Pearl shell treating process as well as ceramic and glaze prepared by materials prepared by same

A pearl shell and processing technology technology, which is applied to the field of ceramic raw materials and ceramic preparation, can solve the problems that the mud production process cannot be implemented, affects the performance of ceramic mud, and increases the surface tension of mud, and achieves a wide firing range and smooth glaze surface. , the effect of increasing hardness and transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

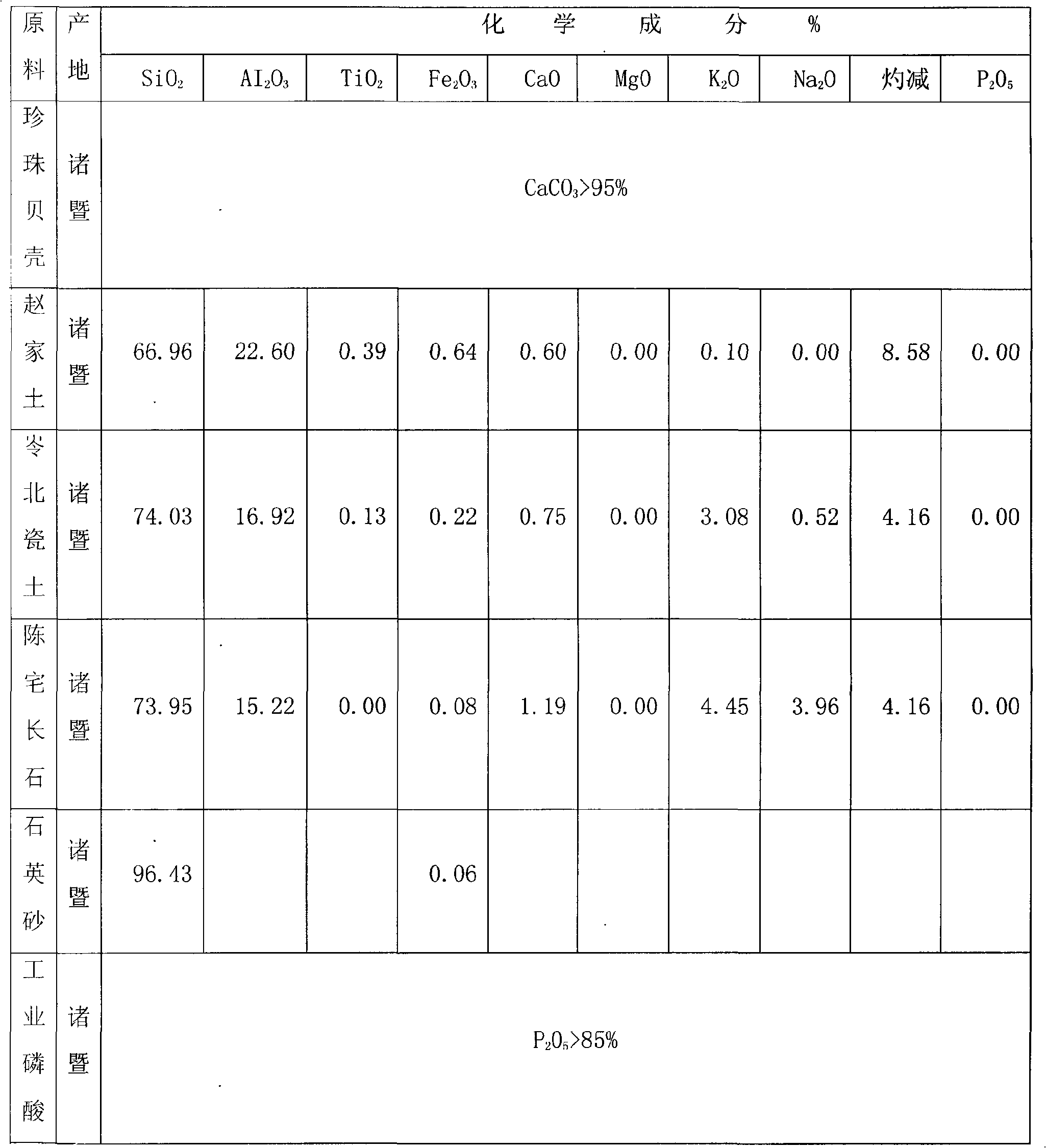

[0031] In this example, discarded shells from Shanxia Lake Freshwater Pearl Breeding Base in Zhuji City, Zhejiang Province and Zhejiang Dongwei Group Freshwater Pearl Farm were selected. First, the shells were washed to remove sediment, drained, and stacked in a high-temperature resistance furnace. Calcined at 400°C and kept warm for 1 hour, then cooled naturally, then placed in a pulverizer, and processed to 30 mesh fine particles. Slowly add the treated particles into the pre-prepared industrial phosphoric acid container in a ratio of 1:1 by weight, and stir evenly. When the pH value is detected to be 4.8, stop stirring, and wash twice with water after standing for 24 hours. . When washing, the weight ratio of powder and water is 1:1.2, then filter out the water with a filter bag and dry naturally, put the dry powder in a sagger, set the temperature in a high-temperature resistance furnace to calcine at 450°C, and keep warm for 1- After 3 hours, after natural cooling, a min...

Embodiment 2

[0041] This example selects the discarded shells from the freshwater pearl breeding base of Shanxia Lake in Zhuji City, Zhejiang Province and the freshwater pearl farm of Zhejiang Dongwei Group. Carry out calcination at 500°C and keep it warm for 1 hour to cool naturally, then place it in a pulverizer and process it into 55 mesh fine particles. Slowly add the treated particles into the pre-prepared industrial phosphoric acid container according to the ratio of 1:1 by weight, and stir evenly. When the pH value is detected to be 5.4, stop stirring, and after standing for 24 hours, wash repeatedly with clean water for two times. all over. When washing, the weight ratio of powder and water is 1:1.2, then filter out the water with a filter bag and dry naturally, put the dry powder in a sagger, set the temperature in a high-temperature resistance furnace to calcine at 525°C, and keep warm for 1- After 3 hours, after natural cooling, a mineral powder mainly composed of calcium phosp...

Embodiment 3

[0050] This example selects the discarded shells from the freshwater pearl breeding base of Shanxia Lake in Zhuji City, Zhejiang Province and the freshwater pearl farm of Zhejiang Dongwei Group. Calcined at 480°C and kept for 1 hour to cool naturally, then placed in a pulverizer and processed to 60 mesh fine particles. Slowly add the treated particles into the pre-prepared industrial phosphoric acid container at a ratio of 1:1 by weight, and stir evenly. When the pH value is detected to be 5.3, stop stirring, and after standing for 24 hours, wash repeatedly with clean water for two times. all over. When washing, the weight ratio of powder and water is 1:1.2, then filter out the water with a filter bag and dry naturally, put the dry powder in a sagger, set the temperature in a high-temperature resistance furnace to calcine at 580°C, and keep warm for 1- After 3 hours, after natural cooling, a mineral powder mainly composed of calcium phosphate was obtained, and the obtained mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com