High-voltage insulated rubber tape and preparation method thereof

A high-voltage insulation and manufacturing method technology, applied in the direction of adhesives, natural rubber adhesives, non-polymer adhesive additives, etc., can solve the problem of non-stretchable insulating tapes, thick insulating materials, and easy-to-scald base film production and other problems, to achieve waterproof and anti-corrosion and good insulation effect, good insulation performance, and beneficial to the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

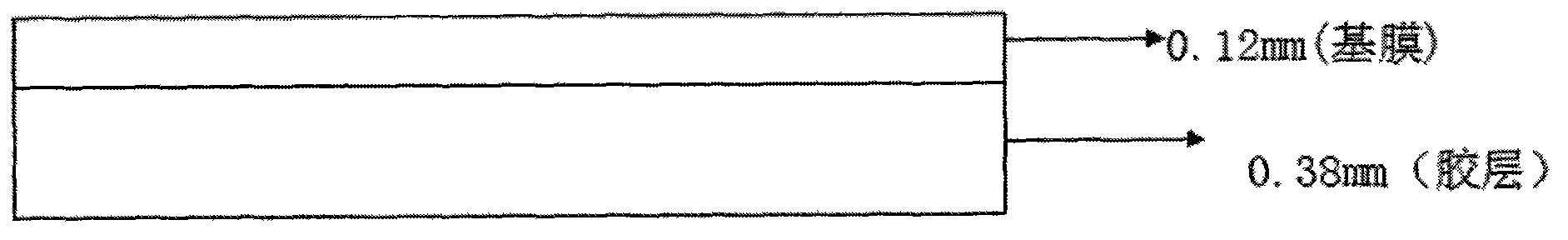

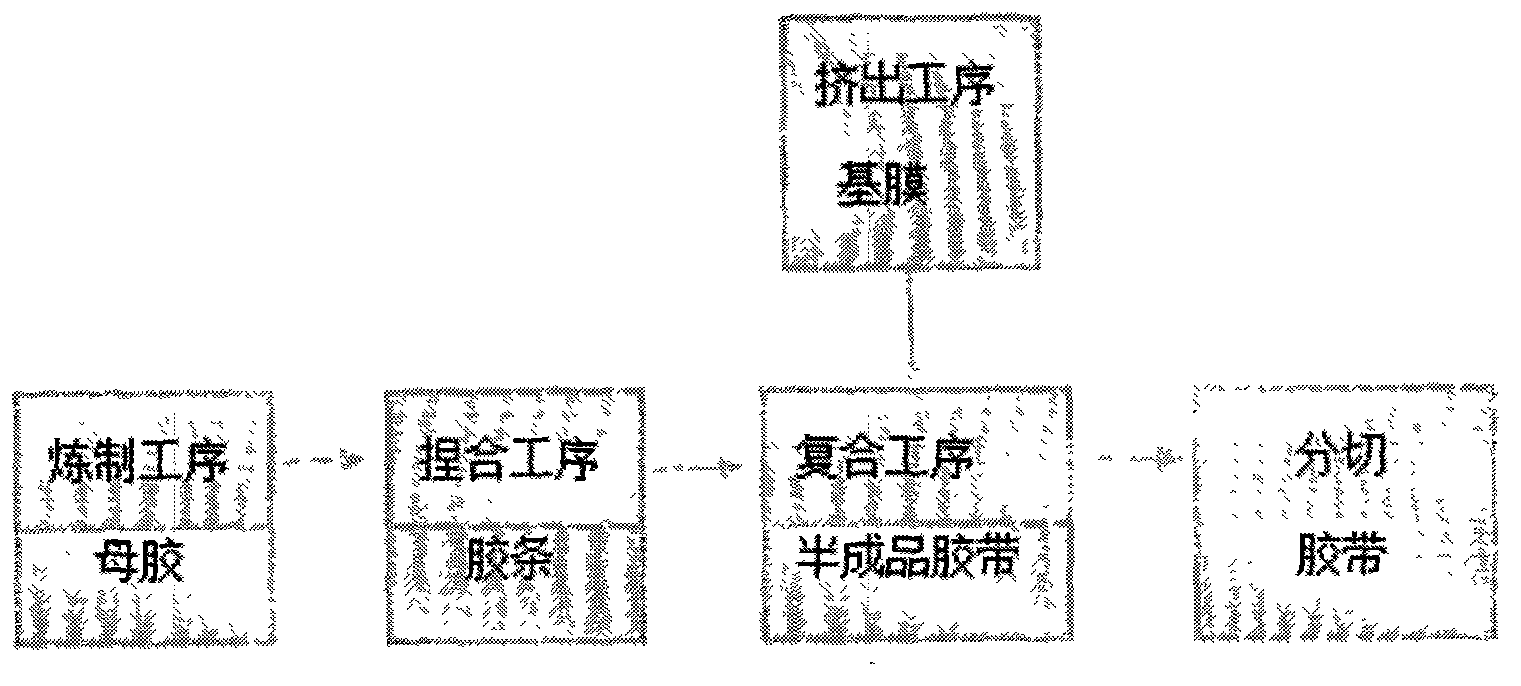

[0026] Such as figure 1 As shown, the embodiment of the present invention provides a kind of high-voltage insulating adhesive tape, comprises base film and the adhesive layer that is attached on the base film, and base film thickness is 0.12mm, and adhesive layer thickness is 0.38mm, and described base film adopts polyethylene material , the quality ratio of the adhesive layer is as follows: masterbatch 150-160, EVA2-4, resin 15-25, antioxidant 1, antioxidant 1-1.5, polyisobutylene 35-50, polyethylene wax 2-4, dioctyl Grease 2-4, asphalt 10-20, light calcium 30-40, wherein the mass ratio of the masterbatch is as follows: butyl rubber 4-6, styrene-butadiene rubber 10-15, natural rubber 23-26, clay 10-15 , white carbon black 1-2, carbon black 1-3, dioctyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com