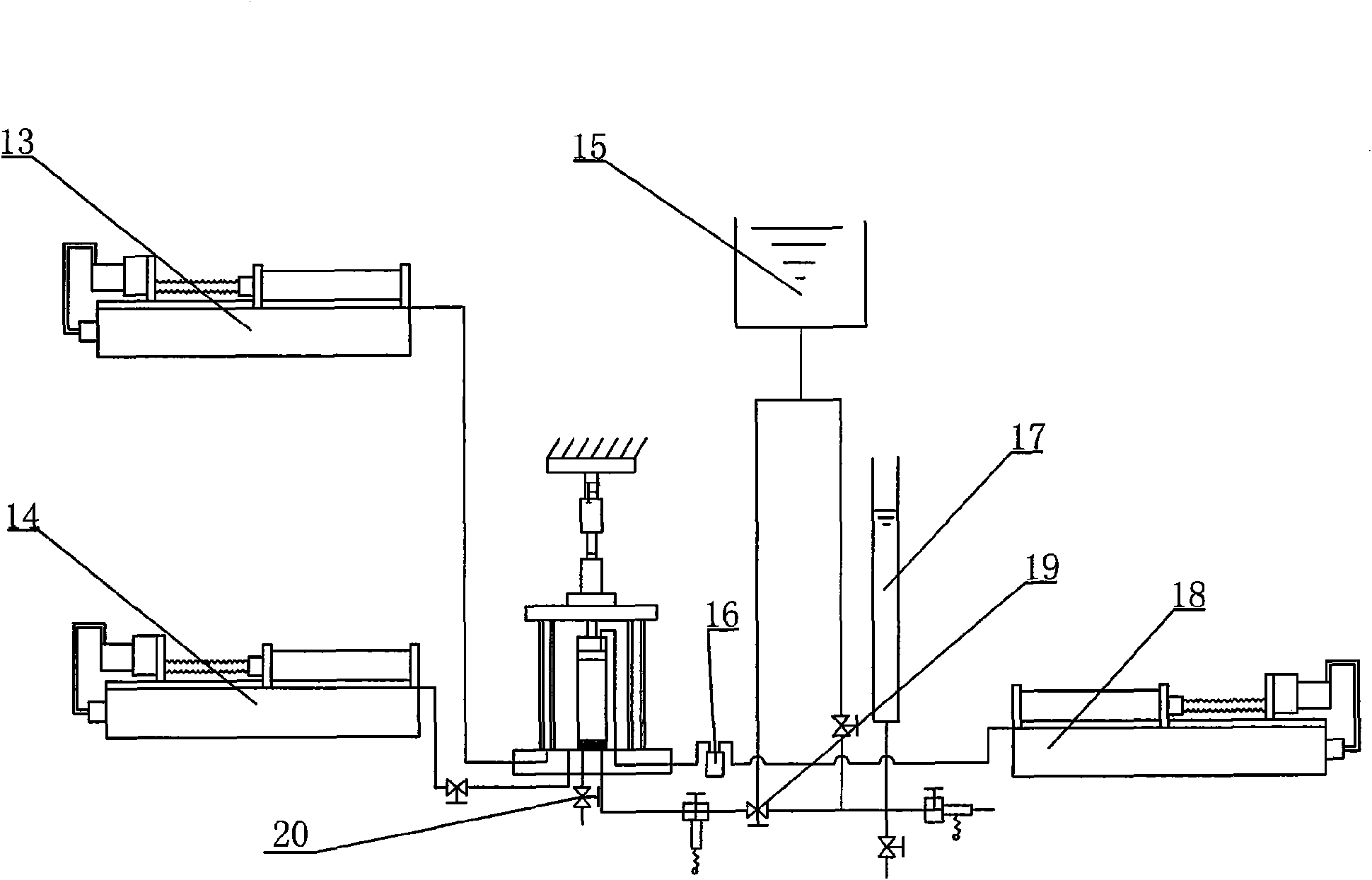

The invention discloses a triaxial creep tester of unsaturated soil, and relates to a geotechnical test apparatus. By inlaying a china clay plate with high air entry value in the pedestal of a pressure chamber, the geotechnical test apparatus allows water in a soil sample to pass through the china clay plate, but exerted gas cannot pass through, thereby realizing the aims of controlling groundmass suction and ensuring waterdrainage. The upper part of the china clay plate has a sample sleeved with a rubber membrane, and the upper part of the sample is provided with a porous plate and a sample cap; the sample cap is connected with a set of pipelines capable of controlling air pressure to exert pore air pressure on the sample and control pore air pressure; and the bottom of the china clay plate is respectively connected with a wash pipe and a drainpipe which play roles in washing air bubbles on the bottom of the china clay plate and waterdrainage respectively. A sample pressure chamber adopts a double-layer pressure chamber, namely a double-layer organic glass cylinder. An inner pressure chamber is filled with air-free water to exert a confining pressure on the sample, while an outer pressure chamber exerts an air pressure of equivalent confining pressure value to eliminate the influence on bulk variate caused by the deformation of the inner pressure chamber.

Owner:CHINA THREE GORGES UNIV +1

Longquan celadon crackle glaze wine bottle and preparation method thereof

ActiveCN104150873ANovel preparation methodSatisfy the wine storage functionClaywaresPotassiumWine bottle

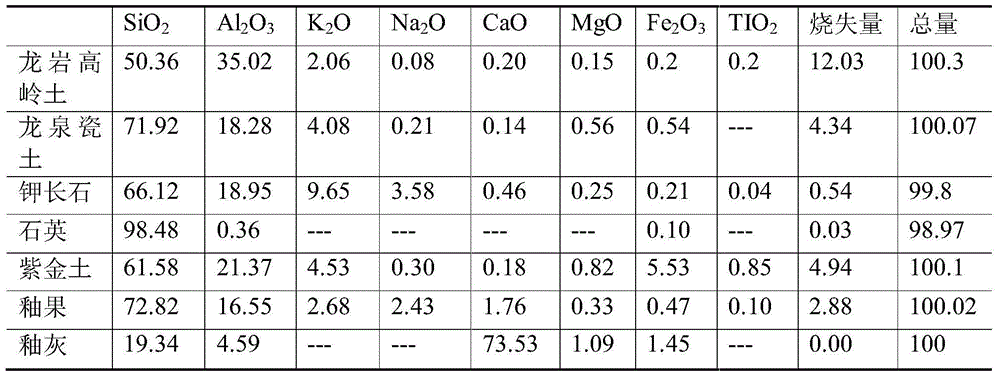

The invention relates to a longquan celadon crackle glaze wine bottle and a preparation method thereof. Raw material proportions of a blank material, an internal glaze and an external glaze of the bottle are respectively described as follows: the blank material comprises: 40-55% of Longyan kaolin, 15-25% of Longquan china clay, 8-20% of potassium feldspar, 7-15% of quartz and 5-10% of zijin clay; the internal glaze comprises: 65-70% of glaze fruit, 12-25% of glaze ash and 5-10% of zijin clay; and the external glaze comprises: 60-70% of potassium feldspar, 8-15% of quartz, 8-13% of Longyan kaolin, 8-15% of glaze ash, 5-13% of zijin clay and 0.2-0.4% of Fe2O3. On the basis of above raw materials, the longquan celadon crackle glaze wine bottle is prepared by following steps: preparing slurry, performing an injection moulding process to obtain a wet blank; performing a drying process, a trimming process and a biscuiting process to complete a blank manufacturing process; and finally applying the internal glaze and the external glaze and performing a glazing firing process to obtain a finished product of the longquan celadon crackle glaze wine bottle. The bottle is free of stripes on the internal glaze. The external glaze is decorated through crackles. The bottle is good in quality and is free of internal leakage of wine. The method is low in cost and good in effect.

Owner:龙泉市尚唐瓷艺发展有限公司 +1

Preparation process of modified china-clay for inserted layer

The invention relates to a method of preparing intercalation modified kaoline, firstly dispersing the kaoline in an intercalation agent solution to form uniform suspension serum, then making ultrasonic treatment, and finally separating, washing, drying and grinding to obtain the products, where the ultrasonic treatment: placing the suspension serum in a ultrasonic reactor, using 30-60 deg. water as medium, regulating ultrasonic frequency to 15-40 KHz, and making mixing ultrasonic treatment for 3-4 hours. It is a method of saving energy sources and benefiting environmental protection, and has high intercalation efficiency, the need time is short, on conditions of relaxative operation and environment, it can make the intercalation ratio up to above 90%.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

