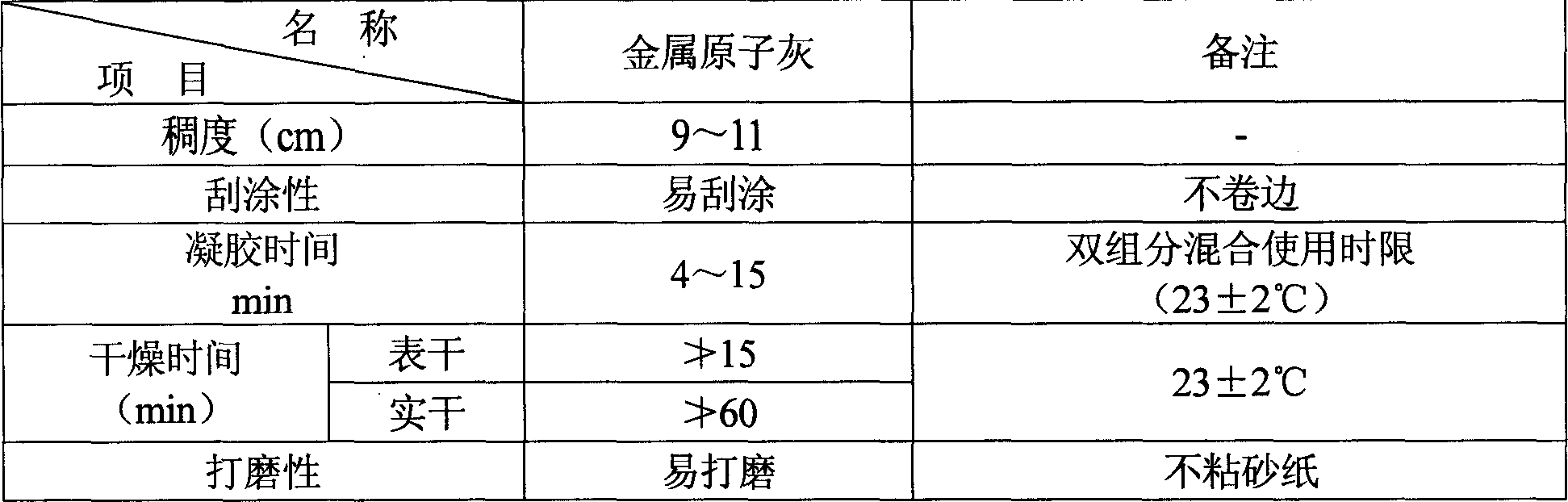

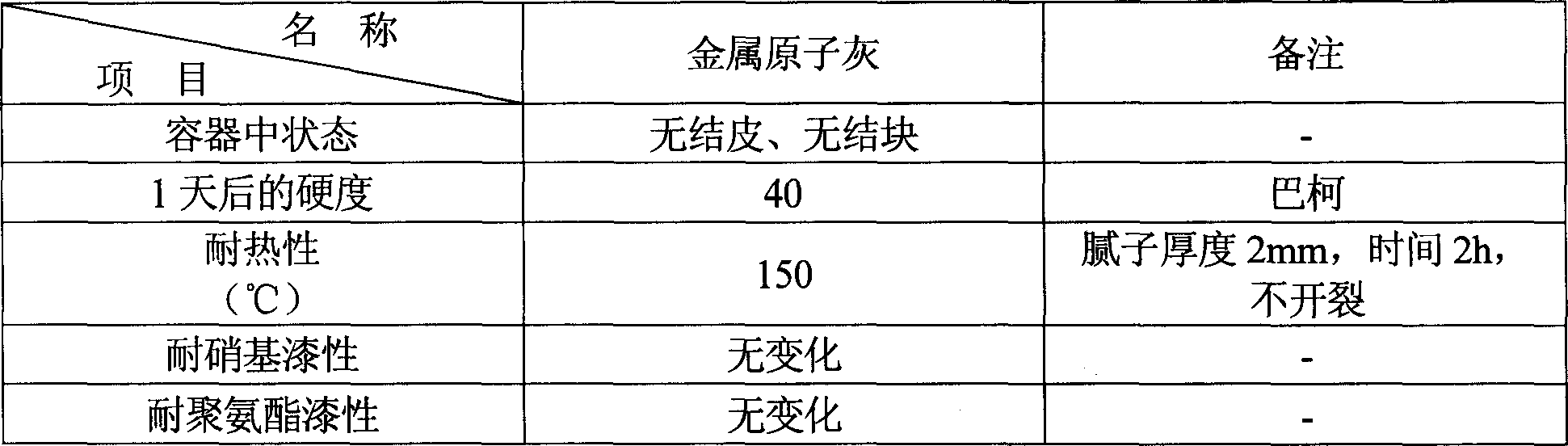

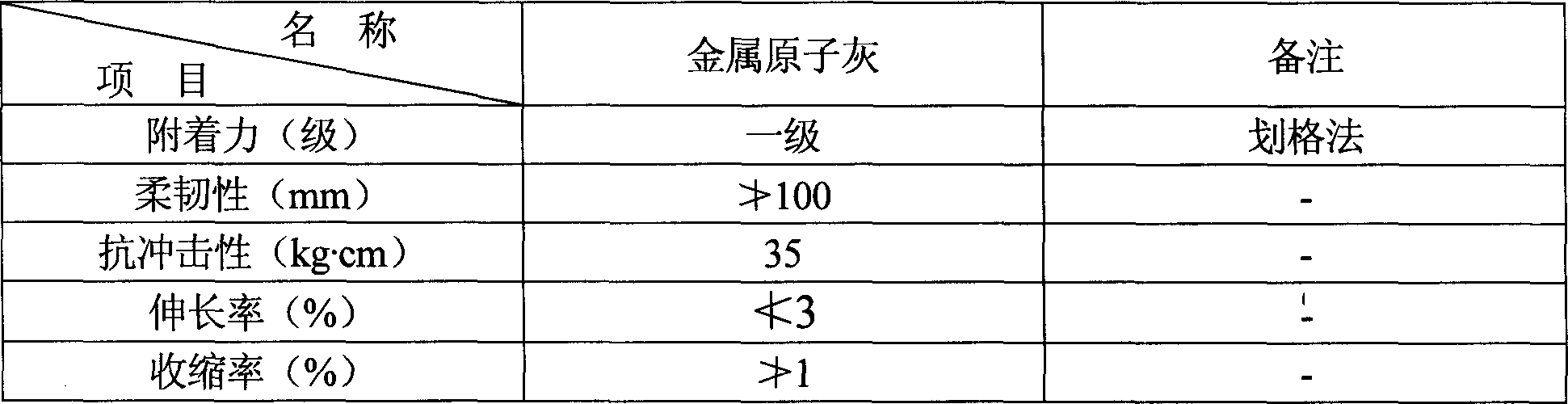

Metal atomic ash

A technology of metal atoms and metal aluminum powder, which is applied in the field of polymerized putty, can solve the problems of slow drying speed, large shrinkage rate, and large solvent volatilization, and achieve the effect of fast drying speed, fine putty film and small shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific Embodiment 1: This embodiment is composed of main body ash and curing agent. The weight ratio of main body ash and curing agent is 100:2, wherein the main body ash is composed of the following components according to the weight ratio: unsaturated polyester resin : 100, Accelerator: 3~5, Styrene: 3~5, Filler: 120~130, Metal Powder: 8~12; The curing agent is composed of the following components according to the weight ratio: Initiator: 100, Filler: 8~ 10. Described accelerator is cobalt and N, N methylaniline; The filler of main body ash is made up of following composition according to weight ratio: gray pigment paste: titanium dioxide: organic bentonite: fumed silicon dioxide: ground calcium carbonate: talcum Powder=0.1~0.5:2~4:2~4:0.01:10~15:100~110. The metal powder is a mixture of one, two or three of aluminum powder, copper powder or iron powder, and its fineness is above 180 mesh, preferably above 325 mesh; the initiator is cyclohexanone peroxide and Meth...

specific Embodiment approach 2

[0021] Embodiment 2: The metal putty in this embodiment is composed of main ash and curing agent. The weight ratio of main ash and curing agent is 100:2. The specific formula is shown in Table 4.

[0022] System composition

[0023] Note: CN-225 is produced by Changzhou Huari New Materials Co., Ltd., and FL-996 is produced by Jiangsu Fuli Chemical Group Company.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com