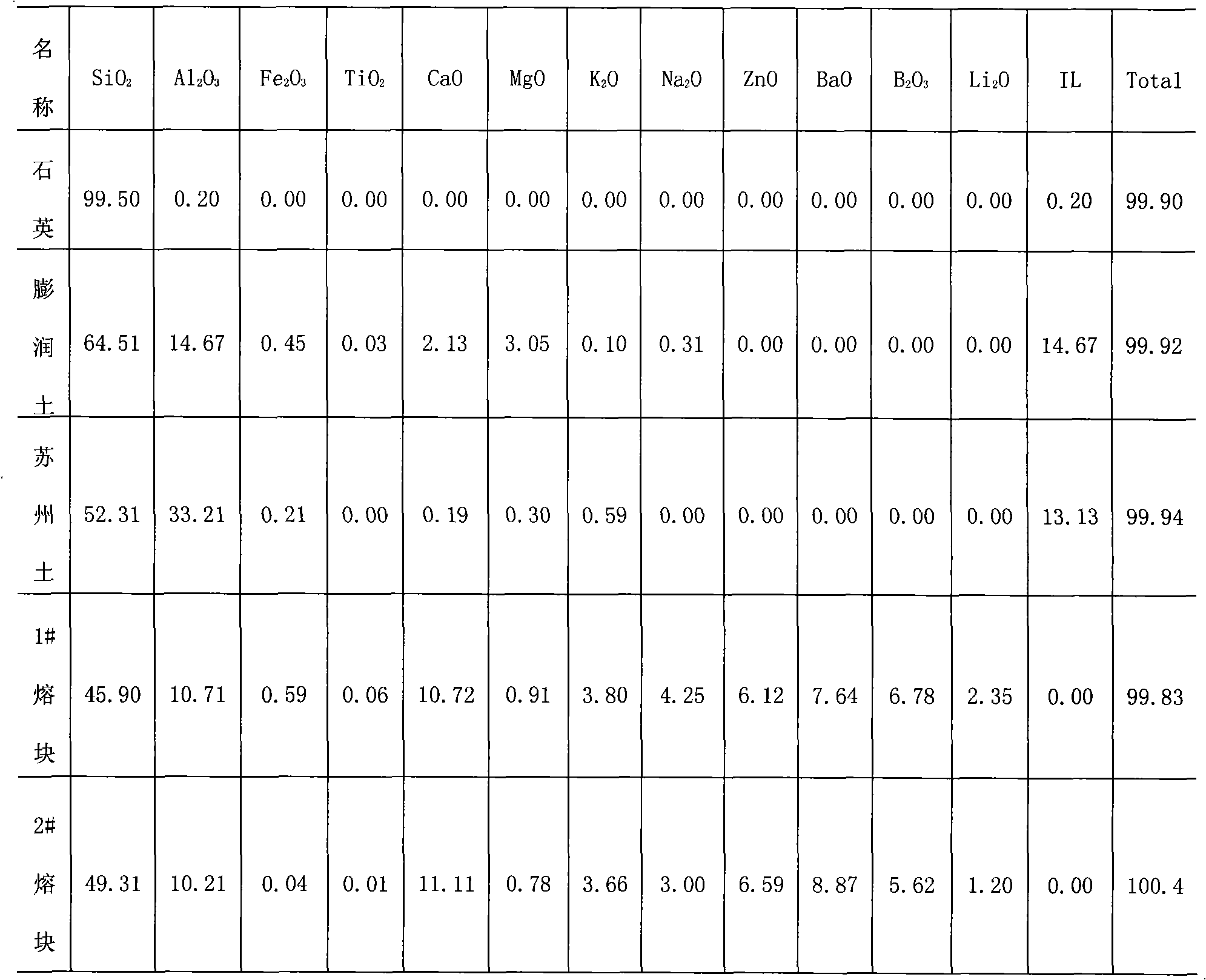

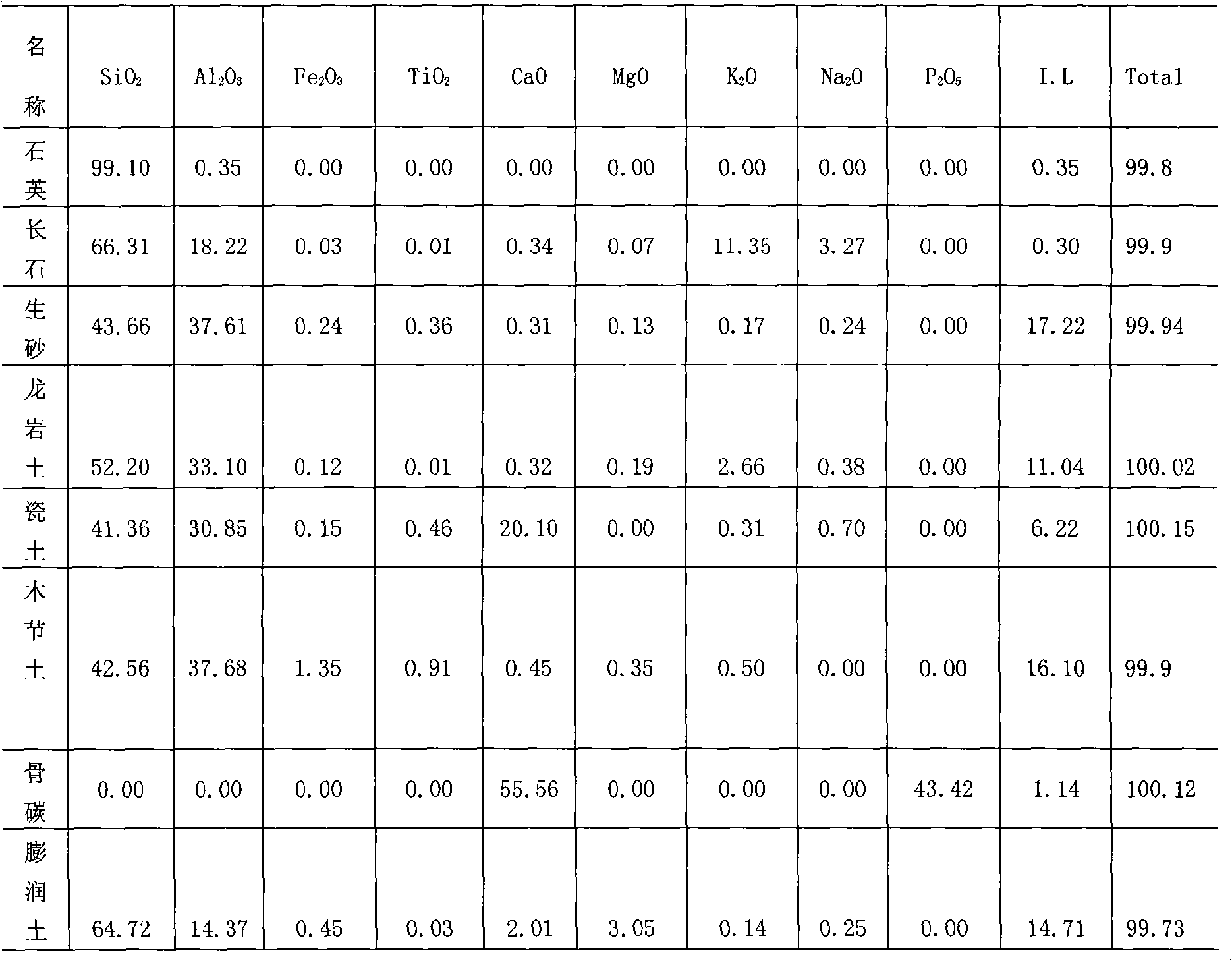

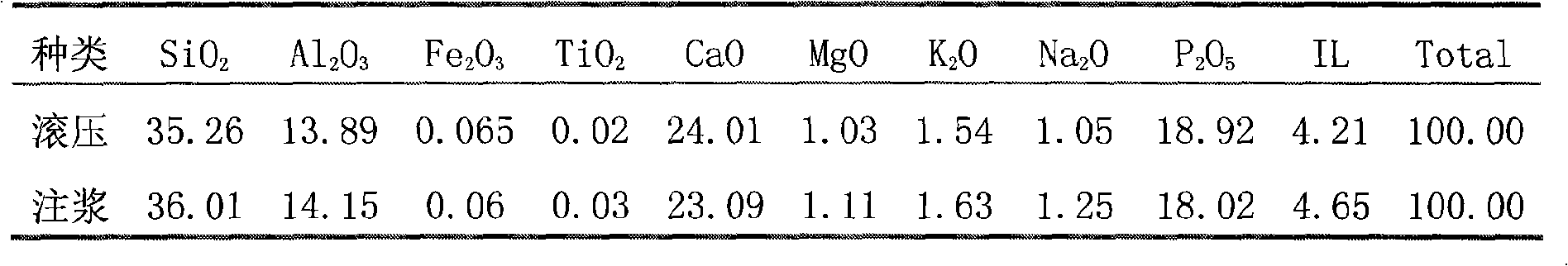

Bone porcelain with high resistance of heat shocks and production method thereof

InactiveCN101289307AReduce contentSmall coefficient of thermal expansionClaywaresHigh resistanceSodium Bentonite

The invention relates to a bone china with high resistance to heat shocks and a manufacture method thereof. The raw material components of the bone china stock and the weight percentages are: 9 to 12 of quartz, 7 to 10 of feldspar, 11 to 14 of greensand, 4 to 7 of Longyan clay, 5 to 8 of china clay, 4 to 7 of kibushi clay, 42 to 46 of bone coal and 7 to 10 of bentonite; the raw material components and the weight percentages of glaze material are: 5 to 8 of the quartz, 2 to 5 of the bentonite, 3 to 6 of Suzhou clay, 50 to 53 of model one fused block and 34 to 37 of model two fused block; the bone china has the resistance to heat shocks that no crack occurs during the heat change in the water with the temperature of 200 to 20 DEG C for once. The manufacture steps are as follows: preparing stock paste, preparing glaze paste, roller forming, grouting and forming, biscuit firing, glazing, glaze firing and decorating firing. The enamel layer of the invention has the advantages of large elasticity, good toughness and mechanical property. The raw material ingredients have no lead and zero radioactivity, which are green. The manufacture method is scientific and reasonable, and the product has the resistance to heat shocks that no crack occurs during the heat change in the water with the temperature of 200 to 20 DEG C at one time.

Owner:唐山隆达骨质瓷有限公司

Lightweight vitreous foamed ceramic

The invention discloses improvement to lightweight vitreous foamed ceramics and is characterized in that: a lightweight vitreous foamed ceramic mainly comprises 50 to 95 wt % of ceramic walls, a floor tile grinding wet powder skeleton material, 5 to 50 wt % of china clay and / or talcum and / or bentonite and / or tremolite and / or saponite fine powder matrix material and 0 to 8 wt % of a foaming agent; the above-mentioned materials are mixed and sintered at a temperature equal to or above a vitrification point of the matrix material. According to the invention, composition and ratio are simplified, composing materials basically comprise only two materials, mutual influence between the materials is small, it is easy to control the process of manufacturing, and therefore, a preparation process has good stability and products of different batches have stable performance and good consistency; a main raw material is waste materials generated in the production of ceramics, and the raw material is easily available and enables preparation cost to be substantially reduced and primary minerals to be saved; tangent planes of a prepared product are basically of a uniform noncommunicating subtle enclosed foam structure, the prepared product has volume density (unit weight) of 0.35 to 0.48 g / cm<3>, compressive strength at normal temperature of 9.0 to 9.6 Mpa and a heat conduction coefficient at a temperature of 70 DEG C (on average) of 0.168 to 0.182 W(m.k), and the natural color of the product (without addition of pigments) is white and greenish and appears to be tattletale gray.

Owner:江苏赛宇环保科技有限公司

Sludge curing agent and sludge curing method using same

The invention discloses a sludge curing agent and a sludge curing method using the same, relating to the field of sludge treatment. The sludge curing agent is prepared by the following method: firstly mixing seven components including expansible graphite, cement, coal ash, carbon black, silicon powder, porcelain clay and quick lime, leading the expansible graphite to expand under the condition without being lower than the expansion temperature of the expansible graphite, stirring mixture and obtaining a semifinished product; adding two components including expansion resin and water glass, stirring together, mixing fully and preparing the curing agent. The sludge curing agent disclosed by the invention is added into sludge, so that the water content of the sludge can be reduced, and the problem of weak acidity of the sludge is solved.

Owner:广州珞珈环境技术有限公司

Celadon cracked-ice pattern tire bone and glaze material, production method for products produced thereof

The present invention relates to a celadon cracked-ice-pattern skeleton and glaze, wherein, the skeleton comprises the ingredients by weight: 38 to 42 percent of Baoxi purple red clay,13 to 17 percent of Lianligen china clay, 13 to 17 percent of china clay,18 to 22 percent of kaolin,9 to 11 percent of aluminum oxide; the glaze comprises the ingredients by weight: 23 to 25 percent of Baoxi purple red clay, 14 to 17 percent of glaze clay, 8 to 12 percent of kaolin, 14 to 17 percent of albite,23 to 27 percent of potassium stone and10 to 12 percent of limestone. The present invention also provides a method for producing the cracked-ice-pattern product with the skeleton ingredients and the glaze materials. The product that is produced with the skeleton and the glaze material in the method not only maintains the properties of the cracked-ice-pattern product that is obtained with the original method, but also resolves the original technical problem that the maximum limit of the baked celadon apparatus is increased from 30 centimeters to 50 centimeters, thereby greatly improving the beauty.

Owner:丁绍杰

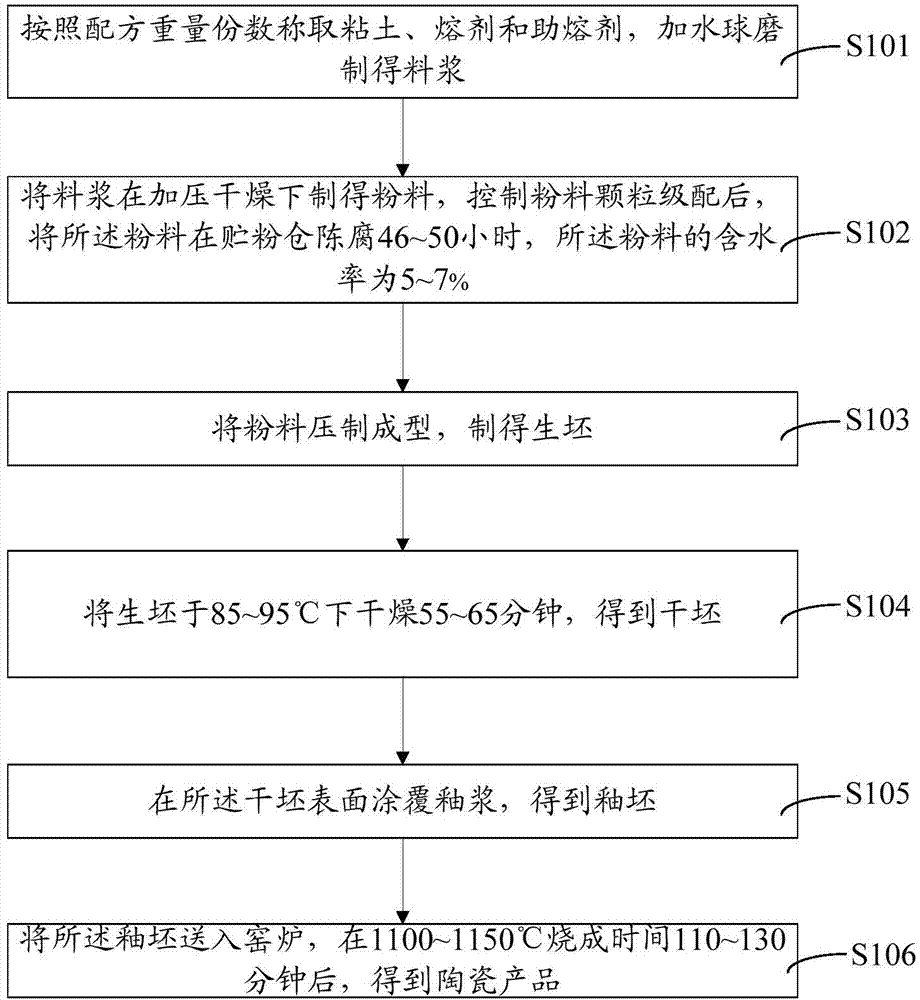

Ceramic formula and preparation method for ceramic product

The invention provides a ceramic formula, comprising, by weight, 55 to 65 parts of clay, 20 to 30 parts of a flux and 15 to 23 parts of a fluxing agent, wherein the clay is a mixture of purple sandshale and china clay mixed according to a weight ratio of 0.67 to 2.0, the flux is shale, and the fluxing agent is one or more selected from the group consisting of limestone, calcite, diopside, wollastonite, dolomite, talcum and industrial waste residue. A preparation method for a ceramic product comprises the following steps: weighing the clay, the flux and the fluxing agent according to the formula, carrying out crushing and screening with a 250-mesh sieve, wherein the weight of screen residue is 1 to 1.5%, adding water, carrying out blending to obtain slurry and then carrying out drying and granulation so as to obtain powder; grading particles and then carrying out molding so as to prepare a green body; carrying out drying so as to prepare a dry body; and carrying out firing so as to prepare a seasonal ceramic body. According to the ceramic formula and the preparation method for the ceramic product in the invention, raw materials are cheap, process is simple, firing temperature is reduced, production cost is decreased, investment for production equipment is lowered down, production efficiency is improved, and energy consumption is reduced.

Owner:怀化市亿智陶瓷有限公司

Method for manufacturing large silicon oxide ceramic sheet

The invention discloses a method for manufacturing a large silicon oxide ceramic sheet. The method comprises the following steps of: preparing blank soil particles serving as raw materials, preparing the green body of the large silicon oxide ceramic sheet, preparing the base body layer plain panel of the large silicon oxide ceramic sheet and preparing the large silicon oxide ceramic sheet finished product. The large silicon oxide ceramic sheet is prepared from the following raw materials in part by weight: 30 to 60 parts of needle-like wollastonite, 25 to 30 parts of clay, 15 to 20 parts of mullite, 15 to 20 parts of china clay, 10 to 20 parts of feldspar and 10 to 30 parts of bentonite; the needle-like wollastonite accounts for 28.57 to 36.36 percent based on the total weight of the raw materials; and the draw ratio of the needle-like wollastonite is (16.5-20):1. The method specifically comprises the following steps of: pressing blank soil particles serving as the raw materials to form the green body under the forming pressure of 6,000 to 7,000tons / m<2>; drying at the temperature of between 80 and 250 DEG C for 40 to 100 minutes; biscuitfiring the base body layer plain panel at the temperature of between 800 and 1,300 DEG C for 50 to 120 minutes; and glazing, printing, firing at the temperature of between 900 and 1,300 DEG C for 30 to 120 minutes to obtain the large silicon oxide ceramic sheet finished product. A rubber pad and redundant green body materials are completely recycled. The specification of the large silicon oxide ceramic sheet finished product is that: the ratio of length to width to thickness is 1,500-2,200mm to 800-1,500mm to 3-6mm.

Owner:山东德惠来装饰瓷板有限公司

Ceramic carving process

InactiveCN101088777AEasy to useGood collection valueDecorative surface effectsOrnamental structuresChina clayCarving

The present invention relates to ceramic carving making process. The ceramic carving making process includes the steps of forming biscuit with high quality china clay, carving patterns with sharp tools, blowing special color glaze and baking. The ceramic carving may be made through porcelain carving, underglaze carving or mold carving. The novel ceramic carving has strong stereo sensation, clear pattern, and high use and collection value.

Owner:谢开强

Method for lithographic printing by use of a lithographic printing plate provided by a heat sensitive non-ablatable wasteless imaging element and a fountain containing water-insoluble compounds

InactiveUS6165691AEffective controlImprove hydrophilic and hydrophobic propertiesSemiconductor/solid-state device manufacturingPhotosensitive material processingWater insolubleLaser exposure

According to the present invention there is provided a method for lithographic printing comprising the following steps: preparing a lithographic printing plate by image-wise laser exposing a heat-sensitive non-ablatable wasteless imaging element comprising a compound capable of transferring light into heat and having on a support as top layer a heat sensitive image forming layer comprising a heat-switchable binder which layer becomes more hydrophilic or more hydrophobic under the action of image-wise laser exposure; mounting said printing element on the press prior to or after the exposure; and applying a fountain solution and ink, characterized in that said fountain solution comprises at least one water insoluble compound selected from the group consisting of silica, alumina, titanium oxide, tin oxyde, china clay, smectic clay and zirconium oxide.

Owner:AGFA NV

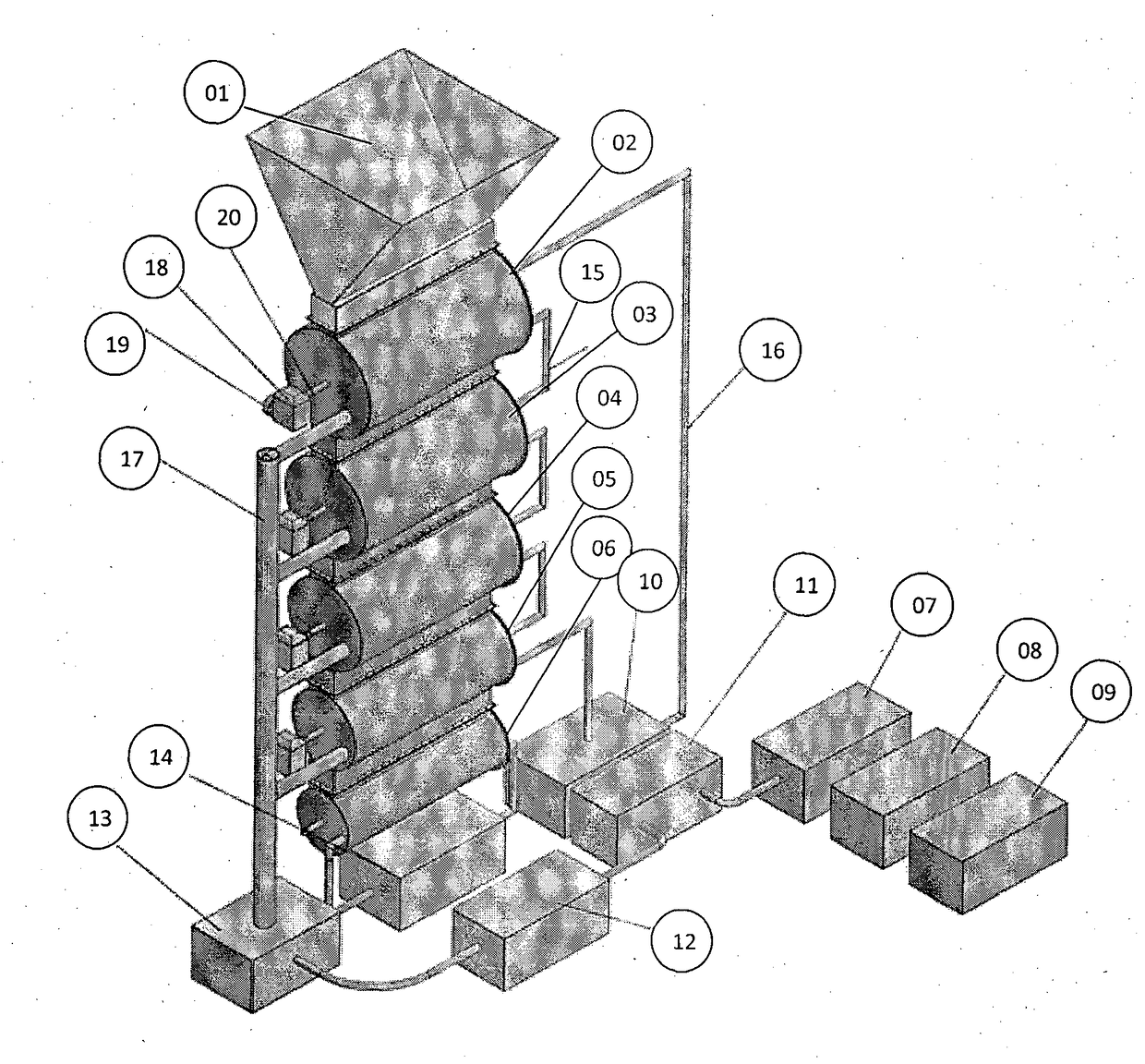

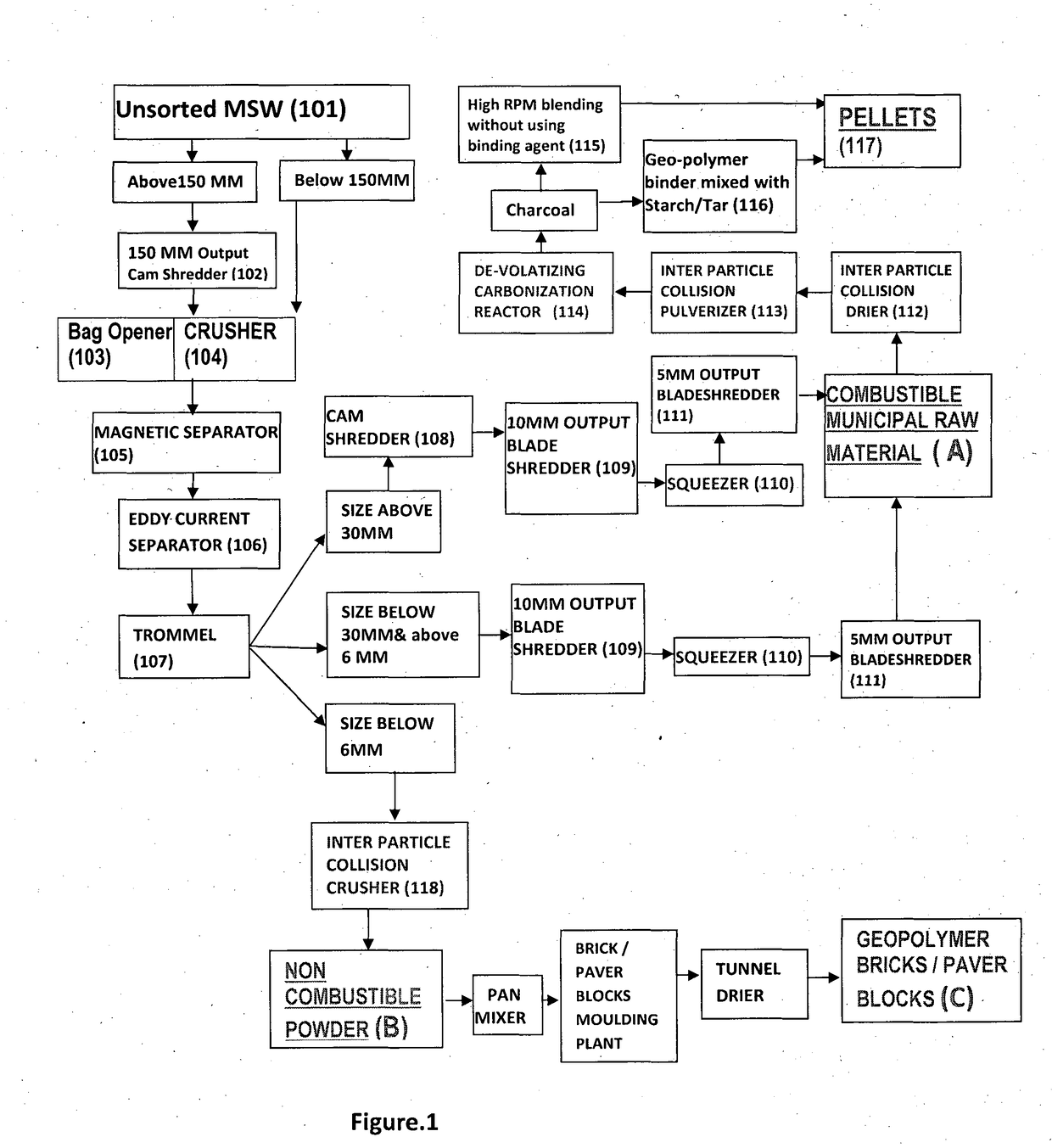

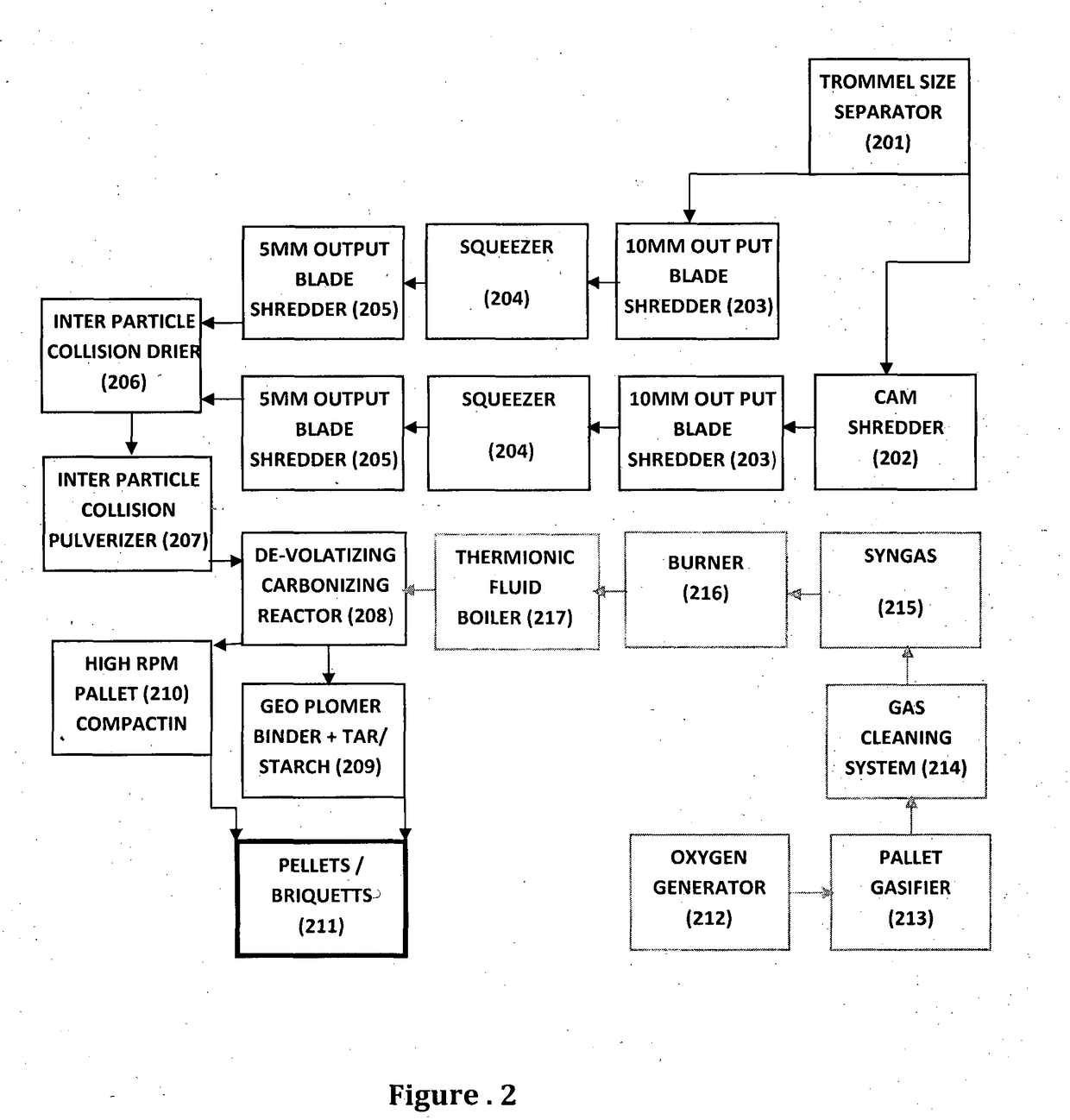

A novel method and an apparatus in converting unsorted municipal solid waste into geo-polymer pellets/briquettes and geo-polymer bricks/paver blocks

InactiveUS20180015515A1High calorific valueLow ashSolid waste disposalTransportation and packagingBrickCarbonization

Apparatus and method in converting municipal solid waste into geo-polymer briquettes and geo-polymer bricks comprising bag opener cum crushers, magnetic separators for ferrous and-eddy current separators for non-ferrous things; squeezer for removing liquid content; inter particle collision driers for drying; pulverizer for pulverizing, and devolatizing carbonization reactor for carbonisation of combustible MSW to produce solid char with low water content. Solid char is mixed with geo-polymer binding agent / starch / tar / to form combustible pellet / briquette. These highly combustible briquette / pellets have high calorific value. The pellet / briquette is formed by rotating combustible char at high rpm and compaction. Pellet has a water content of less than 5% by weight and fuel value of 5500 to 6500 KCAL. This process produces non-combustible geo-polymer brick. The non-combustible MSW separated by a trommel is crushed by inter particle collision crusher and pan mixers mixing with geo-polymer binding agent / fly ash / quarry dust / chips or china clay and moulded.

Owner:NEWAY MSW IP HLDG LLP

Transfer printing paper and production method thereof

InactiveCN102828439AReduce deformationPromote absorptionCoatings with pigmentsCoatingsFiberNetwork structure

The invention relates to transfer printing paper, comprising a base paper layer and a water absorption coating layer coated on a surface of the base paper layer, wherein the water absorption coating layer comprises a pigment and a binder; the pigment comprises heavy calcium carbonate, china clay and nano-silica; and the binder comprises starch and latex. The surface of the transfer printing paper is coated with the water absorption coating layer, the nano-silica in the water absorption coating layer has a three-dimensional network structure and has relatively large specific surface area, thereby enabling the water absorption coating layer to have many micropore structures, so that water content entering into the base paper layer is reduced; and thus deformation caused by water absorption of the transfer printing paper is decreased. The invention also provides a production method of the transfer printing paper.

Owner:GOLD EAST PAPER JIANGSU

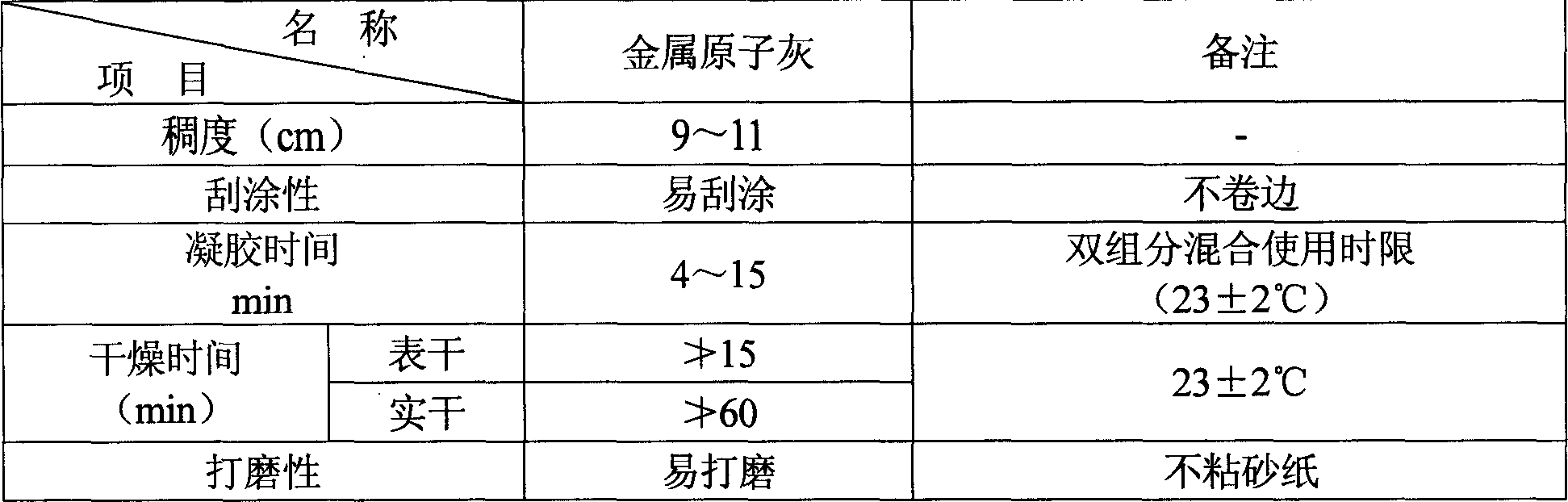

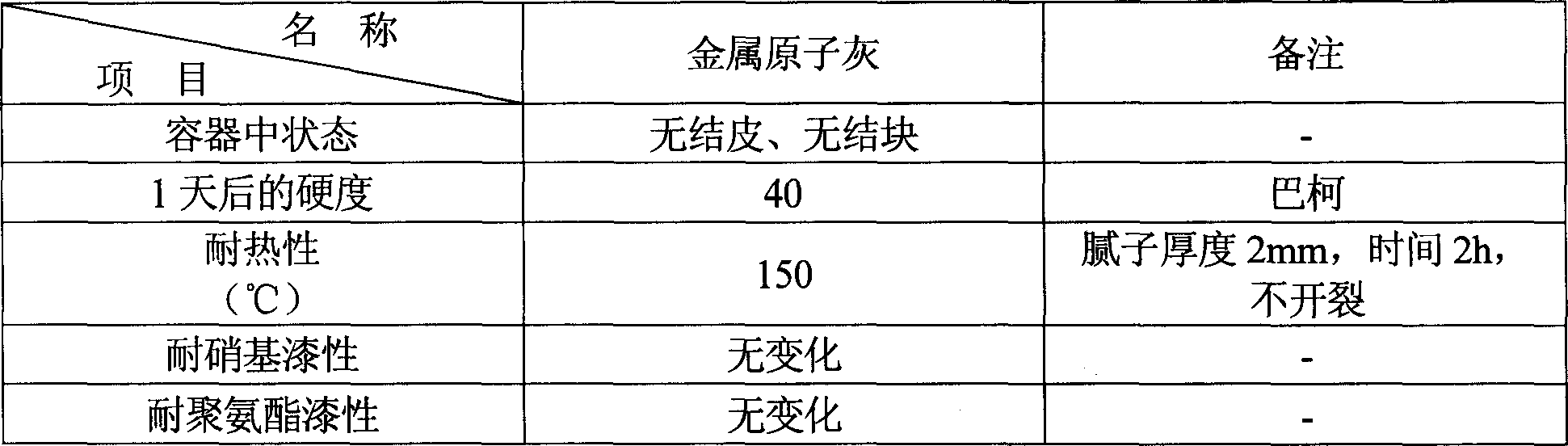

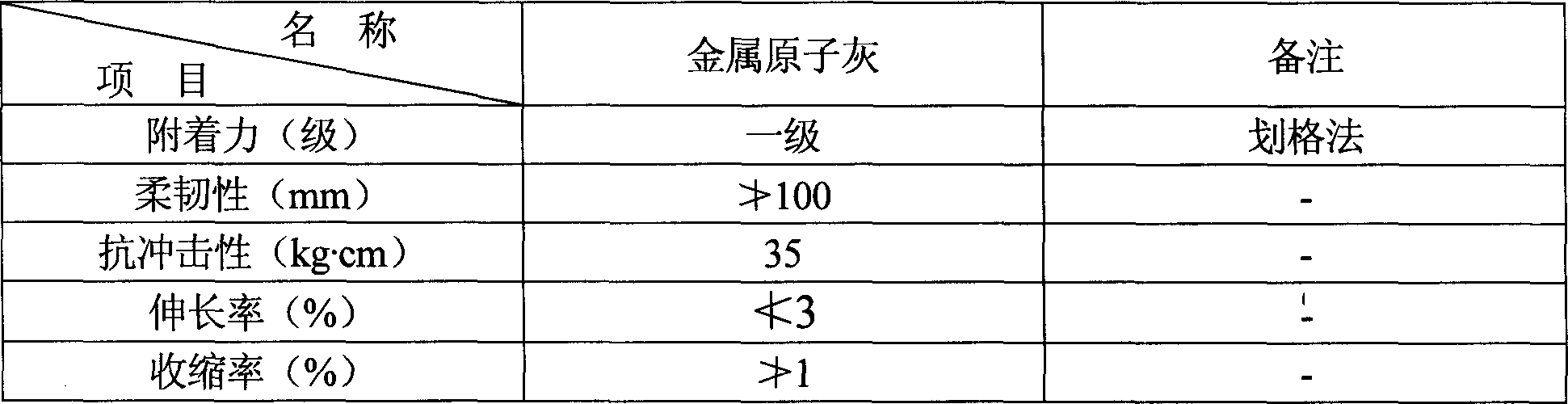

Metal atomic ash

A metal atomic ash consists of main ash and curing agent with weight ratio100:2. The main ash consists of unsaturated polyester resin: 100, improver: 3-5, phenylethylene: 3-5, filling: 120-130,and metal powder: 8-12. The curing agent consists of initiator: 100 and filling: 8-10. The production is carried out by taking special resin or special mixed resin as matrix material, and adding metal powder( iron powder, aluminum powder and copper powder etc. ) besides universal pigment and filling( titanium pigment, bentonite, French white, china clay powder, coarse whiting, and gas-phase silicon dioxide ). It achieves good combing ability, higher hardness and strength of atomic ash.

Owner:HARBIN INST OF TECH

Brominated butyl rubber plug for sterile powder for injection

ActiveCN101759937AExcellent ozone resistanceGood weather resistancePharmaceutical containersMedical packagingPolymer scienceAdditive ingredient

The invention relates to a brominated butyl rubber plug for sterile powder for injection, which belongs to the technical field of medical bottle plugs and is characterized in that the brominated butyl rubber plug for sterile powder for injection comprises following ingredients in parts by weight: 49 to 50 parts of brominated butyl rubber, 42 to 43 parts of calcined china clay, 0.4 to 0.5 parts ofstearic acid, 2 to 3 parts of Tissuemat E, 2 to 3 parts of zinc oxide, 0.7 to 0.8 parts of phenolic resin, 1 to 2 parts of titanium dioxide, 0.1 to 0.2 parts of soot carbon and 0.2 to 0.3 parts of magnesium oxide. The brominated butyl rubber plug of the invention can be vulcanized by using few cleaning vulcanized agents, has low quantity of auxiliary agents and impurities, and has the advantages of high air / vapor penetration resistance, chemical agent and solvent resistance, ozone resistance, weathering resistance, thermal stability, low compression deformation and good bioinert. The brominated butyl rubber plug of the invention can be widely used for subpackage of antibiotic powder-injection medicine.

Owner:SHANDONG PHARMA GLASS

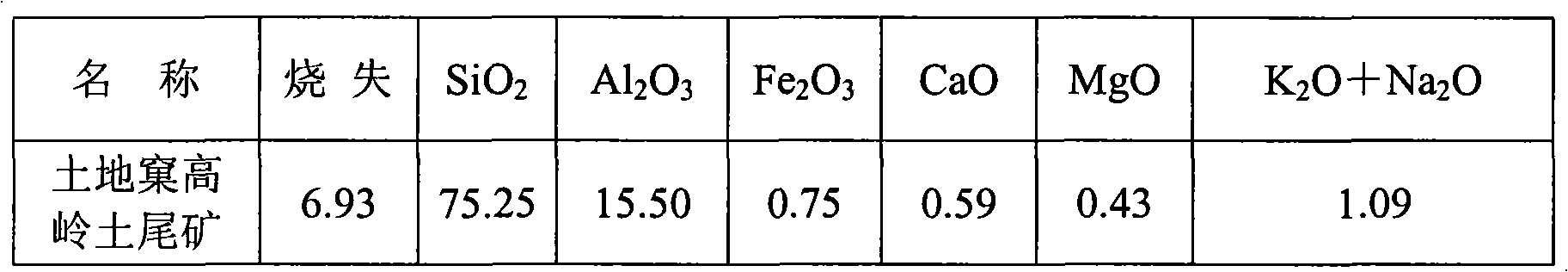

Household ceramic produced by comprehensively utilizing various tailings and manufacturing method thereof

The invention discloses a household ceramic manufacturing method. The blank of the household ceramic is prepared from the following raw materials in percentage by weight: 18 to 20 percent of Chengkeng clay tailing, 15 to 17 percent of Guodong china clay tailing, 19 to 22 percent of Tudike kaolin tailing, 16 to 17 percent of feldspar and 24 to 27 percent of clay. The manufacturing method comprises the following steps of: screening the Chengkeng clay tailing, the Guodong china clay tailing and the Tudike kaolin tailing according to classes, removing impurities, crushing, mixing according to a proportion, performing ball milling, sieving, iron removal, pressure filtration, coarse refining, ageing, and vacuum pugging to obtain a blank, drying, and glazing; and firing to obtain the household ceramic finished product. Various tailings are compounded, and the tailings account for 52 to 59 percent of the total mass of the raw materials. The household ceramic has the advantages of low production cost, high finished product ratio, stable structure, lower firing temperature, effective prevention of waste and energy waste, light environmental pollution and suitability for popularization.

Owner:广东宝丰陶瓷科技发展股份有限公司

Insulation material for medium voltage rubber insulation cable

This invention relates to the insulation and conduction compound material especially to an insulation material used in a high soft medium voltage plastic insulating cable computed in the component mass including: EPT rubber: 100, calcined china clay: 50-100, anti-aged agent: 1-3, organic peroxide: 2-4, coupler: 1-2, wax: 2-8, processed oil: 5-20, which can prepare a cable with the bending diameter 6 times of external diameter.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Preparation method of concrete mixed with addition and aggregate

InactiveCN1994709AImprove interfacial bond strengthHigh compressive strengthMixing operation control apparatusCement mixing apparatusSlagCompressive strength

The invention relates to a method for producing concrete dipped with skeleton material, wherein said method comprises that: packing dipping material layer on the face of skeleton, to be mixed with cement and water, to obtain the mixture. And said mixture comprises: mineral slag, silicon powder, coal powder ash, and sinter China clay; the weigh ratio between mixture and cement is 1:1-9. The invention can reduce or eliminate the interface transition area, to improve the adhesive strength between skeleton and cement stone. And compared with common technique, the invention can improve 20-40% anti-compress strength.

Owner:ZHEJIANG UNIV OF TECH

Method for manufacturing purple mud pottery

The invention discloses a method for manufacturing purple mud pottery. The method comprises the following steps: selecting drying and crushing kaolin, red porcelain clay and yellow clay, adding water into the mixture, adding screened river sand to prepare mud, molding, drying in the shade, patching, manually manufacturing a mouth, a kettle handle and the like, assembling the mouth, the kettle handle and the like with a kettle body, polishing, performing press polish, drawing, sculpturing, carving, drying in the shade at low temperature, drying at medium temperature, drying at high temperature, firing in a kiln, discharging from the kiln to obtain a finished product. Because the raw material formula is improved, the large-scale kaolin and river sand are added on the basis of the original yellow clay and red porcelain clay, the density of the pottery products is improved, particularly the firing temperature is increased, the problems that the sintering hardness and the density can not be meet during low-temperature firing are solved, the problem that high-temperature firing water seepage can not be realized is solved, and the pottery is bright in color, ideal in air permeability and exquisite in workmanship and is a brand new pottery product.

Owner:SUILING TAOYUAN POTTERY CULTURE & ARTS DEV CO LTD

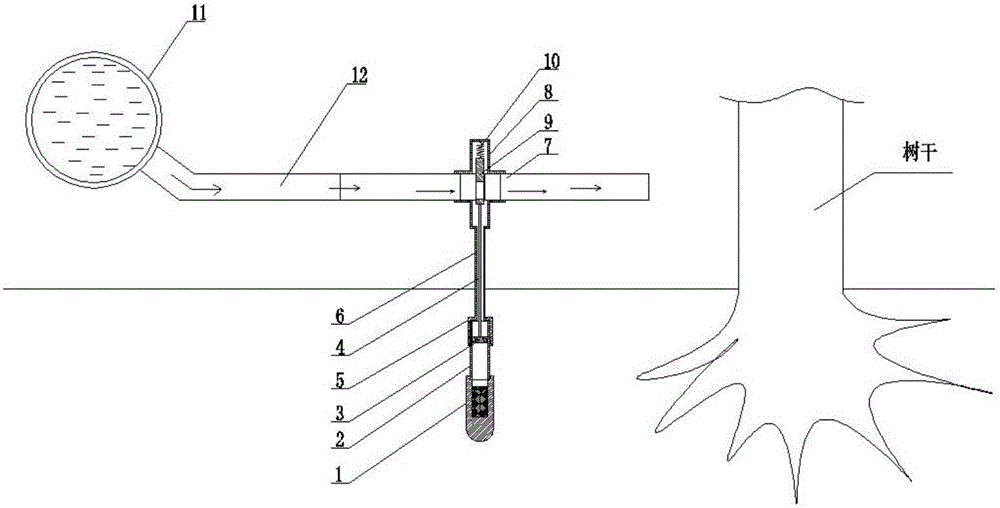

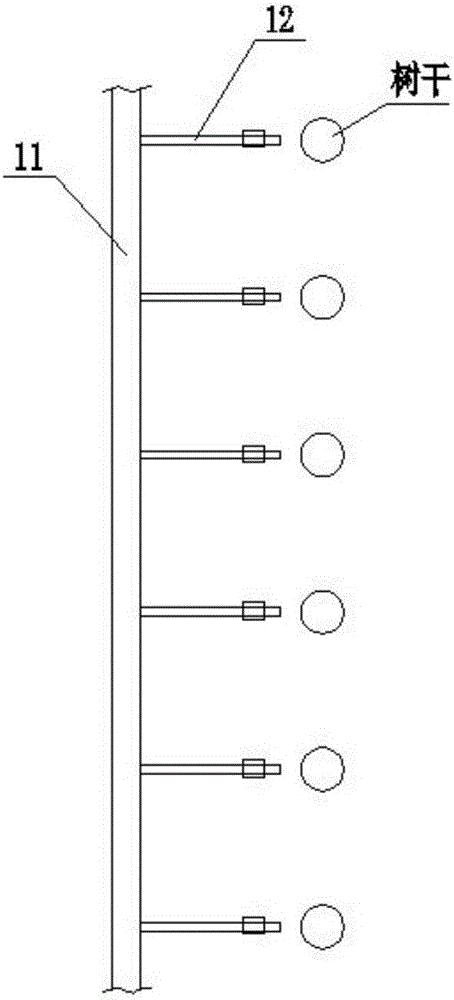

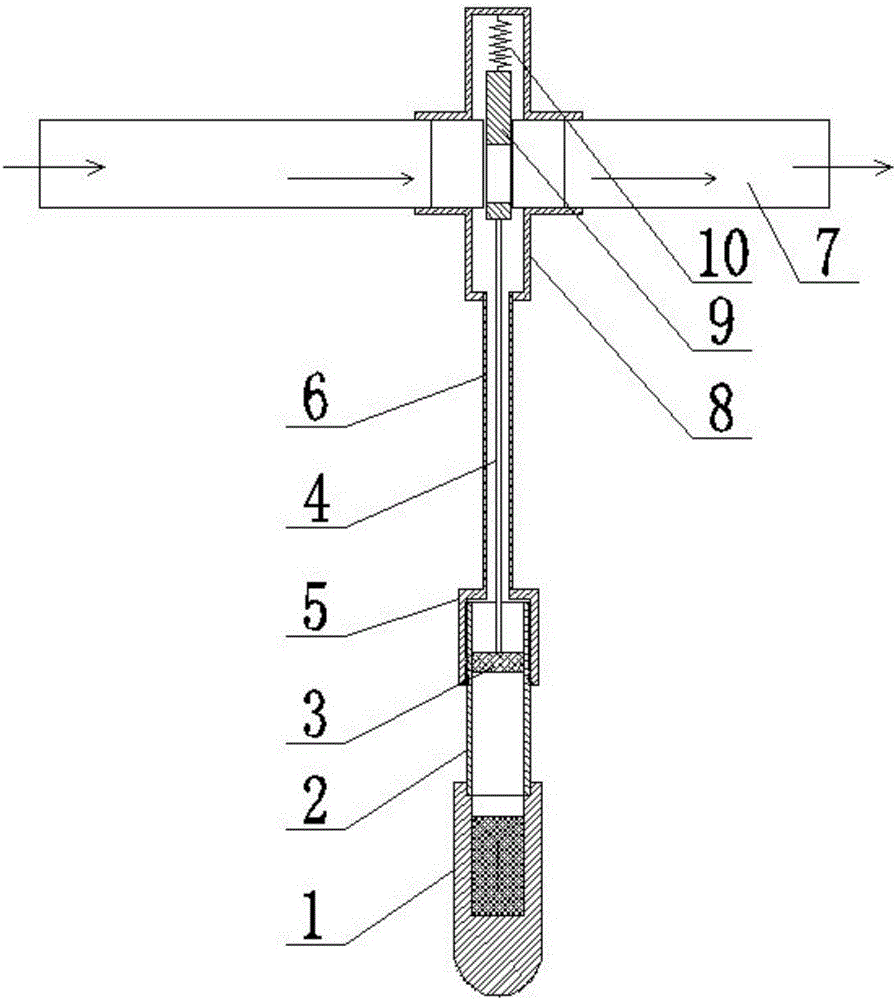

Control method and device for performing trickle irrigation according to requirement of fruit tree for soil water content

InactiveCN105746310AEnsure moisture content requirementsReasonable irrigationWatering devicesCultivating equipmentsFruit treeEngineering

The invention discloses a device for performing trickle irrigation according to the requirement of fruit trees for the soil water content. The device comprises a driven waterway control device and a soil water content feedback active control device for controlling the action of the driven waterway control device, wherein the soil water content feedback active control device comprises a hollow china clay head, a shell pipe, a piston, a push rod, a screw cap and a guide connecting pipe; the driven waterway control device comprises a water pipe, a valve shell, a valve plate and a spring, and a space formed by the hollow china clay head under the piston and the shell pipe is filled with a high polymer material which has the capability of expansion when absorbing water and expansion when losing water. The device is applied to trickle irrigation without manual operation or electric power supplying, the requirement of the fruit tree for soil water content can be met, reasonable irrigation is realized, and the influence of the artificial irrigation error on the fruit tree is reduced.

Owner:INST OF FRUIT & FLORICULTURE RES GANSU ACADEMY OF AGRI SCI

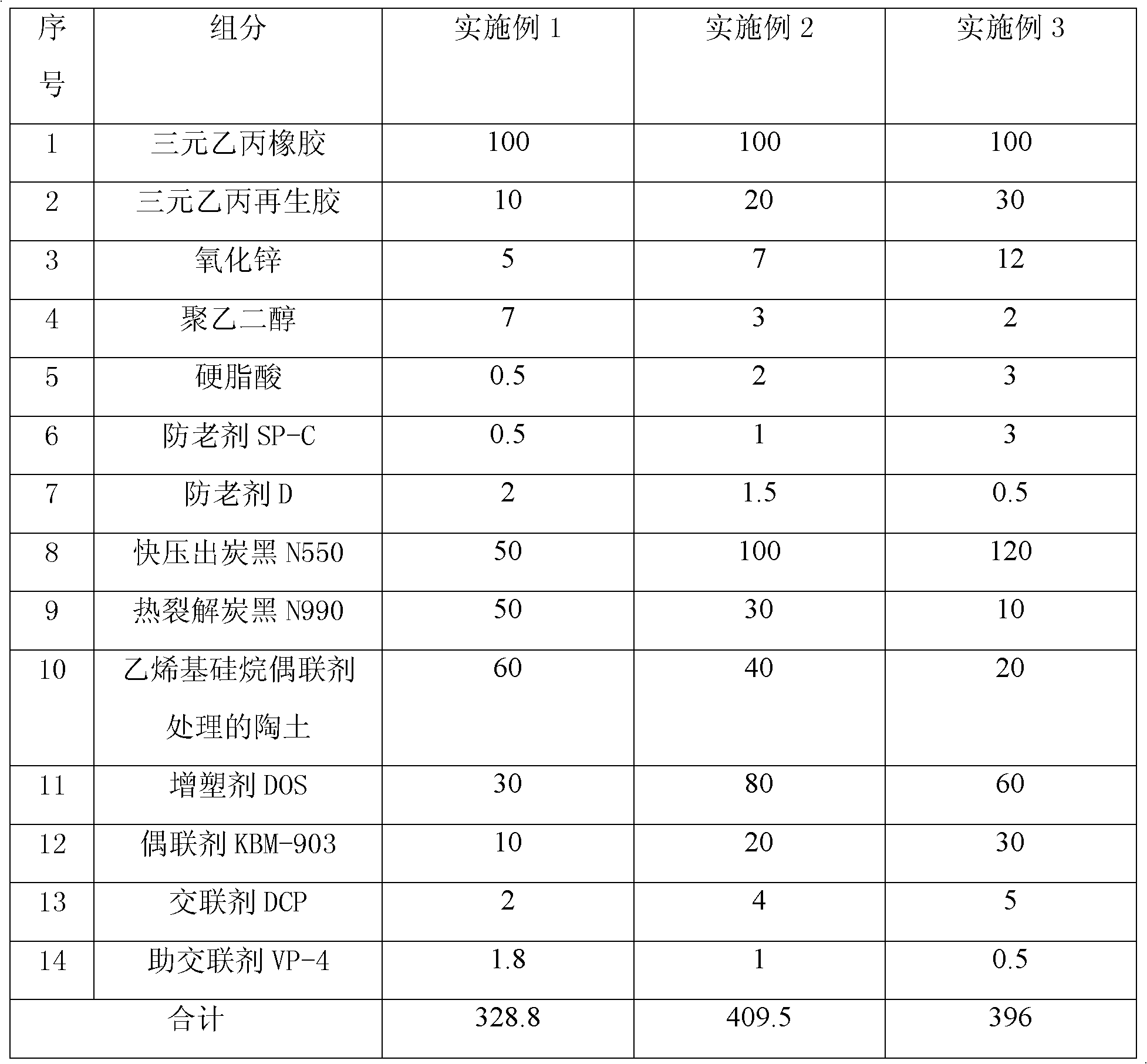

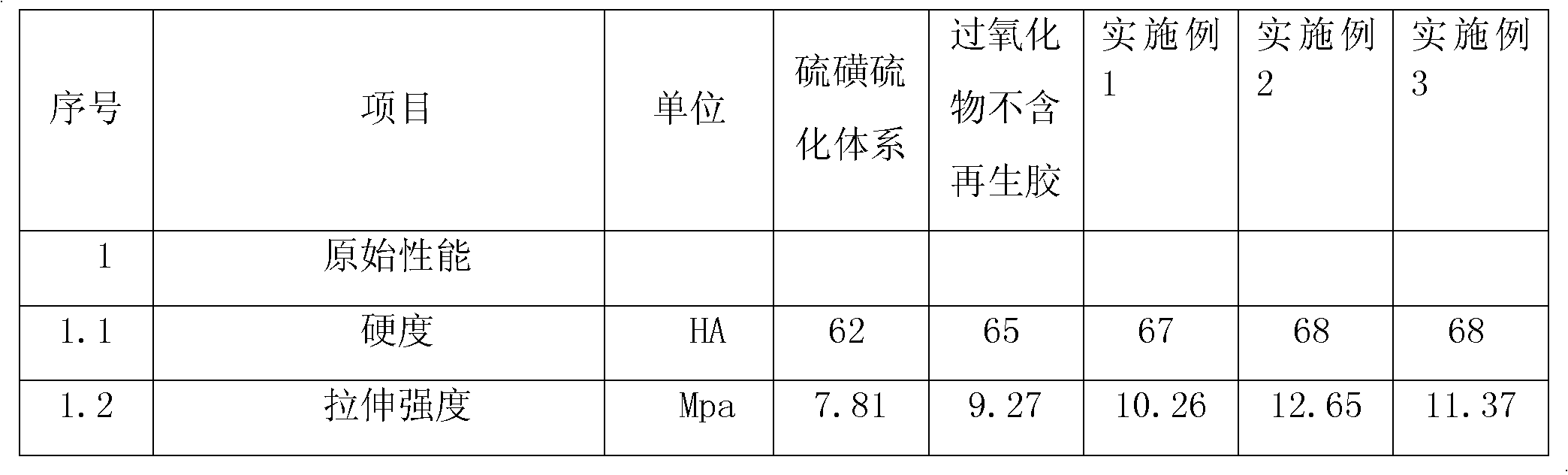

Cold-resistant rubber tube using both peroxide ternary ethylene-propylene rubber and reclaimed rubber

ActiveCN102093638AExcellent ozone resistanceImprove cold resistanceFlexible pipesThermal ageingCross-link

The invention relates to a cold-resistant rubber tube using both peroxide ternary ethylene-propylene rubber and a reclaimed rubber. The cold-resistant rubber tube comprises the following components: ternary ethylene-propylene rubber, ternary ethylene-propylene reclaimed rubber, zinc oxide, polyethylene glycol, stearic acid, an age resister SP-C, an age resister D, fast extruding carbon black N550, thermal cracking carbon black N990, china clay processed by a vinyl silane coupling agent, a plasticizer DOS, a coupling agent KBM-903, a cross-linking agent DCP and an auxiliary cross-linking agent VP-4. Compared with a sulfur vulcanizing system and a peroxide system which do not contain a reclaimed rubber tube, the formula of the cold-resistant rubber tube using both the peroxide ternary ethylene-propylene rubber and the reclaimed rubber has higher cold resistance, cooled liquid resistance, electric property resistance, ozone resistance and thermal ageing resistance, lower compression set, higher elongation, breaking strength and tearing strength and can better meet the requirements of a cooling system circulating water pipe and a connecting hose pipe which are used for a long time at a low temperature.

Owner:TIANJIN PENGYI GRP CO LTD

Soil or settlement soluble iron in-situ sampling device and in-situ sampling and testing method thereof

InactiveCN101915682AAvoid harmSimple and orderly operationMaterial analysis by observing effect on chemical indicatorWithdrawing sample devicesBottleChina clay

The invention discloses a soil or settlement soluble iron in-situ sampling device and an in-situ sampling and testing method thereof, which relate to a soil or settlement soluble iron sampling device and a sampling and testing method thereof. The method solves the problems of high destructiveness, long time consumption, incapability of stabilizing Fe<2+> and Fe<3+> at the same time and low measurement result accuracy of the conventional soluble iron in-situ sampling and testing method. In the sampling device of the invention, a stainless steel drilling bit, a china clay water collecting tube and a second stainless steel are arranged from bottom up; and a plastic exhaust pipe and a plastic water draining pipe are inserted into a second stainless steel pipe. The method comprises the following process steps: drilling a sampling point with the drill bit; exhausting air to produce negative pressure; waiting for collecting water; preparing a color-developing agent; absorbing the color-developing agent and pore water; injecting into a brown ground glass stoppered bottle; measuring the Fe<2+> content by using a colorimetric method; measuring the total iron content by using the colorimetric method; and obtaining the Fe<3+> content by substracting the Fe<2+> content from the total iron content. The device and the method are suitable to be used in soil or settlement soluble iron in-situ sampling and test techniques.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

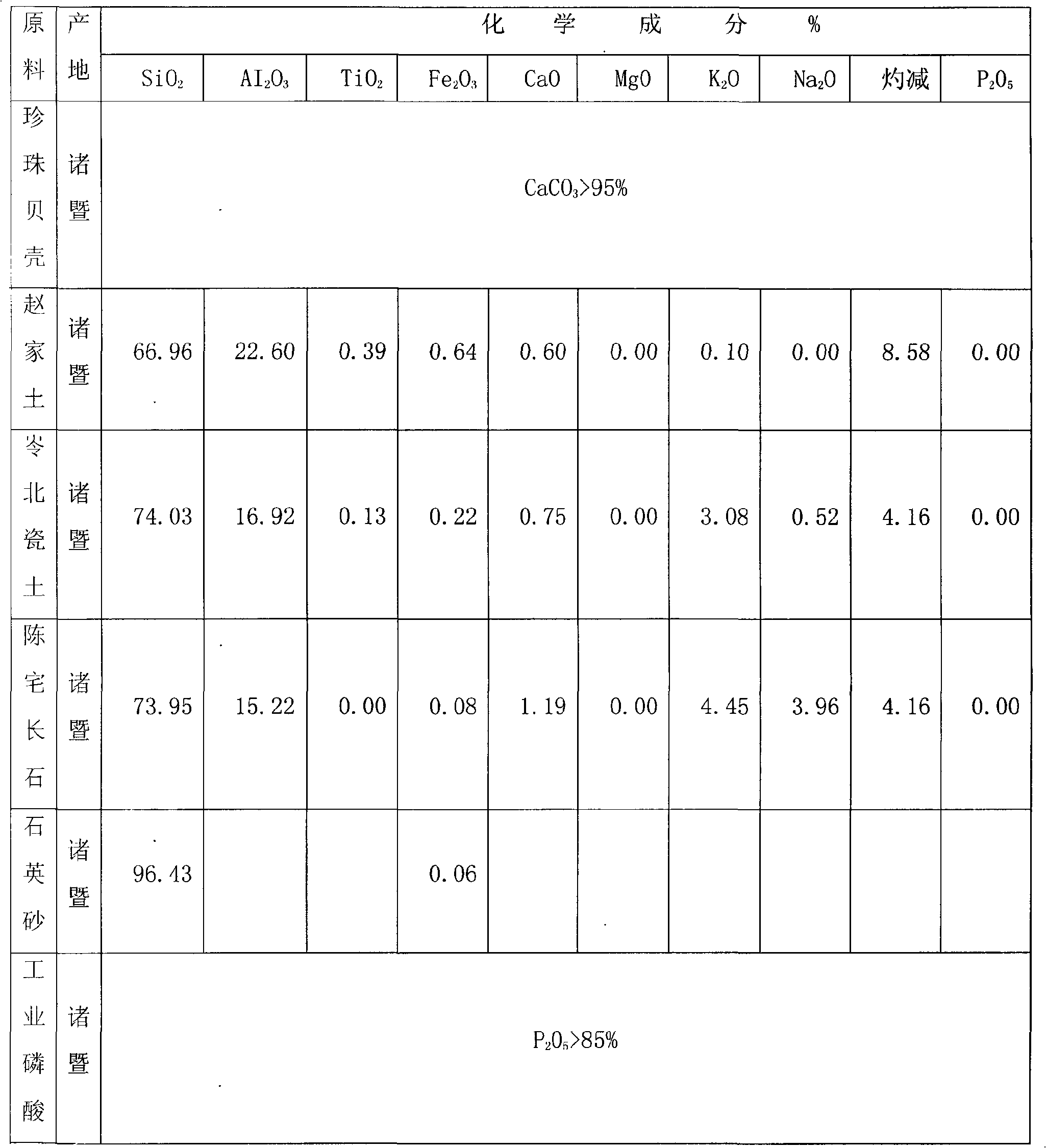

Pearl shell treating process as well as ceramic and glaze prepared by materials prepared by same

The invention discloses a treating process for preparing ceramic materials by pearl shells and wasted pearl bodies, and simultaneously further discloses a formula and a sintering technology for preparing daily-used ceramic and glaze by powder materials prepared by the treating process. The formula of shell porcelain body is as follows: 17-30 percent of mineral powder prepared by treatment, 10-20 percent of porcelain clay, 45-58 percent of kaoline, 0-5 percent of quartz, and 5-15 percent of feldspar; the formula of glaze of shell porcelain body is as follows: 1.36-4 percent of mineral powder prepared by treatment, 0,8-4 percent of porcelain clay, 3.6-11.6 percent of kaoline, 0-1 percent of quartz, 0.4-3 percent of feldspar, and 80-92 percent of high-boron high-zinc lead-free transparent frit; and the sintering technology of the shell porcelain is as follows: 1170-1220 DEG C of high-temperature plain temperature, and 1050-1100 DEG C of low-temperature glaze firing temperature. The invention has the advantages of energy conservation and consumption reduction, safety and environmental protection, and economy and practicalness.

Owner:ZHEJIANG DONGWEI CERAMICS

Enamel prepared from waste ceramic and its preparation method

The invention provides a ceramic glaze and preparation method from waste ceramic. Wherein, the product comprises: 18~25% waste ceramic powder, 20~30% quartz, 10~20% feldsparú¼8~12% China clayú¼0~5% zinc oxide, 0~10% dolomiteú¼7~15% calciteú¼and 0.2~0.5% methylcellulose. The preparation method comprises: cleaning and dedusting the ceramic powder, drying, breaking, and screening; putting said materials into ball grinder with proper water; screening, adding prepared ceramic powder; grinding and screening to prepare glaze slurry; adding methylcellulose into slurry to mix and obtain the product. This invention reduces cost and pollution.

Owner:林伟河

Preparation method of reinforced jade-based porcelain and product made of reinforced jade-based porcelain

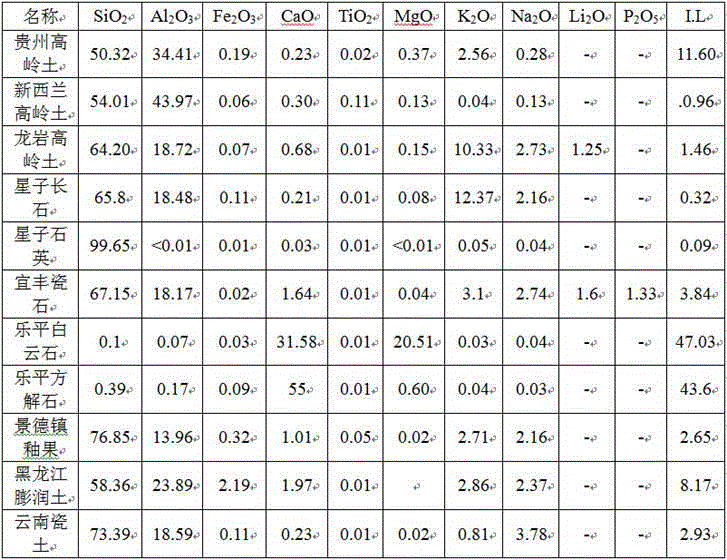

The invention relates to a preparation method of reinforced jade-based porcelain and a product made of the reinforced jade-based porcelain. The reinforced jade-based porcelain comprises a blank material and a glaze material, wherein the blank material comprises the following raw materials by weight: 10 to 15 percent of Longyan kaolinite, 8 to 15 percent of Guizhou kaolinite, 5 to 10 percent of New Zealand kaolinite, 10 to 15 percent of Xingzi feldspar, 40 to 50 percent of Xingzi quartz, 5 to 10 percent of Yifeng low-temperature porcelain stone, 3 to 5 percent of Jingdezhen glaze stone, 3 to 5 percent of Heilongjiang bentonite, and 3 to 5 percent of Yunnan porcelain clay; the glaze material comprises the following raw materials by weight: 8 to 12 percent of Longyan kaolinite, 3 to 5 percent of New Zealand kaolinite, 10 to 15 percent of Xingzi feldspar, 30 to 37 percent of Xingzi quartz, 8 to 12 percent of Yifeng low-temperature porcelain stone, 15 to 20 percent of Leping dolomite, 5 to 10 percent of Leping calcite, 8 to 10 percent of Jingdezhen glaze stone, and 5 to 10 percent of Yunnan porcelain clay. The preparation method and the product have the advantages that the production method is scientific and reasonable; the production cost is relatively low; the implementation is easy; the yield is high; the product quality is good. Therefore, the market prospect is wide.

Owner:景德镇红叶陶瓷股份有限公司

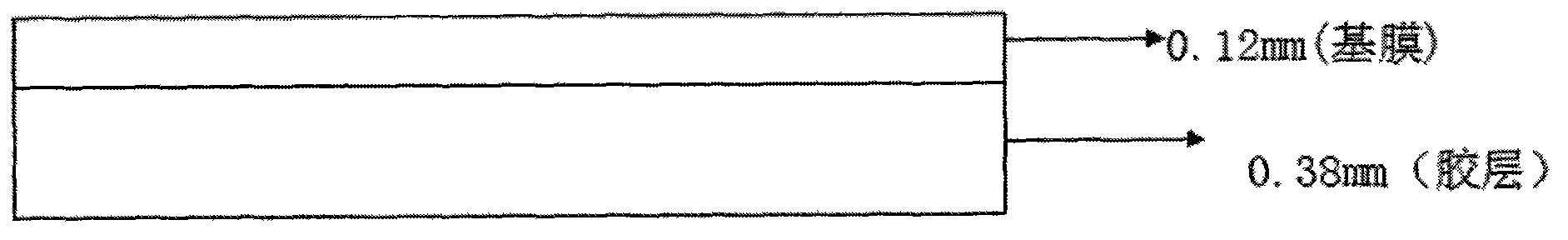

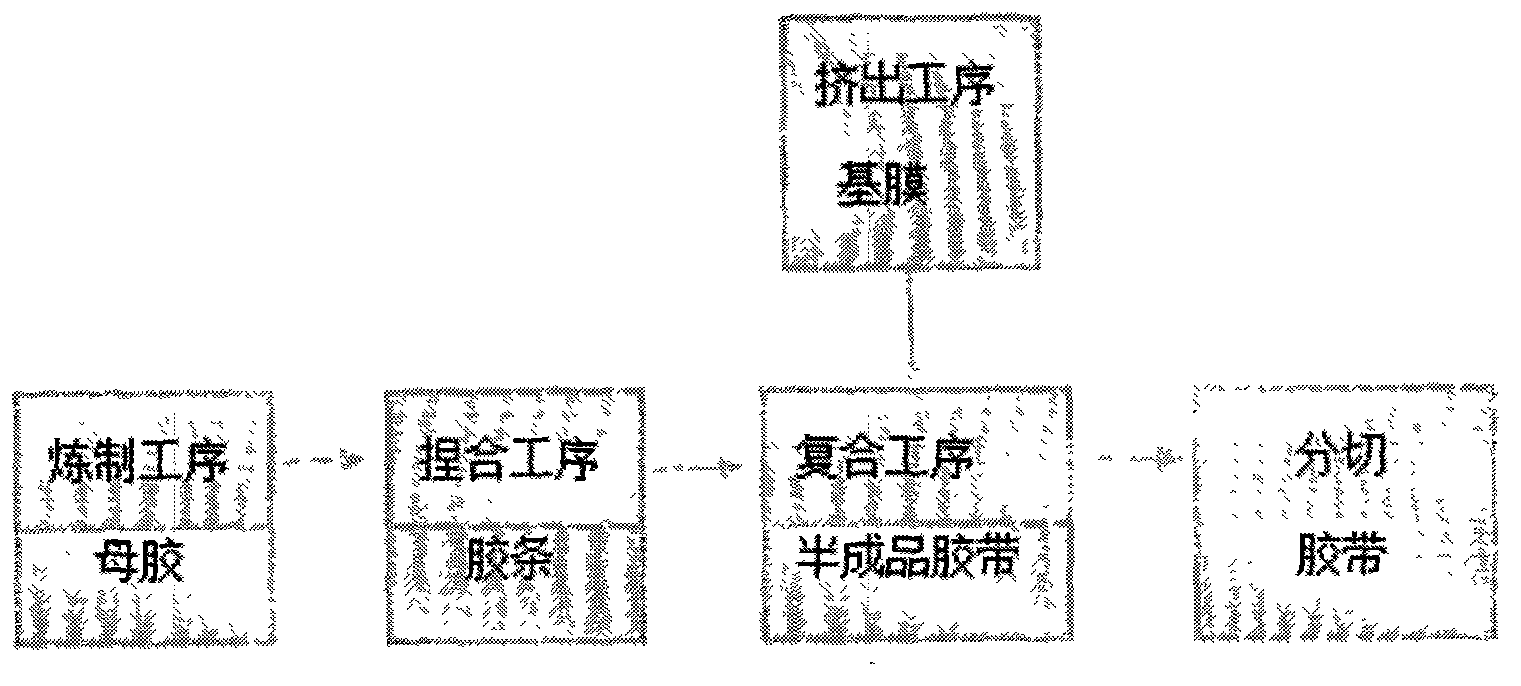

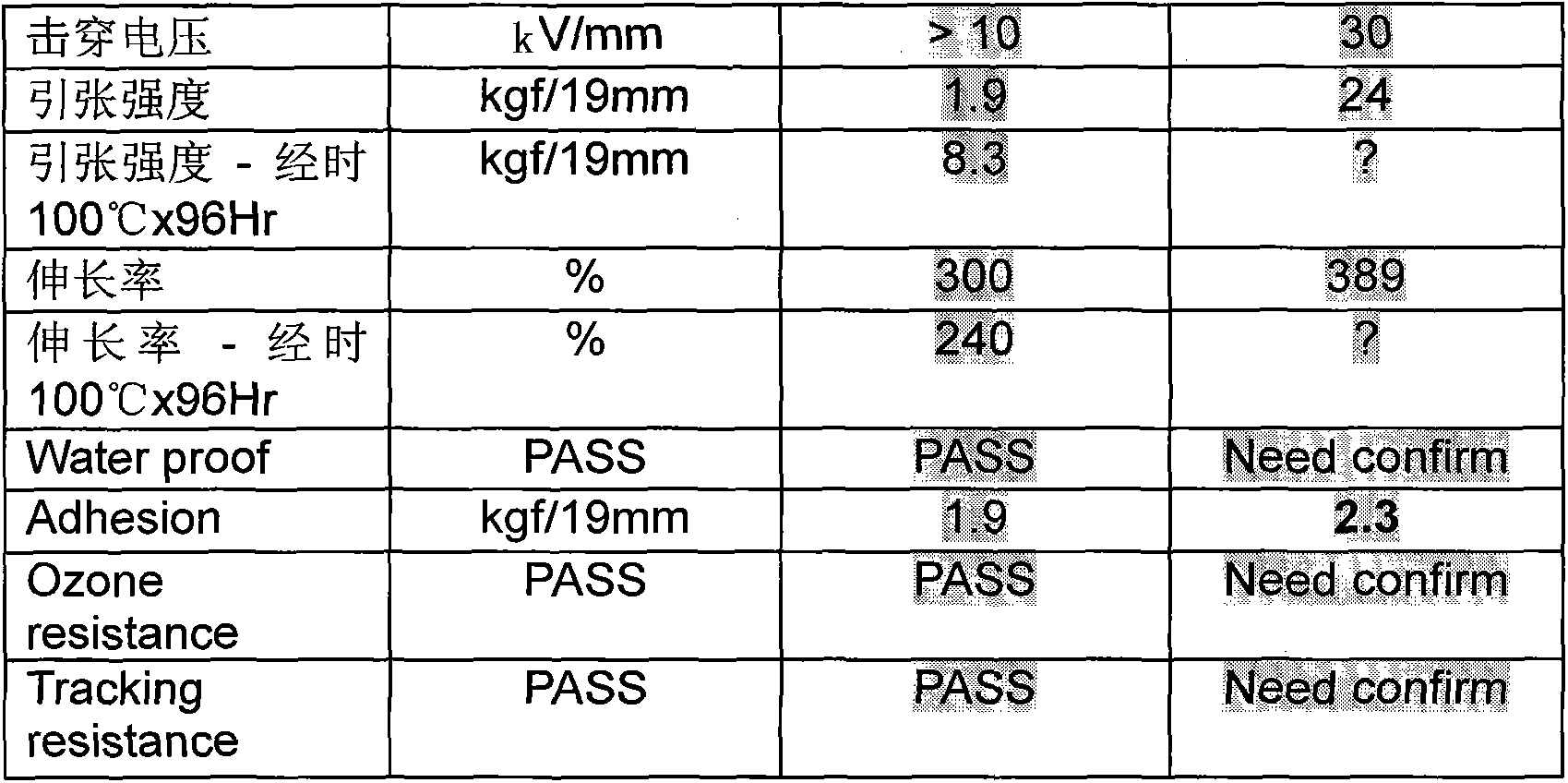

High-voltage insulated rubber tape and preparation method thereof

ActiveCN103320038AExcellent electrical propertiesImprove insulation performanceNatural rubber adhesivesNon-macromolecular adhesive additivesHigh pressureButyl rubber

The invention provides a high-voltage insulated rubber tape, comprising a base film and an adhesive layer which is attached to the base film, wherein the base film adopts a polyethylene material; the adhesive layer is prepared from the following materials by mass ratio: 4-6% of butyl rubber, 10-15% of butadiene styrene rubber, 23-26% of natural rubber, 10-15% of china clay, 1-2% of white carbon black, 1-3% of carbon black and 2-4% of dioctyl-phthalate. The high-pressure insulated rubber tape disclosed by the invention is good in electrical characteristics, good in water resistance and wet fastness, good in ozone resistance, chemical resistance and weather fastness, good in ageing resistance, and good in operation, is an excellent insulated material, and can be stored for a long period of time; the product is good in insulating property and small in thickness.

Owner:内蒙古驰邦电力工程有限公司

Process for preparing vapour pressure air-entrained concrete light heat-insulation fireproof bricks by porcelain clay tailings

The invention relates to a firebrick preparation method, in particular to a method of preparing an autoclaved aerated concrete light heat insulating firebrick with porcelain clay tailings. The invention takes the porcelain clay tailings as the main raw material, a certain amount of cement, lime, foam stabilizer of nekal bx or soap pod powder and aluminum power paste are added, and then plaster and self-made compound admixtures are added to prepare into a sizing agent. The later preparing procedures are as follows: pour mold for gas-molding and stilling, dry heat pre-curing, cutting and stacking, being steamed in a caldron and being taken out of the caldron, and finally the firebrick is formed. The firebrick is put into the caldron to steam for 5 to 7 hours under constant voltage; the steam pressure is 1.1 to 1.5 MPa and the temperature is from 185 DEG C to 195 DEG C. The firebricks prepared by the method have good effect of thermal insulation in stove owing to low coefficient of heat conductivity, thereby being used in the low temperature section of ceramics kiln collapses, tunnels, resistance furnace and being capable of realizing energy saving. The firebricks prepared by the method also have the advantage of being light owing to the volume and density being less than those of the majority of light heat insulating firebricks.

Owner:福建省万旗非金属材料有限公司

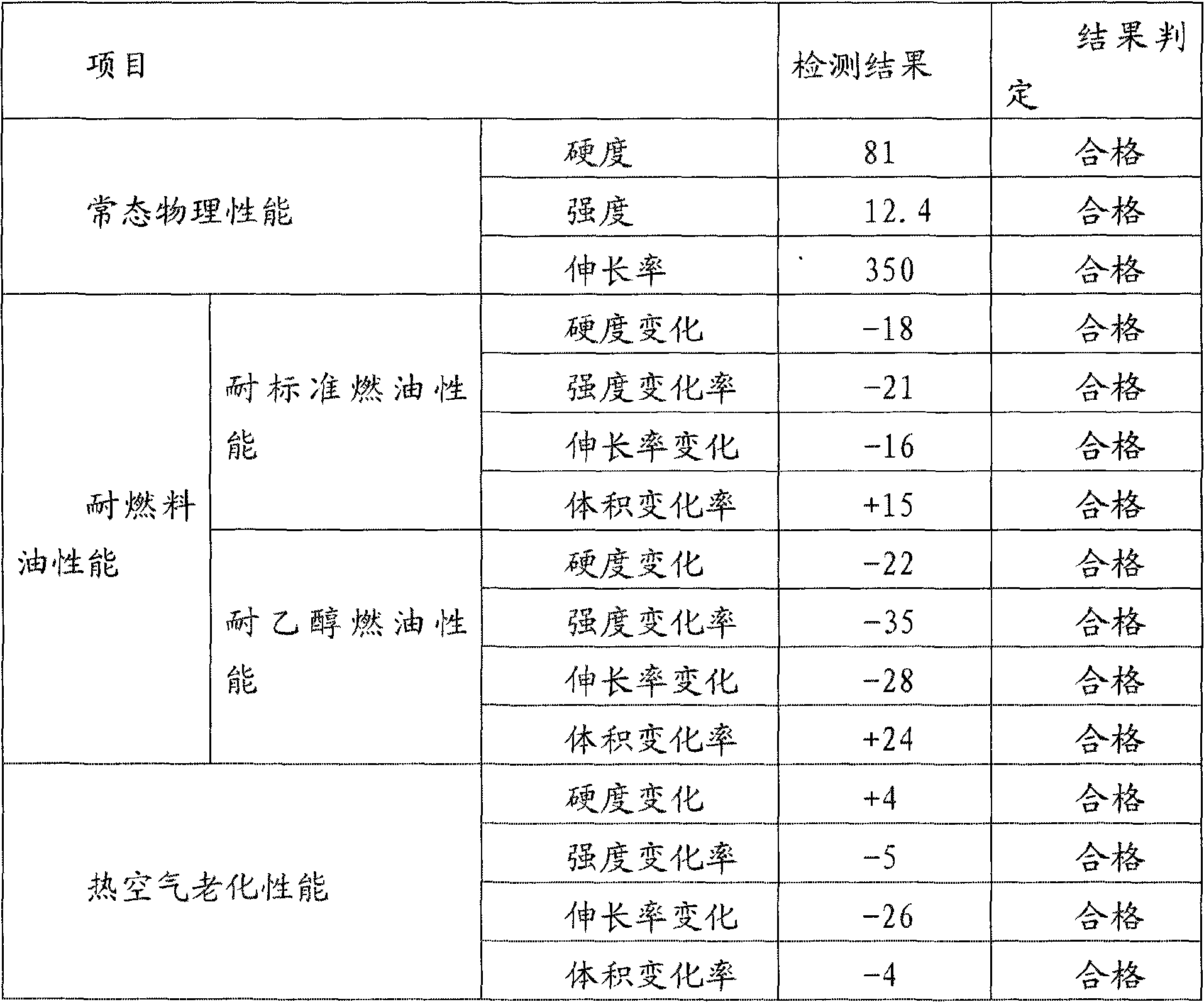

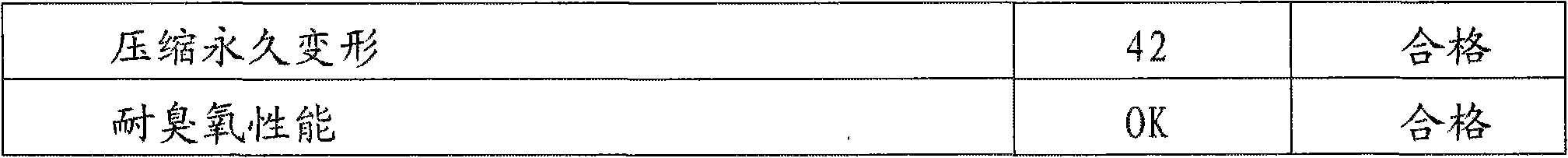

Ethanol fuel oil resistance rubber

The invention relates to the field of rubber combination, in particular discloses ethanol fuel oil resistance rubber. The rubber includes the components by weight: 60 to 70 parts of 40 to 50 percent acrylonitrile containing butadiene-acrylonitrile rubber, 30 to 40 parts of polyvinyl chloride, 26 to 36 parts of plasticiser, 1.5 to 3.5 parts of stearic acid, 67 to 90 parts of reinforcing filler and 5 to 13.5 parts of antiager, wherein, the plasticiser is at least one of dibutyl phthalate or dioctyl phthalate, the reinforcing filler is at least one of china clay, spraying carbon black, or carbon black, and the antiager is at least one of antiager NAPM, antiager MB, or antiager 4020. Rubber products produced by the technical scheme achieve the standard of ethanol fuel oil resistance HESD 3207-06 on vehicle rubber products of Japan Honda, and not only meet the requirement of the rubber products on normal performance, but also further solve the defect that the existing rubber products can not resist the ethanol fuel oil.

Owner:ZIGONG FUYUAN VEHICLE PARTS

Tea dust art porcelain and preparation method thereof

ActiveCN105693207AFast gatheringDistribute quicklyCeramic materials productionClaywaresPhosphateCalcite

The invention discloses tea dust art porcelain and a preparation method thereof and belongs to the technical field of porcelain preparation. The tea dust art porcelain comprises a green body and glaze wrapping the surface of the green body. The green body is composed of, by weight, 28-42 parts of kaolin, 12-25 parts of potassium feldspar, 8-18 parts of quartz, 12-25 parts of china clay tailings, 1-3 parts of talc, 12-25 parts of beef liver stone and 1-3 parts of calcite; the glaze is composed of, by weight, 2-15 parts of kaolin, 28-45 parts of potassium feldspar, 10-25 parts of quartz, 12-25 parts of calcite, 8-20 parts of talc, 1-3 parts of tricalcium phosphate and 2-15 parts of ferric oxide. The tea dust art porcelain is scientific in formula, low in cost and good in product fineness, and the preparation method is used for preparing the tea dust art porcelain.

Owner:GUANGDONG DABU CERAMIC IND RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com